- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

20 Aug 2018 17:35 #116377

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Something else must be set wrong, did test to edit speedratio but still nothing.

I can hear that motor relay is activated so it seems VFD is not getting any voltage from 7i76e output.

I can hear that motor relay is activated so it seems VFD is not getting any voltage from 7i76e output.

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1119

- Thank you received: 393

20 Aug 2018 18:04 - 20 Aug 2018 18:06 #116378

by Hakan

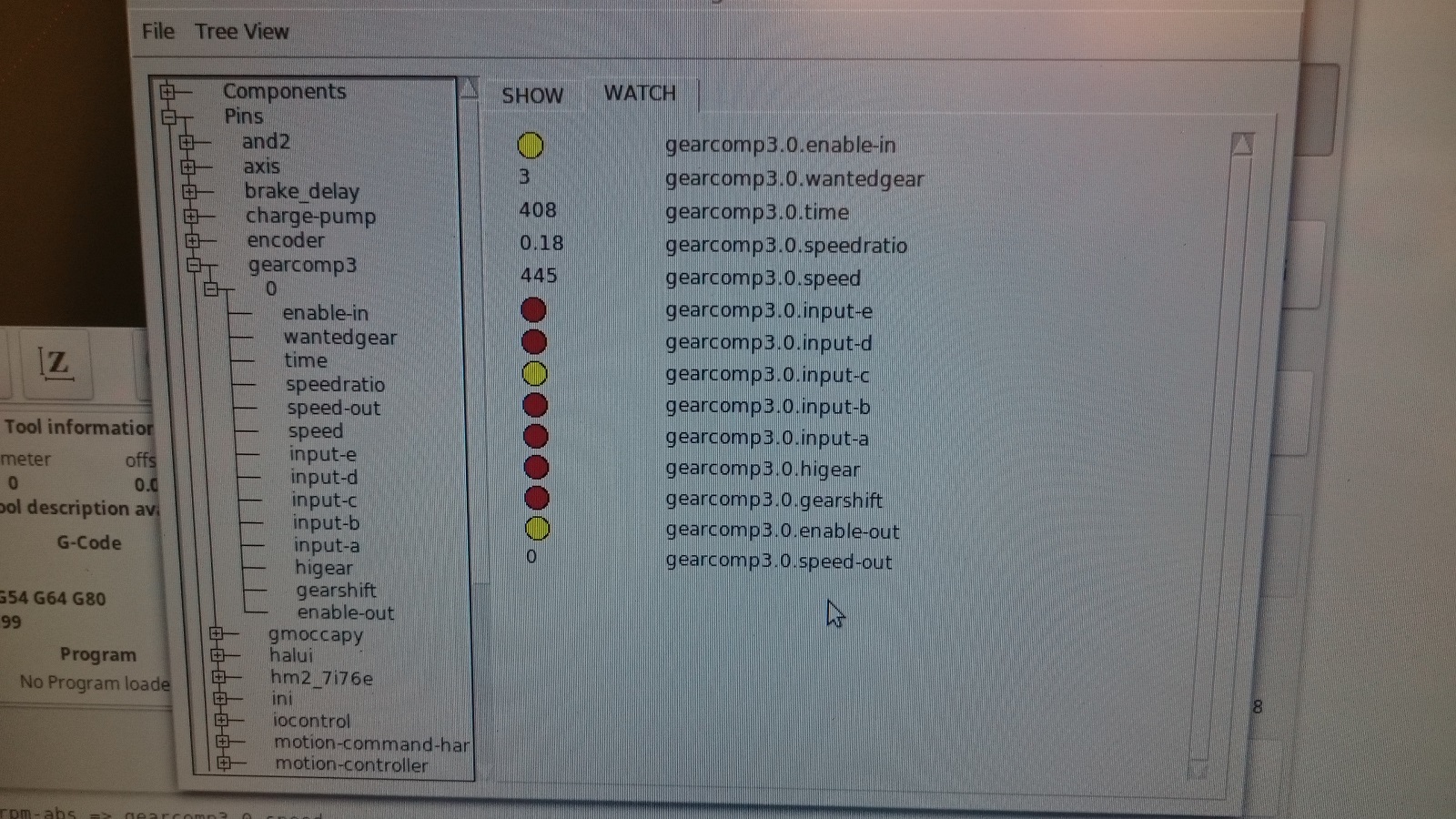

Ok, let's look at the screen.

