- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

23 Aug 2018 08:35 #116476

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

23 Aug 2018 09:34 #116477

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

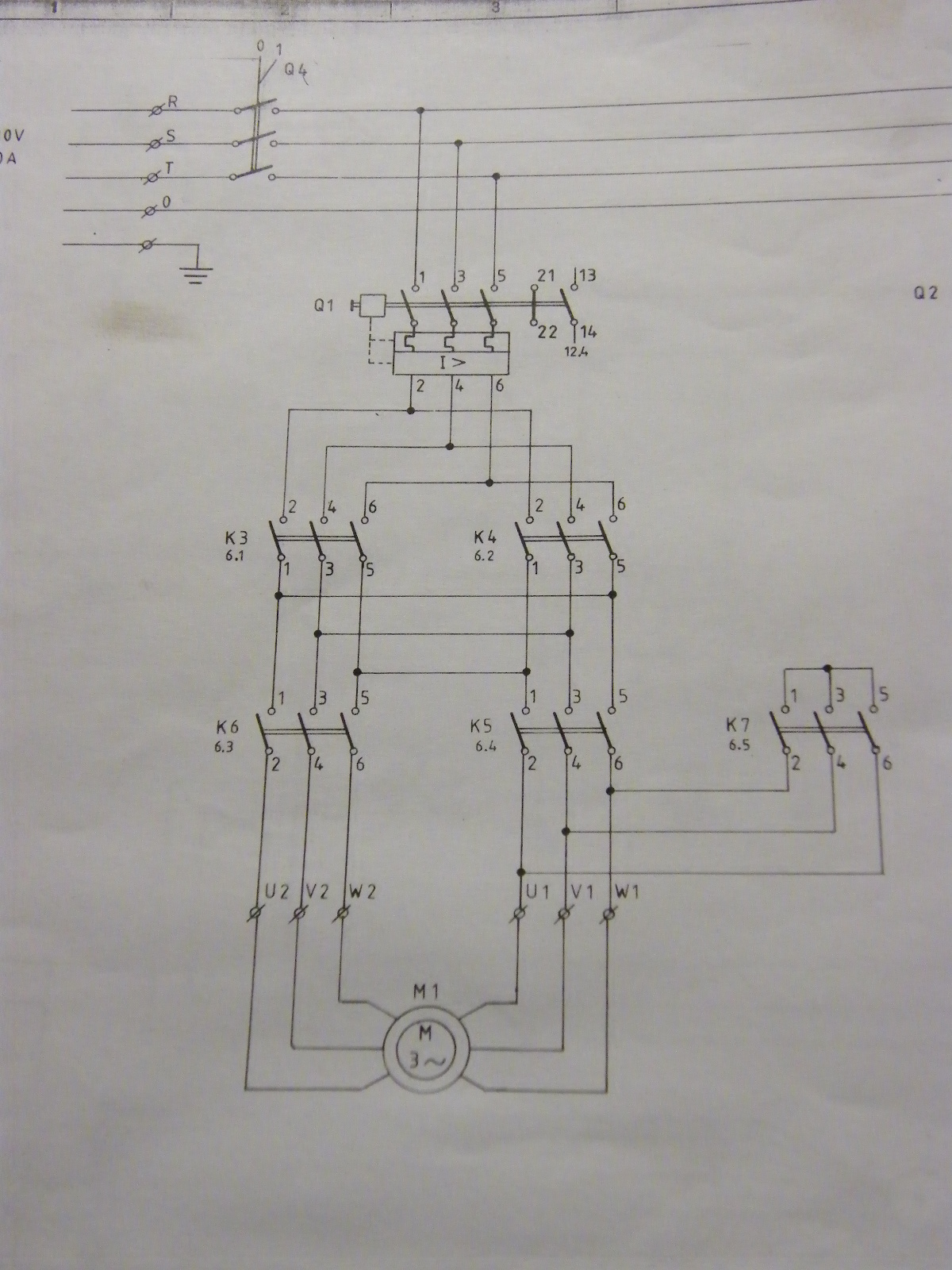

This is what I think will be the solution to get most out of speed range without too many gears/switches to handle.

