Search Results (Searched for: )

- PCW

11 Oct 2024 16:01

Replied by PCW on topic 7i95T spindle control via Modbus RS485 and SPINX1A

7i95T spindle control via Modbus RS485 and SPINX1A

Category: Driver Boards

- Leintz2

- Leintz2

11 Oct 2024 15:59

Replied by Leintz2 on topic Slider (scale) to change stepper acceleration

Slider (scale) to change stepper acceleration

Category: pyVCP

- vmihalca

- vmihalca

11 Oct 2024 15:52

Replied by vmihalca on topic 7i95T spindle control via Modbus RS485 and SPINX1A

7i95T spindle control via Modbus RS485 and SPINX1A

Category: Driver Boards

- Todd Zuercher

11 Oct 2024 15:49

Replied by Todd Zuercher on topic Adding a DRO and want to integrate with linuxcnc, recommended hardware?

Adding a DRO and want to integrate with linuxcnc, recommended hardware?

Category: CNC Machines

- abarry

- abarry

11 Oct 2024 15:04

Replied by abarry on topic Adding a DRO and want to integrate with linuxcnc, recommended hardware?

Adding a DRO and want to integrate with linuxcnc, recommended hardware?

Category: CNC Machines

- mBender

- mBender

11 Oct 2024 14:33

Replied by mBender on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- PCW

11 Oct 2024 14:08

Replied by PCW on topic 7i95T spindle control via Modbus RS485 and SPINX1A

7i95T spindle control via Modbus RS485 and SPINX1A

Category: Driver Boards

- royka

- royka

11 Oct 2024 13:57 - 11 Oct 2024 14:22

Replied by royka on topic Can the OPI5 be Configured to Run LCNC?

Can the OPI5 be Configured to Run LCNC?

Category: Computers and Hardware

- snowgoer540

11 Oct 2024 13:37 - 11 Oct 2024 13:42

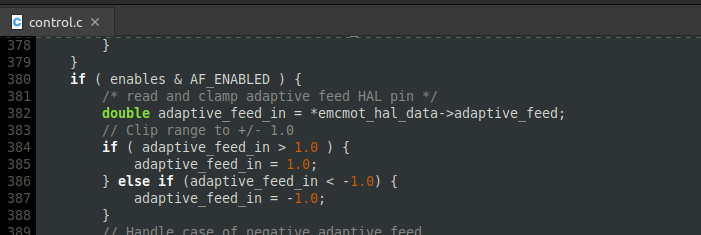

Replied by snowgoer540 on topic motion.adaptive-feed range problem

motion.adaptive-feed range problem

Category: Advanced Configuration

- Aciera

11 Oct 2024 13:19 - 11 Oct 2024 14:20

Replied by Aciera on topic motion.adaptive-feed range problem

motion.adaptive-feed range problem

Category: Advanced Configuration

- vmihalca

- vmihalca

11 Oct 2024 12:52 - 11 Oct 2024 12:55

Replied by vmihalca on topic 7i95T spindle control via Modbus RS485 and SPINX1A

7i95T spindle control via Modbus RS485 and SPINX1A

Category: Driver Boards

- JT

11 Oct 2024 12:21

Replied by JT on topic siemens 1200 safety for sale

siemens 1200 safety for sale

Category: User Exchange

- BaxEDM

11 Oct 2024 11:08

Replied by BaxEDM on topic motion.adaptive-feed range problem

motion.adaptive-feed range problem

Category: Advanced Configuration

- tommylight

11 Oct 2024 11:03

Replied by tommylight on topic motion.adaptive-feed range problem

motion.adaptive-feed range problem

Category: Advanced Configuration

- BaxEDM

11 Oct 2024 10:59 - 11 Oct 2024 11:07

Replied by BaxEDM on topic motion.adaptive-feed range problem

motion.adaptive-feed range problem

Category: Advanced Configuration

Time to create page: 0.435 seconds