Search Results (Searched for: )

- greg23_78

- greg23_78

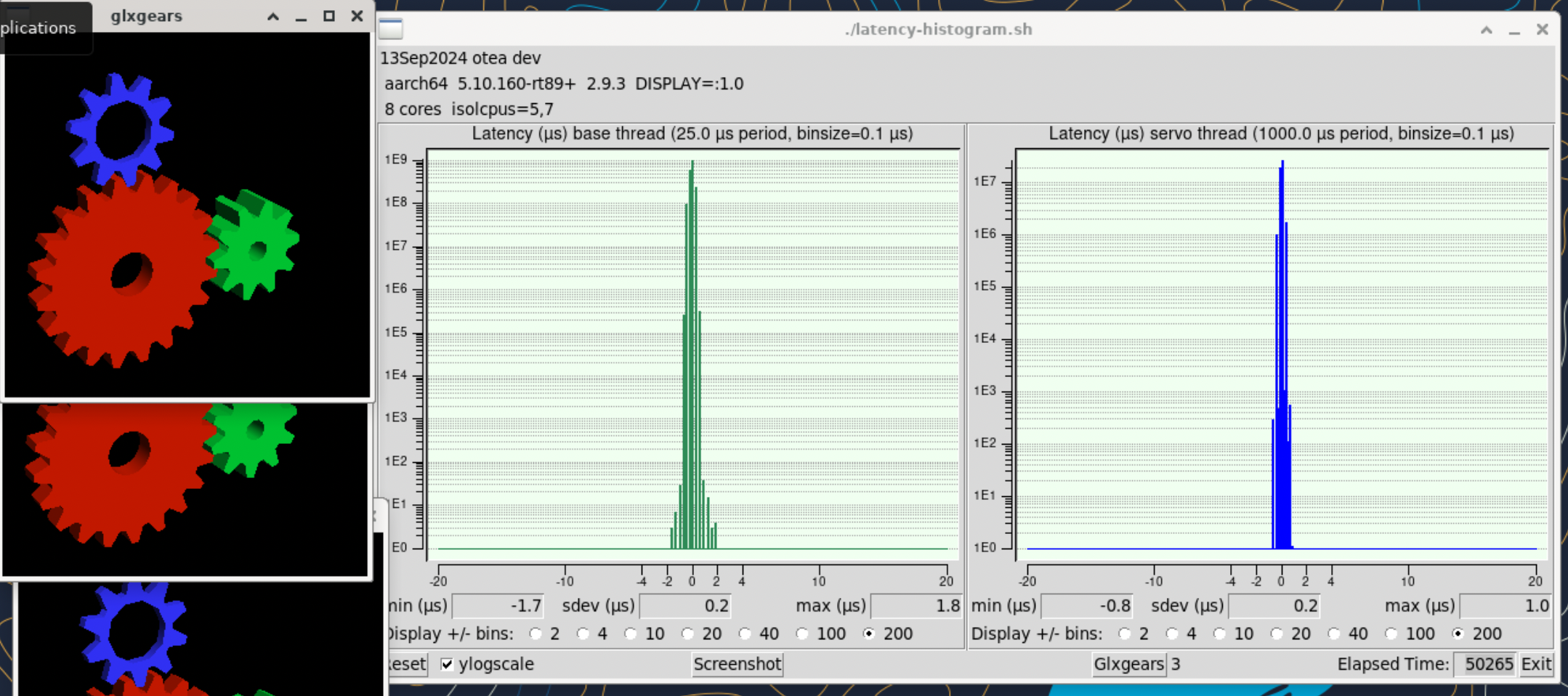

13 Sep 2024 18:52

- briansm

- briansm

13 Sep 2024 17:52

Replied by briansm on topic Can the OPI5 be Configured to Run LCNC?

Can the OPI5 be Configured to Run LCNC?

Category: Computers and Hardware

- programador

13 Sep 2024 17:44

Replied by programador on topic Encoder feedback 7i77 sensor magnetic BALLUFF

Encoder feedback 7i77 sensor magnetic BALLUFF

Category: HAL

- ekbiker

- ekbiker

13 Sep 2024 16:39 - 14 Sep 2024 01:18

Replied by ekbiker on topic Clearpath SDSK steps per inch

Clearpath SDSK steps per inch

Category: PnCConf Wizard

- spacemanspiffee

13 Sep 2024 15:10 - 13 Sep 2024 15:49

Replied by spacemanspiffee on topic User Prompt Custom M Code

User Prompt Custom M Code

Category: G&M Codes

- royka

- royka

13 Sep 2024 15:03

Replied by royka on topic Can the OPI5 be Configured to Run LCNC?

