Lathe Macros

- andypugh

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

Very difficult to say as it changes all the time. I have a very aggressive lowpass filter on the feedback.

What I just noticed is that the feedrate remains the same no matter what spindle speed I select. Surely that does not seem right?

You shouldn't have any filtering between encoder position and motion.spindle-revs.

Also you need to make sure that motion.spindle-revs is spindle _position_ not spindle _speed_.

Please Log in or Create an account to join the conversation.

- andypugh

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

Will this feature be included in production (2.6.x) at any stage or will I have to make sure that I apply a fix after any update?

Unfortunately when I suggested adding this feature to the release version there was some disagreement with how I had implemented it.

There was a feeling that the code should be aware of the machine units, and should only convert once, etc etc.

That makes is a lot more difficult and complicated, so I gave up trying to sell the idea.

At the moment, for example, you can type "1in" and get "25.4" and then type "in" again in the same box and get "645.16"

From my point of view the extra characters are just short-cuts "in" for "convert from inches to mm" and "mm" for "convert from mm to inches" but others didn't see it that way :-/

I don't know if you have spotted it, but you can also type "3 25/64in" and get "86.122" though you do have to move the insertion point to the end before typing the "in" as the conversion after "/64" leaves it in the middle of the number in a way I haven't managed to fix yet.

Please Log in or Create an account to join the conversation.

- mariusl

-

- Offline

- Platinum Member

-

You shouldn't have any filtering between encoder position and motion.spindle-revs.

Also you need to make sure that motion.spindle-revs is spindle _position_ not spindle _speed_

No filtering between the two and it is connected to position.

From my point of view the extra characters are just short-cuts "in" for "convert from inches to mm" and "mm" for "convert from mm to inches" but others didn't see it that way :-/

Why not make a new widget rather than modify the old. Call it something else then the choice is that of the user whether he want to use it or not. That would be the democratic way I think.

Obviously this kind of widget is needed as can be proven already.

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

- mariusl

-

- Offline

- Platinum Member

-

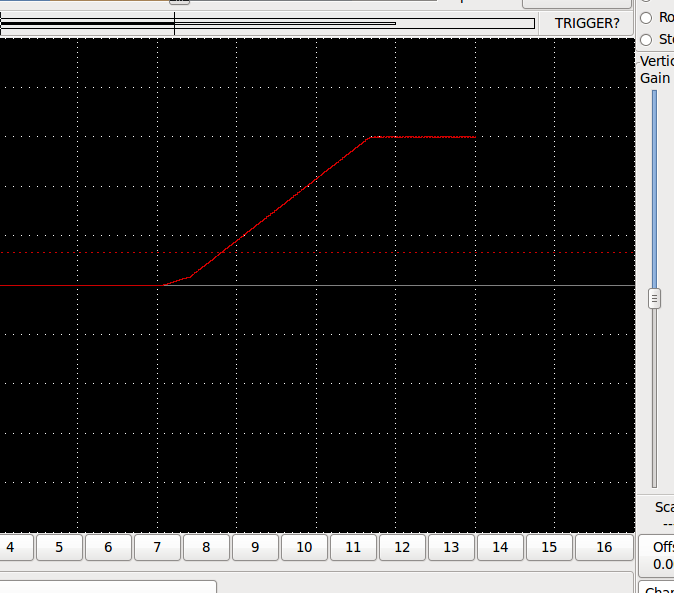

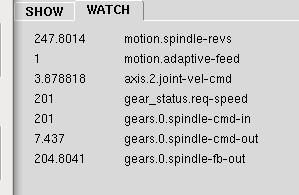

The first is the halscope capture of the velocity command and the second a halshow of some of the signals

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

- andypugh

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

I have a feeling that this problem comes down to the spindle gearing. Is the encoder on the motor and not the spindle?

Please Log in or Create an account to join the conversation.

- mariusl

-

- Offline

- Platinum Member

-

motion.spindle-revs changed by 50 on one revolution

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

- andypugh

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

motion.spindle-revs changed by 50 on one revolution

Ah, well, there's the problem

You need to change the encoder position scale so that the number changes by 1.000 for one revolution.

Please Log in or Create an account to join the conversation.

- andypugh

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

You need to change the encoder position scale so that the number changes by 1.000 for one revolution.

Just to be clear, and not knowing what decimal separator you use in SA. I was trying to say "exactly one" not "one thousand"

Please Log in or Create an account to join the conversation.

- mariusl

-

- Offline

- Platinum Member

-

I checked to see and encoder count is 2024 per revolution. So it uses one edge of the pulse not both sides as I believed.

Oh and I dont really care what we use for separator. I try any until things work. But I got what you meant thanks.

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

- mariusl

-

- Offline

- Platinum Member

-

Your'e Biscuit

And on top of it all it is rps not rpm. That is what caused the confusion for me. I just changed the encoder scale to 2048 and multiplied the feedback by 60

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.