Motor in Hi only for A and B in Hi/Lo gear ~1001 to 2500rpm

Motor in Lo for B to E in Hi/Lo gear ~80 to 1000rpm

Motor in Hi only for A and B in Hi/Lo gear ~1001 to 2500rpm

Motor in Lo for B to E in Hi/Lo gear ~80 to 1000rpm

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

23 Aug 2018 12:44 #116485

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Andy

Is this close to a working comp with the new arrangement of gears and motorspeed + part of hal??

Is this close to a working comp with the new arrangement of gears and motorspeed + part of hal??

component gearblocker;

pin in bit spindle-enable-in;

pin out bit spindle-enable-out;

pin in float spindle-speed-in;

pin out float motor-speed-out;

pin in float gear.#.min-speed[12];

pin in float gear.#.max-speed[12];

pin in float gear.#.ratio[12]; >>>>>>>>>>> is this needed as motor goes H/L and small adjusts via VFD within min/max of gear?

pin in bit high-gear;

pin in bit gear-AH;

pin in bit gear-BH;

pin in bit gear-B;

pin in bit gear-C;

pin in bit gear-D;

pin in bit gear-E;

license "gpl";

function _;

;;

FUNCTION(_){

int i;

int gear;

if (spindle_speed_in == 0) return;

switch (gear_AH + gear_BH * 2 + gear_B * 4 + gear_C * 8 + gear_D * 16 + gear_E *32) {

case 1: // Gear AH

gear = (high_gear != 0) ? 1 : 7;

break;

case 2: // Gear BH

gear = (high_gear != 0) ? 2 : 8;

break;

case 4: // Gear B

gear = (high_gear != 0) ? 3 : 9;

break;

case 1: // Gear C

gear = (high_gear != 0) ? 4 : 10;

break;

case 1: // Gear D

gear = (high_gear != 0) ? 5 : 11;

break;

case 1: // Gear E

gear = (high_gear != 0) ? 6 : 12;

break;

case else: // gear selection is bitmasked to be able to spot double-engagement

gear = 0;

}

if (spindle_speed_in >= min_speed(gear) && spindle_speed_in <= max_speed(gear)) {

motor_speed_out = spindle_speed_ * gear_ratio(gear);

spindle_enable_out = spindle_enable_in;

} else {

motor_speed_out = 0;

spindle_enable_out = 0;

}

}

hal

net input-ah-signal => gearblocker.0.input-ah <= hm2_7i76e.0.7i76.0.0.input-09

net input-bh-signal => gearblocker.0.input-bh <= hm2_7i76e.0.7i76.0.0.input-10

net input-ah-signal => hm2_7i76e.0.7i76.0.0.output-10

net input-bh-signal => hm2_7i76e.0.7i76.0.0.output-10

net input-b-signal => gearblocker.0.input-b <= hm2_7i76e.0.7i76.0.0.input-10

net input-c-signal => gearblocker.0.input-c <= hm2_7i76e.0.7i76.0.0.input-11

net input-d-signal => gearblocker.0.input-d <= hm2_7i76e.0.7i76.0.0.input-12

net input-e-signal => gearblocker.0.input-e <= hm2_7i76e.0.7i76.0.0.input-13Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

24 Aug 2018 11:19 #116532

by andypugh

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Well, the repeated case 1: is a definite fault. Didn't I post an updated version?

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

24 Aug 2018 11:22 #116533

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Oboy that´s a typo from my part as I did copy and paste.

No I have not seen any updated version.

No I have not seen any updated version.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

24 Aug 2018 11:24 #116534

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Hope this part is more OK

FUNCTION(_){

int i;

int gear;

if (spindle_speed_in == 0) return;

switch (gear_AH + gear_BH * 2 + gear_B * 4 + gear_C * 8 + gear_D * 16 + gear_E *32) {

case 1: // Gear AH

gear = (high_gear != 0) ? 1 : 7;

break;

case 2: // Gear BH

gear = (high_gear != 0) ? 2 : 8;

break;

case 3: // Gear B

gear = (high_gear != 0) ? 3 : 9;

break;

case 4: // Gear C

gear = (high_gear != 0) ? 4 : 10;

break;

case 5: // Gear D

gear = (high_gear != 0) ? 5 : 11;

break;

case 6: // Gear E

gear = (high_gear != 0) ? 6 : 12;

break;

case else: // gear selection is bitmasked to be able to spot double-engagement

gear = 0;

}

if (spindle_speed_in >= min_speed(gear) && spindle_speed_in <= max_speed(gear)) {

motor_speed_out = spindle_speed_ * gear_ratio(gear);

spindle_enable_out = spindle_enable_in;

} else {

motor_speed_out = 0;

spindle_enable_out = 0;

}

}Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

24 Aug 2018 11:28 #116535

by andypugh

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

The version here:

forum.linuxcnc.org/39-pncconf/33069-help...ing?start=460#116030

Should work better.

