- GCode and Part Programs

- O Codes (subroutines) and NGCGUI

- rigid tapping fail advice and "discriminant" err

rigid tapping fail advice and "discriminant" err

- tome

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 11

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17577

- Thank you received: 5141

(and probably what confuses the motion planner)

If you want to do rigid tapping I don't think you have many reasonable options except

a full quadrature encoder ( with A and B ) and index on the spindle.

Please Log in or Create an account to join the conversation.

- tome

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 11

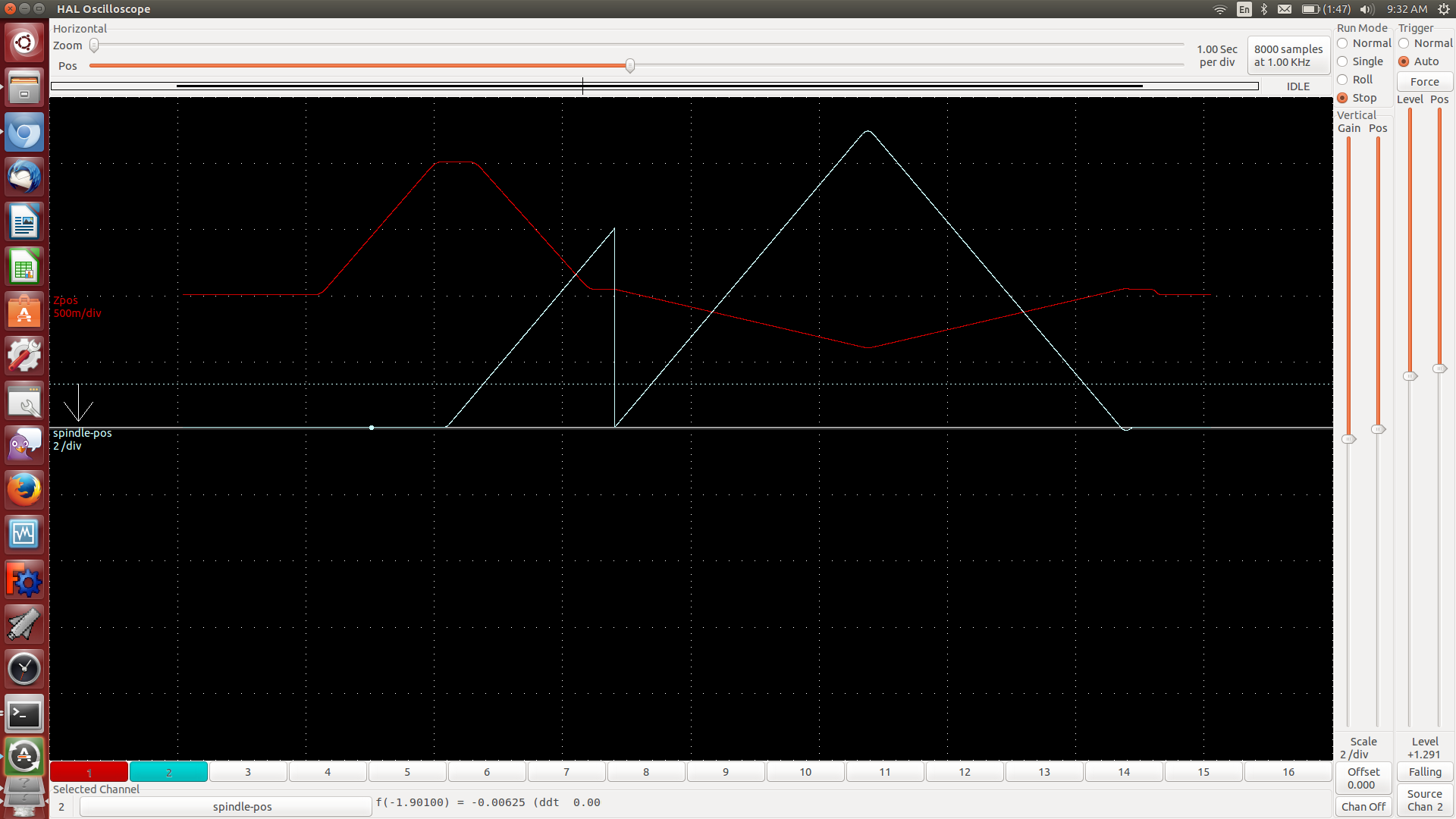

Looking at your plot, there's a huge position step, so that cannot work

(and probably what confuses the motion planner)

If you want to do rigid tapping I don't think you have many reasonable options except

a full quadrature encoder ( with A and B ) and index on the spindle.

Peter,

Isn't that just where the spindle reverses direction and Z begins to move back out? Why is that a huge position step? I guess I don't know what a successful graph of tapping should look like but I thought this looked ok. Is it not? Why is quadrature required?

-Tom

Please Log in or Create an account to join the conversation.

- skunkworks

- Offline

- Moderator

-

- Posts: 349

- Thank you received: 152

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17577

- Thank you received: 5141

Peter,

Isn't that just where the spindle reverses direction and Z begins to move back out? Why is that a huge position step? I guess I don't know what a successful graph of tapping should look like but I thought this looked ok. Is it not? Why is quadrature required?