Can the OPI5 be Configured to Run LCNC?

Category: Computers and Hardware

- bertoldo

- bertoldo

13 Sep 2024 15:02

Replied by bertoldo on topic Problems with Lichuan Ethercat servo drive

Problems with Lichuan Ethercat servo drive

Category: EtherCAT

- Krulli_Fräser

- Krulli_Fräser

13 Sep 2024 14:57

- ekbiker

- ekbiker

13 Sep 2024 14:36

- bertoldo

- bertoldo

13 Sep 2024 14:33

Replied by bertoldo on topic Problems with Lichuan Ethercat servo drive

Problems with Lichuan Ethercat servo drive

Category: EtherCAT

- rockcnc

- rockcnc

13 Sep 2024 14:28

- F41TH

- F41TH

13 Sep 2024 14:25

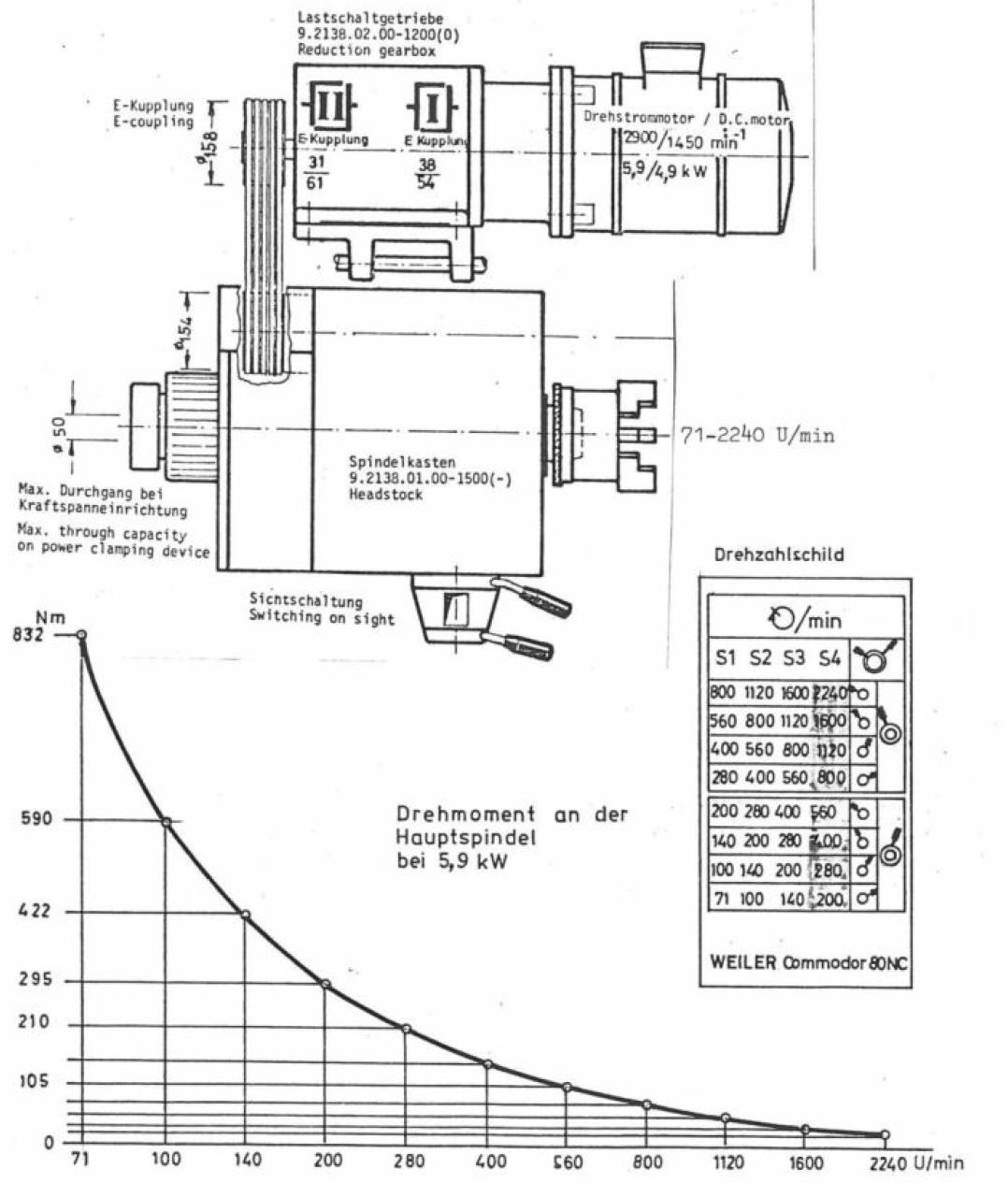

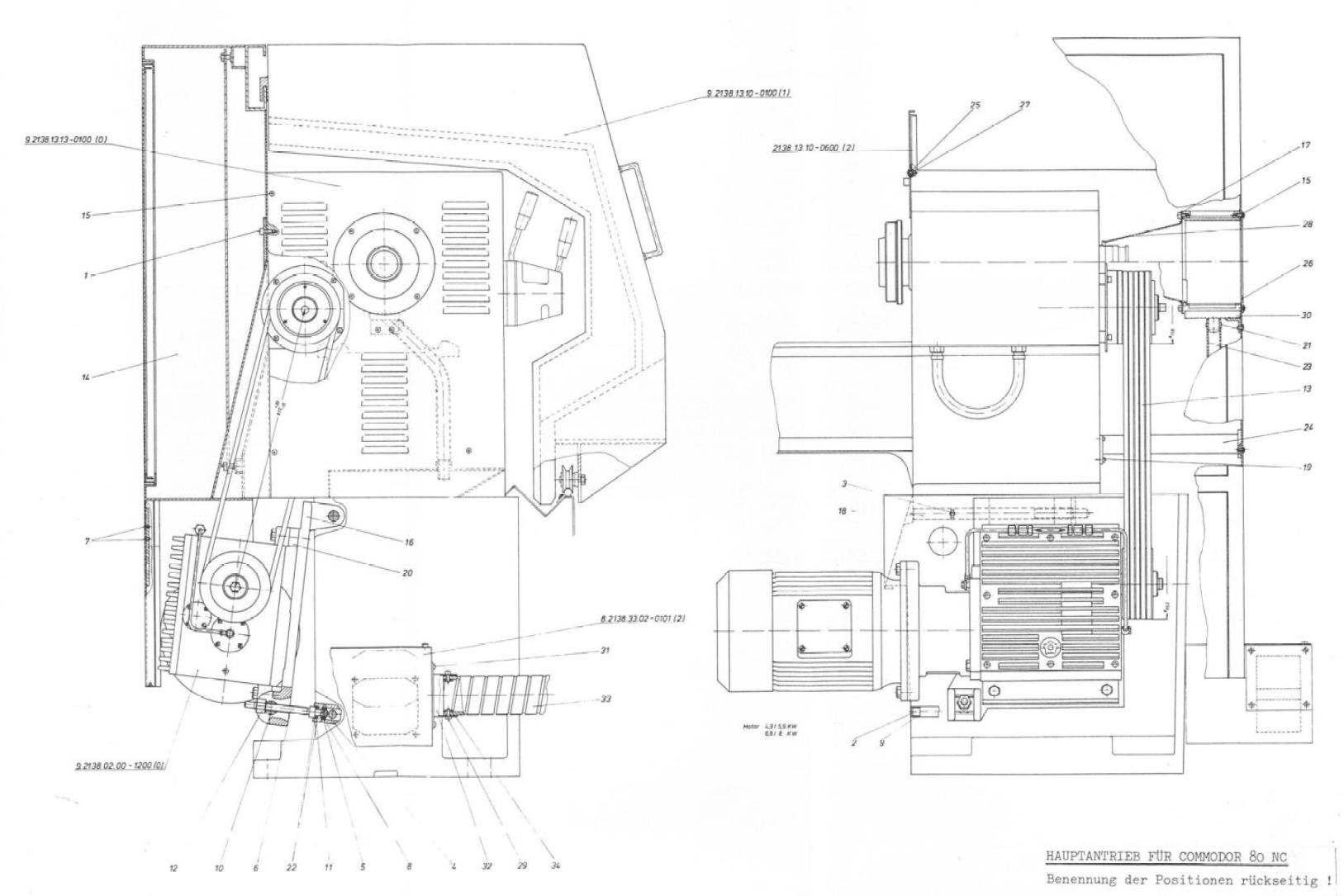

