Mesa 5i25 + 7i77D can't cofig

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21178

- Thank you received: 7235

29 Apr 2021 13:49 #207375

by tommylight

Replied by tommylight on topic Mesa 5i25 + 7i77D can't cofig

OK that seems good, for Z set it to 1 or 2 and try again.

Then set the jog velocity to very slow and try to jog very shortly in both directions for each axis. If any of them "jump" the direction for the output or the encoder has to be reversed in hal.

Then set the jog velocity to very slow and try to jog very shortly in both directions for each axis. If any of them "jump" the direction for the output or the encoder has to be reversed in hal.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17605

- Thank you received: 5147

29 Apr 2021 15:03 #207380

by PCW

Replied by PCW on topic Mesa 5i25 + 7i77D can't cofig

Jerks/overshoots when jogging can be caused by incorrect (too high) FF1

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Taichi

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 0

29 Apr 2021 20:18 #207394

by Taichi

Replied by Taichi on topic Mesa 5i25 + 7i77D can't cofig

Can you explain me what means that all parameters in servo tune?

I read your instructions maybe hundred times.

In English can't fully understand what you mean. Google translate bad working with technical words. Excuse me if i make stupid question.

I understood what you said about different direction of encoder and motor. Motor drift to positive side and encoder counting to negative side. Linuxcnc think that need to compensate in analogoutN. Encoder counting faster to same direction, close loop and we have rise amplitude vibration.

jog.n.f-error its that parameter who show bad fluctuations when PID controller try to move servo?

Minimum fluctuations = maximum performance

I read your instructions maybe hundred times.

In English can't fully understand what you mean. Google translate bad working with technical words. Excuse me if i make stupid question.

I understood what you said about different direction of encoder and motor. Motor drift to positive side and encoder counting to negative side. Linuxcnc think that need to compensate in analogoutN. Encoder counting faster to same direction, close loop and we have rise amplitude vibration.

jog.n.f-error its that parameter who show bad fluctuations when PID controller try to move servo?

Minimum fluctuations = maximum performance

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21178

- Thank you received: 7235

29 Apr 2021 21:01 #207401

by tommylight

Replied by tommylight on topic Mesa 5i25 + 7i77D can't cofig

I think wee need to do this step by step since a lot of info gets lost in translation.

Do the drives disable and enable with F2 ?

This is the first thing to have working.

Do the drives disable and enable with F2 ?

This is the first thing to have working.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17605

- Thank you received: 5147

29 Apr 2021 21:05 #207403

by PCW

Replied by PCW on topic Mesa 5i25 + 7i77D can't cofig

To avoid jerks/oscillations set all P terms to say 2

and _all_ other PID terms to 0 to start

Then you need to look at one of the tuning tutorials,

open the calibrate menus and tune one parameter

on one axis at a time.

and _all_ other PID terms to 0 to start

Then you need to look at one of the tuning tutorials,

open the calibrate menus and tune one parameter

on one axis at a time.

Please Log in or Create an account to join the conversation.