-Tom

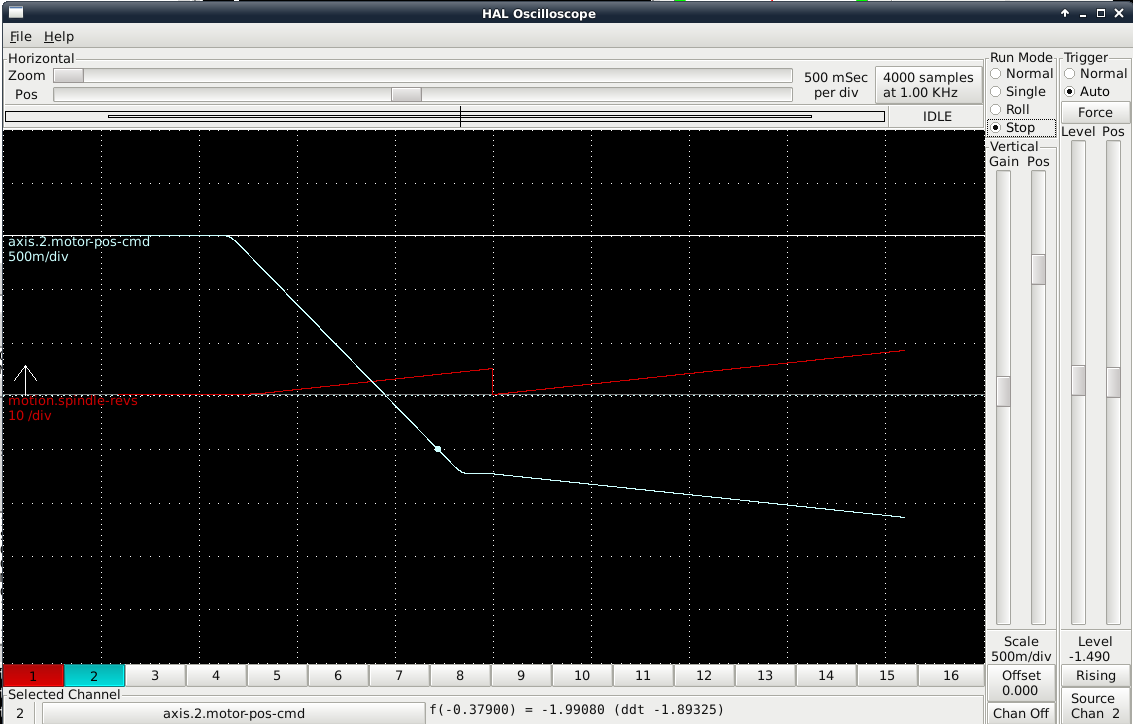

Its a bit hard to tell because you only have part of the plot, but no steps are allowed in the spindle position

except the step to 0 when the index occurs (motion is paused until the index is detected at the beginning

of the tapping cycle) After index is detected, the Z axis motion is "geared" with spindle rotations to allow tapping.

The apparent step in spindle angle (that the Z axis cannot accurately follow) is a tap breaker.

You need a quadrature encoder as thats the simplest reliable way to know the actual rotational position of the

spindle as it goes through the reversal at the bottom of the tapping plunge. That is, you know when you commanded the spindle to reverse, but not when the actual reversal occurred, another tap breaker...

Please Log in or Create an account to join the conversation.

- tome

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 11

Its a bit hard to tell because you only have part of the plot,

I think this is the entire plot...

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17577

- Thank you received: 5141

(as you would expect without the proper feedback as provided by a quadrature counter)

Please Log in or Create an account to join the conversation.

- tome

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 11

Please Log in or Create an account to join the conversation.

- skunkworks

- Offline

- Moderator

-

- Posts: 349

- Thank you received: 152

Please Log in or Create an account to join the conversation.

- tome

- Offline

- Premium Member

-

- Posts: 116

- Thank you received: 11

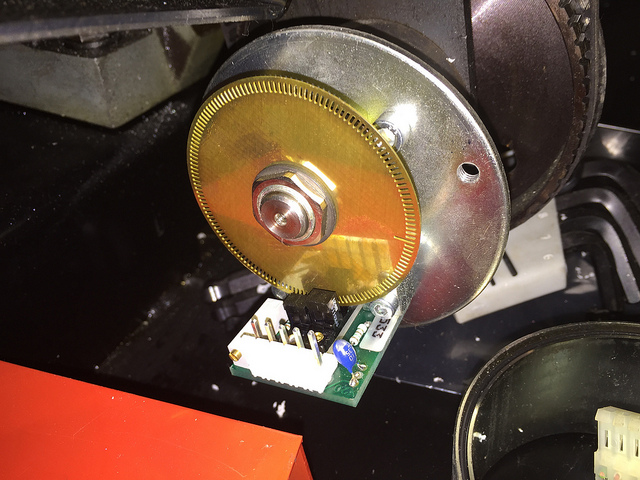

you would have to add one more optical sensor. Could you get one exactly the same as what is there?

Maybe, but what I was really looking for was a new disk-type encoder that I could buy and mount in essentially the same position... That encoder is only 150ppr, I assume that more would be better?

I was thinking I wouldn't have to re-wire but I currently only have 4 wires to that encoder so I will likely need to run a 5 or 6 wire cable for quadrature.

-Tom

Please Log in or Create an account to join the conversation.

- GCode and Part Programs

- O Codes (subroutines) and NGCGUI

- rigid tapping fail advice and "discriminant" err