Random stuff, reduction, servo motors, ideas and thoughts

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21332

- Thank you received: 7280

27 Mar 2020 19:35 #161737

by tommylight

Random stuff, reduction, servo motors, ideas and thoughts was created by tommylight

Starting a new topic as we keep hijacking other threads.

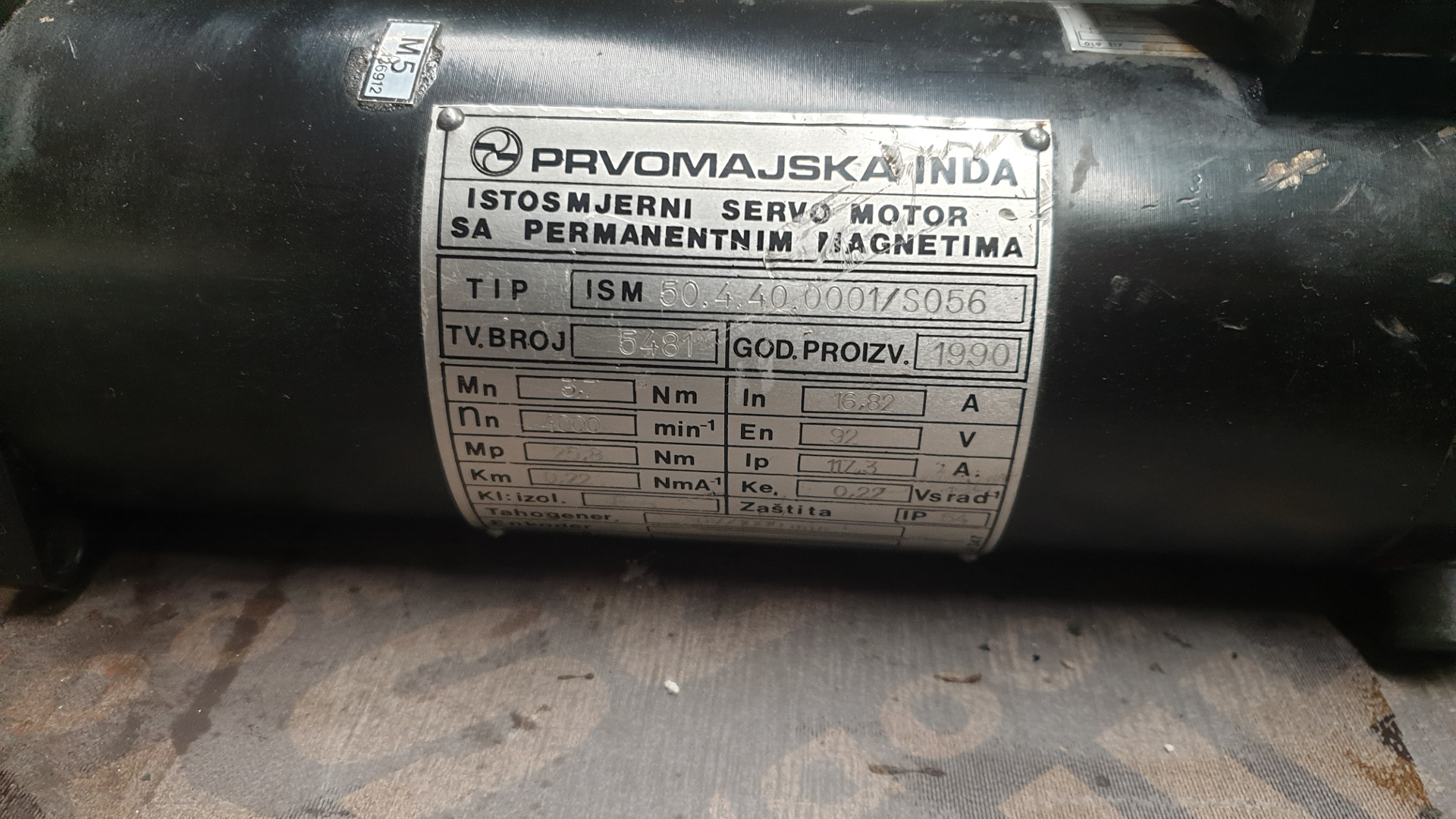

Use this as random everything, so to start here are some pictures of 4 servo motors i bought used for 120 Euros a while back, they seem to be 1.5KW, 4000RPM, 3.7MN and 25.8MN peak, they have tachos but no encoders and there is no easy way to mount them.