- Taichi

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 0

30 Apr 2021 18:58 - 30 Apr 2021 19:02 #207474

by Taichi

Replied by Taichi on topic Mesa 5i25 + 7i77D can't cofig

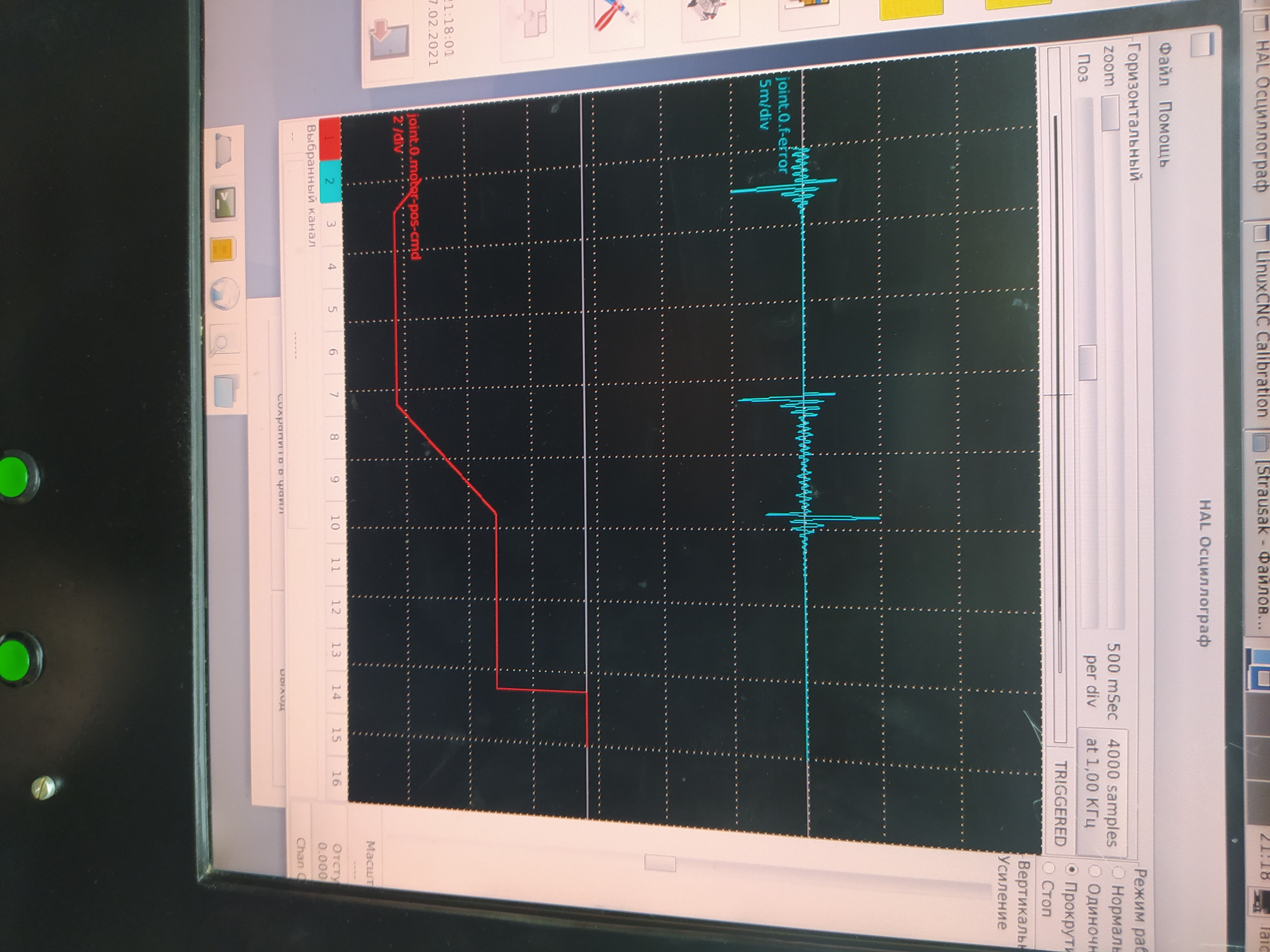

Today i worked with one axes X.

I set P value to 20 and FF1 to 0

Then stepped by instructions i got:

P value: 40

FF1:0.22

Motor on 60mm/m run smooth and silent.

But in stop position, DRO make little jumps and in f-error line was some little amplitude noise. I heard vibration.

I decided to grounded computer directly to ground line.

And know what, noise disappeared. I got nice horizontal line in f-error signal. Motor stand still, DRO not moved.

In calibration menu i corrected FF1 to 0.24 and line f-error stand at center. On start/stop ware splash line. So i changed FF2 value to 0.0008.

