- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

22 Oct 2017 12:41 #100629

by andypugh

Replied by andypugh on topic This post is for "Andypugh"

It would be almost identical with a 7i76. Except that the "encoder.N.." pins become "hm2_5i25.0.encoder.00..." and the VFD outputs become hm2_5i25.0.7i76.0.0.spindir / spinena / spinout.

Please Log in or Create an account to join the conversation.

- zinsade

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 2

23 Oct 2017 20:45 #100697

by zinsade

Replied by zinsade on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Hello Andy,

I can not do it.

the following error appears:

>>> hal: 86: signal 'spindle-pwm' of type 'bit' can not add pin 'hm2_5i25.0.7i76.0.0.spinout' of type 'float' <<<

What is wrong?

This is my .hal

best regards

peter

I can not do it.

the following error appears:

>>> hal: 86: signal 'spindle-pwm' of type 'bit' can not add pin 'hm2_5i25.0.7i76.0.0.spinout' of type 'float' <<<

What is wrong?

This is my .hal

# Dateiname = 8AMP-Test-Spindel-vismach.hal

############################################################

#--- 8AMP-Test-Spindel-vismach.hal ---Stand 2017-10-22 ---#

############################################################

#-----------------------------------------------------------

# HAL config file for vismach simulation of vertical milling machine

# This file deomstrates closed-loop spindle control in both position and

# Velocity modes.

# see http://wiki.linuxcnc.org/cgi-bin/wiki.pl?SpindleOrient for a diagram

# Note that the connections of the signals to "hardware" are all in the

# sim_vmc.hal file rather than here

# First load 2x pid components. These would normally have to be loaded at

# the same time as the Axis PID components

# Initialize the pwmgen ------ nachgetragen

loadrt pwmgen output_type=0

addf pwmgen.update servo-thread

addf pwmgen.make-pulses servo-thread

setp pwmgen.0.pwm-freq 100.0

#setp pwmgen.0.min-dc 0.18

setp pwmgen.0.scale 400

#setp pwmgen.0.dither-pwm true

loadrt pid num_chan=2

addf pid.0.do-pid-calcs servo-thread # Velocity

addf pid.1.do-pid-calcs servo-thread # Position

loadrt orient

addf orient.0 servo-thread

#loadrt mux2 -- This has already been loaded in the sim_vmc.hal

loadrt mux2

addf mux2.0 servo-thread # chooses which pid output goes to the spindle speed control

#Use this to detect that the spindle is oriented

#in the 2.8 release there will be a pin for this as an output of the orient comp

#and the edge-detector is not needed

#loadrt near count=1 (loaded in sim_vmc.hal)

loadrt near count=1

loadrt edge

addf near.0 servo-thread

addf edge.0 servo-thread

setp edge.0.both 0

setp edge.0.in-edge 0

setp edge.0.out-width-ns 10000000

#----------nachgetragen

# connect the HAL encoder inputs to the real encoder.

net spindle-phase-a encoder.1.phase-A <= hm2_5i25.0.encoder.00.input-a

net spindle-phase-b encoder.1.phase-B <= hm2_5i25.0.encoder.00.input-b

net spindle-index encoder.1.phase-Z <= hm2_5i25.0.encoder.00.input-index

net spindle-pos pid.1.feedback orient.0.position

net spindle-vel pid.0.feedback hm2_5i25.0.encoder.00.velocity

net spindle-vel-cmd motion.spindle-speed-out pid.0.command

net spindle-vel-pid pid.0.output mux2.0.in0

net spindle-pos pid.1.feedback orient.0.position near.0.in1 hm2_5i25.0.encoder.00.position

net spindle-pos-cmd orient.0.command pid.1.command near.0.in2

net spindle-angle motion.spindle-orient-angle orient.0.angle

net spindle-pos-pid pid.1.output mux2.0.in1

setp near.0.difference 0.0005

net spindle-in-pos-raw near.0.out edge.0.in #not needed v2.8+, use orient.0.is-oriented

