Search Results (Searched for: )

- ihavenofish

- ihavenofish

25 Dec 2024 11:58

Replied by ihavenofish on topic PathPilot V2 source code

PathPilot V2 source code

Category: PathPilot

- abdulasis12

- abdulasis12

25 Dec 2024 11:51 - 25 Dec 2024 11:58

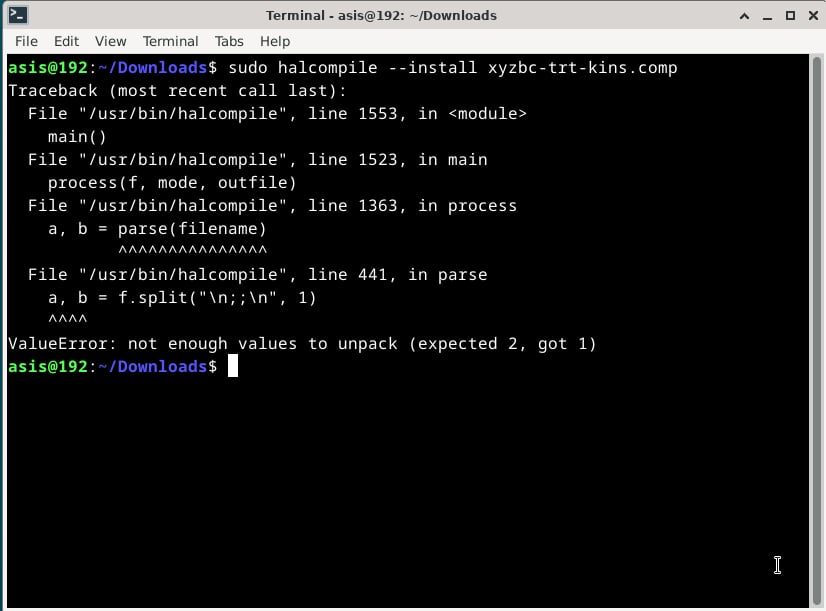

Replied by abdulasis12 on topic Skew correction/perpendicularity correction (millkins or millkins_xyz)

Skew correction/perpendicularity correction (millkins or millkins_xyz)

Category: Basic Configuration

- Hakan

- Hakan

25 Dec 2024 11:41 - 25 Dec 2024 12:29

- papagno-source

- papagno-source

25 Dec 2024 11:29

- aikiaviator

- aikiaviator

25 Dec 2024 11:29

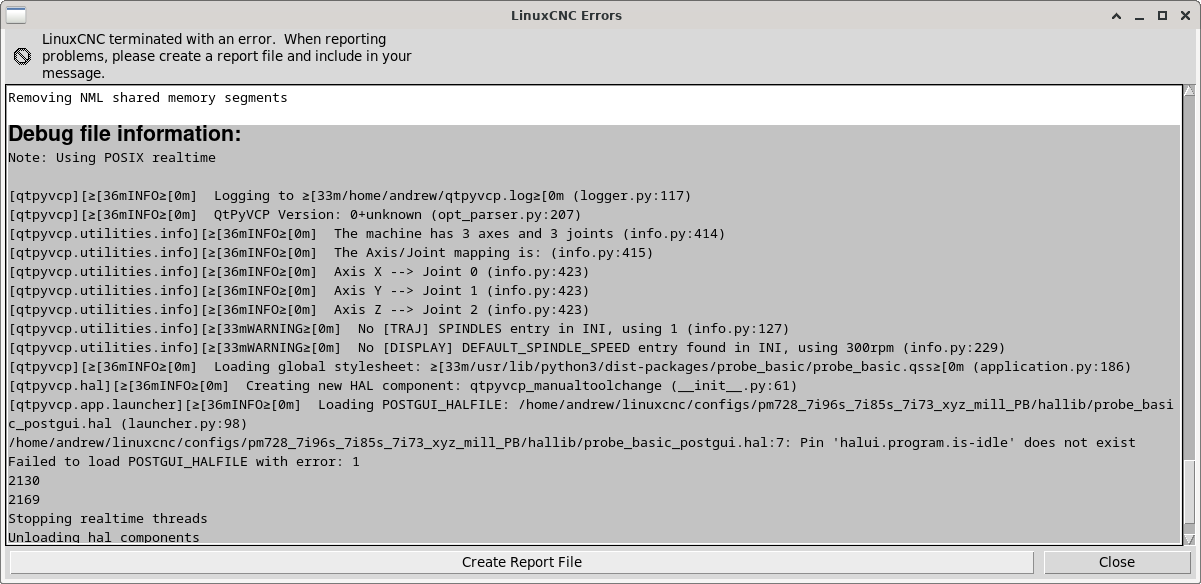

Replied by aikiaviator on topic To Probe Basic from Gmoccapy

To Probe Basic from Gmoccapy

Category: QtPyVCP

- Hakan

- Hakan

25 Dec 2024 11:16

- papagno-source

- papagno-source

25 Dec 2024 11:07

- Sandro

- Sandro

25 Dec 2024 10:17

Replied by Sandro on topic Probe Basic M6G43 (m6_tool_call_tool_page) not working

Probe Basic M6G43 (m6_tool_call_tool_page) not working

Category: QtPyVCP

- Hakan

- Hakan

25 Dec 2024 09:58

- papagno-source

- papagno-source

25 Dec 2024 09:50

- csurimilan

- csurimilan

25 Dec 2024 09:48

- papagno-source

- papagno-source

25 Dec 2024 09:41

- bharath12

- bharath12

25 Dec 2024 09:32

Retrofit Engraving machine was created by bharath12

Retrofit Engraving machine

Category: Milling Machines

- bkt

25 Dec 2024 09:29 - 25 Dec 2024 09:33

good day to all (in some gtp languages) was created by bkt

good day to all (in some gtp languages)

Category: Off Topic and Test Posts

- stefan63

25 Dec 2024 09:02

Time to create page: 0.396 seconds