What i have:

P = 40

FF1 = 0.24

FF2 = 0.0008

From 1 to 240mm/m motor move without hits and f-error signal so little change. But in 250mm/m amplitude f-error rise over 20 times and motor start/stop with hits.

In manual written thar servo/joint can move with 10000/5000 mm/m (reduction ratio 2/1)

Need to tune more?

Photo after tune.

I set P value to 20 and FF1 to 0

Then stepped by instructions i got:

P value: 40

FF1:0.22

Motor on 60mm/m run smooth and silent.

But in stop position, DRO make little jumps and in f-error line was some little amplitude noise. I heard vibration.

I decided to grounded computer directly to ground line.

And know what, noise disappeared. I got nice horizontal line in f-error signal. Motor stand still, DRO not moved.

In calibration menu i corrected FF1 to 0.24 and line f-error stand at center. On start/stop ware splash line. So i changed FF2 value to 0.0008.

What i have:

P = 40

FF1 = 0.24

FF2 = 0.0008

From 1 to 240mm/m motor move without hits and f-error signal so little change. But in 250mm/m amplitude f-error rise over 20 times and motor start/stop with hits.

In manual written thar servo/joint can move with 10000/5000 mm/m (reduction ratio 2/1)

Need to tune more?

Photo after tune.

# Generated by PNCconf at Wed Feb 17 18:23:45 2021

# Using LinuxCNC version: 2.8

# Все изменения в этом файле будут перезаписаны

# overwritten when you run PNCconf again

[EMC]

MACHINE = Strausak

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = gmoccapy

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/taichi/linuxcnc/nc_files

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 6.000000

MAX_LINEAR_VELOCITY = 25.000000

MIN_LINEAR_VELOCITY = 0.500000

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

GEOMETRY = xyzab

#EMBED_TAB_NAME = left_side_panel

#EMBED_TAB_LOCATION = box_left

#EMBED_TAB_COMMAND = gladevcp -g 64x697+997+10 -H v_buttonlist.hal v_buttonlist.glade

#EMBED_TAB_NAME = right_side_panel

#EMBED_TAB_LOCATION = box_right

#EMBED_TAB_COMMAND = gladevcp -g 995x64+0+805 -H h_buttonlist.hal h_buttonlist.glade

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1000000

[HMOT]

# **** This is for info only ****

CARD0=hm2_5i25.0

[HAL]

HALUI = halui

HALFILE = Strausak.hal

HALFILE = custom.hal

POSTGUI_HALFILE = postgui_call_list.hal

SHUTDOWN = shutdown.hal

[HALUI]

[KINS]

JOINTS = 5

KINEMATICS = trivkins coordinates=XYZAB

[TRAJ]

COORDINATES = XYZAB

MAX_ANGULAR_VELOCITY = 33.33

DEFAULT_ANGULAR_VELOCITY = 3.33

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 5.00

MAX_LINEAR_VELOCITY = 50.00

NO_FORCE_HOMING = 1

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#******************************************

[AXIS_X]

MAX_VELOCITY = 50.0

MAX_ACCELERATION = 200.0

MIN_LIMIT = -0.01

MAX_LIMIT = 350.0

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 50.0

MAX_ACCELERATION = 200.0

P = 40

I = 0

D = 0

FF0 = 0

FF1 = 0.238

FF2 = 0.0011

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 1

ENCODER_SCALE = -20000

OUTPUT_SCALE = -10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -0.01

MAX_LIMIT = 350.0

HOME_OFFSET = 0.0

#******************************************

#******************************************

[AXIS_Y]

MAX_VELOCITY = 50.0

MAX_ACCELERATION = 200.0

MIN_LIMIT = -0.01

MAX_LIMIT = 2350000.0

[JOINT_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 50.0

MAX_ACCELERATION = 200.0

P = 30

I = 0

D = 0

FF0 = 0

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

ENCODER_SCALE = 20000

OUTPUT_SCALE = 10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -0.01

MAX_LIMIT = 2350000.0

HOME_OFFSET = 0.0

#******************************************

#******************************************

[AXIS_Z]

