Search Results (Searched for: )

- gm001

- gm001

22 Mar 2025 19:29

- PCW

22 Mar 2025 19:28

Replied by PCW on topic dead Outputs on Mesa 7i76E and blown up 7i85S

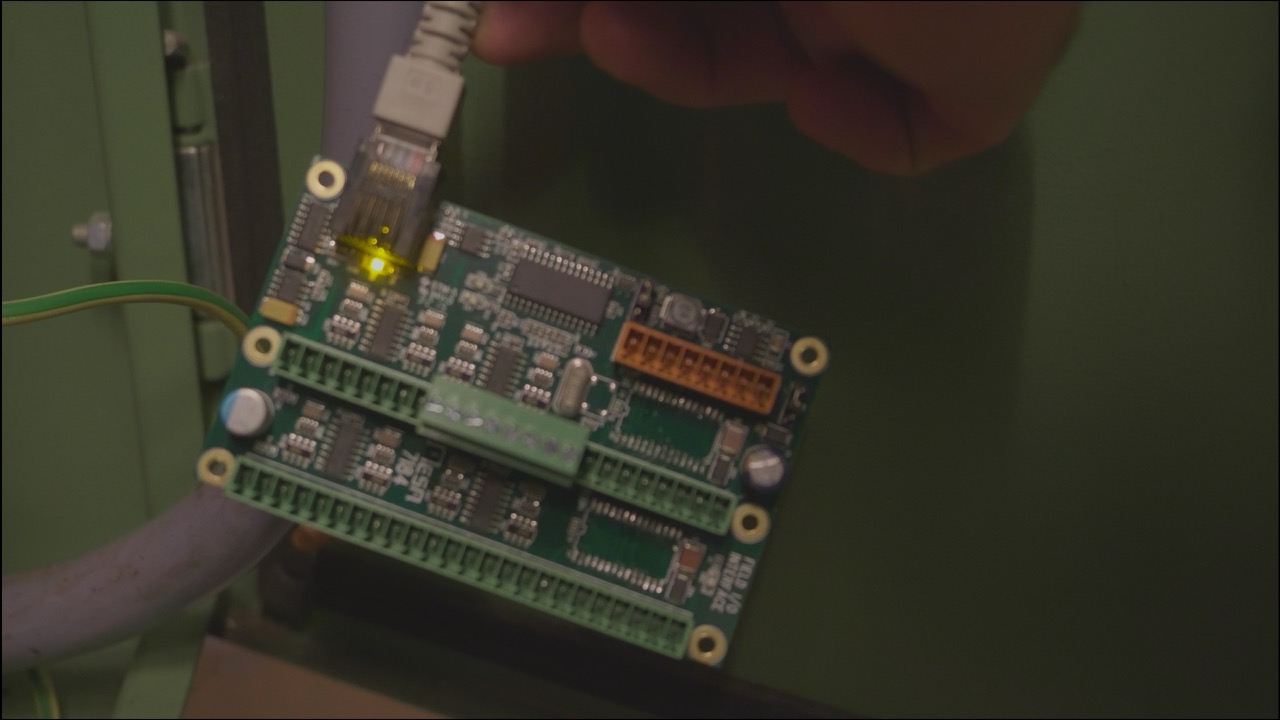

dead Outputs on Mesa 7i76E and blown up 7i85S

Category: Driver Boards

- maxi177

- maxi177

22 Mar 2025 19:15

Replied by maxi177 on topic dead Outputs on Mesa 7i76E and blown up 7i85S

dead Outputs on Mesa 7i76E and blown up 7i85S

Category: Driver Boards

- mclien

- mclien

22 Mar 2025 19:08

Replied by mclien on topic Any experience with cnc-step machines?

Any experience with cnc-step machines?

Category: Milling Machines

- PCW

22 Mar 2025 19:05 - 22 Mar 2025 19:14

Replied by PCW on topic 7i95t pin and firmware files with Stepgens and Inputs 5Axis BoB

7i95t pin and firmware files with Stepgens and Inputs 5Axis BoB

Category: Driver Boards

- RotarySMP

22 Mar 2025 18:56 - 22 Mar 2025 18:57

- looping

- looping

22 Mar 2025 18:07

Replied by looping on topic QTDragon_hd won't display a larger file.

QTDragon_hd won't display a larger file.

Category: Qtvcp

- Nathan40

- Nathan40

22 Mar 2025 17:39 - 22 Mar 2025 18:37

Replied by Nathan40 on topic 7i95t pin and firmware files with Stepgens and Inputs 5Axis BoB

7i95t pin and firmware files with Stepgens and Inputs 5Axis BoB

Category: Driver Boards

- RotarySMP

22 Mar 2025 17:37

- PCW

22 Mar 2025 17:19

Replied by PCW on topic dead Outputs on Mesa 7i76E and blown up 7i85S

dead Outputs on Mesa 7i76E and blown up 7i85S

Category: Driver Boards

- maxi177

- maxi177

22 Mar 2025 17:18

Replied by maxi177 on topic dead Outputs on Mesa 7i76E and blown up 7i85S

dead Outputs on Mesa 7i76E and blown up 7i85S

Category: Driver Boards

- tommylight

22 Mar 2025 17:13

Replied by tommylight on topic dead Outputs on Mesa 7i76E and blown up 7i85S

dead Outputs on Mesa 7i76E and blown up 7i85S

Category: Driver Boards

- scotth

- scotth

22 Mar 2025 17:07

- tommylight

22 Mar 2025 17:07

- FPM

- FPM

22 Mar 2025 16:59

Replied by FPM on topic converting a tos/intos fngj 40

converting a tos/intos fngj 40

Category: Milling Machines

Time to create page: 0.392 seconds