- Configuring LinuxCNC

- Basic Configuration

- Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17624

- Thank you received: 5155

15 Feb 2025 19:14 #321656

by PCW

Replied by PCW on topic Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

That looks like maybe an electrical/wiring issue with the encoder.

Is differential signaling used?

Is differential signaling used?

Please Log in or Create an account to join the conversation.

- Traken

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 0

17 Feb 2025 16:39 - 17 Feb 2025 16:49 #321846

by Traken

Replied by Traken on topic Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

Yes, it is a differential signal.

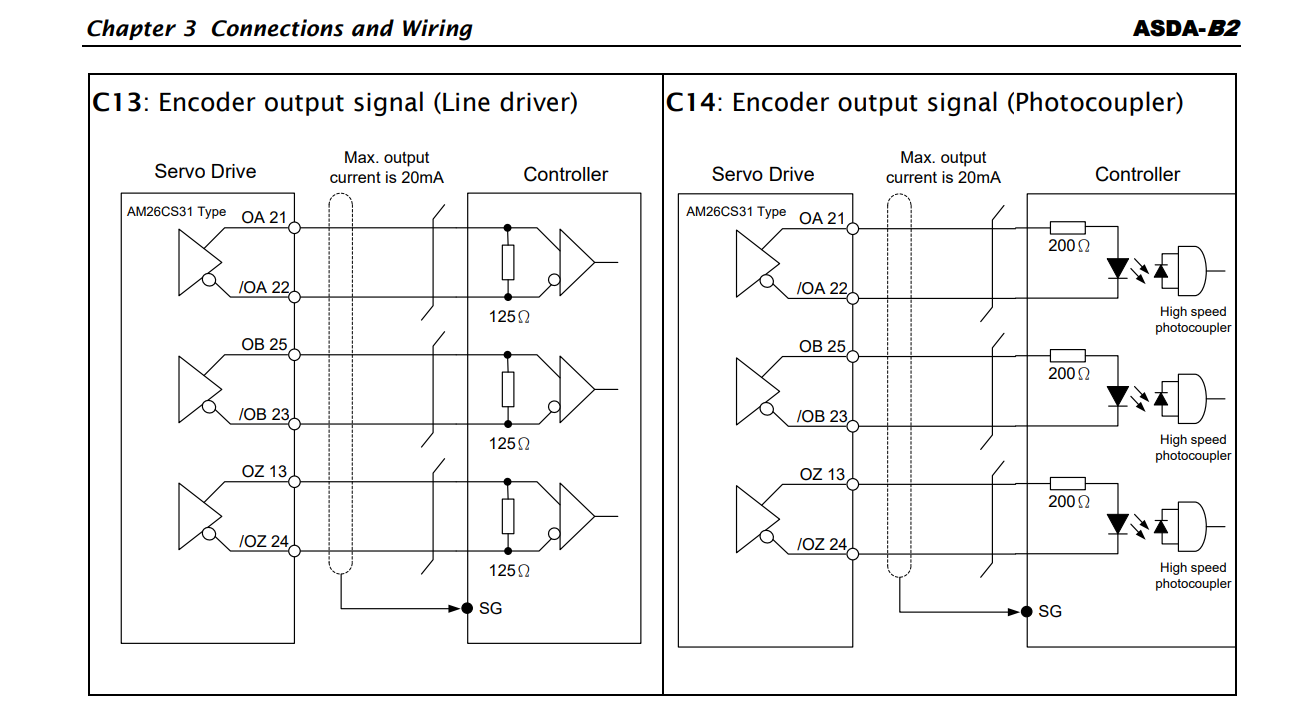

I am attaching a screen manual from the servopack.

Two servos are Delta asda-b2 750w and one on the z axis is the Chinese a1-svd 750w and in total there are such symptoms on each axis.

The encoder cable is shielded and a separate analog cable is also shielded, the shield is only connected to the servopack.

Maybe I need to use resistors?

I am attaching a screen manual from the servopack.

Two servos are Delta asda-b2 750w and one on the z axis is the Chinese a1-svd 750w and in total there are such symptoms on each axis.

The encoder cable is shielded and a separate analog cable is also shielded, the shield is only connected to the servopack.

Maybe I need to use resistors?

Attachments:

Last edit: 17 Feb 2025 16:49 by Traken.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17624

- Thank you received: 5155

17 Feb 2025 19:12 #321856

by PCW

Replied by PCW on topic Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

Is the 7I77 jumpered for differential inputs?

