Search Results (Searched for: )

- AndyDM01

- AndyDM01

30 Jul 2024 16:44

Replied by AndyDM01 on topic Ethercat build from source - full instructions

Ethercat build from source - full instructions

Category: EtherCAT

- my1987toyota

30 Jul 2024 16:36 - 30 Jul 2024 17:07

Replied by my1987toyota on topic Was the SPAM topic a test

Was the SPAM topic a test

Category: Off Topic and Test Posts

- my1987toyota

30 Jul 2024 16:14 - 30 Jul 2024 16:17

Replied by my1987toyota on topic Was the SPAM topic a test

Was the SPAM topic a test

Category: Off Topic and Test Posts

- my1987toyota

30 Jul 2024 15:50

Replied by my1987toyota on topic Interesting Youtube Video

Interesting Youtube Video

Category: Off Topic and Test Posts

- my1987toyota

30 Jul 2024 15:37

Replied by my1987toyota on topic Who wants to use MODBUS ? Video.

Who wants to use MODBUS ? Video.

Category: Off Topic and Test Posts

- my1987toyota

30 Jul 2024 15:33 - 30 Jul 2024 16:01

Replied by my1987toyota on topic Was the SPAM topic a test

Was the SPAM topic a test

Category: Off Topic and Test Posts

- cakeslob

- cakeslob

30 Jul 2024 15:25

Replied by cakeslob on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Remora - ethernet NVEM / EC300 / EC500 cnc board

Category: Computers and Hardware

- AirRacer

- AirRacer

30 Jul 2024 15:09

Replied by AirRacer on topic Mesa CT Huge Improvements Coming

Mesa CT Huge Improvements Coming

Category: Driver Boards

- Krulli_Fräser

- Krulli_Fräser

30 Jul 2024 14:48

Replied by Krulli_Fräser on topic Verify my Mesa selection

Verify my Mesa selection

Category: Driver Boards

- PCW

30 Jul 2024 14:47

- manfrel

- manfrel

30 Jul 2024 14:22

Replied by manfrel on topic Mesa 7i96s + DM556T -> Motors not moving

Mesa 7i96s + DM556T -> Motors not moving

Category: Driver Boards

- ffffrf

- ffffrf

30 Jul 2024 13:56 - 30 Jul 2024 13:57

Replied by ffffrf on topic help with millrun and/or custom Z-X-A(or C) lathe/machine

