Search Results (Searched for: )

- tommylight

21 Feb 2025 21:06

Replied by tommylight on topic Can't eek out that last bit of jitter

Can't eek out that last bit of jitter

Category: General LinuxCNC Questions

- tommylight

21 Feb 2025 21:02

- Muftijaja

- Muftijaja

21 Feb 2025 21:02 - 21 Feb 2025 21:02

Replied by Muftijaja on topic motor-0-position error beim Abbremsen aus 4-7,5 m/min

motor-0-position error beim Abbremsen aus 4-7,5 m/min

Category: Deutsch

- PCW

21 Feb 2025 20:26

Replied by PCW on topic 7I97T joint following error

7I97T joint following error

Category: General LinuxCNC Questions

- Tinker

- Tinker

21 Feb 2025 20:24

Replied by Tinker on topic 7I97T joint following error

7I97T joint following error

Category: General LinuxCNC Questions

- PCW

21 Feb 2025 20:23 - 21 Feb 2025 20:25

Replied by PCW on topic motor-0-position error beim Abbremsen aus 4-7,5 m/min

motor-0-position error beim Abbremsen aus 4-7,5 m/min

Category: Deutsch

- Tinker

- Tinker

21 Feb 2025 20:23

Replied by Tinker on topic 7I97T joint following error

7I97T joint following error

Category: General LinuxCNC Questions

- Tinker

- Tinker

21 Feb 2025 20:18

Replied by Tinker on topic 7I97T joint following error

7I97T joint following error

Category: General LinuxCNC Questions

- PCW

21 Feb 2025 20:00

Replied by PCW on topic 7I97T joint following error

7I97T joint following error

Category: General LinuxCNC Questions

- Tinker

- Tinker

21 Feb 2025 19:44

Replied by Tinker on topic 7I97T joint following error

7I97T joint following error

Category: General LinuxCNC Questions

- Muftijaja

- Muftijaja

21 Feb 2025 19:27 - 21 Feb 2025 19:35

Replied by Muftijaja on topic motor-0-position error beim Abbremsen aus 4-7,5 m/min

