- International LinuxCNC Users

- Deutsch

- Strategie bei Hurco BMC20 refit / Interfacing the Drives to MESA

Strategie bei Hurco BMC20 refit / Interfacing the Drives to MESA

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

02 Feb 2018 15:21 #105331

by Todd Zuercher

Replied by Todd Zuercher on topic Strategie bei Hurco BMC20 refit / Regler rausschmeißen

Not completely sure if you are asking for hardware recommendations,

For the 7i80HD+7i33TA+7i64, you would also need to add a 7i34 in order to be able to connect the 7i64

But a far less expensive route would be a 7i92 + 7i77 and if you need more digital IO maybe a 7i84. That would give you up to 5 axis + spindle (or 6 without spindle) + 16out + 32in just on the 7i77 and 16out + 32in more if you add the7i84 (The 7i84 could connect directly to the 7i77's Smart Serial port. or you could use another Smart Serial card like the 7i64)

If you need to connect more than 1 Smart Serial card to this combo, you would need to add a 7i74 to the other port on the 7i92.

For the 7i80HD+7i33TA+7i64, you would also need to add a 7i34 in order to be able to connect the 7i64

But a far less expensive route would be a 7i92 + 7i77 and if you need more digital IO maybe a 7i84. That would give you up to 5 axis + spindle (or 6 without spindle) + 16out + 32in just on the 7i77 and 16out + 32in more if you add the7i84 (The 7i84 could connect directly to the 7i77's Smart Serial port. or you could use another Smart Serial card like the 7i64)

If you need to connect more than 1 Smart Serial card to this combo, you would need to add a 7i74 to the other port on the 7i92.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21364

- Thank you received: 7287

02 Feb 2018 17:43 #105334

by tommylight

Replied by tommylight on topic Strategie bei Hurco BMC20 refit / Regler rausschmeißen

I agree with PCW and Todd, 7i92 and 7i77 and a 7i84.

It is all you need for the Hurco, although i personally use a 7i70 and 7i71 for inputs and outputs through a 7i74. Overkill i know but i like it and used it on several machines .

I can also check the wiring and take some close up pictures of the wiring as that would make it a lot easier for you.

Basicaly you would have to remove old computer/control and everything on the console, put an STP cable through to the console, mount a computer and monitor in the console, mount MESA stuff in the box behind the machine, wire the drives and the toolchanger control board to Mesa boards, and fire it up !

With a bit of attention you can do it in 2 days! It took me 9 days, 4 to 6 hours a day to do it as i did not have schematics or wiring diagrams.

It is all you need for the Hurco, although i personally use a 7i70 and 7i71 for inputs and outputs through a 7i74. Overkill i know but i like it and used it on several machines .

I can also check the wiring and take some close up pictures of the wiring as that would make it a lot easier for you.

Basicaly you would have to remove old computer/control and everything on the console, put an STP cable through to the console, mount a computer and monitor in the console, mount MESA stuff in the box behind the machine, wire the drives and the toolchanger control board to Mesa boards, and fire it up !

With a bit of attention you can do it in 2 days! It took me 9 days, 4 to 6 hours a day to do it as i did not have schematics or wiring diagrams.

Please Log in or Create an account to join the conversation.

- poolizei

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 3

02 Feb 2018 18:59 #105336

by poolizei

Replied by poolizei on topic Strategie bei Hurco BMC20 refit / choosing MESA equipment

Thanks for your Input,

I will follow your suggestions and go for 7i92 + 7i77 with optional 7i84

Is this setup straight forward enough for a beginner?

Or could it be a better decision to use the same hardware as Tom (he has the same machine) and if he supports me so far? wire the machine identical to rely on his setup as close as possible?

Another question is the PC Hardware i already contacted the Chinese Supplier of the PanelPC and i Could get this J19000 based PC with 64GB SSD and 4GB Ram and dual NIC in 18.5" touch with 1280x1024 for round about 550€ to the door!

Is it expectable that this hardware is good enough?

