Search Results (Searched for: 7i76e)

- PCW

Today 14:36

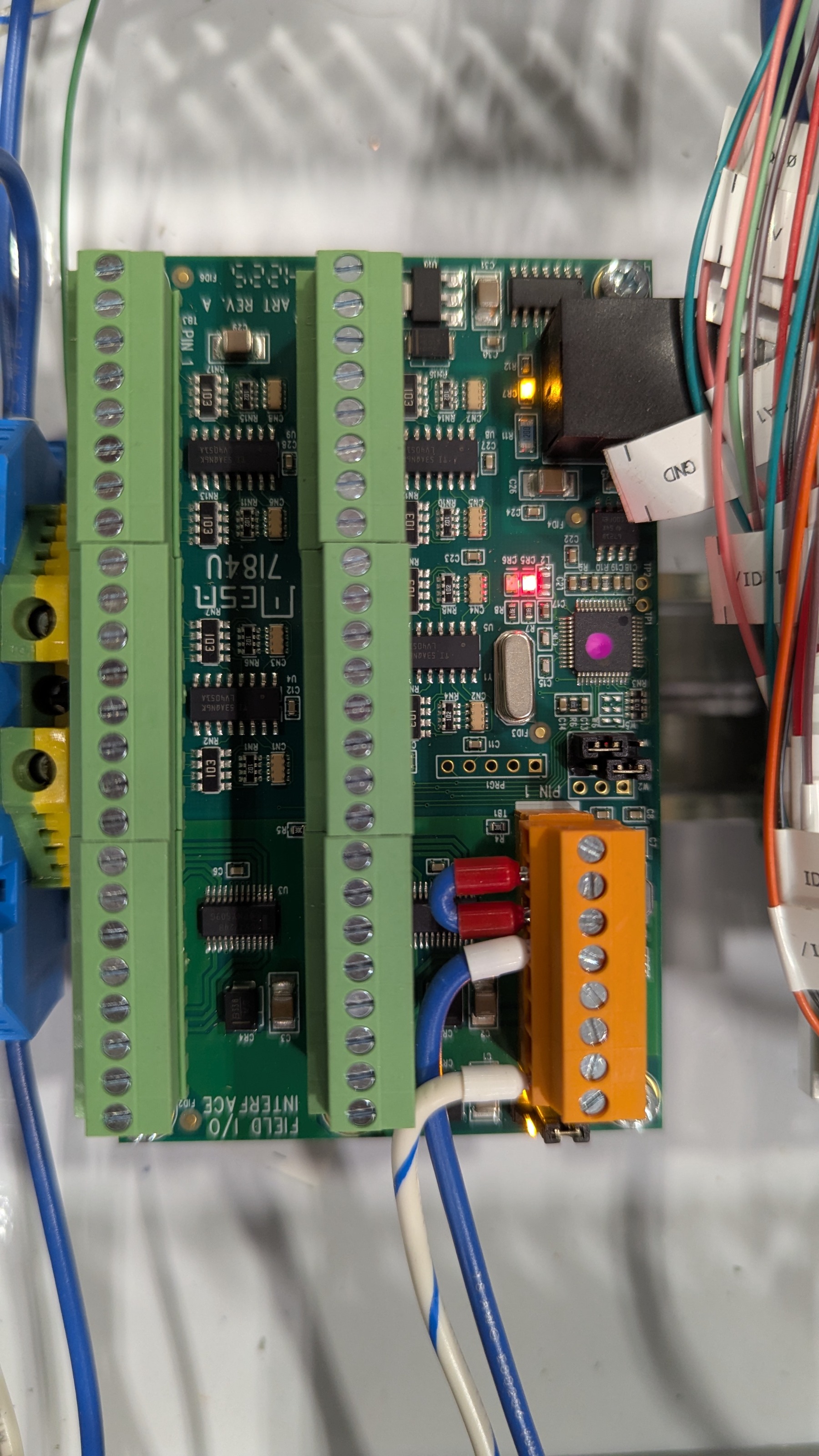

Replied by PCW on topic Wiring Leadshine DM856 Ena+ and ENA- -> Mesa 7i76e

Wiring Leadshine DM856 Ena+ and ENA- -> Mesa 7i76e

Category: Milling Machines

- DerKlotz

- DerKlotz

Today 08:35 - Today 08:36

Wiring Leadshine DM856 Ena+ and ENA- -> Mesa 7i76e was created by DerKlotz

Wiring Leadshine DM856 Ena+ and ENA- -> Mesa 7i76e

Category: Milling Machines

- DerKlotz

- DerKlotz

Yesterday 09:52 - Yesterday 09:58

Verdrahtung Leadshine DM856 Ena+ und - bei Mesa 7i76e was created by DerKlotz

Verdrahtung Leadshine DM856 Ena+ und - bei Mesa 7i76e