motor-0-position error beim Abbremsen aus 4-7,5 m/min

Category: Deutsch

- Tinker

- Tinker

21 Feb 2025 19:25

Replied by Tinker on topic 7I97T joint following error

7I97T joint following error

Category: General LinuxCNC Questions

- webbyguy

- webbyguy

21 Feb 2025 18:45

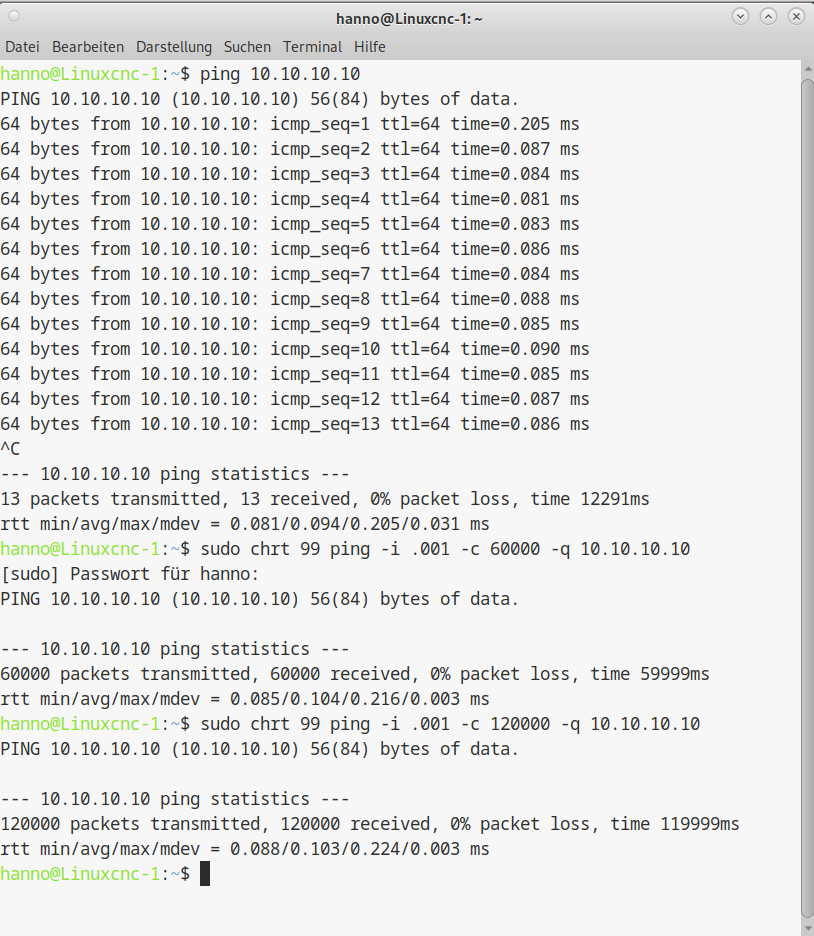

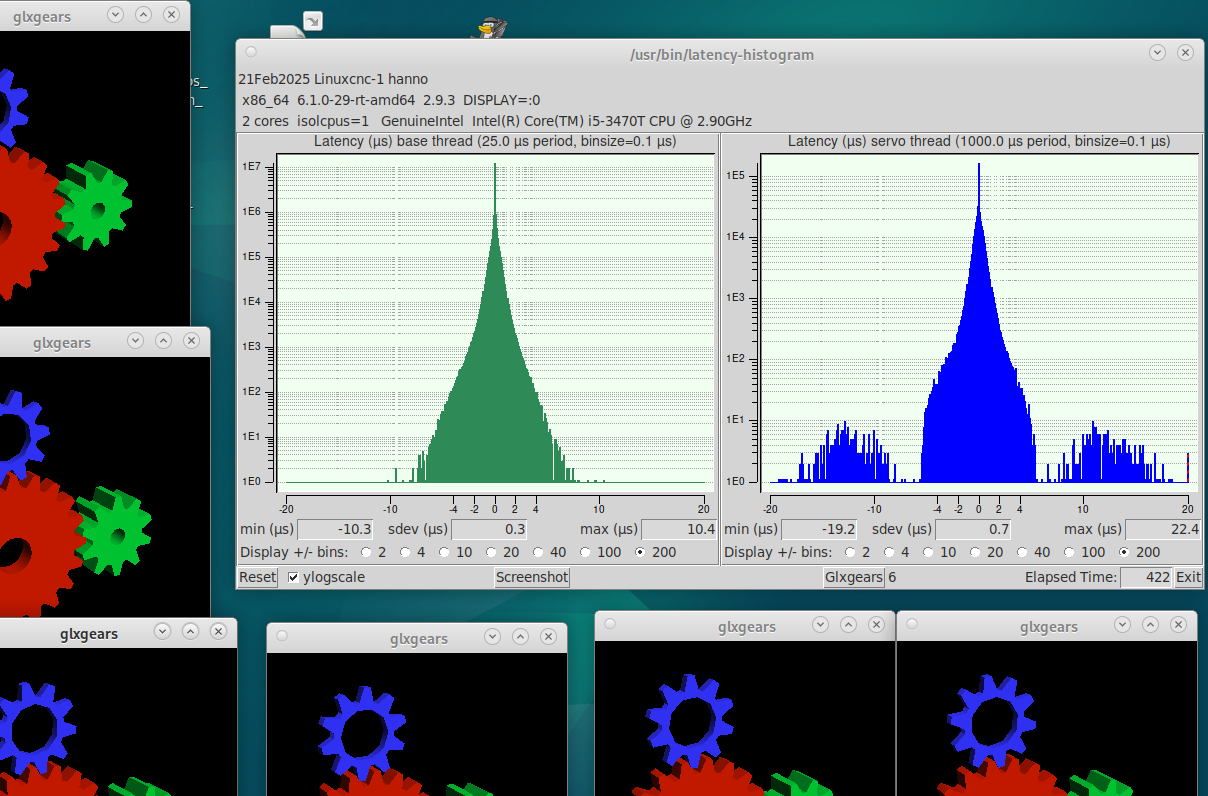

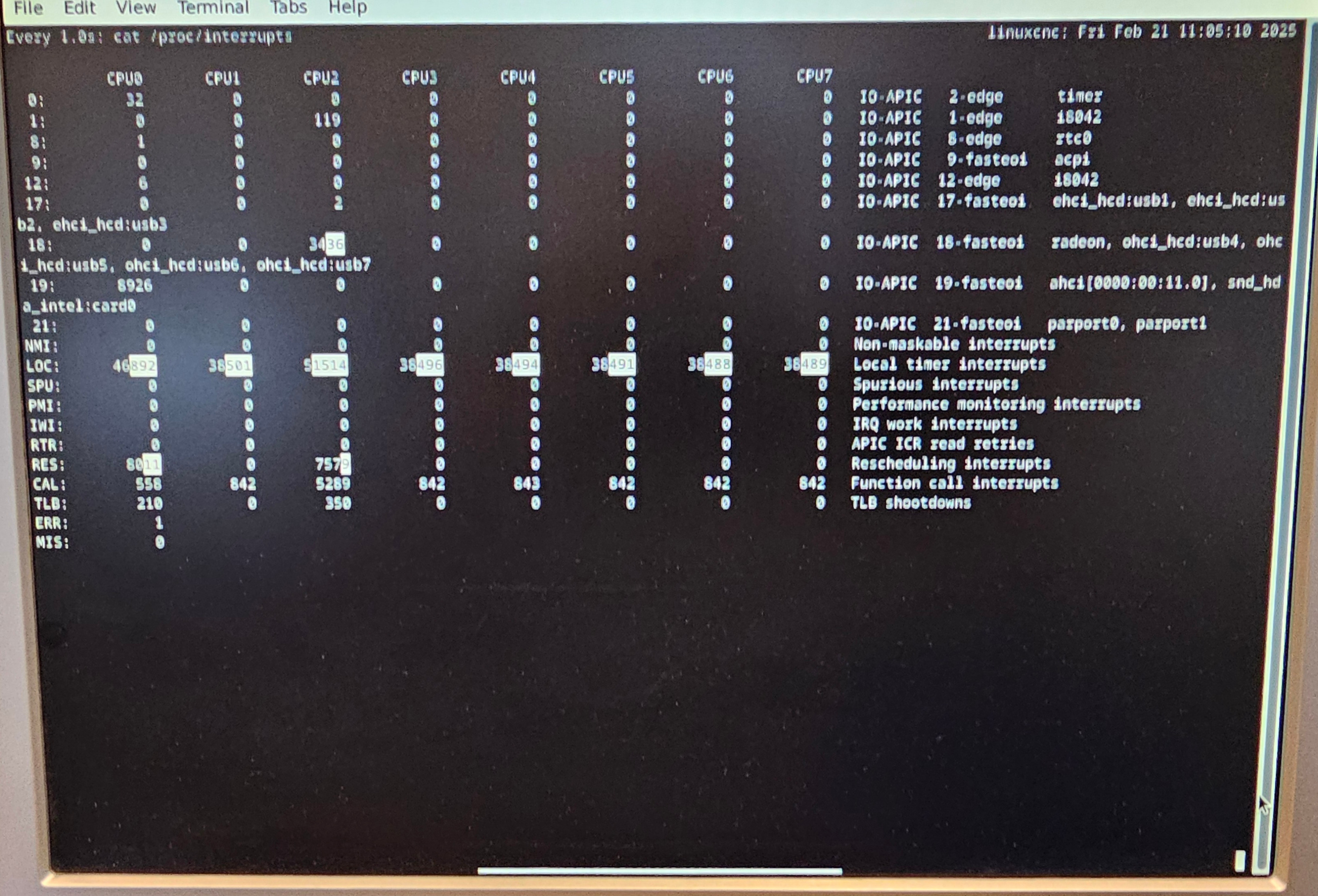

Replied by webbyguy on topic Can't eek out that last bit of jitter

Can't eek out that last bit of jitter

Category: General LinuxCNC Questions

- Sziggy_NC

- Sziggy_NC

21 Feb 2025 17:34

Replied by Sziggy_NC on topic Proof reading please. "unknown control command in o word"

Proof reading please. "unknown control command in o word"

Category: O Codes (subroutines) and NGCGUI

- denhen89

21 Feb 2025 17:06

Time to create page: 0.662 seconds