You have input-c high which is third gear. gearcomp3 also wants you to use third gear so that is okay.

The speedratio is chosen to 0.18 which is fine for third gear. You have enable-in high and enable-out high, so the gearcomp3 clearly thinks you have the right gear.

But speed_out is 0.0. So there must be something wrong with the code you entered. Can you copy-paste the last if-statement in the component. I tend to think you placed the calculation of speed_out in the wrong place, setting it to zero when right gear is chosen and giving it a value when the wrong gear is chosen. But lets see.

Replied by Hakan on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

I think the intention was to merge your version with another version.

The speed_out pin was lost in that process.

Bengt, you need to

1. Add the speed_out pin in the gearcomp3 componentpin out float speed_out "Motor speed needed";

2. In the "if" statement at the end, add at the endwhen the right gear is engaged, andspeed_out = speed/speedratio;when the wrong gear is engaged.speed_out = 0.0;

3. halcompile and resinstall component

4. Change the hal file tonet spindlespeed <= gearcomp3.0.speed_out => hm2_7i76e.0.7i76.0.0.spinout

]net spindlespeed <= gearcomp3.0.speed-out => hm2_7i76e.0.7i76.0.0.spinout[

PROGRESS

I think there is something wrong with speedratio that is shown as 0.18 and should be just about 1.0 or a bit less.

Some tweaking but what to change?

Ok, let's look at the screen.

You have input-c high which is third gear. gearcomp3 also wants you to use third gear so that is okay.

The speedratio is chosen to 0.18 which is fine for third gear. You have enable-in high and enable-out high, so the gearcomp3 clearly thinks you have the right gear.

But speed_out is 0.0. So there must be something wrong with the code you entered. Can you copy-paste the last if-statement in the component. I tend to think you placed the calculation of speed_out in the wrong place, setting it to zero when right gear is chosen and giving it a value when the wrong gear is chosen. But lets see.

Last edit: 20 Aug 2018 18:06 by Hakan.

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1119

- Thank you received: 393

20 Aug 2018 18:08 #116379

by Hakan

From the figure in the previous post, speed_out is zero, so it should not run. See above.

Replied by Hakan on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Something else must be set wrong, did test to edit speedratio but still nothing.

I can hear that motor relay is activated so it seems VFD is not getting any voltage from 7i76e output.

From the figure in the previous post, speed_out is zero, so it should not run. See above.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

20 Aug 2018 18:08 #116380

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

if (inputs_sum > 0 && geartouse == gearengaged) { // Everything ok

gearshift = 0;

wantedgear = gearengaged;

speedratio = ratios[gearengaged-1];

enable_out = enable_in;

} else { // Should change gear

gearshift = 1;

wantedgear = geartouse;

speedratio = ratios[geartouse-1];

enable_out = 0;

speed_out = speed/speedratio;

speed_out = 0.0;

}

}

gearshift = 0;

wantedgear = gearengaged;

speedratio = ratios[gearengaged-1];

enable_out = enable_in;

} else { // Should change gear

gearshift = 1;

wantedgear = geartouse;

speedratio = ratios[geartouse-1];

enable_out = 0;

speed_out = speed/speedratio;

speed_out = 0.0;

}

}

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1119

- Thank you received: 393

20 Aug 2018 18:12 #116381

by Hakan

I moved the speed_out speed calculation to the right place. Now it should work. Remove the arrow.

Replied by Hakan on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

if (inputs_sum > 0 && geartouse == gearengaged) { // Everything ok

gearshift = 0;

wantedgear = gearengaged;

speedratio = ratios[gearengaged-1];

enable_out = enable_in;

speed_out = speed/speedratio; <===============

} else { // Should change gear

gearshift = 1;

wantedgear = geartouse;

speedratio = ratios[geartouse-1];

enable_out = 0;

speed_out = 0.0;

}I moved the speed_out speed calculation to the right place. Now it should work. Remove the arrow.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

20 Aug 2018 18:14 #116382

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

OK, will go down to the workshop and try y´this out now.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19753

- Thank you received: 4586

20 Aug 2018 18:15 #116383

by andypugh

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

I think I still prefer my switch{} as a way to determine the gear, it can detect invalid combinations.