MAX_VELOCITY = 50.0

MAX_ACCELERATION = 200.0

MIN_LIMIT = -350.0

MAX_LIMIT = 0.01

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 50.0

MAX_ACCELERATION = 200.0

P = 30

I = 0

D = 0

FF0 = 0

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

ENCODER_SCALE = -20000

OUTPUT_SCALE = -10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -350.0

MAX_LIMIT = 0.01

HOME_OFFSET = 0.0

#******************************************

#******************************************

[AXIS_A]

MAX_VELOCITY = 33.3333333333

MAX_ACCELERATION = 100.0

MIN_LIMIT = -9999.0

MAX_LIMIT = 9999.0

[JOINT_3]

TYPE = ANGULAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 33.3333333333

MAX_ACCELERATION = 100.0

P = 30

I = 0

D = 0

FF0 = 0

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

ENCODER_SCALE = 4166.667

OUTPUT_SCALE = 10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -9999.0

MAX_LIMIT = 9999.0

HOME_OFFSET = 0.0

#******************************************

#******************************************

[AXIS_B]

MAX_VELOCITY = 33.3333333333

MAX_ACCELERATION = 100.0

MIN_LIMIT = -9999.0

MAX_LIMIT = 9999.0

[JOINT_4]

TYPE = ANGULAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 33.3333333333

MAX_ACCELERATION = 100.0

P = 30

I = 0

D = 0

FF0 = 0

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

ENCODER_SCALE = 4166.667

OUTPUT_SCALE = 10

OUTPUT_MIN_LIMIT = -10

OUTPUT_MAX_LIMIT = 10

MIN_LIMIT = -9999.0

MAX_LIMIT = 9999.0

HOME_OFFSET = 0.0

#******************************************

[SPINDLE_0]

P = 0

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 2000# Generated by PNCconf at Wed Feb 17 18:23:45 2021

# Using LinuxCNC version: 2.8

# Все изменения в этом файле будут перезаписаны

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_pci config=" num_encoders=6 num_pwmgens=0 num_stepgens=0 sserial_port_0=000xxx"

setp hm2_5i25.0.watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.a,pid.b,pid.s

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.a.do-pid-calcs servo-thread

addf pid.b.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_5i25.0.write servo-thread

# external output signals

# --- MACHINE-IS-ENABLED ---

net machine-is-enabled => hm2_5i25.0.7i77.0.0.output-00

# external input signals

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout0-scalemax [JOINT_0]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout0-minlim [JOINT_0]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout0-maxlim [JOINT_0]OUTPUT_MAX_LIMIT

net x-output => hm2_5i25.0.7i77.0.1.analogout0

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-enable <= joint.0.amp-enable-out

# enable _all_ sserial pwmgens

net x-enable => hm2_5i25.0.7i77.0.1.analogena

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.00.counter-mode 0

setp hm2_5i25.0.encoder.00.filter 1

setp hm2_5i25.0.encoder.00.index-invert 0

setp hm2_5i25.0.encoder.00.index-mask 0

setp hm2_5i25.0.encoder.00.index-mask-invert 0

setp hm2_5i25.0.encoder.00.scale [JOINT_0]ENCODER_SCALE

net x-pos-fb <= hm2_5i25.0.encoder.00.position

net x-vel-fb <= hm2_5i25.0.encoder.00.velocity

net x-pos-fb => joint.0.motor-pos-fb

net x-index-enable joint.0.index-enable <=> hm2_5i25.0.encoder.00.index-enable

net x-pos-rawcounts <= hm2_5i25.0.encoder.00.rawcounts

# ---setup home / limit switch signals---

net x-home-sw => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Y JOINT 1

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

net y-index-enable <=> pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-pos-fb => pid.y.feedback