It may be a noise issue. One way to check if it's a common mode noise issue

(noise that exceeds the common mode range of the RS-422 receivers)

is to enable encoder error reporting:

setp hm2_5i25.0.encoder.00.quad-error-enable true

Once this has been done, inputs that violate the quadrature sequence

(often noise will do this) will set the quadrature error flag:

hm2_5i25.0.encoder.00.quad-error

It may be a noise issue. One way to check if it's a common mode noise issue

(noise that exceeds the common mode range of the RS-422 receivers)

is to enable encoder error reporting:

setp hm2_5i25.0.encoder.00.quad-error-enable true

Once this has been done, inputs that violate the quadrature sequence

(often noise will do this) will set the quadrature error flag:

hm2_5i25.0.encoder.00.quad-error

Please Log in or Create an account to join the conversation.

- Traken

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 0

20 Feb 2025 12:07 - 20 Feb 2025 12:19 #322049

by Traken

Replied by Traken on topic Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

It checks your method and shows no error. I will try to turn on linuxcnc and control from the servopack to read a higher speed and exclude the encoder reading.

Because it still seems to me that it is not related to the encoder reading but to the analog power supply.

What still surprises me is that if I drive the axle in the positive direction, I can achieve 10 m/min, and if I drive the axle in the negative direction, 8.3 m/min.

Because it still seems to me that it is not related to the encoder reading but to the analog power supply.

What still surprises me is that if I drive the axle in the positive direction, I can achieve 10 m/min, and if I drive the axle in the negative direction, 8.3 m/min.

Last edit: 20 Feb 2025 12:19 by Traken.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17624

- Thank you received: 5155

20 Feb 2025 14:56 #322074

by PCW

Replied by PCW on topic Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

It sure looks like an encoder issue, especially the speed limit

(in one plot the encoder velocity dropped to 0 in basically an instant)

Did you set the encoder filter to 0 on all encoder channels?

(in one plot the encoder velocity dropped to 0 in basically an instant)

Did you set the encoder filter to 0 on all encoder channels?

Please Log in or Create an account to join the conversation.

- Traken

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 0

21 Feb 2025 06:16 #322169

by Traken

Replied by Traken on topic Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

No, I set it on one axis I was testing. Should I set it on all axes?

Please Log in or Create an account to join the conversation.

- Traken

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 0

24 Feb 2025 19:06 #322517

by Traken

Replied by Traken on topic Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

I changed the encoder filter to 0 on each axis, it had no effect. I wonder if I can somehow drive the servo without a closed loop and see if it works.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17624

- Thank you received: 5155

24 Feb 2025 19:40 #322523

by PCW

Replied by PCW on topic Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

Yes, if you decouple the linear axis (and comment out the net statement that connects

the PID output to the 7I77 analog output pin, you can simply setp the output voltage

with halcmd.

the PID output to the 7I77 analog output pin, you can simply setp the output voltage

with halcmd.

Please Log in or Create an account to join the conversation.

- Traken

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 0

03 Jun 2025 06:30 #329586

by Traken

Replied by Traken on topic Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

After a long break I'm back to the topic. I did some research, tried to swap the wires between the mesa and the servopack, but no changes. It's not a problem with the analog voltage as in the topic because if I set P=0 I can normally drive at high speed without a closed loop.

What should the encoder accuracy be set to?

Maybe I have set the scale too large or too small?

But I tried changing it to less and it didn't have any effect.

I'm still wondering if the analog wire can go parallel to the encoder wire, maybe it creates some interference.

What should the encoder accuracy be set to?

Maybe I have set the scale too large or too small?

But I tried changing it to less and it didn't have any effect.

I'm still wondering if the analog wire can go parallel to the encoder wire, maybe it creates some interference.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17624

- Thank you received: 5155

03 Jun 2025 14:24 #329607

by PCW

Replied by PCW on topic Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

Yes, looks like an encoder issue of some kind (especially the sudden drop to 0 velocity)

I would try lowering the emulated encoder output scale, as

maybe the drive has an issue with quadrature generation at high

speeds and high resolutions.

I would try lowering the emulated encoder output scale, as

maybe the drive has an issue with quadrature generation at high

speeds and high resolutions.

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Basic Configuration

- Servo Oscillation Issue at ±6.6V 5i25 + 7i77, Analog Control

Time to create page: 0.124 seconds