Search Results (Searched for: )

- PCW

06 Jan 2025 21:31

Replied by PCW on topic Resolution and speed with servo motor

Resolution and speed with servo motor

Category: General LinuxCNC Questions

- ihavenofish

- ihavenofish

06 Jan 2025 21:13

Replied by ihavenofish on topic Resolution and speed with servo motor

Resolution and speed with servo motor

Category: General LinuxCNC Questions

- Martin.L

- Martin.L

06 Jan 2025 21:12

Exercise: Turn on output led on EL2809 when machine is turned on was created by Martin.L

Exercise: Turn on output led on EL2809 when machine is turned on

Category: EtherCAT

- Aciera

06 Jan 2025 20:53

Replied by Aciera on topic 2.9.3 INI_VARS issue

2.9.3 INI_VARS issue

Category: General LinuxCNC Questions

- Masiwood123

06 Jan 2025 20:35

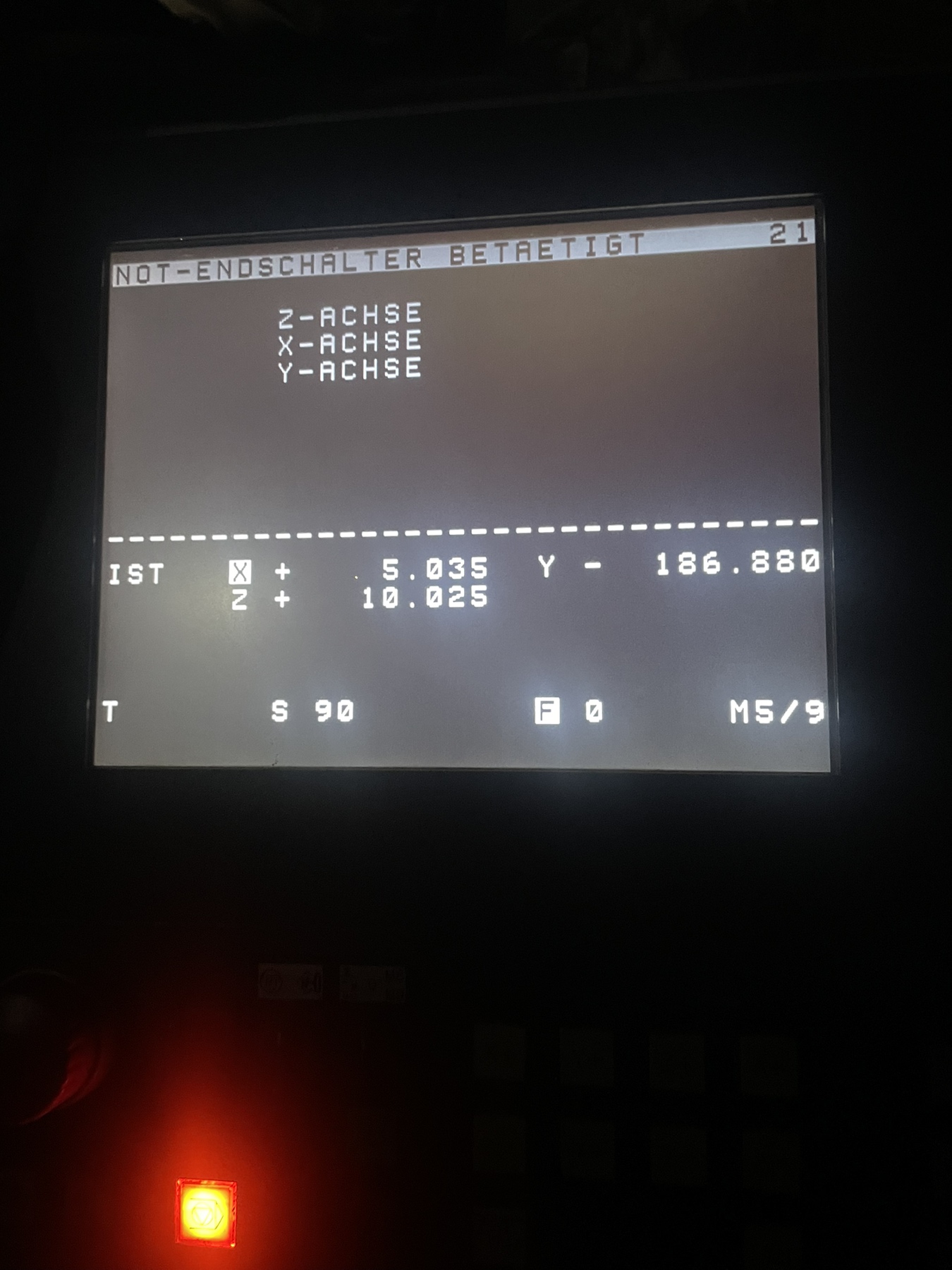

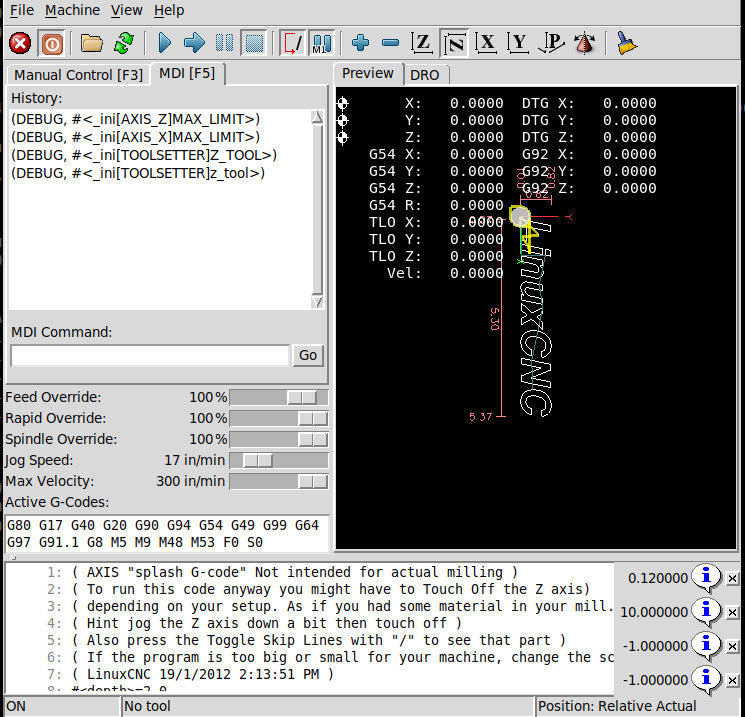

Replied by Masiwood123 on topic Fehlmann Picomax 100 Retrofit

Fehlmann Picomax 100 Retrofit

Category: Milling Machines

- blazini36

- blazini36

06 Jan 2025 20:30

- Aciera

06 Jan 2025 20:24

Replied by Aciera on topic 2.9.3 INI_VARS issue

2.9.3 INI_VARS issue

Category: General LinuxCNC Questions

- shipmodeller

06 Jan 2025 20:01

Replied by shipmodeller on topic 2.9.3 INI_VARS issue