Spec:

Tacho:

I have another 4 much bigger from the same machine/manufacturer on hold at 50$ a piece that i will collect after this "V mess", they should be at least 2.5KW or more, they are to damn heavy.

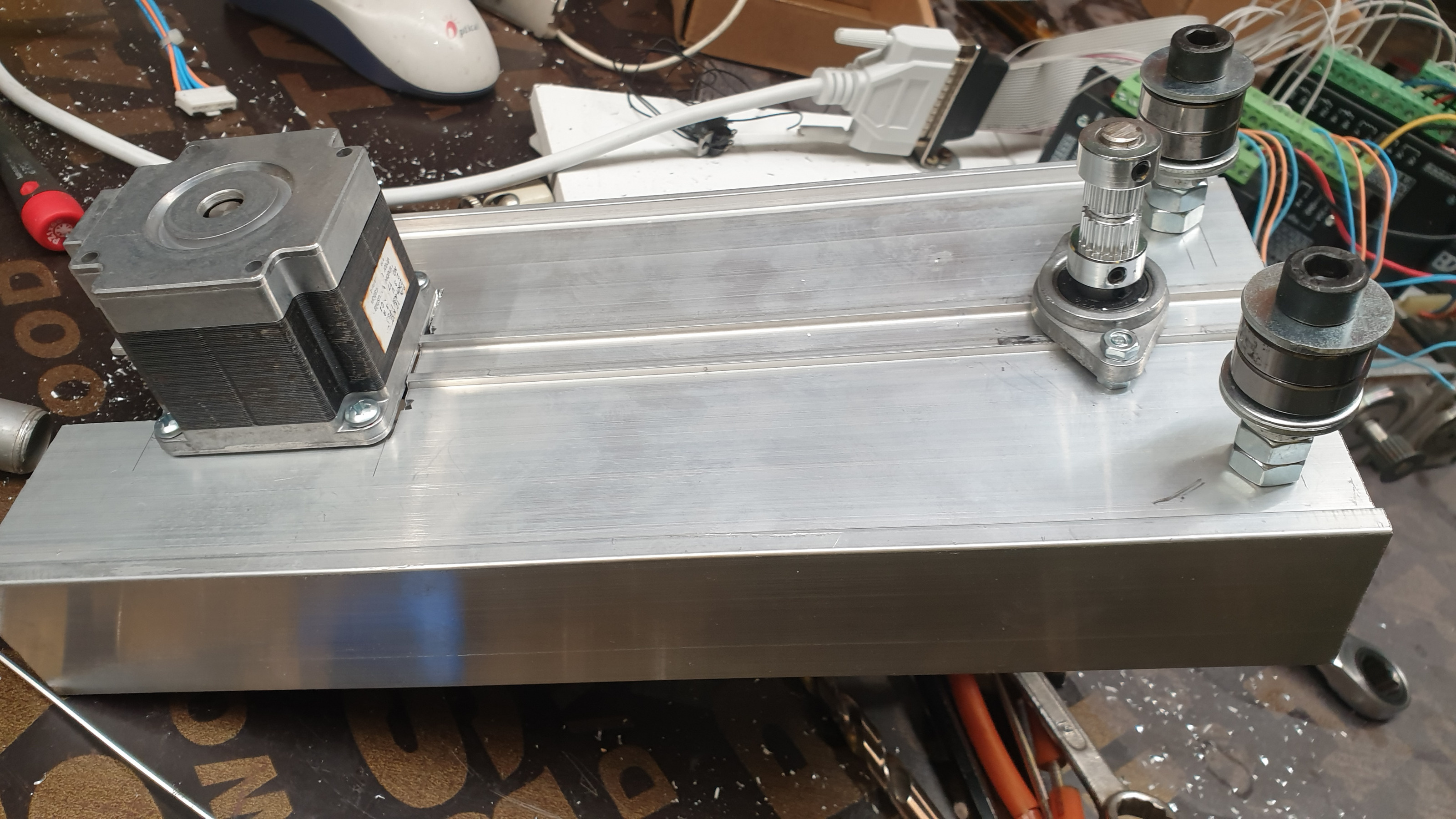

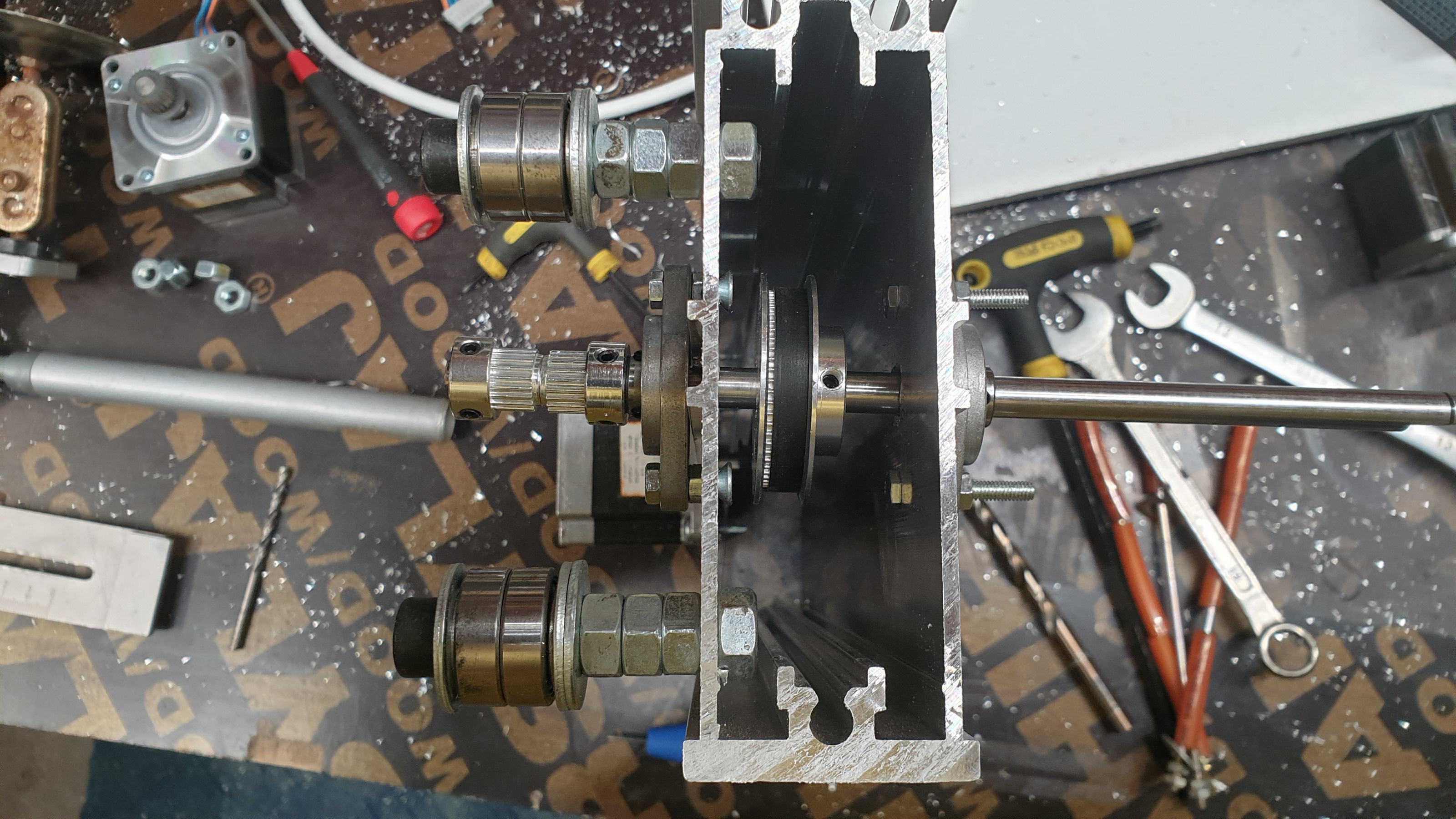

Today i did some experimental work on a reduction for smaller machines with belt drive, using some aluminium profiles, and there is no way on earth i can explain how it is done so here are pictures instead of me yapping to no end:

Front:

And from above so you can see what is going on inside:

Thoughts, ideas, critique ? Free velocity servo drives ???

Use this as random everything, so to start here are some pictures of 4 servo motors i bought used for 120 Euros a while back, they seem to be 1.5KW, 4000RPM, 3.7MN and 25.8MN peak, they have tachos but no encoders and there is no easy way to mount them.

Spec:

Tacho:

I have another 4 much bigger from the same machine/manufacturer on hold at 50$ a piece that i will collect after this "V mess", they should be at least 2.5KW or more, they are to damn heavy.

Today i did some experimental work on a reduction for smaller machines with belt drive, using some aluminium profiles, and there is no way on earth i can explain how it is done so here are pictures instead of me yapping to no end:

