Search Results (Searched for: )

- csurimilan

- csurimilan

16 Dec 2024 12:51

- ABurkD

- ABurkD

16 Dec 2024 12:26

Replied by ABurkD on topic Stefconf: Wizard stellt immer auf Simulator, wie änder ich das?

Stefconf: Wizard stellt immer auf Simulator, wie änder ich das?

Category: Deutsch

- tommylight

16 Dec 2024 12:18

Replied by tommylight on topic Stefconf: Wizard stellt immer auf Simulator, wie änder ich das?

Stefconf: Wizard stellt immer auf Simulator, wie änder ich das?

Category: Deutsch

- JT

16 Dec 2024 12:09

- meister

- meister

16 Dec 2024 12:07

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- ABurkD

- ABurkD

16 Dec 2024 11:53

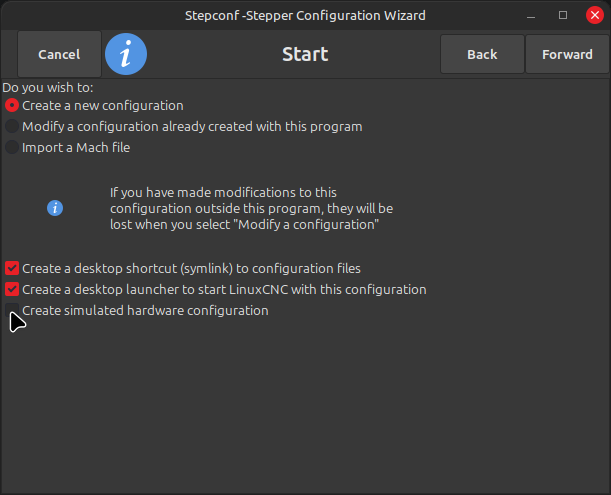

Stefconf: Wizard stellt immer auf Simulator, wie änder ich das? was created by ABurkD

Stefconf: Wizard stellt immer auf Simulator, wie änder ich das?

Category: Deutsch

- epineh

- epineh

16 Dec 2024 11:47

Replied by epineh on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- agima2

- agima2

16 Dec 2024 11:30 - 16 Dec 2024 11:45

Linux CNC auf Virtualbox Simulation was created by agima2

Linux CNC auf Virtualbox Simulation

Category: Deutsch

- meister

- meister

16 Dec 2024 11:06 - 16 Dec 2024 11:10

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- epineh

- epineh

16 Dec 2024 10:38 - 16 Dec 2024 10:39

Replied by epineh on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- meister

- meister

16 Dec 2024 09:58

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- kjlty

- kjlty

16 Dec 2024 09:54

- MirkoCNC

- MirkoCNC

16 Dec 2024 09:50

Replied by MirkoCNC on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- electrosteam

- electrosteam

16 Dec 2024 09:49

- Hakan

- Hakan

Time to create page: 0.439 seconds