net spindle-in-pos edge.0.out motion.spindle-is-oriented

# this switches modes

net orient-mode motion.spindle-orient orient.0.enable pid.1.enable mux2.0.sel

net velocity-mode motion.spindle-on pid.0.enable pwmgen.0.enable

net orient-dir motion.spindle-orient-mode orient.0.mode

# this is simple for the simulated spindle.

net spindle-cmd mux2.0.out

#for a real spindle run by a VFD

loadrt abs count=1

addf abs.0 servo-thread

net spindle-cmd mux2.0.out abs.0.in

net spindle-cmd-abs abs.0.out pwmgen.0.value

net spindle-pwm pwmgen.0.pwm hm2_5i25.0.7i76.0.0.spinout

net spindle-fwd abs.0.is-positive hm2_5i25.0.7i76.0.0.spindir

# Tune the PID from the INI values

setp pid.0.Pgain [SPINDLE_9]PGAIN_V

setp pid.0.Igain [SPINDLE_9]IGAIN_V

setp pid.0.Dgain [SPINDLE_9]DGAIN_V

setp pid.0.FF0 [SPINDLE_9]FF0_V

setp pid.0.FF1 [SPINDLE_9]FF1_V

setp pid.1.Pgain [SPINDLE_9]PGAIN_P

setp pid.1.Igain [SPINDLE_9]IGAIN_P

setp pid.1.Dgain [SPINDLE_9]DGAIN_P

setp pid.1.FF0 [SPINDLE_9]FF0_P

setp pid.1.FF1 [SPINDLE_9]FF1_P

#-----------------------------------------------------------best regards

peter

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17622

- Thank you received: 5155

23 Oct 2017 21:23 #100698

by PCW

Replied by PCW on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

That hal file seems like it came from a parallel port configuration so not really suitable for a 5I25/7I76

I would start with a PNCCONF created configuration for the 5I25/7I76

I would start with a PNCCONF created configuration for the 5I25/7I76

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

23 Oct 2017 21:51 #100699

by andypugh

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

peter: I think the rest is OK, but the spindle pwm is for a parallel port.

Peter: You actually have too _much_ in the HAL file. Delete all references to the pwmgen HAL component, and connect the abs function outputs directly to the 7i76 spindle pins.

You also don't need this section:The only 7i76 encoder pins that you need in the HAL are the position and velocity output pins.

Peter: You actually have too _much_ in the HAL file. Delete all references to the pwmgen HAL component, and connect the abs function outputs directly to the 7i76 spindle pins.

You also don't need this section:

#----------nachgetragen

# connect the HAL encoder inputs to the real encoder.

net spindle-phase-a encoder.1.phase-A <= hm2_5i25.0.encoder.00.input-a

net spindle-phase-b encoder.1.phase-B <= hm2_5i25.0.encoder.00.input-b

net spindle-index encoder.1.phase-Z <= hm2_5i25.0.encoder.00.input-indexPlease Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

21 Dec 2017 18:57 #103440

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

21 Dec 2017 21:39 #103442

by rodw

Replied by rodw on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Looks nice!

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

21 Dec 2017 21:44 #103443

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Gday Rod, thanks.

I hope it will serve me well.

I hope it will serve me well.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

