Rigid Tapping with a speed controlled spindle

- tnl.lambert

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 1

16 Jul 2015 02:10 #60641

by tnl.lambert

Rigid Tapping with a speed controlled spindle was created by tnl.lambert

I'm configuring a 4-axis CNC machine to do rigid tapping.

The spindle has an encoder, and we can command specific positions to achieve a toolchange.

However, a G33.1 command results in a 'missing K-word' error. (input is G33.1 Z-0.25 K0.05)

I've tried slowing the spindle down below 5RPM just in case, and I'm using version 2.6. Any ideas?

The spindle has an encoder, and we can command specific positions to achieve a toolchange.

However, a G33.1 command results in a 'missing K-word' error. (input is G33.1 Z-0.25 K0.05)

I've tried slowing the spindle down below 5RPM just in case, and I'm using version 2.6. Any ideas?

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

17 Jul 2015 18:26 #60680

by BigJohnT

Replied by BigJohnT on topic Rigid Tapping with a speed controlled spindle

Can you provide a bit bigger snippet of the G code, the K word is in what you show but the error always says "near" line so and so.

JT

JT

Please Log in or Create an account to join the conversation.

- tnl.lambert

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 1

17 Jul 2015 20:58 #60687

by tnl.lambert

Replied by tnl.lambert on topic Rigid Tapping with a speed controlled spindle

Please Log in or Create an account to join the conversation.

- johns00056

- Offline

- Premium Member

-

Less

More

- Posts: 110

- Thank you received: 2

18 Jul 2015 17:47 - 18 Jul 2015 17:55 #60719

by johns00056

Replied by johns00056 on topic Rigid Tapping with a speed controlled spindle

I think that you need g80 (cancel canned cycle) after the tapping line. Linuxcnc is still in tapping mode

on line n85 and is looking for the k value.

I usually put g80 g90 g0 after each tapped hole to rapid to the next location.

on line n85 and is looking for the k value.

I usually put g80 g90 g0 after each tapped hole to rapid to the next location.

Last edit: 18 Jul 2015 17:55 by johns00056.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

18 Jul 2015 18:27 #60720

by BigJohnT

G33.1 is not a canned cycle and does not need a G80, you can verify that by reading the manual or try a second pair of coordinates after the G33.1

JT

Replied by BigJohnT on topic Rigid Tapping with a speed controlled spindle

I think that you need g80 (cancel canned cycle) after the tapping line. Linuxcnc is still in tapping mode

on line n85 and is looking for the k value.

I usually put g80 g90 g0 after each tapped hole to rapid to the next location.

G33.1 is not a canned cycle and does not need a G80, you can verify that by reading the manual or try a second pair of coordinates after the G33.1

JT

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

18 Jul 2015 18:31 #60721

by BigJohnT

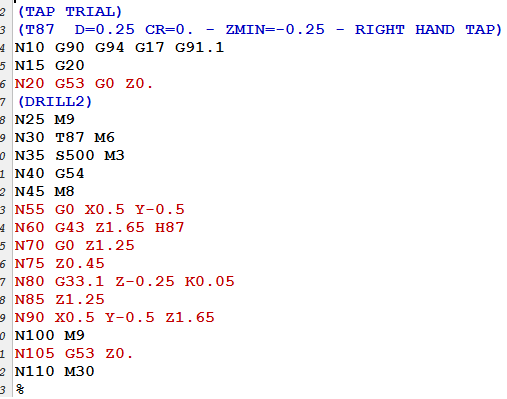

Can you attach the G code instead of photo? It's hard to copy and paste a photo.

I don't see anything that jumps out at me but I would like to run it in sim. I assume line one is %. Be aware of the ramifications of wrapping your code in % instead of using a program stop.

JT

Replied by BigJohnT on topic Rigid Tapping with a speed controlled spindle

The error is highlighted on the G33.1 line directly, and I've attached a picture of the g-code segment.

Can you attach the G code instead of photo? It's hard to copy and paste a photo.

I don't see anything that jumps out at me but I would like to run it in sim. I assume line one is %. Be aware of the ramifications of wrapping your code in % instead of using a program stop.

JT

Please Log in or Create an account to join the conversation.