They claim to support Linux with this hardware?

Another input which came up above in german was to throw the Servo Drivers out because the old ones could be crap... And YES we tested the machine a few days ago and there is a red failure light on... So whats your suggestion throw this servo stuff directly out 1kW Lichuan Servos incl. driver and encoder are around 300€ per axis... Shall I go for it?

I want to have this rebuild done once and properly so it lasts kind of for ever at least next 10 years!

I appreciate your help a lot!

And wanted to thank all of you!

BR Andreas

I will follow your suggestions and go for 7i92 + 7i77 with optional 7i84

Is this setup straight forward enough for a beginner?

Or could it be a better decision to use the same hardware as Tom (he has the same machine) and if he supports me so far? wire the machine identical to rely on his setup as close as possible?

Another question is the PC Hardware i already contacted the Chinese Supplier of the PanelPC and i Could get this J19000 based PC with 64GB SSD and 4GB Ram and dual NIC in 18.5" touch with 1280x1024 for round about 550€ to the door!

Is it expectable that this hardware is good enough?

They claim to support Linux with this hardware?

Another input which came up above in german was to throw the Servo Drivers out because the old ones could be crap... And YES we tested the machine a few days ago and there is a red failure light on... So whats your suggestion throw this servo stuff directly out 1kW Lichuan Servos incl. driver and encoder are around 300€ per axis... Shall I go for it?

I want to have this rebuild done once and properly so it lasts kind of for ever at least next 10 years!

I appreciate your help a lot!

And wanted to thank all of you!

BR Andreas

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21364

- Thank you received: 7287

03 Feb 2018 01:28 #105347

by tommylight

Replied by tommylight on topic Strategie bei Hurco BMC20 refit / choosing MESA equipment

Of course i can help, i still have access to that machine and most of the others i worked on.

You do not need the same hardware as i used, i use all that hardware only so i can have a cleaner installation and easier to follow during install or service.

For computer i used an asus mini ATX board and a 24' monitor without touch screen. Cost 210 Euros.

Drives: i would recommend using existing ones if they work, if they do not work you can change them at any given time later on. Spindle drive try to use the existing one as it has all the controls built in, like spindle orient and load and other stuff. Most of the cheap new ones do not have anything except speed control.

And by the way, the machine is not mine, it belongs to a local company that manufactures stuff for Austria and the machine came from Austria in a very bad condition, with spindle and Y axis drives dead on arrival and the X axis drive died soon after. Then again they got it for 3500 Euros, so it was cheap.

The new drives should be here by the end of the month and promptly installed and tested.

You do not need the same hardware as i used, i use all that hardware only so i can have a cleaner installation and easier to follow during install or service.

For computer i used an asus mini ATX board and a 24' monitor without touch screen. Cost 210 Euros.

Drives: i would recommend using existing ones if they work, if they do not work you can change them at any given time later on. Spindle drive try to use the existing one as it has all the controls built in, like spindle orient and load and other stuff. Most of the cheap new ones do not have anything except speed control.

And by the way, the machine is not mine, it belongs to a local company that manufactures stuff for Austria and the machine came from Austria in a very bad condition, with spindle and Y axis drives dead on arrival and the X axis drive died soon after. Then again they got it for 3500 Euros, so it was cheap.

The new drives should be here by the end of the month and promptly installed and tested.

Please Log in or Create an account to join the conversation.