Front:

And from above so you can see what is going on inside:

Thoughts, ideas, critique ? Free velocity servo drives ???

Attachments:

The following user(s) said Thank You: pommen, jay1st, pinder, cronitro

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

28 Mar 2020 07:43 #161787

by bbsr_5a

Replied by bbsr_5a on topic Random stuff, reduction, servo motors, ideas and thoughts

isent this a standard 42 mount

and the tachos are hooked up

take the backcase off and mount cheep 20USD 2000ppr Hole/Shaft encoders and you got a real good system

and the tachos are hooked up

take the backcase off and mount cheep 20USD 2000ppr Hole/Shaft encoders and you got a real good system

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21332

- Thank you received: 7280

28 Mar 2020 14:01 #161806

by tommylight

Replied by tommylight on topic Random stuff, reduction, servo motors, ideas and thoughts

They are 98mm frame, so not exactly nema42, and i did open them but there is no way to mount anything on them.

I do have 5x of 2500ppr encoders with 8mm shafts that will need mounts and axle made to be mounted beside the motor and driven by the belt. Not the best solution, but it works.

Thank you.

I do have 5x of 2500ppr encoders with 8mm shafts that will need mounts and axle made to be mounted beside the motor and driven by the belt. Not the best solution, but it works.

Thank you.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17721

- Thank you received: 5185

28 Mar 2020 15:03 #161818

by PCW

Replied by PCW on topic Random stuff, reduction, servo motors, ideas and thoughts

Another option is to mount the encoder on the far end of the ballscrew

Though this adds to wiring complexity

Though this adds to wiring complexity

The following user(s) said Thank You: tommylight, pinder

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19798

- Thank you received: 4608

28 Mar 2020 23:29 #161864

by andypugh

Replied by andypugh on topic Random stuff, reduction, servo motors, ideas and thoughts

Use the servos in velocity mode with linear scales for position feedback.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21332

- Thank you received: 7280

28 Mar 2020 23:39 #161871

by tommylight

I do have 2 of the Gecko 320 servo drives collecting dust somewhere in the shop, but i do not like them much.

Replied by tommylight on topic Random stuff, reduction, servo motors, ideas and thoughts

I would, but i have none! Like no servo drives and no linear encoders.Thoughts, ideas, critique ? Free velocity servo drives ???

