How start Config Yaskawa Servo

- aer73

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 0

07 May 2015 01:04 #58448

by aer73

Replied by aer73 on topic How start Config Yaskawa Servo

Please Log in or Create an account to join the conversation.

- Iron-Man

-

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 3

13 Jun 2015 19:43 - 13 Jun 2015 19:45 #59779

by Iron-Man

I am using SGDA 01AS servos. I reprogrammed my drives for torque mode. They run as smooth as silk.

The Yaskawa drives are very advanced and can be programmed. Have you configured the drive's position mode parameters? If not, you should start here first. If you have the digital operator, it can be used to check internal bit settings and verify data. Please see page 430 section 8-1. After that, you will need to do the following things;

1. Make sure that your motor type is selected.

2. Set encoder type and or resolution.

Hope this helps,

Iron-Man

(3) Operating Procedure in Position Control Mode (Pn000 = n.

Replied by Iron-Man on topic How start Config Yaskawa Servo

Hello to @ll.

I have 3 servopack Yaskawa SGDM-04ADA + SGMAH-04AAA21 servomotor.

Some body can tell me how to strat config it?

Stepconfig wizard or PnCConf Wizard , etc....

Many thanks in advance

Kindly regards.

I am using SGDA 01AS servos. I reprogrammed my drives for torque mode. They run as smooth as silk.

The Yaskawa drives are very advanced and can be programmed. Have you configured the drive's position mode parameters? If not, you should start here first. If you have the digital operator, it can be used to check internal bit settings and verify data. Please see page 430 section 8-1. After that, you will need to do the following things;

1. Make sure that your motor type is selected.

2. Set encoder type and or resolution.

Hope this helps,

Iron-Man

(3) Operating Procedure in Position Control Mode (Pn000 = n.

Last edit: 13 Jun 2015 19:45 by Iron-Man.

The following user(s) said Thank You: aer73

Please Log in or Create an account to join the conversation.