- poolizei

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 3

22 Feb 2018 12:43 #106334

by poolizei

Replied by poolizei on topic Strategie bei Hurco BMC20 refit

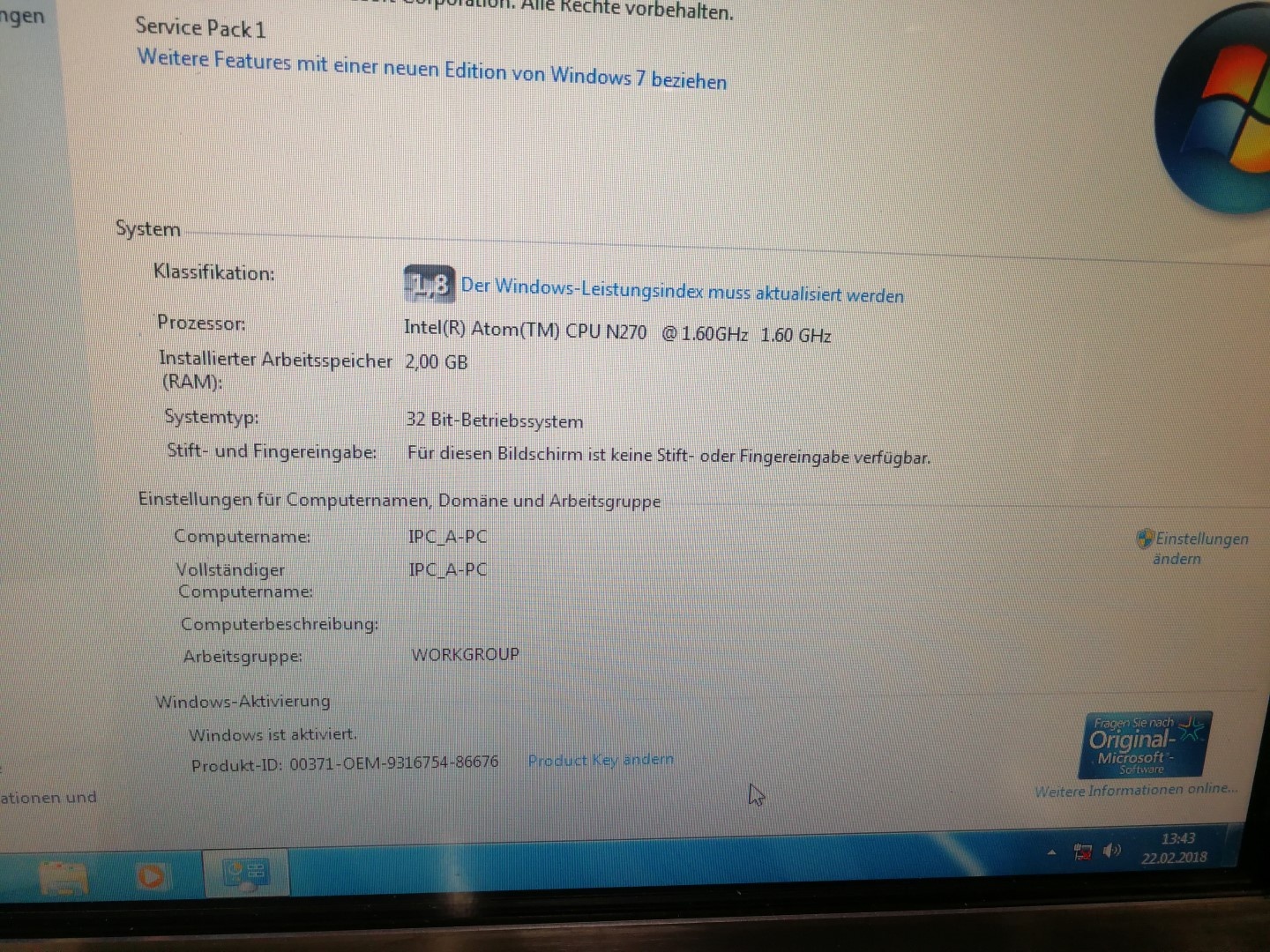

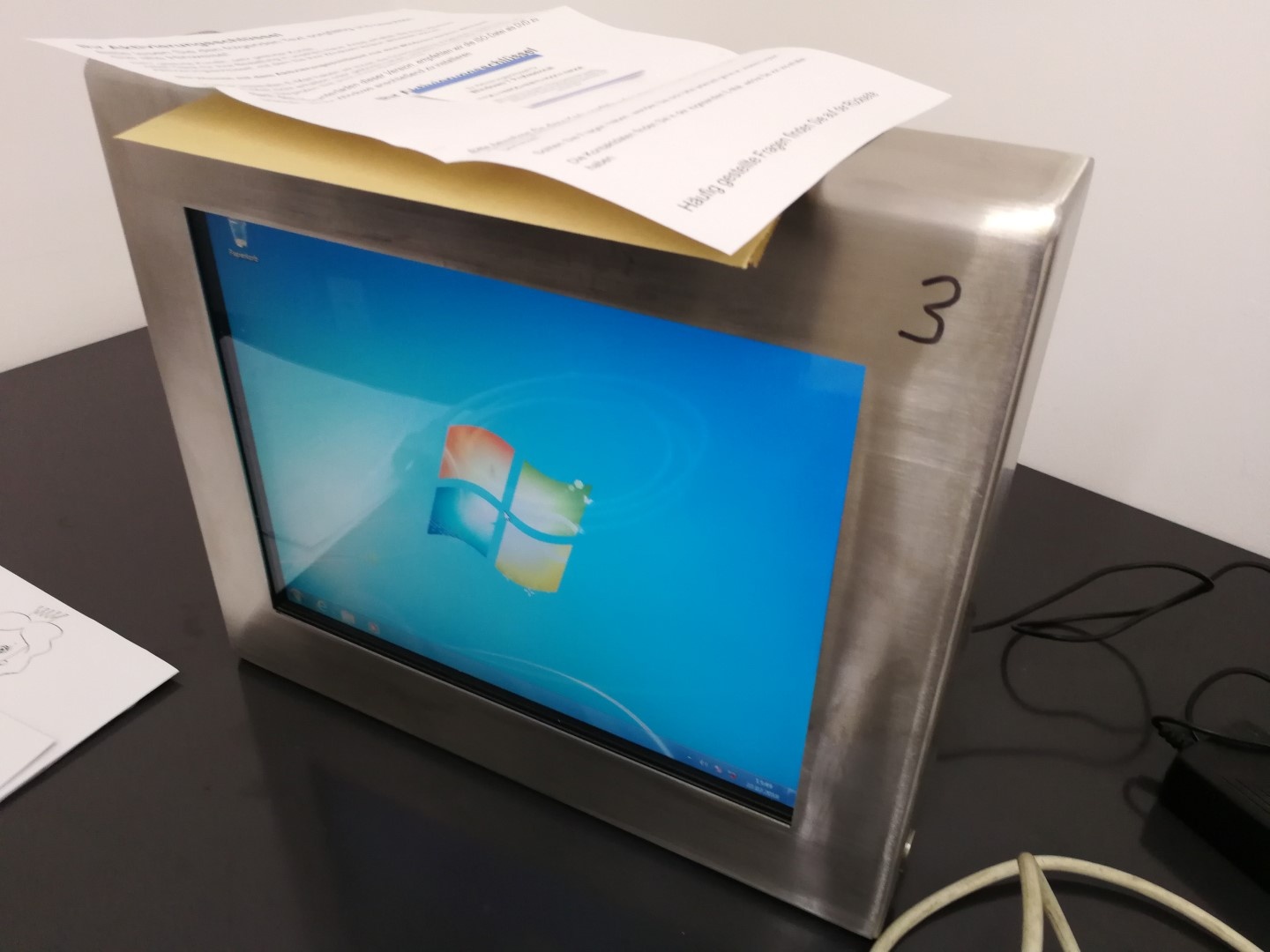

I have an Industrial boxed Panel PC available (2 of them) the are not very high powered but completly waterproof and in a stainless steel case without touchscreen.

Do you think this Intel Atom N270 @ 1.6GHz could be fast enough, it only has 2GB Ram but this could be upgraded.

Thanks for your kind support!

Andreas

Do you think this Intel Atom N270 @ 1.6GHz could be fast enough, it only has 2GB Ram but this could be upgraded.

Thanks for your kind support!

Andreas

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

01 Mar 2018 13:06 #106798

by andypugh

Should be fine. Try running the latency test to make sure.