help with millrun and/or custom Z-X-A(or C) lathe/machine

Category: Fusion 360

- ffffrf

- ffffrf

30 Jul 2024 13:32

help with millrun and/or custom Z-X-A(or C) lathe/machine was created by ffffrf

help with millrun and/or custom Z-X-A(or C) lathe/machine

Category: Fusion 360

- Grotius

30 Jul 2024 13:12 - 30 Jul 2024 14:20

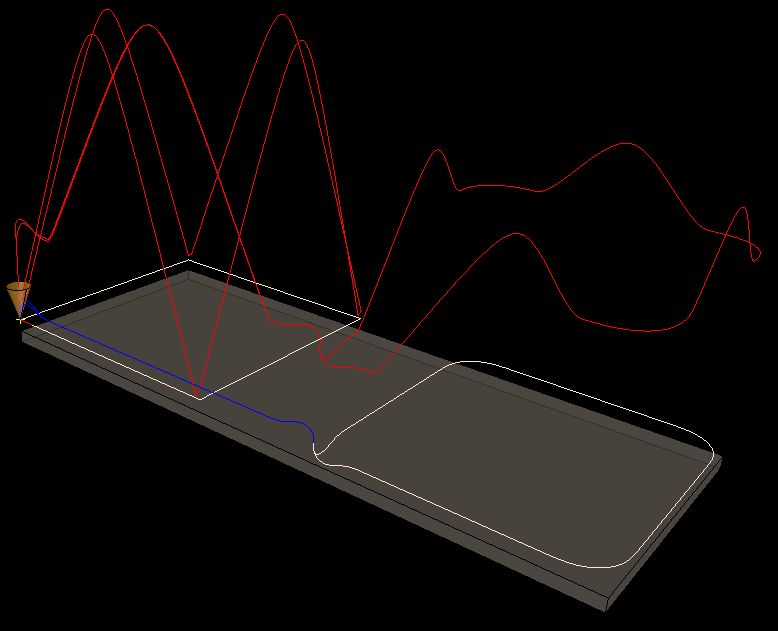