Category: Deutsch

- Lcvette

04 Mar 2026 15:45

- DerKlotz

- DerKlotz

04 Mar 2026 09:03 - 04 Mar 2026 10:52

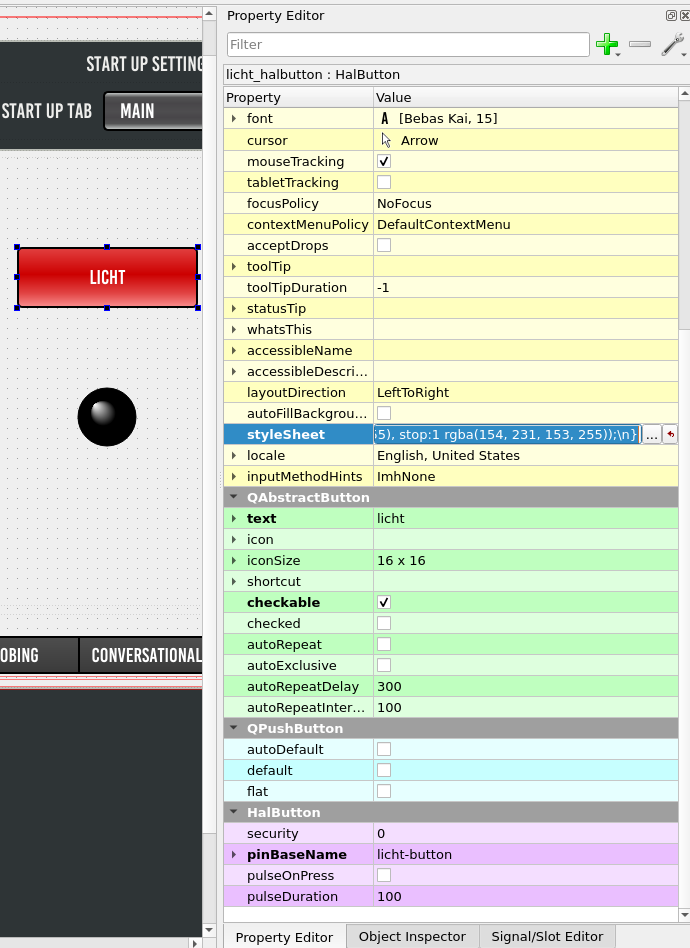

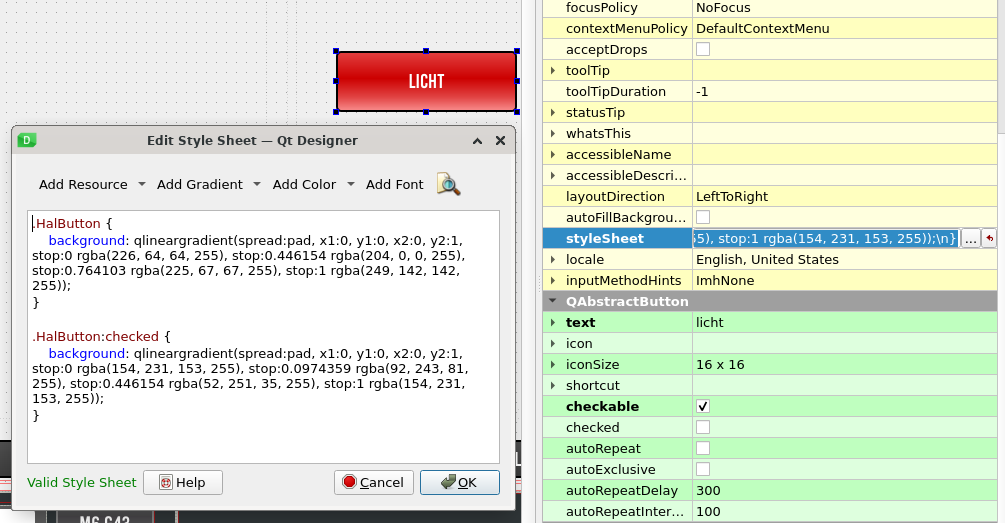

Replied by DerKlotz on topic Add Buttons in Probe Basic

Add Buttons in Probe Basic

Category: QtPyVCP

- Todd Zuercher

25 Feb 2026 11:41

- Todd Zuercher

25 Feb 2026 00:00

- PCW

24 Feb 2026 23:08

- rodw

24 Feb 2026 22:47

- tommylight

24 Feb 2026 22:42

- rodw

24 Feb 2026 22:40

- PCW

24 Feb 2026 18:37

- Todd Zuercher

24 Feb 2026 17:38

- Todd Zuercher

24 Feb 2026 17:15

- tommylight

24 Feb 2026 16:56

Time to create page: 0.486 seconds