Search Results (Searched for: )

- swepeter

- swepeter

08 Sep 2024 14:23

Replied by swepeter on topic Mesa 7i96 Output Wiring

Mesa 7i96 Output Wiring

Category: Driver Boards

- Aciera

08 Sep 2024 14:19

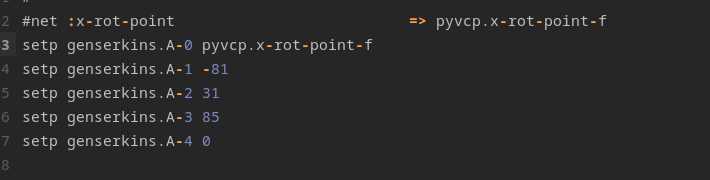

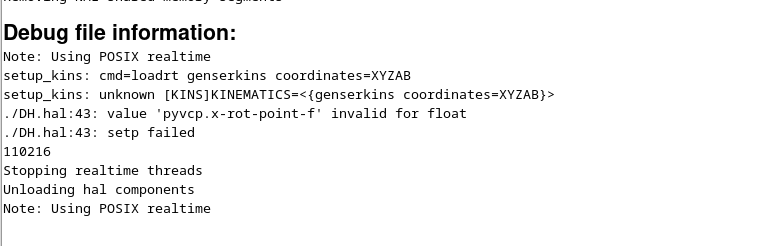

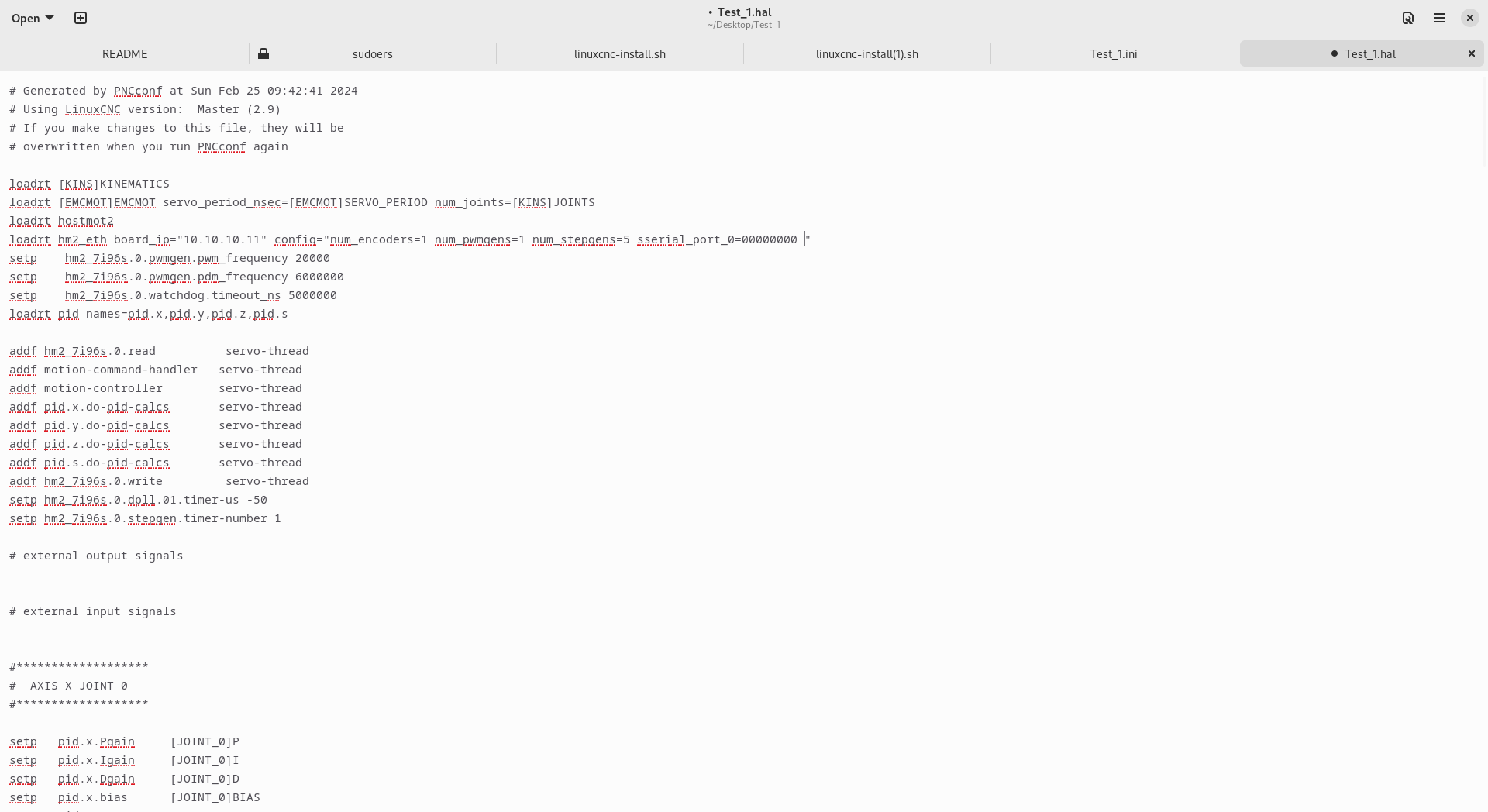

Replied by Aciera on topic Using a HAL pin in DH parameters

Using a HAL pin in DH parameters

Category: HAL

- Abdulkareem

- Abdulkareem

08 Sep 2024 14:06

Using a HAL pin in DH parameters was created by Abdulkareem

Using a HAL pin in DH parameters

Category: HAL

- Saggy_headliner

08 Sep 2024 14:04

Troubleshooting Analog AC Servo - Full Speed at "Analog Scale Max = 0" was created by Saggy_headliner

Troubleshooting Analog AC Servo - Full Speed at "Analog Scale Max = 0"

Category: Basic Configuration

- machinedude

08 Sep 2024 14:00

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

- BICHLER

- BICHLER

08 Sep 2024 13:36 - 08 Sep 2024 13:38

- tommylight

08 Sep 2024 13:05

Replied by tommylight on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

- snowgoer540

08 Sep 2024 12:36

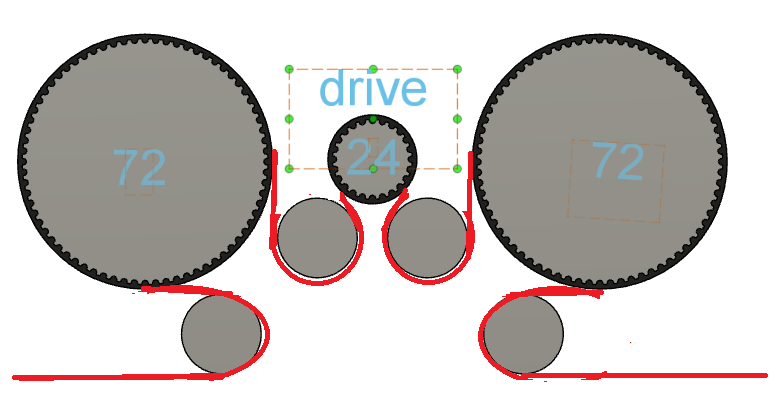

Replied by snowgoer540 on topic Building a chain driven Plasma table.

Building a chain driven Plasma table.