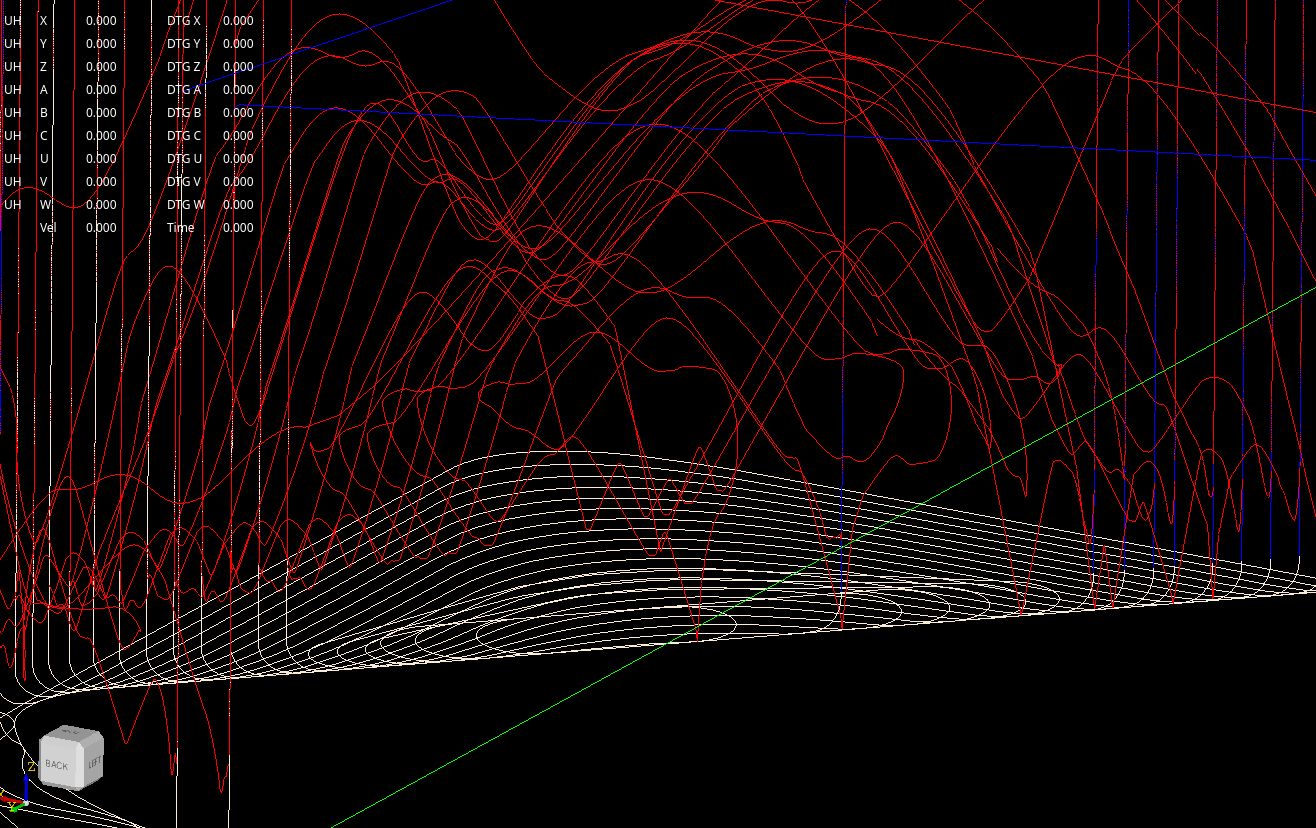

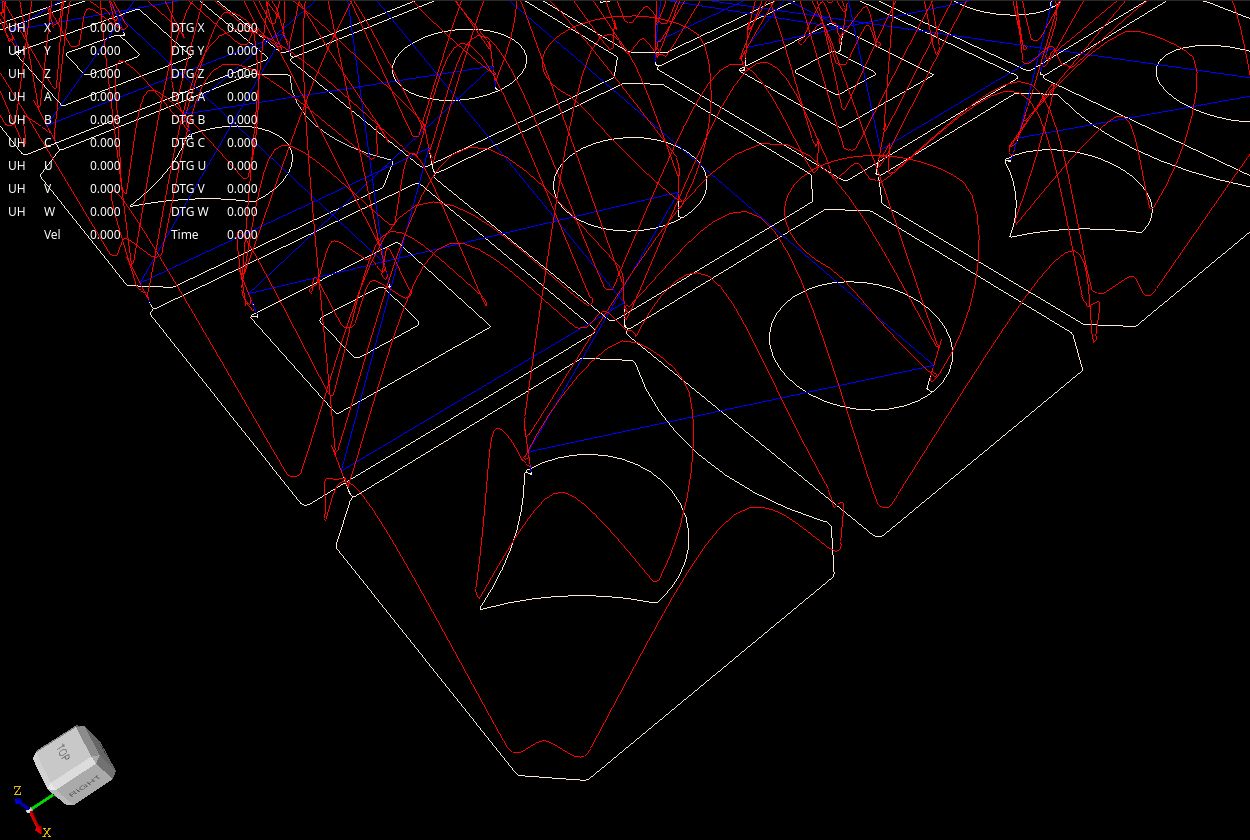

Replied by Grotius on topic Trajectory Planner using Ruckig Lib

Trajectory Planner using Ruckig Lib

Category: General LinuxCNC Questions

- spumco

- spumco

30 Jul 2024 13:05

Replied by spumco on topic Which Mesa Card Should I Buy?

Which Mesa Card Should I Buy?

Category: Driver Boards

Time to create page: 0.701 seconds