- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

19 Aug 2018 17:29 #116332

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

# ---Setup spindle at speed signals---

sets spindle-at-speed true

setp hm2_7i76e.0.7i76.0.0.spinout-scalemax 2400

setp hm2_7i76e.0.7i76.0.0.spinout-maxlim 2500

net spindle-enable hm2_7i76e.0.7i76.0.0.spinena

net spindle-vel-cmd-rpm-abs hm2_7i76e.0.7i76.0.0.spinout

net spindle-ccw hm2_7i76e.0.7i76.0.0.spindir

sets spindle-at-speed true

setp hm2_7i76e.0.7i76.0.0.spinout-scalemax 2400

setp hm2_7i76e.0.7i76.0.0.spinout-maxlim 2500

net spindle-enable hm2_7i76e.0.7i76.0.0.spinena

net spindle-vel-cmd-rpm-abs hm2_7i76e.0.7i76.0.0.spinout

net spindle-ccw hm2_7i76e.0.7i76.0.0.spindir

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

19 Aug 2018 17:31 - 19 Aug 2018 17:31 #116333

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

My thoughts

# ---Setup spindle at speed signals via gearcomp3---

sets spindle-at-speed true

setp hm2_7i76e.0.7i76.0.0.spinout-scalemax 2400

setp hm2_7i76e.0.7i76.0.0.spinout-maxlim 2500

net spindle-enable => gearcomp3.0.enable-in

net spinenable => gearcomp3.0.enable-out => hm2_7i76e.0.7i76.0.0.spinena

net spindle-vel-cmd-rpm-abs => gearcomp3.0.speed

net spindlespeed => gearcomp3.0.speedratio => hm2_7i76e.0.7i76.0.0.spinout

net spindle-ccw hm2_7i76e.0.7i76.0.0.spindir

# ---Setup spindle at speed signals via gearcomp3---

sets spindle-at-speed true

setp hm2_7i76e.0.7i76.0.0.spinout-scalemax 2400

setp hm2_7i76e.0.7i76.0.0.spinout-maxlim 2500

net spindle-enable => gearcomp3.0.enable-in

net spinenable => gearcomp3.0.enable-out => hm2_7i76e.0.7i76.0.0.spinena

net spindle-vel-cmd-rpm-abs => gearcomp3.0.speed

net spindlespeed => gearcomp3.0.speedratio => hm2_7i76e.0.7i76.0.0.spinout

net spindle-ccw hm2_7i76e.0.7i76.0.0.spindir

Last edit: 19 Aug 2018 17:31 by tecno. Reason: edit text

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1134

- Thank you received: 399

19 Aug 2018 18:53 #116339

by Hakan

Replied by Hakan on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Did you try it yet?

In principle I think it is okay.

But the speedratio I mentioned. There is an issue.

From the speedratio pin you only get out 0.064 0.108 etc depending on which gear is engaged.

Either you keep it that way, and then you need to get the motorspeed as speed/ratio and do that in hal using for example mult2.

Or modify the component to instead of speedratio deliver speed_out calculated as speed/ratio inside the component.

Depends if you need the ratio for something else. If all you need is the motor_speed I would say best to modify the component.

In principle I think it is okay.

But the speedratio I mentioned. There is an issue.

From the speedratio pin you only get out 0.064 0.108 etc depending on which gear is engaged.

Either you keep it that way, and then you need to get the motorspeed as speed/ratio and do that in hal using for example mult2.

Or modify the component to instead of speedratio deliver speed_out calculated as speed/ratio inside the component.

Depends if you need the ratio for something else. If all you need is the motor_speed I would say best to modify the component.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

19 Aug 2018 19:18 #116340

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

No, will try it tomorrow.

As I see this is, that whatever gear is involved the speed VFD gets max at max speed and drops down to achieve necessary min speed of motor.

Today S2500 revs up the motor to max at 10V (or is it 5V I don´t remember)

and min in Higear + A would be 1500 so 40% less = 6V

This is what it should be on all gears. The comp is there to calculate gear from Sxxxx input only and only give OK if the gear condition is OK. Also I think a short delay should be implemented so no accidents will happen with gearbox.

As I see this is, that whatever gear is involved the speed VFD gets max at max speed and drops down to achieve necessary min speed of motor.