Category: General LinuxCNC Questions

- machinedude

08 Sep 2024 12:02

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

- tommylight

08 Sep 2024 11:40

Replied by tommylight on topic Ethercat build from source - full instructions

Ethercat build from source - full instructions

Category: EtherCAT

- tommylight

08 Sep 2024 11:36

Replied by tommylight on topic Building a chain driven Plasma table.

Building a chain driven Plasma table.

Category: General LinuxCNC Questions

- Stormbird

- Stormbird

08 Sep 2024 11:29

Replied by Stormbird on topic Threading with A B phase only?

Threading with A B phase only?

Category: General LinuxCNC Questions

- tommylight

08 Sep 2024 11:28

Replied by tommylight on topic USB ports quit working?

USB ports quit working?

Category: Installing LinuxCNC

- routerman22

- routerman22

08 Sep 2024 11:17 - 08 Sep 2024 11:50

Replied by routerman22 on topic Fanuc 2S AC spindle motor on Delta C2000+

Fanuc 2S AC spindle motor on Delta C2000+

Category: Milling Machines

- machinedude

08 Sep 2024 11:10

Replied by machinedude on topic What do you really get for a $350 desk top engraver ?

What do you really get for a $350 desk top engraver ?

Category: Show Your Stuff

Time to create page: 0.665 seconds