net y-output <= pid.y.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout1-scalemax [JOINT_1]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout1-minlim [JOINT_1]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout1-maxlim [JOINT_1]OUTPUT_MAX_LIMIT

net y-output => hm2_5i25.0.7i77.0.1.analogout1

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-enable <= joint.1.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.01.counter-mode 0

setp hm2_5i25.0.encoder.01.filter 1

setp hm2_5i25.0.encoder.01.index-invert 0

setp hm2_5i25.0.encoder.01.index-mask 0

setp hm2_5i25.0.encoder.01.index-mask-invert 0

setp hm2_5i25.0.encoder.01.scale [JOINT_1]ENCODER_SCALE

net y-pos-fb <= hm2_5i25.0.encoder.01.position

net y-vel-fb <= hm2_5i25.0.encoder.01.velocity

net y-pos-fb => joint.1.motor-pos-fb

net y-index-enable joint.1.index-enable <=> hm2_5i25.0.encoder.01.index-enable

net y-pos-rawcounts <= hm2_5i25.0.encoder.01.rawcounts

# ---setup home / limit switch signals---

net y-home-sw => joint.1.home-sw-in

net y-neg-limit => joint.1.neg-lim-sw-in

net y-pos-limit => joint.1.pos-lim-sw-in

#*******************

# AXIS Z JOINT 2

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout2-scalemax [JOINT_2]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout2-minlim [JOINT_2]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout2-maxlim [JOINT_2]OUTPUT_MAX_LIMIT

net z-output => hm2_5i25.0.7i77.0.1.analogout2

net z-pos-cmd <= joint.2.motor-pos-cmd

net z-enable <= joint.2.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.02.counter-mode 0

setp hm2_5i25.0.encoder.02.filter 1

setp hm2_5i25.0.encoder.02.index-invert 0

setp hm2_5i25.0.encoder.02.index-mask 0

setp hm2_5i25.0.encoder.02.index-mask-invert 0

setp hm2_5i25.0.encoder.02.scale [JOINT_2]ENCODER_SCALE

net z-pos-fb <= hm2_5i25.0.encoder.02.position

net z-vel-fb <= hm2_5i25.0.encoder.02.velocity

net z-pos-fb => joint.2.motor-pos-fb

net z-index-enable joint.2.index-enable <=> hm2_5i25.0.encoder.02.index-enable

net z-pos-rawcounts <= hm2_5i25.0.encoder.02.rawcounts

# ---setup home / limit switch signals---

net z-home-sw => joint.2.home-sw-in

net z-neg-limit => joint.2.neg-lim-sw-in

net z-pos-limit => joint.2.pos-lim-sw-in

#*******************

# AXIS A JOINT 3

#*******************

setp pid.a.Pgain [JOINT_3]P

setp pid.a.Igain [JOINT_3]I

setp pid.a.Dgain [JOINT_3]D

setp pid.a.bias [JOINT_3]BIAS

setp pid.a.FF0 [JOINT_3]FF0

setp pid.a.FF1 [JOINT_3]FF1

setp pid.a.FF2 [JOINT_3]FF2

setp pid.a.deadband [JOINT_3]DEADBAND

setp pid.a.maxoutput [JOINT_3]MAX_OUTPUT

setp pid.a.error-previous-target true

net a-index-enable <=> pid.a.index-enable

net a-enable => pid.a.enable

net a-pos-cmd => pid.a.command

net a-pos-fb => pid.a.feedback

net a-output <= pid.a.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout3-scalemax [JOINT_3]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout3-minlim [JOINT_3]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout3-maxlim [JOINT_3]OUTPUT_MAX_LIMIT

net a-output => hm2_5i25.0.7i77.0.1.analogout3

net a-pos-cmd <= joint.3.motor-pos-cmd

net a-enable <= joint.3.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.03.counter-mode 0

