- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

28 Aug 2017 07:52 #98080

by tecno

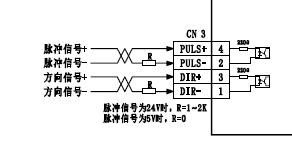

This is what I have set on the drivers

Page 23 Pr1.01 is set to 2 (I believe = will confirm)

Page 24 Pr1.22 is set to 0

Page 41 5.2.1 External position mode (3 pages) These are the pages I do not any clear picture of - no timing figures.

5mm pitch on ballscrews, belt reduction 2:1

2500rpm max and 2500ppr encoders.

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

G'day Rod,

I have no microstepping settings on these AC servodrives not that I can find anyways. Chinese Lichuan B2.

www.europages.se/SHENZHEN-XINLICHUAN-ELE...uction%20Book~2.html

The documentation is very hard to read as it is probably google translated.

Will try to do some more testing to get rid of error message and reach acceptable speed.

These motors/drivers was working OK with Mach3/Kflop where I got very high speeds = just too much

Only difference what I can see is that now I use as in picture instead of only step/dir for input signals to driver.

This is what I have set on the drivers

Page 23 Pr1.01 is set to 2 (I believe = will confirm)

Page 24 Pr1.22 is set to 0

Page 41 5.2.1 External position mode (3 pages) These are the pages I do not any clear picture of - no timing figures.

5mm pitch on ballscrews, belt reduction 2:1

2500rpm max and 2500ppr encoders.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4688

- Thank you received: 1433

28 Aug 2017 12:27 #98082

by Todd Zuercher

It takes one line of hal code per encoder to tie it to the setting in the INI file.

This is what is in my hal file on a machine using a 5i25+7i85S combo.

setp hm2_5i25.0.encoder.00.scale [AXIS_0]ENCODER_SCALE

Yours should be something simular, you just need to start Linuxcnc and look up what the parameter name should be.

Replied by Todd Zuercher on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

A1

OK, how is this done (step by step)? Is it not like spindle encoder setting in INI?

It takes one line of hal code per encoder to tie it to the setting in the INI file.

This is what is in my hal file on a machine using a 5i25+7i85S combo.

setp hm2_5i25.0.encoder.00.scale [AXIS_0]ENCODER_SCALE

Yours should be something simular, you just need to start Linuxcnc and look up what the parameter name should be.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

28 Aug 2017 12:32 #98083

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

OK, thanks for clarification Todd.

I did read that the BIT file had to be fixed and Mesaflash etc...

Will have a look later on today or tomorrow, have to go away.

I did read that the BIT file had to be fixed and Mesaflash etc...

Will have a look later on today or tomorrow, have to go away.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4688

- Thank you received: 1433

28 Aug 2017 14:48 - 28 Aug 2017 14:50 #98089

by Todd Zuercher

"Microstepping" is really a misnomer when referring to the distance moved by one step plus sent to a position mode servo. Usually the default amount is the length of one encoder count. The manual you linked to refers to it as "Electronic Gear Ratio", and is covered on pg 42-43.

Replied by Todd Zuercher on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

G'day Rod,

I have no microstepping settings on these AC servodrives not that I can find anyways. Chinese Lichuan B2.

www.europages.se/SHENZHEN-XINLICHUAN-ELE...uction%20Book~2.html

The documentation is very hard to read as it is probably google translated.

Will try to do some more testing to get rid of error message and reach acceptable speed.

These motors/drivers was working OK with Mach3/Kflop where I got very high speeds = just too much

Only difference what I can see is that now I use as in picture instead of only step/dir for input signals to driver.

This is what I have set on the drivers

Page 23 Pr1.01 is set to 2 (I believe = will confirm)

Page 24 Pr1.22 is set to 0

Page 41 5.2.1 External position mode (3 pages) These are the pages I do not any clear picture of - no timing figures.

5mm pitch on ballscrews, belt reduction 2:1

2500rpm max and 2500ppr encoders.

"Microstepping" is really a misnomer when referring to the distance moved by one step plus sent to a position mode servo. Usually the default amount is the length of one encoder count. The manual you linked to refers to it as "Electronic Gear Ratio", and is covered on pg 42-43.

Last edit: 28 Aug 2017 14:50 by Todd Zuercher.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

28 Aug 2017 15:09 #98090

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

And it is here I get confused as set to 4000 X-axis moves 100mm when commanded G0X100.

Is so that I need to set gear ratio to 2:1 and then have 2000 in scale? 4:1 = 1000 etc?

So this would result in no errors and higher speed maybe?

Difficult with CHINGLISH when I have troubles with English technical manuals.

when I have troubles with English technical manuals.

Is so that I need to set gear ratio to 2:1 and then have 2000 in scale? 4:1 = 1000 etc?

So this would result in no errors and higher speed maybe?

Difficult with CHINGLISH

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4688

- Thank you received: 1433

28 Aug 2017 16:15 #98094

by Todd Zuercher

Replied by Todd Zuercher on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Since step generation speed isn't an issue, I would suggest leaving the "Electronic Gear Ratio" at 1:1 so that one step is equal to one encoder pulse (quadrature). You have 2500 (X4 for quad) ppr encoders and 2:1 belt reduction and 5mm screws. I think your encoder scale should be 4000, and I would set the step scale the same. If you were more limited in the rate you could generate steps (software stepping for example) you could set the "Electronic Gear Ratio" to make it move farther/step at the cost of reduced resolution.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

28 Aug 2017 16:22 #98095

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

This is what I calculated and have step scale set at 4000.

There must be something wrong as I get the error messages, but what?

forum.linuxcnc.org/39-pncconf/33069-help...oing?start=230#98045

There must be something wrong as I get the error messages, but what?

forum.linuxcnc.org/39-pncconf/33069-help...oing?start=230#98045

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17423

- Thank you received: 5071

28 Aug 2017 16:35 - 28 Aug 2017 16:35 #98096

by PCW

Replied by PCW on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

If the scale is correct, are your maximum velocities reasonable?

Have you read the LInuxCNC ini file documentation?

Have you read the LInuxCNC ini file documentation?

Last edit: 28 Aug 2017 16:35 by PCW.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4688

- Thank you received: 1433

28 Aug 2017 17:44 #98099

by Todd Zuercher

Replied by Todd Zuercher on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

4000 steps/mm with a 1000ns step length and 1000ns step space, would have a max theoretical velocity of 125mm/sec (if I calculated it right.)

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

28 Aug 2017 18:15 #98101

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

So I ´m back from a hunting meeting.

PCW

No I am not satisfied with velocity, will look at settings in the drivers tomorrow. Maybe I have forgotten to set drivers to quad.

Todd

I am nowhere near those figures

Still the big Q is why do I get those error messages?

PCW

No I am not satisfied with velocity, will look at settings in the drivers tomorrow. Maybe I have forgotten to set drivers to quad.

Todd

I am nowhere near those figures

Still the big Q is why do I get those error messages?

Please Log in or Create an account to join the conversation.

Moderators: cmorley

- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Time to create page: 0.195 seconds