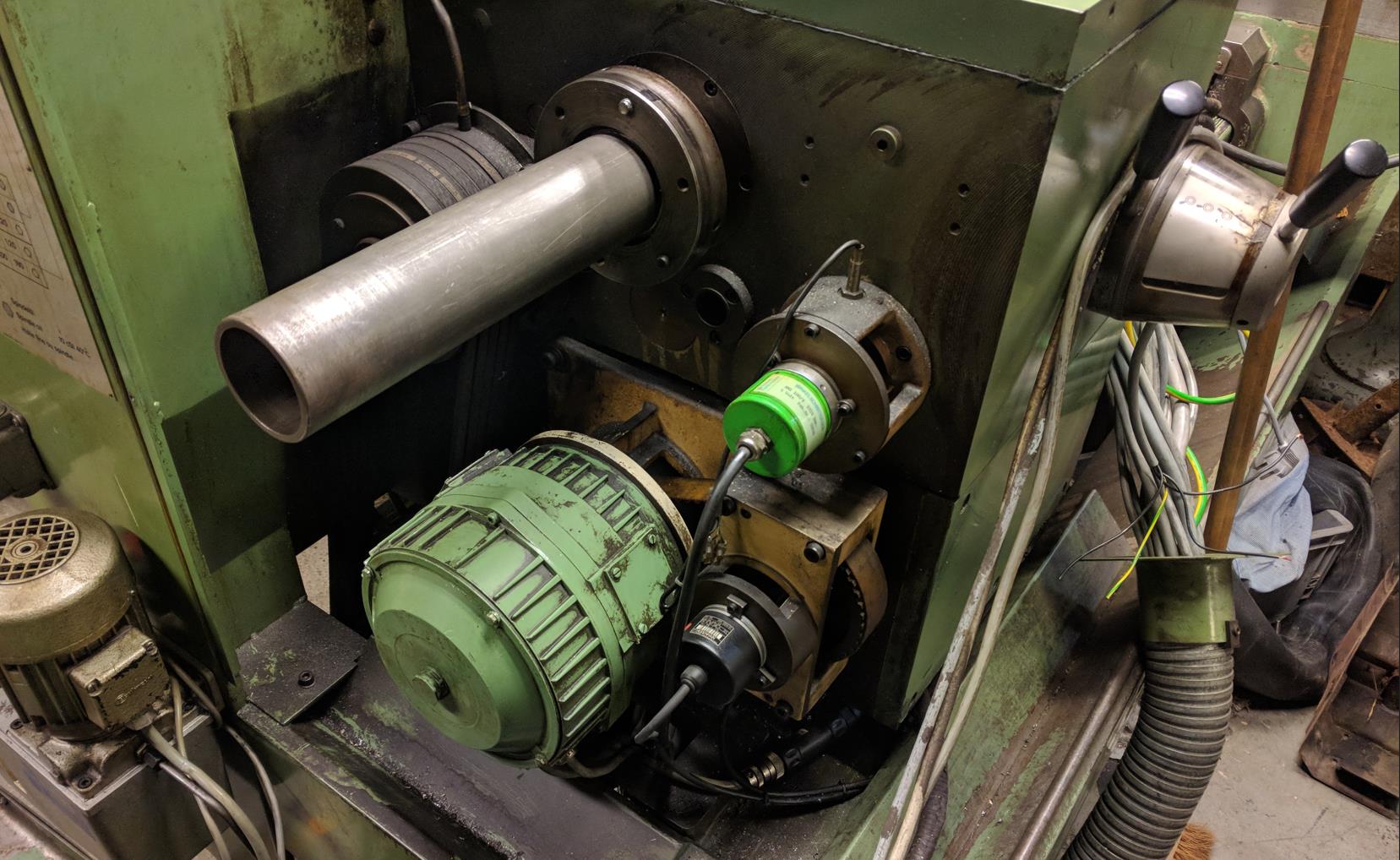

Weiler Commodor 80NC gearbox implementation / control was created by F41TH

Weiler Commodor 80NC gearbox implementation / control

Category: Turning

- rockcnc

- rockcnc

13 Sep 2024 14:23

- rockcnc

- rockcnc

13 Sep 2024 14:21

- PCW

13 Sep 2024 14:07

Time to create page: 0.637 seconds