LinuxCNC doesn't need much CPU power. It ran perfectly well 15 years ago on the computers available then, and hasn't got any more complex in the core areas.

Replied by andypugh on topic Strategie bei Hurco BMC20 refit

I have an Industrial boxed Panel PC available (2 of them) the are not very high powered but completly waterproof and in a stainless steel case without touchscreen.

Do you think this Intel Atom N270 @ 1.6GHz could be fast enough,

Should be fine. Try running the latency test to make sure.

LinuxCNC doesn't need much CPU power. It ran perfectly well 15 years ago on the computers available then, and hasn't got any more complex in the core areas.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17731

- Thank you received: 5187

01 Mar 2018 14:03 #106803

by PCW

Replied by PCW on topic Strategie bei Hurco BMC20 refit

What Andy says is true for RTAI and non-Ethernet interfaces, but If you are using a Ethernet card and Preempt-RT you would probably need more horsepower. The dual core version of the N270 (N330) is just barely able to run a 1 KHz thread reliably on Preempt-RT...

I would suggest nothing slower than a J1800/J1900

I would suggest nothing slower than a J1800/J1900

Please Log in or Create an account to join the conversation.

- poolizei

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 3

01 Apr 2018 14:13 #108212

by poolizei

Replied by poolizei on topic Strategie bei Hurco BMC20 refit

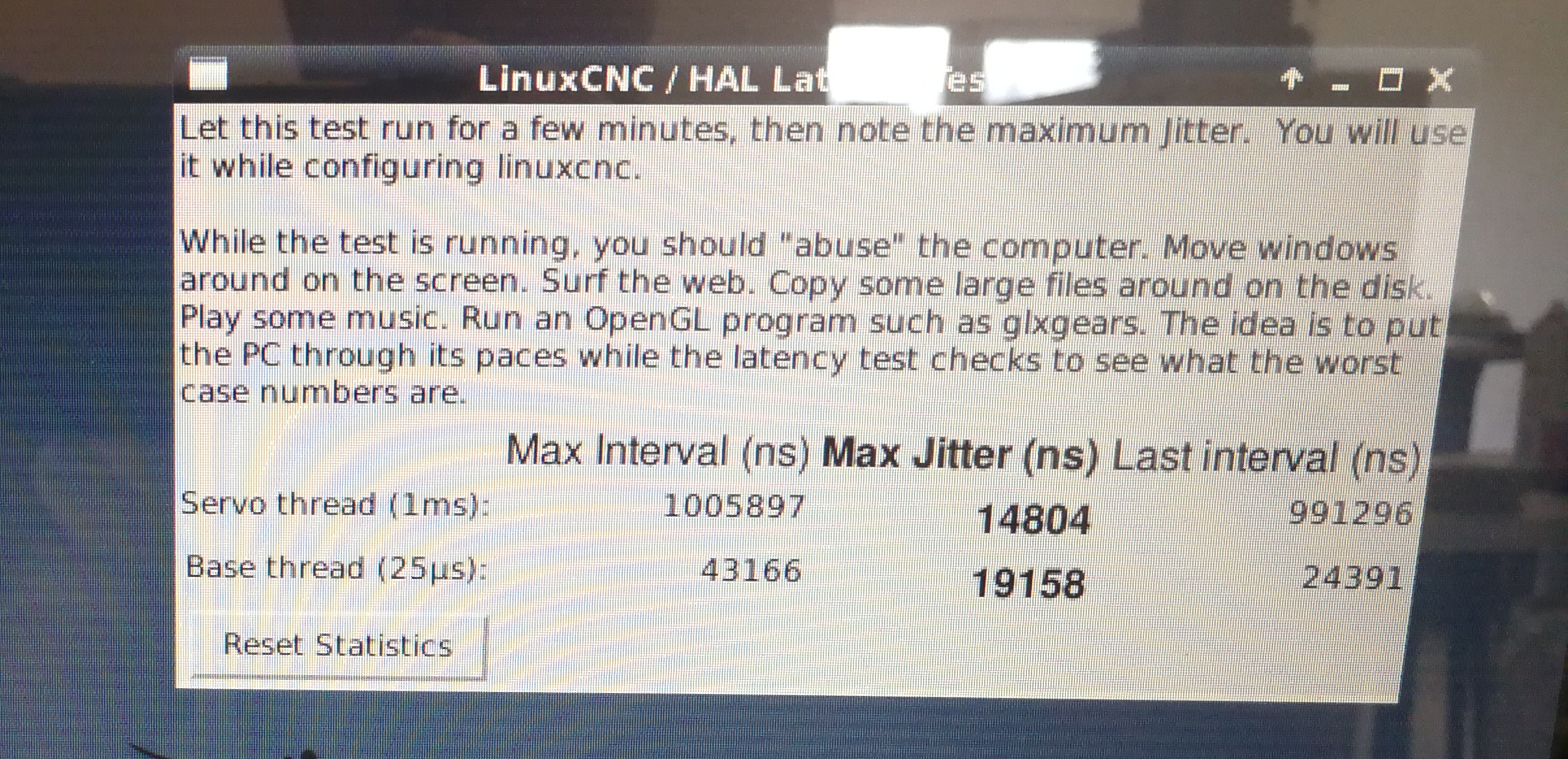

So today I took some time and performed the Latency Test and tried some random Stuff while the test was performed (moving files, connecting ethernet, opening and playing youtube videos, moving windows) the outcome seems quite promising to me what do you think?

Please keep in mind I plan to use this hardware with Ethernet based Mesa Stuff and Or Ethercat based Servo-Drives

I have 3 of these units available got them nearly for free...

If they won't be suitable I would try to fit another small Mainboard into the case...

I appreciate your support!

and want to which all of you happy Easter.

Please keep in mind I plan to use this hardware with Ethernet based Mesa Stuff and Or Ethercat based Servo-Drives

I have 3 of these units available got them nearly for free...