setp hm2_5i25.0.encoder.03.filter 1

setp hm2_5i25.0.encoder.03.index-invert 0

setp hm2_5i25.0.encoder.03.index-mask 0

setp hm2_5i25.0.encoder.03.index-mask-invert 0

setp hm2_5i25.0.encoder.03.scale [JOINT_3]ENCODER_SCALE

net a-pos-fb <= hm2_5i25.0.encoder.03.position

net a-vel-fb <= hm2_5i25.0.encoder.03.velocity

net a-pos-fb => joint.3.motor-pos-fb

net a-index-enable joint.3.index-enable <=> hm2_5i25.0.encoder.03.index-enable

net a-pos-rawcounts <= hm2_5i25.0.encoder.03.rawcounts

# ---setup home / limit switch signals---

net a-home-sw => joint.3.home-sw-in

net a-neg-limit => joint.3.neg-lim-sw-in

net a-pos-limit => joint.3.pos-lim-sw-in

#*******************

# AXIS B JOINT 4

#*******************

setp pid.b.Pgain [JOINT_4]P

setp pid.b.Igain [JOINT_4]I

setp pid.b.Dgain [JOINT_4]D

setp pid.b.bias [JOINT_4]BIAS

setp pid.b.FF0 [JOINT_4]FF0

setp pid.b.FF1 [JOINT_4]FF1

setp pid.b.FF2 [JOINT_4]FF2

setp pid.b.deadband [JOINT_4]DEADBAND

setp pid.b.maxoutput [JOINT_4]MAX_OUTPUT

setp pid.b.error-previous-target true

net b-index-enable <=> pid.b.index-enable

net b-enable => pid.b.enable

net b-pos-cmd => pid.b.command

net b-pos-fb => pid.b.feedback

net b-output <= pid.b.output

# ---PWM Generator signals/setup---

setp hm2_5i25.0.7i77.0.1.analogout4-scalemax [JOINT_4]OUTPUT_SCALE

setp hm2_5i25.0.7i77.0.1.analogout4-minlim [JOINT_4]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i77.0.1.analogout4-maxlim [JOINT_4]OUTPUT_MAX_LIMIT

net b-output => hm2_5i25.0.7i77.0.1.analogout4

net b-pos-cmd <= joint.4.motor-pos-cmd

net b-enable <= joint.4.amp-enable-out

# ---Encoder feedback signals/setup---

setp hm2_5i25.0.encoder.04.counter-mode 0

setp hm2_5i25.0.encoder.04.filter 1

setp hm2_5i25.0.encoder.04.index-invert 0

setp hm2_5i25.0.encoder.04.index-mask 0

setp hm2_5i25.0.encoder.04.index-mask-invert 0

setp hm2_5i25.0.encoder.04.scale [JOINT_4]ENCODER_SCALE

net b-pos-fb <= hm2_5i25.0.encoder.04.position

net b-vel-fb <= hm2_5i25.0.encoder.04.velocity

net b-pos-fb => joint.4.motor-pos-fb

net b-index-enable joint.4.index-enable <=> hm2_5i25.0.encoder.04.index-enable

net b-pos-rawcounts <= hm2_5i25.0.encoder.04.rawcounts

# ---setup home / limit switch signals---

net b-home-sw => joint.4.home-sw-in

net b-neg-limit => joint.4.neg-lim-sw-in

net b-pos-limit => joint.4.pos-lim-sw-in

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]MAX_OUTPUT

setp pid.s.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-vel-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

sets spindle-at-speed true

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-y halui.axis.y.select

net jog-y-pos halui.axis.y.plus

net jog-y-neg halui.axis.y.minus

net jog-y-analog halui.axis.y.analog

net y-is-homed halui.joint.1.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.2.is-homed

net axis-select-a halui.axis.a.select

net jog-a-pos halui.axis.a.plus

net jog-a-neg halui.axis.a.minus

net jog-a-analog halui.axis.a.analog

net a-is-homed halui.joint.3.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-in