2.9.3 INI_VARS issue

Category: General LinuxCNC Questions

- shipmodeller

06 Jan 2025 20:00

Replied by shipmodeller on topic 2.9.3 INI_VARS issue

2.9.3 INI_VARS issue

Category: General LinuxCNC Questions

- Aciera

06 Jan 2025 19:55 - 06 Jan 2025 20:57

Replied by Aciera on topic 2.9.3 INI_VARS issue

2.9.3 INI_VARS issue

Category: General LinuxCNC Questions

- shipmodeller

06 Jan 2025 19:48

Replied by shipmodeller on topic 2.9.3 INI_VARS issue

2.9.3 INI_VARS issue

Category: General LinuxCNC Questions

- Aciera

06 Jan 2025 19:32

Replied by Aciera on topic 2.9.3 INI_VARS issue

2.9.3 INI_VARS issue

Category: General LinuxCNC Questions

- shipmodeller

06 Jan 2025 19:28

Replied by shipmodeller on topic 2.9.3 INI_VARS issue

2.9.3 INI_VARS issue

Category: General LinuxCNC Questions

- Aciera

06 Jan 2025 19:20 - 06 Jan 2025 19:28

Replied by Aciera on topic 2.9.3 INI_VARS issue

2.9.3 INI_VARS issue

Category: General LinuxCNC Questions

- slowpoke

- slowpoke

06 Jan 2025 19:06 - 06 Jan 2025 19:17

Jog from external pushbutton only works after a move say G0 X1 was created by slowpoke

Jog from external pushbutton only works after a move say G0 X1

Category: HAL

Time to create page: 0.393 seconds