If they won't be suitable I would try to fit another small Mainboard into the case...

I appreciate your support!

and want to which all of you happy Easter.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

01 Apr 2018 15:54 #108214

by andypugh

Replied by andypugh on topic Strategie bei Hurco BMC20 refit

That looks pretty good. That would be fine for software stepping too.

The following user(s) said Thank You: poolizei

Please Log in or Create an account to join the conversation.

- poolizei

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 3

05 Apr 2018 09:26 #108429

by poolizei

Replied by poolizei on topic Strategie bei Hurco BMC20 refit

HI folks,

I am currently about to decide which Servos I will go for, in generall NEMA51 types will fit pretty good not direct bolt on but easy to adapt.

I made inquirys about Lichuan and Leadshine not Delta because there is no 1kW NEMA51 type which would fit

So I hope you can help me with the decission, I personally see that the +/-10V Interface plus Encoder Feedback seems to be very common BUT some of you use ETHERCAT and I personally think this is a very smart solution only Leadshine is able to provide ETHERCAT as an option for there servo drivers BUT I found nobody using these servo drives through Ethercat any doubts???

I appriciate all your Input a LOT!

Thank You!

I am currently about to decide which Servos I will go for, in generall NEMA51 types will fit pretty good not direct bolt on but easy to adapt.

I made inquirys about Lichuan and Leadshine not Delta because there is no 1kW NEMA51 type which would fit

So I hope you can help me with the decission, I personally see that the +/-10V Interface plus Encoder Feedback seems to be very common BUT some of you use ETHERCAT and I personally think this is a very smart solution only Leadshine is able to provide ETHERCAT as an option for there servo drivers BUT I found nobody using these servo drives through Ethercat any doubts???

I appriciate all your Input a LOT!

Thank You!

Please Log in or Create an account to join the conversation.

- International LinuxCNC Users

- Deutsch

- Strategie bei Hurco BMC20 refit / Interfacing the Drives to MESA

Time to create page: 0.367 seconds