- aer73

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 0

13 Jun 2015 20:08 #59780

by aer73

Replied by aer73 on topic How start Config Yaskawa Servo

Many Thanks Iron-Man

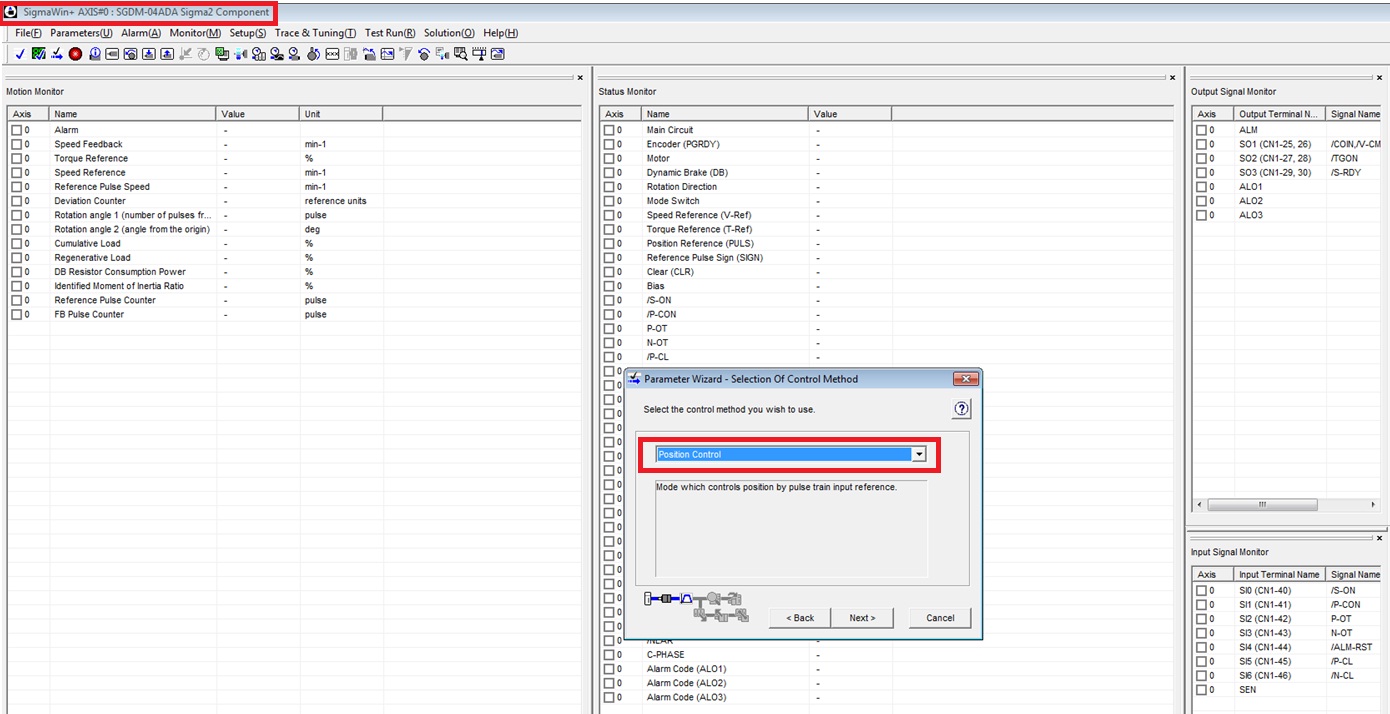

Yes i have conigured my Drives position Mode parameters with Sigmawin+.

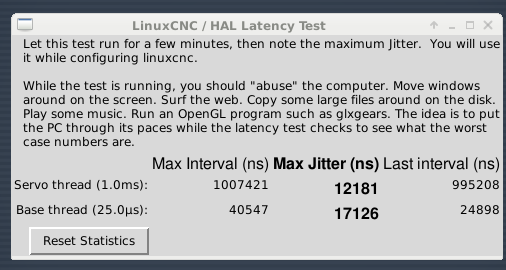

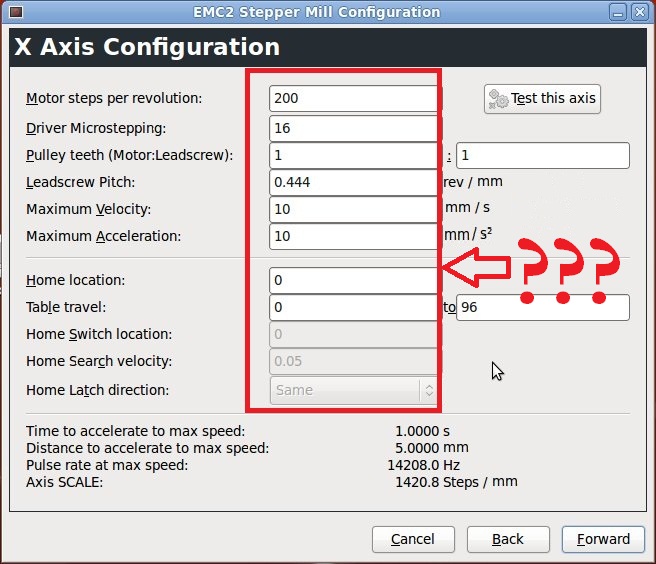

I start configuring Linuxcnc , have my latency test result but now don´t know where to find the necesary values for continue with config Linuxcnc.

I must learn more about it. Many thanks again for your help.

Kindly regards.

Yes i have conigured my Drives position Mode parameters with Sigmawin+.

I start configuring Linuxcnc , have my latency test result but now don´t know where to find the necesary values for continue with config Linuxcnc.

I must learn more about it. Many thanks again for your help.

Kindly regards.

Please Log in or Create an account to join the conversation.

- aer73

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 0

13 Jun 2015 20:08 - 13 Jun 2015 20:09 #59781

by aer73

Replied by aer73 on topic How start Config Yaskawa Servo

Moderator, Please delete

Last edit: 13 Jun 2015 20:09 by aer73.

Please Log in or Create an account to join the conversation.

