Search Results (Searched for: )

- DemonClaW

- DemonClaW

21 Feb 2026 19:16

- NWE

21 Feb 2026 19:15 - 21 Feb 2026 19:17

Replied by NWE on topic How good is Ethercat motion control?

How good is Ethercat motion control?

Category: EtherCAT

- NWE

21 Feb 2026 19:12

Replied by NWE on topic How good is Ethercat motion control?

How good is Ethercat motion control?

Category: EtherCAT

- ihavenofish

- ihavenofish

21 Feb 2026 19:07 - 21 Feb 2026 19:11

Replied by ihavenofish on topic How good is Ethercat motion control?

How good is Ethercat motion control?

Category: EtherCAT

- ihavenofish

- ihavenofish

21 Feb 2026 19:06

Replied by ihavenofish on topic How good is Ethercat motion control?

How good is Ethercat motion control?

Category: EtherCAT

- bmoo

- bmoo

21 Feb 2026 18:28

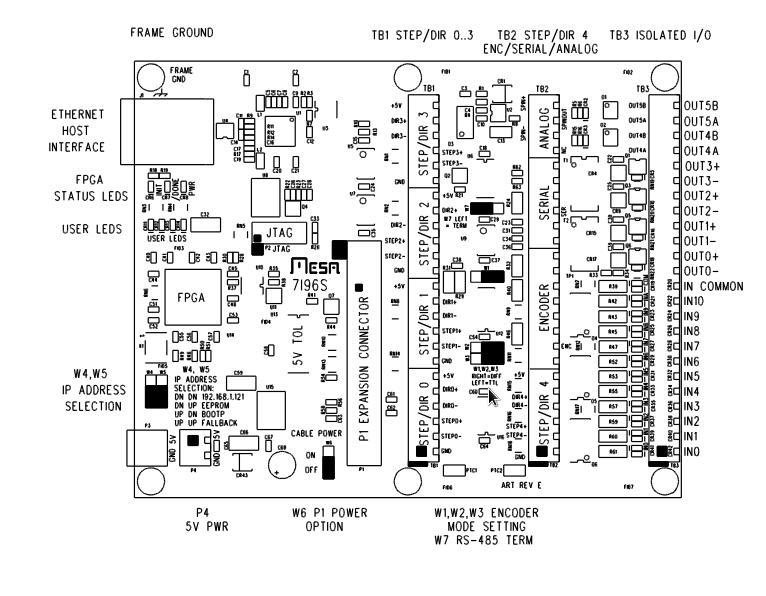

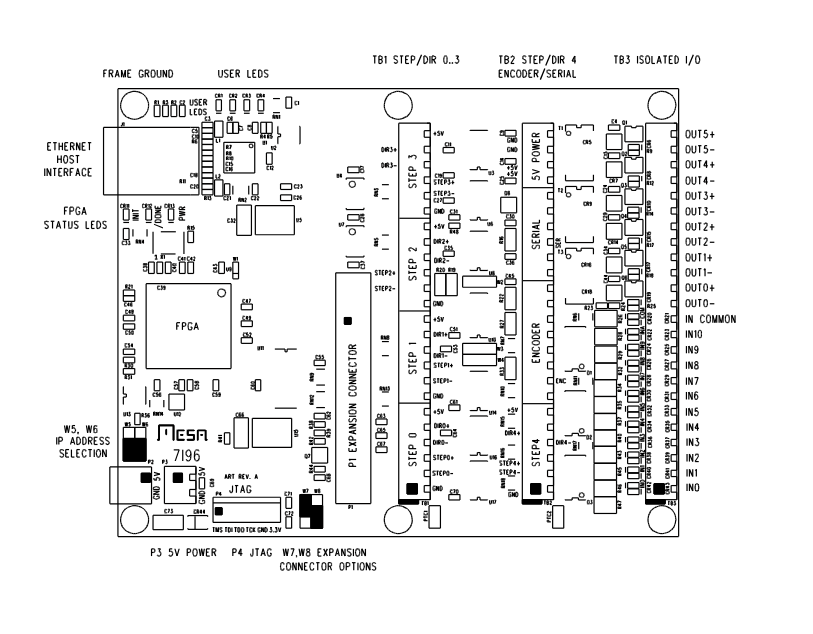

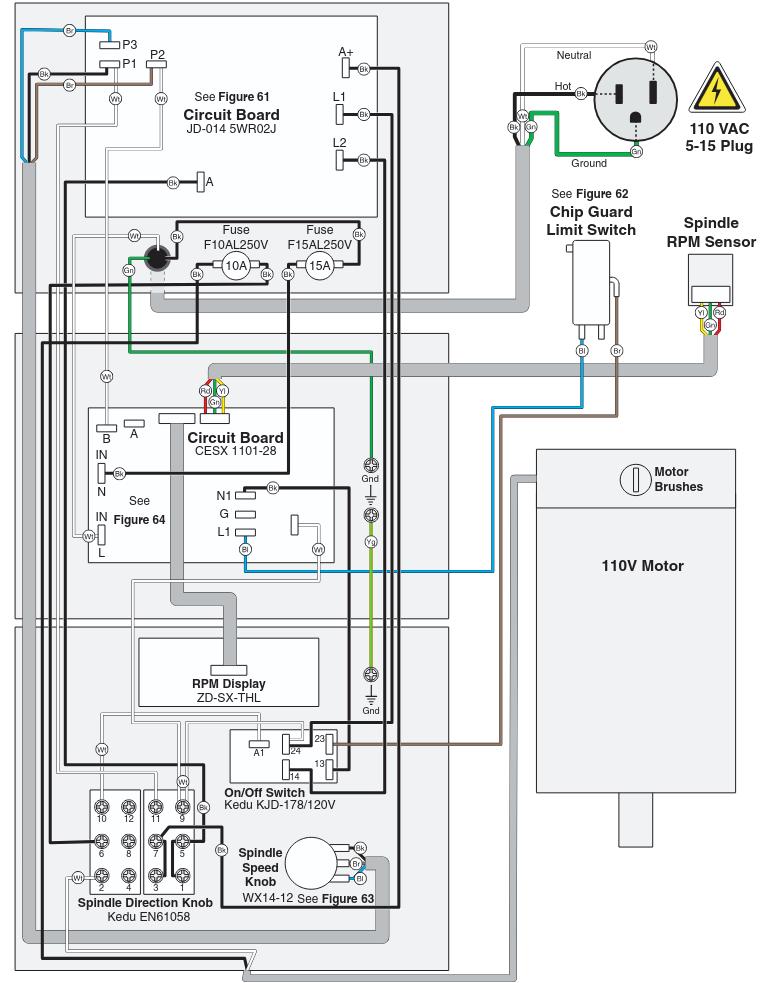

Replied by bmoo on topic Help wiring G0704 Spindle to Mesa 7i96s

Help wiring G0704 Spindle to Mesa 7i96s

Category: Milling Machines

- bmoo

- bmoo

21 Feb 2026 18:06

Replied by bmoo on topic Help wiring G0704 Spindle to Mesa 7i96s

Help wiring G0704 Spindle to Mesa 7i96s

Category: Milling Machines

- PCW

21 Feb 2026 17:44