I do have 2 of the Gecko 320 servo drives collecting dust somewhere in the shop, but i do not like them much.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

05 Apr 2020 02:47 #162740

by thefabricator03

Replied by thefabricator03 on topic Random stuff, reduction, servo motors, ideas and thoughts

I am a little late to the party Tom.

Where do you come across all your motors?

In the other plasma thread with the round frame steppers you posted. How old are those motors?

I am in a rural city in Australia so its hard for me to come across these kinds of things without driving 500km north,south or east. Not many old factories out here.

Where do you come across all your motors?

In the other plasma thread with the round frame steppers you posted. How old are those motors?

I am in a rural city in Australia so its hard for me to come across these kinds of things without driving 500km north,south or east. Not many old factories out here.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21332

- Thank you received: 7280

05 Apr 2020 22:34 #162808

by tommylight

Replied by tommylight on topic Random stuff, reduction, servo motors, ideas and thoughts

Yeah old factories, we had plenty of them before that war, now they all got sold for scrap and shopping centres opened in their place. Miserable!!!

I tend to buy big old xerox photocopiers and dismantle them, they always have Japanese motors, the big ones are usually from the machines mentioned in the above factories that got to the scrap yard.

Of the over 20 big factories ( my father worked for Zastava, car manufacturing, very crappy cars, for over 30 years, it had 2200 workers ), the only one still working is the beer factory.

I tend to buy big old xerox photocopiers and dismantle them, they always have Japanese motors, the big ones are usually from the machines mentioned in the above factories that got to the scrap yard.

Of the over 20 big factories ( my father worked for Zastava, car manufacturing, very crappy cars, for over 30 years, it had 2200 workers ), the only one still working is the beer factory.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

06 Apr 2020 00:01 #162827

by thefabricator03

Replied by thefabricator03 on topic Random stuff, reduction, servo motors, ideas and thoughts

Seems to be a sign of the times with factories shutting down. Although maybe that might change after the world gets over the virus. If it has done one thing well, it has shown how fragile the worlds product supply chains have become.

Funny how putting all your eggs into one basket can cause havoc.

I for one would like to see the return of local manufacturing. Its going to be interesting to see the aftermath of all this.

Funny how putting all your eggs into one basket can cause havoc.

I for one would like to see the return of local manufacturing. Its going to be interesting to see the aftermath of all this.

Please Log in or Create an account to join the conversation.

- tommylight

-

Topic Author

Topic Author

- Away

- Moderator

-

Less

More

- Posts: 21332

- Thank you received: 7280

06 Apr 2020 10:15 #162879

by tommylight

I am refraining from going off the handle again about how humanity got messed up with the bloody phones to the point that humanity does not exist any more, we still look like humans, but there is not much humanity left in us. Maybe this teaches us how to be humans again.

BTW, i use my phone for calls and e-mails, nothing more, except some drawings and writings i do from time to time on a Note 8.

No anti-social networking, i still like to socialise with humans, not phones.

Replied by tommylight on topic Random stuff, reduction, servo motors, ideas and thoughts

Agreed!Seems to be a sign of the times with factories shutting down. Although maybe that might change after the world gets over the virus. If it has done one thing well, it has shown how fragile the worlds product supply chains have become.

Funny how putting all your eggs into one basket can cause havoc.

I for one would like to see the return of local manufacturing. Its going to be interesting to see the aftermath of all this.

I am refraining from going off the handle again about how humanity got messed up with the bloody phones to the point that humanity does not exist any more, we still look like humans, but there is not much humanity left in us. Maybe this teaches us how to be humans again.

BTW, i use my phone for calls and e-mails, nothing more, except some drawings and writings i do from time to time on a Note 8.

No anti-social networking, i still like to socialise with humans, not phones.

The following user(s) said Thank You: CORBETT

Please Log in or Create an account to join the conversation.

Time to create page: 0.275 seconds