Today S2500 revs up the motor to max at 10V (or is it 5V I don´t remember)

and min in Higear + A would be 1500 so 40% less = 6V

This is what it should be on all gears. The comp is there to calculate gear from Sxxxx input only and only give OK if the gear condition is OK. Also I think a short delay should be implemented so no accidents will happen with gearbox.

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1134

- Thank you received: 399

19 Aug 2018 19:32 - 19 Aug 2018 19:33 #116342

by Hakan

Replied by Hakan on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

But where will you calculate the motor rpms for the different gears?

First gear running at max 160 rpm => 2500 rpm on the motor. This give 10V at 160 spindle-rpm when the first gear is engaged.

160 / 0.064 = 2500 motor-rpms.

This calculation need to be done. Either in hal. Or in the component.

First gear running at max 160 rpm => 2500 rpm on the motor. This give 10V at 160 spindle-rpm when the first gear is engaged.

160 / 0.064 = 2500 motor-rpms.

This calculation need to be done. Either in hal. Or in the component.

Last edit: 19 Aug 2018 19:33 by Hakan.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

19 Aug 2018 19:50 - 19 Aug 2018 19:51 #116343

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Well that is a good question, motor rpm is the same for all gears max down to min always the same.

Last edit: 19 Aug 2018 19:51 by tecno.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4600

19 Aug 2018 20:58 #116345

by andypugh

The component I wrote did this. But I see that you seem to have abandoned my version about 40 posts ago.

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

But where will you calculate the motor rpms for the different gears?.

The component I wrote did this. But I see that you seem to have abandoned my version about 40 posts ago.

Please Log in or Create an account to join the conversation.

- Hakan

- Offline

- Platinum Member

-

Less

More

- Posts: 1134

- Thank you received: 399

20 Aug 2018 07:33 #116364

by Hakan

Replied by Hakan on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

I think the intention was to merge your version with another version.

The speed_out pin was lost in that process.

Bengt, you need to

1. Add the speed_out pin in the gearcomp3 component

2. In the "if" statement at the end, add at the endwhen the right gear is engaged, andwhen the wrong gear is engaged.

3. halcompile and resinstall component

4. Change the hal file to

The speed_out pin was lost in that process.

Bengt, you need to

1. Add the speed_out pin in the gearcomp3 component

pin out float speed_out "Motor speed needed";2. In the "if" statement at the end, add at the end

speed_out = speed/speedratio;speed_out = 0.0;3. halcompile and resinstall component

4. Change the hal file to

net spindlespeed <= gearcomp3.0.speed_out => hm2_7i76e.0.7i76.0.0.spinoutPlease Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

20 Aug 2018 08:55 #116365

by tecno

Not abandoned but put on hold as I can not solve the puzzle. I´m a novice at this so it is what it is on my part I put things on hold whenever I can not solve task at hand.

Cheers

Bengt

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

But where will you calculate the motor rpms for the different gears?.

The component I wrote did this. But I see that you seem to have abandoned my version about 40 posts ago.

Not abandoned but put on hold as I can not solve the puzzle. I´m a novice at this so it is what it is on my part I put things on hold whenever I can not solve task at hand.