- johns00056

- Offline

- Premium Member

-

Less

More

- Posts: 110

- Thank you received: 2

18 Jul 2015 19:03 - 18 Jul 2015 19:58 #60724

by johns00056

Replied by johns00056 on topic Rigid Tapping with a speed controlled spindle

I just tried my machine (linuxcnc 2.5.3 ) and It seems like I always get a "k word missing " error if the next line

after g33.1 does not have a g80.

Edit - a g1 or a go in the next line, before movement, also seems to correct the problem.

after g33.1 does not have a g80.

Edit - a g1 or a go in the next line, before movement, also seems to correct the problem.

Last edit: 18 Jul 2015 19:58 by johns00056.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

18 Jul 2015 19:17 - 18 Jul 2015 19:18 #60725

by BigJohnT

Replied by BigJohnT on topic Rigid Tapping with a speed controlled spindle

Here is my ngcgui rigid tapping subroutine that I use daily on 2.5 on my CHNC.

(info: Rigid Tapping)

o<tap>sub

#<thread-type> = #1 (=0 0=TPI 1=MM)

#<thread> = #2 (TPI/Pitch)

#<Z_Start> = #3 (=0.100 Z Clearance)

#<T_Depth> = #4 (End of Thread)

#<RPM> = #5 (Spindle RPM)

#<ToolNumber> = #6 (Tool Number)

#<Coolant> = #7 (=8 Coolant 8 On 9 Off)

G7 G17 G20 G40 G80

T#<ToolNumber> M6 G43

o110 if [#<thread-type> EQ 0]

#<pitch> = [1 / #<thread>]

G20

o110 else

#<pitch> = #<thread>

G21

o110 endif

; Tap the Hole

o120 if [#<thread-type> EQ 0 OR #<thread-type> EQ 1]

S#<RPM> M3 M#<Coolant>

G0 X0.000 Z#<Z_Start>

G33.1 X0.000 Z#<T_Depth> K#<pitch>

M5 M9

G53 G0 X0 Z0

o120 else

(msg, you dufus you didn't use a proper thread type)

o120 endif

; Restore to normal units

G20

o<tap>endsub

Last edit: 18 Jul 2015 19:18 by BigJohnT.

The following user(s) said Thank You: tnl.lambert

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

18 Jul 2015 19:20 - 18 Jul 2015 19:22 #60726

by BigJohnT

Replied by BigJohnT on topic Rigid Tapping with a speed controlled spindle

And here is a G code file that I run regularly on my 2.6 mill... and you can see that G33.1 is called for every hole and is not a canned cycle.

Canned Cycles:

www.linuxcnc.org/docs/html/gcode/gcode.html#sec:G80-G89

Canned Cycles:

www.linuxcnc.org/docs/html/gcode/gcode.html#sec:G80-G89

(PART - )

(NOTES - CUP HOLDER VELCRO OP1 DRILL AND TAP)

G17 G20 G40 G49 G54 G64 P0.005 G80 G90 G94

M05 G40 G49 G80

M09

(0.1495" #25 DRILL)

T1 M06 G43

G00 X0.1875 Y-0.261 S1800 M03

M0

Z0.25

G00 X0.1875 Y-0.261 Z0.25

Z0.1

G01 Z-0.556 F12.0 S1800

G00 Z0.1

Z0.25

X1.0625

Z0.1

G01 Z-0.556

G00 Z0.1

G00 Z0.25

M05 G40 G49 G80

M09

(10-24 HSS TAP)

T2 M06 G43

G00 X0.1875 Y-0.261 S900 M03

M0

Z0.25

G00 X0.1875 Y-0.261 Z0.25

G33.1 X0.1875 Y-0.261 Z-0.400 K0.0416

G0 X1.0625

G33.1 X1.0625 Y-0.261 Z-0.400 K0.0416

M5

G53 G0 Z0

G0 X0 Y0

M2

Last edit: 18 Jul 2015 19:22 by BigJohnT.

Please Log in or Create an account to join the conversation.

- tnl.lambert

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 1

18 Jul 2015 19:28 #60727

by tnl.lambert

Replied by tnl.lambert on topic Rigid Tapping with a speed controlled spindle

Ok, so there is no major reason in the g-code that would cause the error? Maybe this is sliding towards an advanced configuration post, but I'll provide a theory of mine - I use a custom orient code that uses a separate PID loop. It is connected to motion.spindle-index-enable, so the PID loops change over when M19 is called. Will that be an issue?

Please Log in or Create an account to join the conversation.

Time to create page: 0.089 seconds