Search Results (Searched for: )

- jblanscett

- jblanscett

05 Mar 2026 16:32

Replied by jblanscett on topic Trying to set up position control mode

Trying to set up position control mode

Category: HAL

- HM

- HM

05 Mar 2026 16:17

Replied by HM on topic RPI5_7i80HDT_7i52s+7i49+7i44+BISS

RPI5_7i80HDT_7i52s+7i49+7i44+BISS

Category: Driver Boards

- mrgksworld

- mrgksworld

05 Mar 2026 15:48

- PCW

05 Mar 2026 15:48 - 05 Mar 2026 15:48

Replied by PCW on topic Trying to set up position control mode

Trying to set up position control mode

Category: HAL

- Hakan

- Hakan

05 Mar 2026 14:01

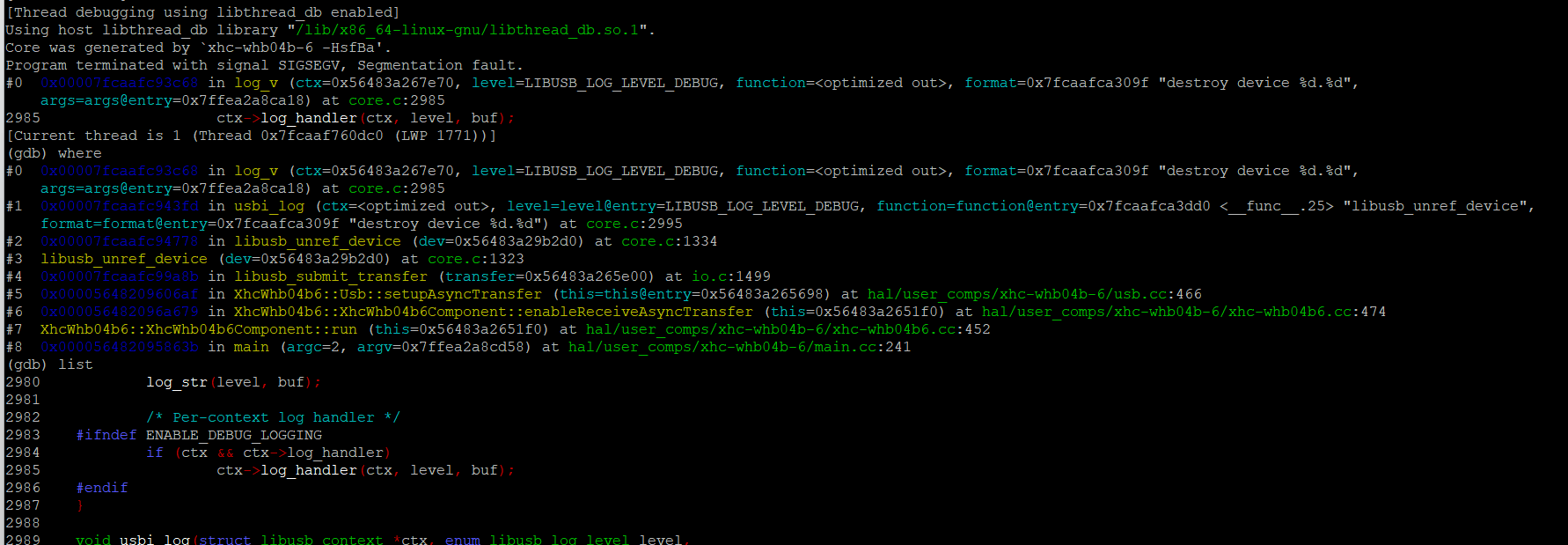

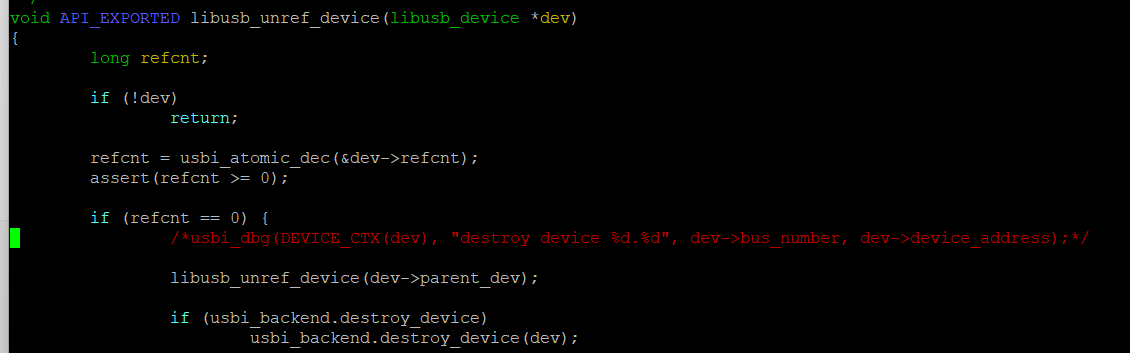

Replied by Hakan on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Lcvette

05 Mar 2026 13:39

- T_D

- T_D

05 Mar 2026 13:36

- RotarySMP

05 Mar 2026 13:00

Replied by RotarySMP on topic chineese mesa 7i92 custom bit file

chineese mesa 7i92 custom bit file

Category: Driver Boards

- meister

- meister

05 Mar 2026 12:27 - 05 Mar 2026 12:29

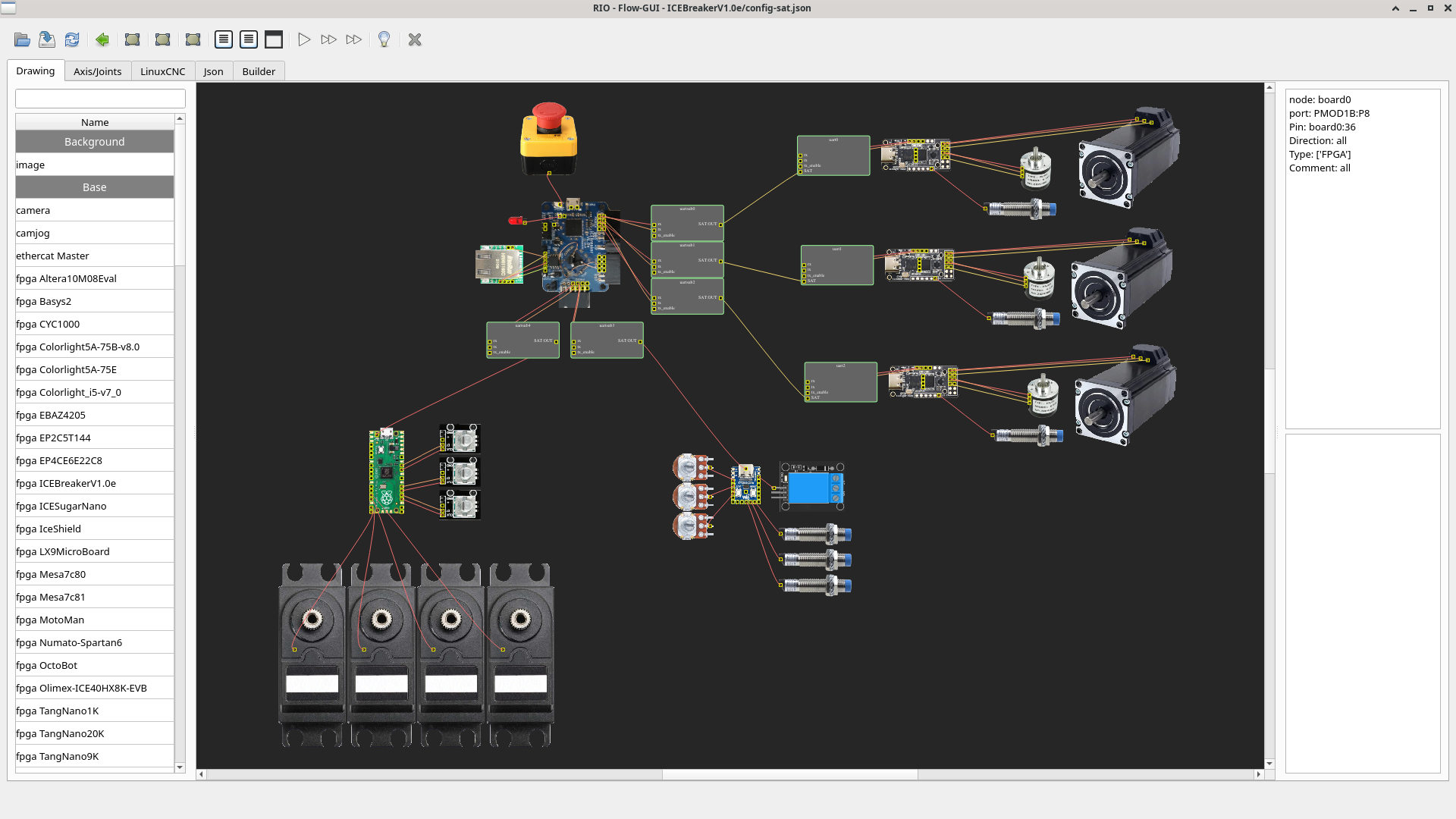

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- ClarkSavage

- ClarkSavage

05 Mar 2026 12:17

Replied by ClarkSavage on topic 7i92T and mx3660 request for help

7i92T and mx3660 request for help

Category: PnCConf Wizard

- meister

- meister

05 Mar 2026 12:09

Replied by meister on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- epineh

- epineh

05 Mar 2026 11:49

Replied by epineh on topic LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

LinuxCNC-RIO - RealtimeIO for LinuxCNC based on FPGA (ICE40 / ECP5)

Category: Computers and Hardware

- jblanscett

- jblanscett

05 Mar 2026 11:12

Replied by jblanscett on topic Trying to set up position control mode

Trying to set up position control mode

Category: HAL

- DerKlotz

- DerKlotz

05 Mar 2026 09:52 - 05 Mar 2026 09:58

Verdrahtung Leadshine DM856 Ena+ und - bei Mesa 7i76e was created by DerKlotz

Verdrahtung Leadshine DM856 Ena+ und - bei Mesa 7i76e

Category: Deutsch

- DerKlotz

- DerKlotz

05 Mar 2026 09:13

Replied by DerKlotz on topic Add Buttons in Probe Basic

Add Buttons in Probe Basic

Category: QtPyVCP

Time to create page: 0.474 seconds