But doesn't actually disallow high speed in low gears.

But the other component does a better job of suggesting which gear should be used.

forum.linuxcnc.org/39-pncconf/33069-help...ing?start=460#116030

Should work better.

But doesn't actually disallow high speed in low gears.

But the other component does a better job of suggesting which gear should be used.

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

24 Aug 2018 11:35 #116537

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Same same but different mine is.

I have yours as a base but now motor speeds HI and LO needs to be implemented.

Have a closer look at

forum.linuxcnc.org/39-pncconf/33069-help...ing?start=560#116477

I have yours as a base but now motor speeds HI and LO needs to be implemented.

Have a closer look at

forum.linuxcnc.org/39-pncconf/33069-help...ing?start=560#116477

Please Log in or Create an account to join the conversation.

- tecno

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

27 Aug 2018 11:58 #116645

by tecno

Replied by tecno on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

This compiles, but I would like to know what following lines actually does (as I think it is wrong).

pin in float gear.#.ratio[12];

motor_speed_out = spindle_speed_in * gear_ratio(gear);

As the spindle should go max at HI/LO motorspeed on each gear max and only adjust to min speed of that gear via VFD.

pin in float gear.#.ratio[12];

motor_speed_out = spindle_speed_in * gear_ratio(gear);

As the spindle should go max at HI/LO motorspeed on each gear max and only adjust to min speed of that gear via VFD.

component GB_2speed;

pin in bit spindle-enable-in;

pin out bit spindle-enable-out;

pin in float spindle-speed-in;

pin out float motor-speed-out;

pin in float gear.#.min-speed[12];

pin in float gear.#.max-speed[12];

pin in float gear.#.ratio[12];

pin in bit high-gear;

pin in bit gear-AH;

pin in bit gear-BH;

pin in bit gear-B;

pin in bit gear-C;

pin in bit gear-D;

pin in bit gear-E;

license "gpl";

function _;

;;

FUNCTION(_){

int gear;

if (spindle_speed_in == 0) return;

switch (gear_AH + gear_BH * 2 + gear_B * 4 + gear_C * 8 + gear_D * 16 + gear_E *32) {

case 1: // Gear AH

gear = (high_gear != 0) ? 1 : 7;

break;

case 2: // Gear BH

gear = (high_gear != 0) ? 2 : 8;

break;

case 3: // Gear B

gear = (high_gear != 0) ? 3 : 9;

break;

case 4: // Gear C

gear = (high_gear != 0) ? 4 : 10;

break;

case 5: // Gear D

gear = (high_gear != 0) ? 5 : 11;

break;

case 6: // Gear E

gear = (high_gear != 0) ? 6 : 12;

break;

default: // gear selection is bitmasked to be able to spot double-engagement

gear = 0;

}

if (gear >= 0 && spindle_speed_in >= gear_min_speed(gear) && spindle_speed_in <= gear_max_speed(gear)) {

motor_speed_out = spindle_speed_in * gear_ratio(gear);

spindle_enable_out = spindle_enable_in;

} else {

motor_speed_out = 0;

spindle_enable_out = 0;

}

}Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

28 Aug 2018 12:24 #116704

by andypugh

Replied by andypugh on topic Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

The cases need to be 1, 2, 4, 8, 16 etc.

(Like the updated version that I posted, and gave you a link to).

Are you saying that you want to always run the VFD at 50 Hz?

The code that you have highlighted is intended to calculate the motor speed for the current spindle speed. as input it has a HAL pin where you need to set the ratio for each gear.

(Like the updated version that I posted, and gave you a link to).

Are you saying that you want to always run the VFD at 50 Hz?

The code that you have highlighted is intended to calculate the motor speed for the current spindle speed. as input it has a HAL pin where you need to set the ratio for each gear.

Please Log in or Create an account to join the conversation.

Moderators: cmorley

- Configuring LinuxCNC

- Configuration Tools

- PnCConf Wizard

- Help needed to get my 7i76E + 7i85S + 7i73 on my mill going.

Time to create page: 0.174 seconds