It might be better to multiply by speedratio, just so that there is no chance of a divide-by-zero if a config mistake makes speedratio=0

It might be better to multiply by speedratio, just so that there is no chance of a divide-by-zero if a config mistake makes speedratio=0

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1119

- Thank you received: 393

20 Aug 2018 18:22 #116384

by Hakan

Replied by Hakan on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

You have a good point. The way it is done now is not very error-proof.

One way to ensure only one input is active is to

if (input_a + input_b + input_c + input_d + input_e != 1) .......

I also have a feeling there are other erroneous combinations possible,

especially in combinations with the Glade input that is coming.

I don't mind if like you to bring back the switch-case.

One way to ensure only one input is active is to

if (input_a + input_b + input_c + input_d + input_e != 1) .......

I also have a feeling there are other erroneous combinations possible,

especially in combinations with the Glade input that is coming.

I don't mind if like you to bring back the switch-case.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

20 Aug 2018 18:59 #116385

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

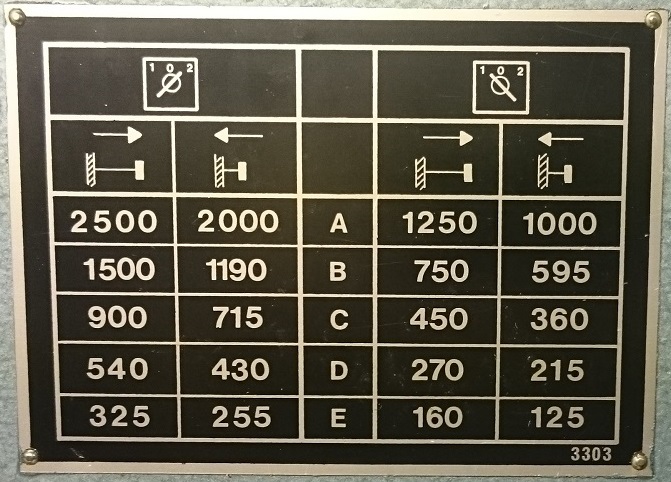

OK, it works but does not work correctly. S445 spindle is moving very slow due to speedratio.

first of all I have been misleading myself as well as you guys as regards rpm range.

This mill has a 2-speed 3-phase motor (Dahlander type)

So there is 2 ranges for the motor where now only the higher speed is active in my setup just now.

So in effect this gives 255 to 2500 rpm and if motor is switched to low speed 125 to 1250

So if I want the whole range I need to implement the low speed relay and I will do that as I want the whole range + some extra.

Honestly I don´t think if motor is in high speed to try to crank it down that much via VFD that I wanted is good for the motor as it surely will overheat.

So back to the drawingboard.

first of all I have been misleading myself as well as you guys as regards rpm range.

This mill has a 2-speed 3-phase motor (Dahlander type)

So there is 2 ranges for the motor where now only the higher speed is active in my setup just now.

So in effect this gives 255 to 2500 rpm and if motor is switched to low speed 125 to 1250

So if I want the whole range I need to implement the low speed relay and I will do that as I want the whole range + some extra.

Honestly I don´t think if motor is in high speed to try to crank it down that much via VFD that I wanted is good for the motor as it surely will overheat.

So back to the drawingboard.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19753

- Thank you received: 4586

20 Aug 2018 21:43 #116388

by andypugh

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Can I suggest reading about using VFDs with Dahlander motors?

There are things to consider. (One of which is that Dahlander-wound motors are generally quite old).

I think that it might work better to run the motor at 100Hz in low mode than 25 Hz in high mode.

If you choose to use both then you need to avoid re-arranging the windings with the VFD enabled.

There are things to consider. (One of which is that Dahlander-wound motors are generally quite old).

I think that it might work better to run the motor at 100Hz in low mode than 25 Hz in high mode.

If you choose to use both then you need to avoid re-arranging the windings with the VFD enabled.

Please Log in or Create an account to join the conversation.

Moderators: cmorley

- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Time to create page: 0.183 seconds