22 Dec 2017 17:03 #103461

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

23 Dec 2017 16:40 #103487

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

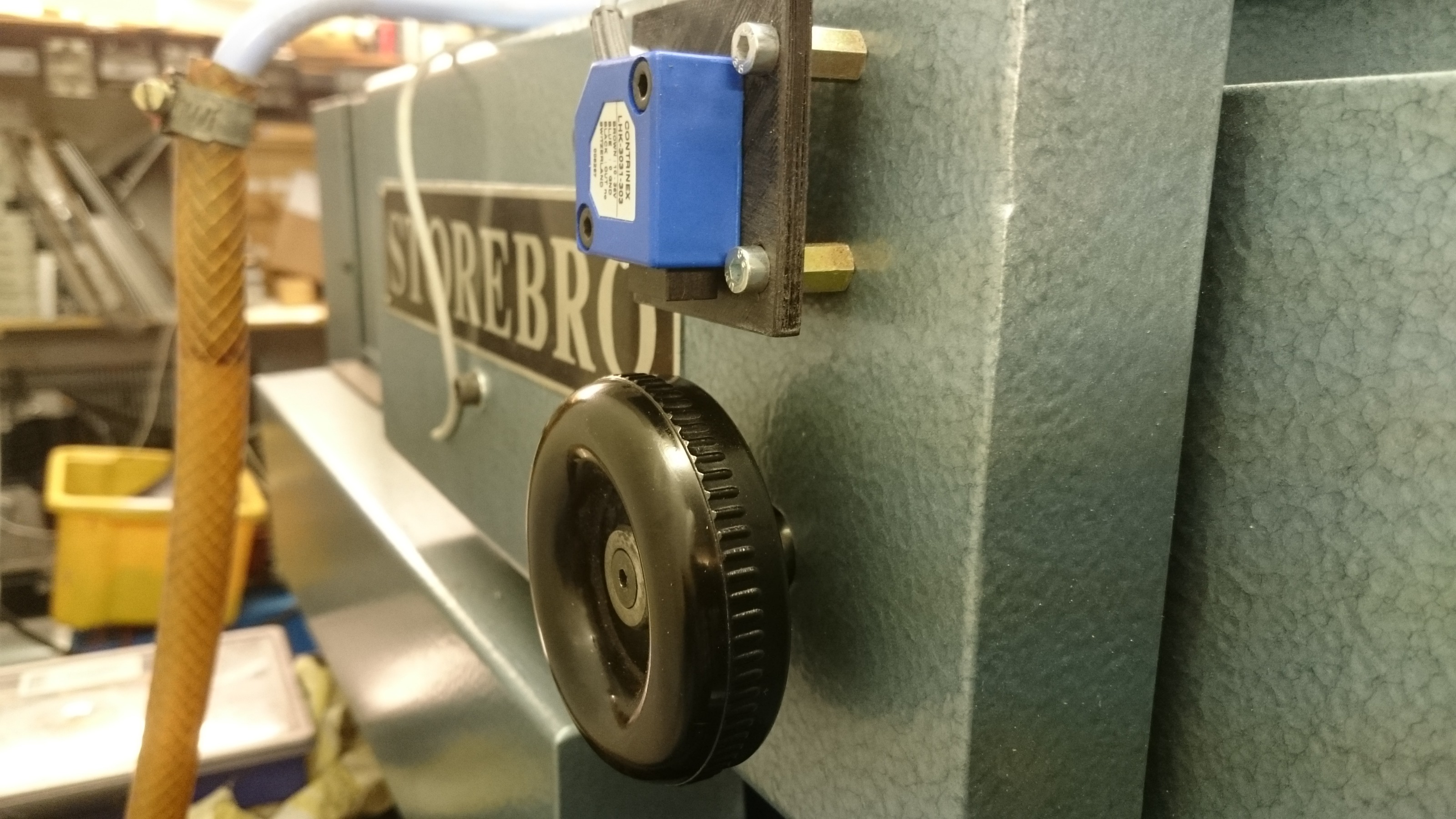

Cabling ready and tested so now it is time to tinker how to get this all working.