- Iron-Man

-

- Offline

- Senior Member

-

Less

More

- Posts: 72

- Thank you received: 3

14 Jun 2015 02:16 - 16 Jun 2015 00:51 #59786

by Iron-Man

Replied by Iron-Man on topic How start Config Yaskawa Servo

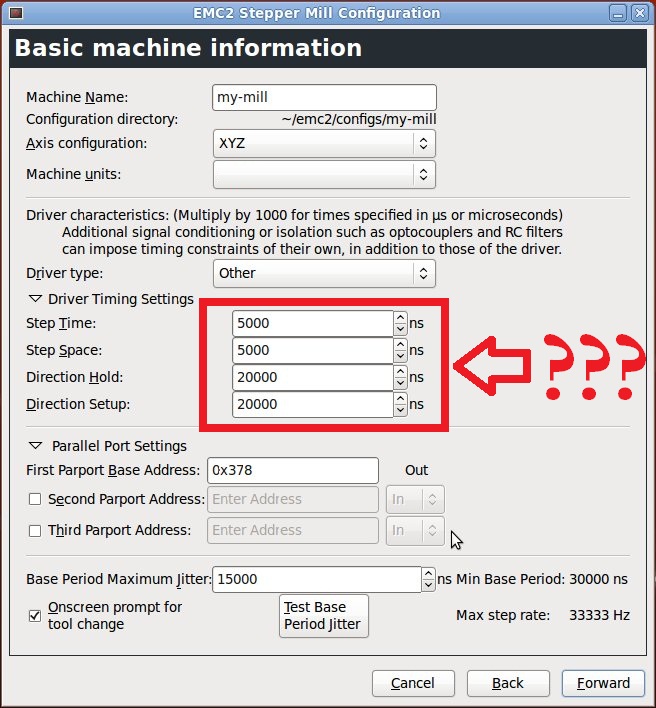

Please see this for timing ( Table 8.1 Reference Pulse Input Signal Timing, page 471 ), Reference Pulse Signal Form.

Look at the first part of the table where ( τ ≥ 1.0 μs). Your set-up shows 5000ns or 5us. This should be OK. Direction hold shows 20000ns or 20us. t(tau) is >= 1us. You could reduce this (20000ns) to say 5us. But do not reduce it below 1us.

Set your motor steps to your encoder count x4. Set micro-stepping to 1. Are you using incremental or absolute encoders?

I built my own DC servo drives and learned a lot about tuning. Sometimes trial and error can be the best for tuning. When you start tuning keep a dedicated log on the values you use. Also listen to how the motors sound. When properly tuned there will be no, or little audible sound, and or vibration from the servo motors.

If possible test a motor that is not connected to a machine. The other parameters can be determined from your machine setup, lead-screw etc.

Hope this helps,

Iron-Man

Look at the first part of the table where ( τ ≥ 1.0 μs). Your set-up shows 5000ns or 5us. This should be OK. Direction hold shows 20000ns or 20us. t(tau) is >= 1us. You could reduce this (20000ns) to say 5us. But do not reduce it below 1us.

Set your motor steps to your encoder count x4. Set micro-stepping to 1. Are you using incremental or absolute encoders?

I built my own DC servo drives and learned a lot about tuning. Sometimes trial and error can be the best for tuning. When you start tuning keep a dedicated log on the values you use. Also listen to how the motors sound. When properly tuned there will be no, or little audible sound, and or vibration from the servo motors.

If possible test a motor that is not connected to a machine. The other parameters can be determined from your machine setup, lead-screw etc.

Hope this helps,

Iron-Man

Last edit: 16 Jun 2015 00:51 by Iron-Man. Reason: Should read 5us.

The following user(s) said Thank You: aer73

Please Log in or Create an account to join the conversation.

- aer73

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 0

14 Jun 2015 11:27 - 14 Jun 2015 14:15 #59798

by aer73

Replied by aer73 on topic How start Config Yaskawa Servo

Many thanks again Iron-MAn.

I use 13-bit Incremental Encoder , number of encoder pulses :2048 P/Rev

I take a deep look to all that details you say.

Kindly regards.

I use 13-bit Incremental Encoder , number of encoder pulses :2048 P/Rev

I take a deep look to all that details you say.

Kindly regards.

Last edit: 14 Jun 2015 14:15 by aer73.

Please Log in or Create an account to join the conversation.

Time to create page: 0.145 seconds