Cheers

Bengt

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

20 Aug 2018 12:20 #116370

by tecno

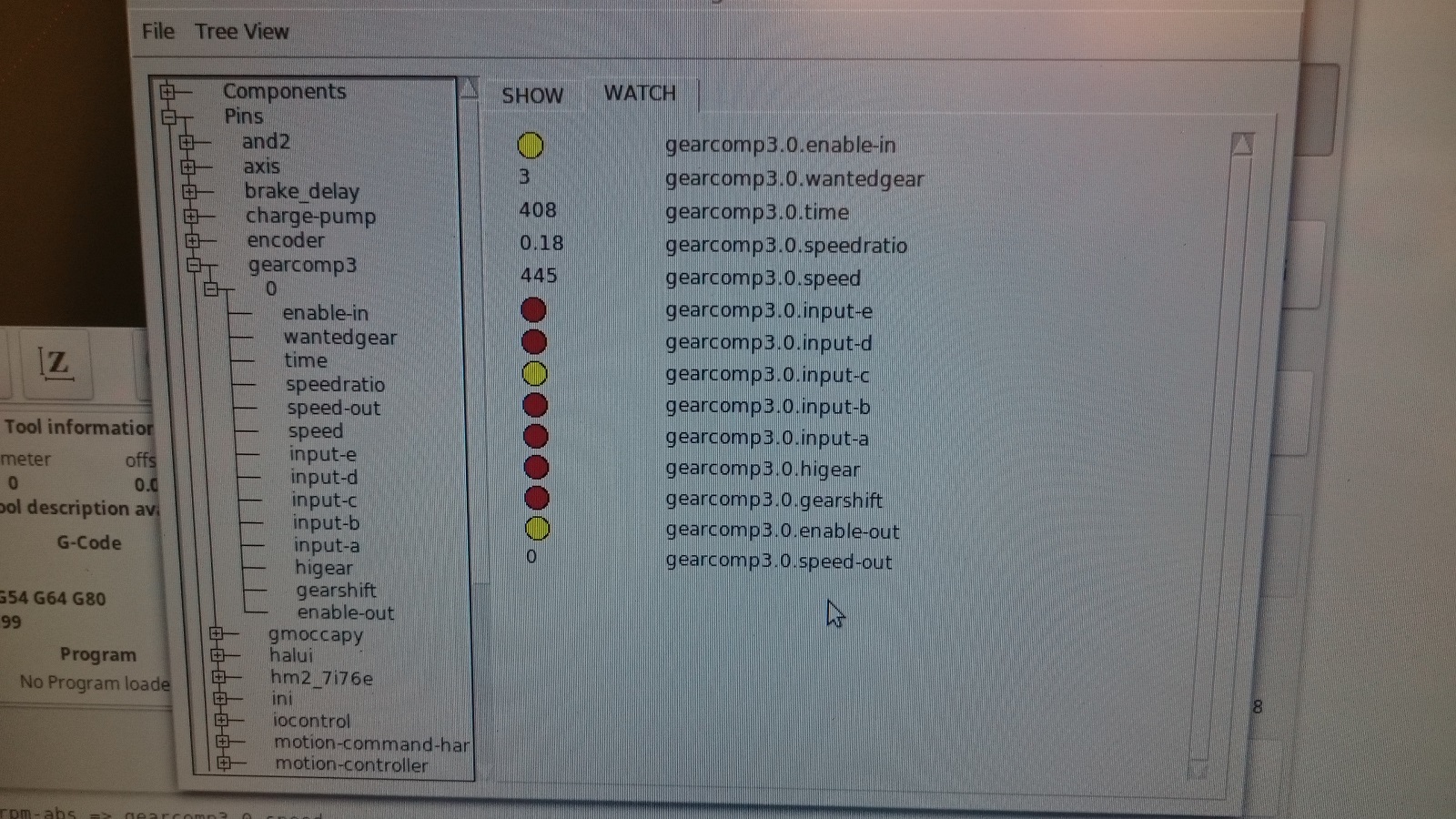

]net spindlespeed <= gearcomp3.0.speed-out => hm2_7i76e.0.7i76.0.0.spinout[

PROGRESS

I think there is something wrong with speedratio that is shown as 0.18 and should be just about 1.0 or a bit less.

Some tweaking but what to change?

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

I think the intention was to merge your version with another version.

The speed_out pin was lost in that process.

Bengt, you need to

1. Add the speed_out pin in the gearcomp3 componentpin out float speed_out "Motor speed needed";

2. In the "if" statement at the end, add at the endwhen the right gear is engaged, andspeed_out = speed/speedratio;when the wrong gear is engaged.speed_out = 0.0;

3. halcompile and resinstall component

4. Change the hal file tonet spindlespeed <= gearcomp3.0.speed_out => hm2_7i76e.0.7i76.0.0.spinout

]net spindlespeed <= gearcomp3.0.speed-out => hm2_7i76e.0.7i76.0.0.spinout[

PROGRESS

I think there is something wrong with speedratio that is shown as 0.18 and should be just about 1.0 or a bit less.

Some tweaking but what to change?

Please Log in or Create an account to join the conversation.

Moderators: cmorley

- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Time to create page: 0.408 seconds