Labview UI project for Linuxcnc

- auto-mation-assist

-

Topic Author

- Offline

- Platinum Member

-

- Posts: 425

- Thank you received: 81

Please Log in or Create an account to join the conversation.

- auto-mation-assist

-

Topic Author

- Offline

- Platinum Member

-

- Posts: 425

- Thank you received: 81

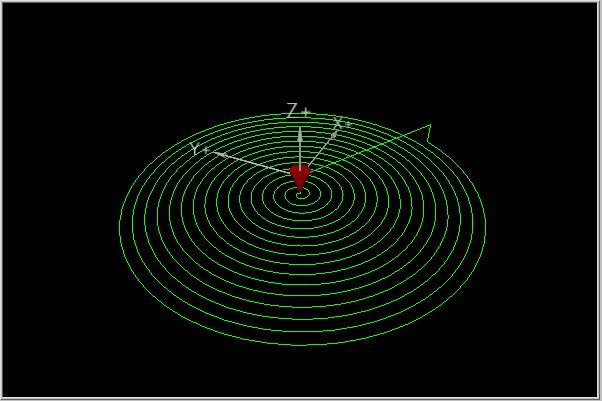

Here is a rendering of the code as I have it right now. Size of the display is 600x400.

Attachments:

Please Log in or Create an account to join the conversation.

- auto-mation-assist

-

Topic Author

- Offline

- Platinum Member

-

- Posts: 425

- Thank you received: 81

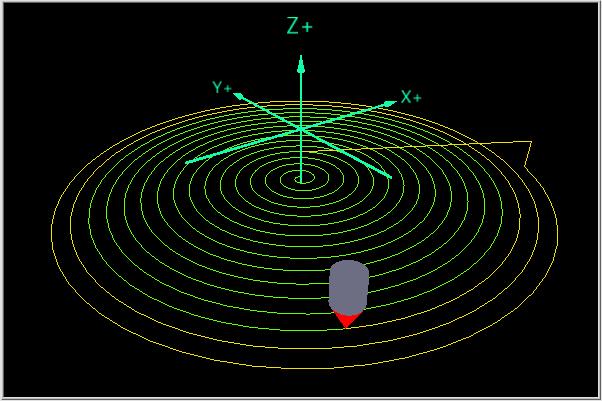

It is good for now and with this working work can proceed on other items.

Attachments:

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2345

Nice to see you cross platform developing !

Is your project more or less resulting in a cross platform driver?

If you would use Beckhoff Ethercat, you can code magnificent things outside of the linuxcnc code, straight to the device.

My vision is that when u use Ethercat, you have much more option's than using Labview.

One example is : you can connect different open source code's together.

Pyton and C, connect's a cnc microscope with a digital canon camera, ethercat, etc. All integrated for example in the linuxcnc

gui python code. This is one of the powers of linux.

This guy has not joined the different source codes together, or made a cross platform driver, to be clear..

I am more a C++ guy, if you walk that way, it can result less progress in the beginning.

Good luck with your program from Holland !

Please Log in or Create an account to join the conversation.

- auto-mation-assist

-

Topic Author

- Offline

- Platinum Member

-

- Posts: 425

- Thank you received: 81

Please Log in or Create an account to join the conversation.

- auto-mation-assist

-

Topic Author

- Offline

- Platinum Member

-

- Posts: 425

- Thank you received: 81

Please Log in or Create an account to join the conversation.

- auto-mation-assist

-

Topic Author

- Offline

- Platinum Member

-

- Posts: 425

- Thank you received: 81

Copied notes here from my another post today below.

For the most part I have traced this problem down to halui.cc which wants to be run at local host with the ID of xemc. Likely all part of the status polling system that GStat uses that listens to messages being sent internally by NML, and uses the them to control how and what a local gui can do. Unfortunately this totally conflicts with commands coming from a network interface.

As an example recently I was doing some testing with my networked gui. For this test I replaced my normal 'dummy' Gui running the Linux computer that interfaces with my milling machine with Gmoccapy which uses Gstat a lot. I switched my networked gui running on a windows machine to auto mode and send the commands to load a file and run it. As soon as I did this Gmoccapy changed from its initial mode screen to its auto mode screen and followed along, including displaying the file I loaded with my remote gui and also tracing it out in its preview display. It should be noted that my commands are sent directly to the NML interface via the network on port 5005 and not tied to Gmoccapy in any way.

I think there needs to be a way to completely disable Gstat but I'm thinking that as it is built right now it might take halui with it. My networked gui does its won polling directly from the status buffer and has no use for Gstat.

In version 2.9 the size if the status buffer reply has increased substantially from 8244 bytes to 9196 bytes but I have found no information on what is placed in the added area or a map on how to access what ever is there by byte offset..

Please Log in or Create an account to join the conversation.

- auto-mation-assist

-

Topic Author

- Offline

- Platinum Member

-

- Posts: 425

- Thank you received: 81

Grotius gave a link to a user using Machinekit several posts back and it reminded my that about a year ago I had started working on encoding and decoding Protobuff messages in Labview for use with Machinekit and dug out some of that code. In looking at my options to proceed I feel that right now Machinekit is a better choice for me since it is able to export NML messages and thus eliminate the conflicts that I have run into with Linuxcnc.

I will dig out the Labview ZMQ and ProtoBuff code and the enthought python integration toolkit for labview and see what I can come up with for interfacing with Machinekit. Its possible that the python module may not need to be used. I have the latest version of MachineKit installed and it is able to control my milling machine which uses a Mesa 7I80 board as its networked interface.

Please Log in or Create an account to join the conversation.

- Reinhard

- Offline

- Platinum Member

-

- Posts: 508

- Thank you received: 94

Well, I would have tried to leave internal communication work with shared memory and develop a bridge from shared memory to your network ...I have been thinking about the best way to proceed with my project. I have used Linuxcnc for testing and developed a method to be able to interface with NML but there are a number of issues with this due to the fact that many processes that have been developed over the years also interface with NML and conflict with direct access with NML from the outside world via port 5005 now.

.

Hm, MachineKit looks like a fork that already is driven far away from linuxcnc. Some of their solutions are good stuff (i.e. generalized logging or changed shared memory handling). They work on replacement of nml, so you have to recode your whole project.I have the latest version of MachineKit installed and it is able to control my milling machine which uses a Mesa 7I80 board as its networked interface.

is it worth that amount of time?

Please Log in or Create an account to join the conversation.

- auto-mation-assist

-

Topic Author

- Offline

- Platinum Member

-

- Posts: 425

- Thank you received: 81

The way I see the future of Linuxcnc is that all Guis would interface to it via TCP connections either using localhost or remotely, and all user interfaces would be removed from Linuxcnc proper and replaced a standard well documented network interface. Machinekit developers have already accomplished this with their more distributed way of looking at things and handling interfaces. Thus my focus will be on working with Machinekit for a while.

It is not a minor task to develop remote interface such as the one the Machinekit developers have developed. I have run into comments on the internet that it took over two years for developers of Machinekit to develop the present version of their haltalk network interface.

Back to my project: Changing over the TCP interfaces of the Gui that I'm working on from Linuxcnc nml to Machinekit remote will likely not be to difficult. The TCP network interfaces are actually just a small fragment of the Gui code.

Please Log in or Create an account to join the conversation.