Replied by PCW on topic Considering a Full Rewire on a Working Schaublin 125 CNC

Considering a Full Rewire on a Working Schaublin 125 CNC

Category: Turning

- tommylight

21 Feb 2026 17:44

Replied by tommylight on topic Help wiring G0704 Spindle to Mesa 7i96s

Help wiring G0704 Spindle to Mesa 7i96s

Category: Milling Machines

- Dudelbert

- Dudelbert

21 Feb 2026 17:04

Replied by Dudelbert on topic Considering a Full Rewire on a Working Schaublin 125 CNC

Considering a Full Rewire on a Working Schaublin 125 CNC

Category: Turning

- freemoore

- freemoore

21 Feb 2026 16:22

AT903 VFD modbus register map was created by freemoore

AT903 VFD modbus register map

Category: Advanced Configuration

- bmoo

- bmoo

21 Feb 2026 16:21

Help wiring G0704 Spindle to Mesa 7i96s was created by bmoo

Help wiring G0704 Spindle to Mesa 7i96s

Category: Milling Machines

- PCW

21 Feb 2026 16:21

Replied by PCW on topic Considering a Full Rewire on a Working Schaublin 125 CNC

Considering a Full Rewire on a Working Schaublin 125 CNC

Category: Turning

- Marcos DC

21 Feb 2026 16:20

Replied by Marcos DC on topic How good is Ethercat motion control?

How good is Ethercat motion control?

Category: EtherCAT

- Konstantin

- Konstantin

21 Feb 2026 15:38 - 21 Feb 2026 15:41

Time to create page: 0.276 seconds