# ---toolchange signals for custom tool changer---

net tool-number <= iocontrol.0.tool-prep-number

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-prepare-request <= iocontrol.0.tool-prepare

net tool-prepare-confirmed => iocontrol.0.tool-prepared

Attachments:

Last edit: 30 Apr 2021 19:02 by Taichi.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17605

- Thank you received: 5147

30 Apr 2021 19:07 - 30 Apr 2021 19:11 #207475

by PCW

Replied by PCW on topic Mesa 5i25 + 7i77D can't cofig

1. Can you post your current hal and ini files?

Edit I see you added these, I don't see anything wrong at first glance

2. A screen shot of the halscope plot would be a lot more legible

3. Plotting the following error versus velocity rather than position is easier to interpret

Edit I see you added these, I don't see anything wrong at first glance

2. A screen shot of the halscope plot would be a lot more legible

3. Plotting the following error versus velocity rather than position is easier to interpret

Last edit: 30 Apr 2021 19:11 by PCW.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17605

- Thank you received: 5147

30 Apr 2021 19:37 - 30 Apr 2021 19:38 #207476

by PCW

This statement will limit the maximum output voltage to +-1V

or 1/10th of full velocity. This is likely the reason you get a following error

when attempting to move at higher speeds. it should be set to 0 or 10

Replied by PCW on topic Mesa 5i25 + 7i77D can't cofig

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 10.0

MIN_FERROR = 1.0

.................................

MAX_OUTPUT = 1

^^^^^^^^^^^^^^^^^^^^^

This statement will limit the maximum output voltage to +-1V

or 1/10th of full velocity. This is likely the reason you get a following error

when attempting to move at higher speeds. it should be set to 0 or 10

Last edit: 30 Apr 2021 19:38 by PCW.

Please Log in or Create an account to join the conversation.

- Taichi

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 43

- Thank you received: 0

30 Apr 2021 20:24 #207481

by Taichi

Replied by Taichi on topic Mesa 5i25 + 7i77D can't cofig

I set max_output = 1 on first start pncconfig.

And successfully forgot about it.

Ok, weekend will end, i will try to make graphics f-error vs velocity.

You know, I don't know what the end result should look like. I have no experience in this.

Do I have to achieve a perfectly smooth graph or should the graph not go beyond of max_error in all operating modes?

Also, the time zone prevents us from communicating normally. Anyway, thanks you for the help.

And successfully forgot about it.

Ok, weekend will end, i will try to make graphics f-error vs velocity.

You know, I don't know what the end result should look like. I have no experience in this.

Do I have to achieve a perfectly smooth graph or should the graph not go beyond of max_error in all operating modes?

Also, the time zone prevents us from communicating normally. Anyway, thanks you for the help.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17605

- Thank you received: 5147

30 Apr 2021 20:58 #207488

by PCW

Replied by PCW on topic Mesa 5i25 + 7i77D can't cofig

The errors will always be there depending on how much you magnify them...

Your plot currently shows a peak error of 5 microns

and a error during (slow) motion of less than 1 micron.

I would say that is quite good for a standard mill,

If you can maintain that accuracy up to higher speeds.

Your current following error limits are huge (1 to 10 MM!)

If you have errors of this size it means a setup error or

hardware fault. These large following error limits are good

for tuning but should be reduced once tuning is complete

Your plot currently shows a peak error of 5 microns

and a error during (slow) motion of less than 1 micron.

I would say that is quite good for a standard mill,

If you can maintain that accuracy up to higher speeds.

Your current following error limits are huge (1 to 10 MM!)

If you have errors of this size it means a setup error or

hardware fault. These large following error limits are good

for tuning but should be reduced once tuning is complete

Please Log in or Create an account to join the conversation.

Moderators: cmorley

Time to create page: 0.148 seconds