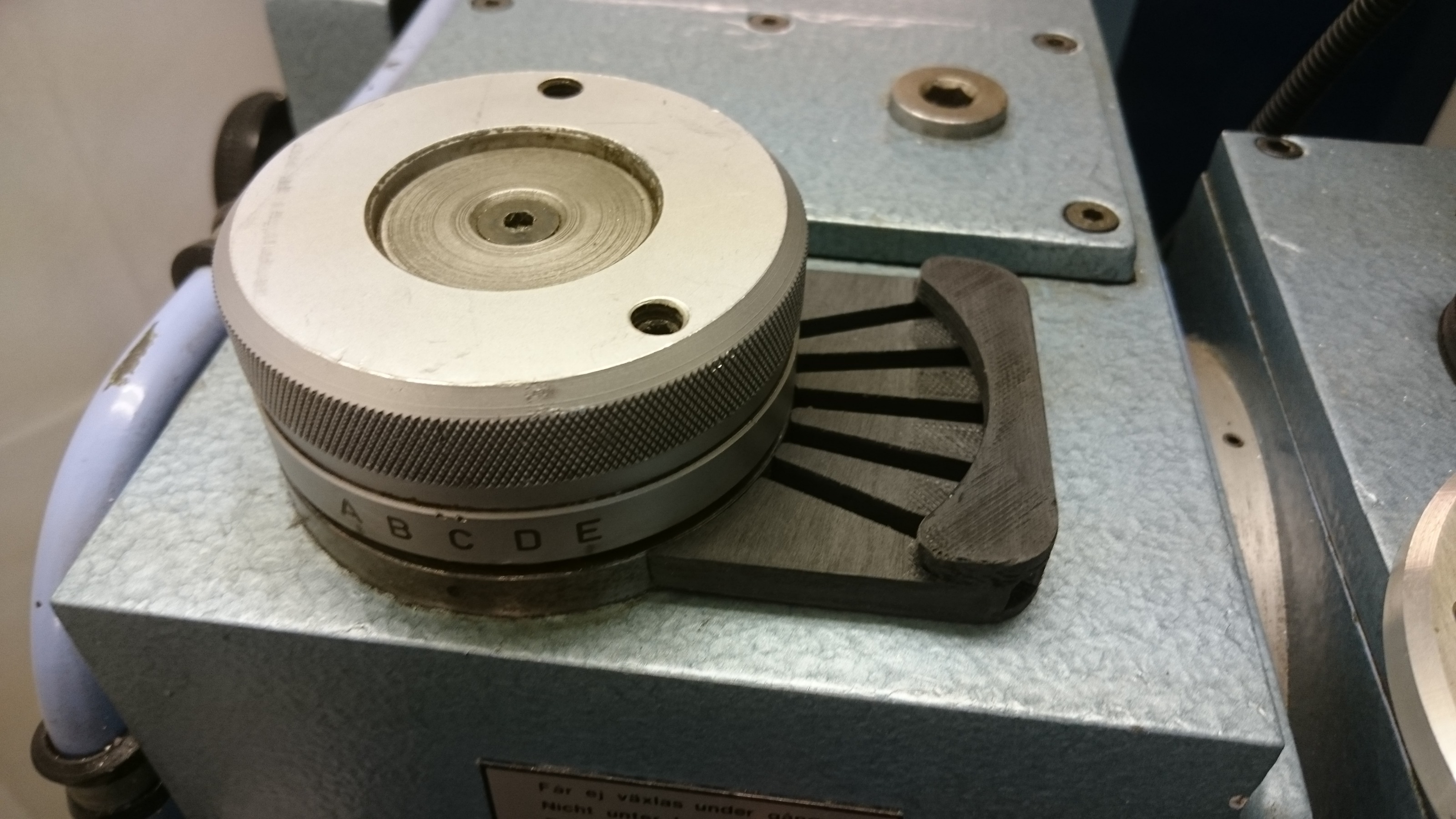

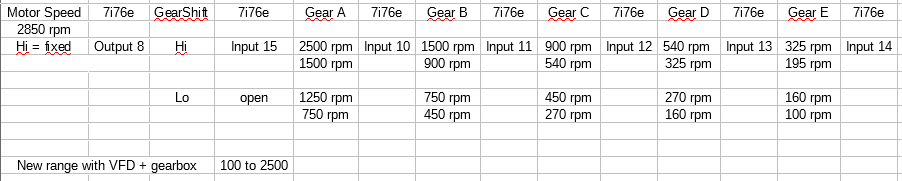

With above I get 100 to 2500 rpm, spindle motor fixed to high speed = 2850 rpm and Hi / Lo + Gears A to E.

So what would be the best way to get this working? Yes there are combinations of settings allowing two ranges.

Any pointers on what to read?

With above I get 100 to 2500 rpm, spindle motor fixed to high speed = 2850 rpm and Hi / Lo + Gears A to E.

So what would be the best way to get this working? Yes there are combinations of settings allowing two ranges.

Any pointers on what to read?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11654

- Thank you received: 3924

23 Dec 2017 17:11 #103488

by rodw

Replied by rodw on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Have a look at lut5 as that gives you 5 bits of input. Its pretty cryptic but I am sure Andy will help you. He's the expert on it.

I think once you resolve lut 5 to a speed, you should be able to use a mux2 to multiply the result by 1 or 2 depending on the hi/lo gear selection.

I think once you resolve lut 5 to a speed, you should be able to use a mux2 to multiply the result by 1 or 2 depending on the hi/lo gear selection.

Please Log in or Create an account to join the conversation.

Moderators: cmorley

- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Time to create page: 0.298 seconds