Search Results (Searched for: )

- abcdefg

14 Jan 2026 06:58

Can my account and post history be deleted please was created by abcdefg

Can my account and post history be deleted please

Category: Forum Questions

- RotarySMP

14 Jan 2026 06:33 - 14 Jan 2026 06:34

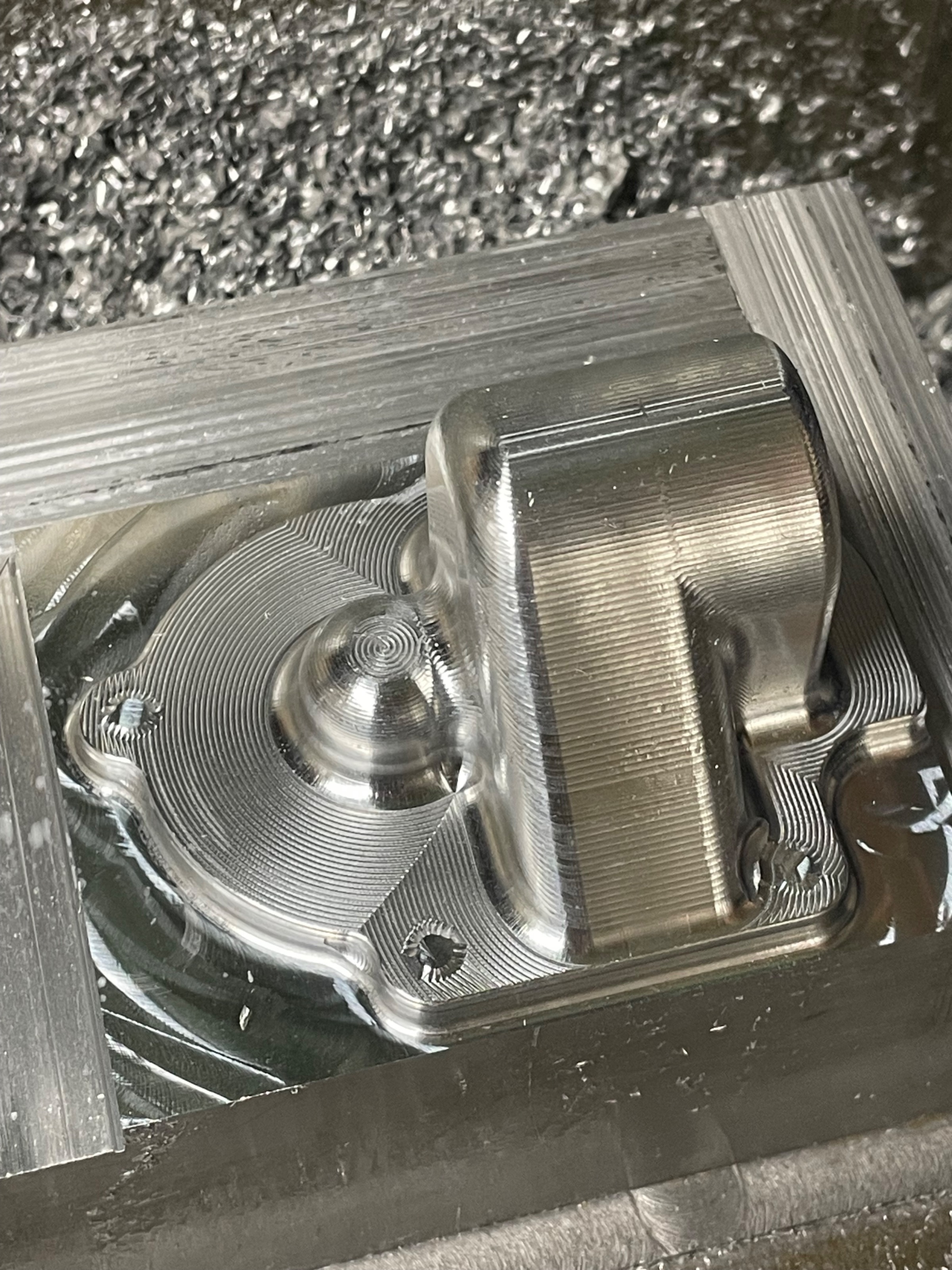

Replied by RotarySMP on topic Retrofitting Deckel FP4ATC

Retrofitting Deckel FP4ATC

Category: Milling Machines

- Mark Kraus

- Mark Kraus

14 Jan 2026 05:29

- ajc771

- ajc771

14 Jan 2026 05:01

Problems with Linuxcnc 2.9.4 and GladeVCP was created by ajc771

Problems with Linuxcnc 2.9.4 and GladeVCP

Category: GladeVCP

- djdelorie

- djdelorie

14 Jan 2026 00:36

Replied by djdelorie on topic Tool Lengths Offsets and Touch off

Tool Lengths Offsets and Touch off

Category: AXIS

- NT4Boy

- NT4Boy

13 Jan 2026 23:01 - 13 Jan 2026 23:03

Replied by NT4Boy on topic Tool Lengths Offsets and Touch off

Tool Lengths Offsets and Touch off

Category: AXIS

- dschultz

- dschultz

13 Jan 2026 22:23

- rodw

13 Jan 2026 21:12

- MaHa

- MaHa

13 Jan 2026 19:55

Replied by MaHa on topic Tool Lengths Offsets and Touch off

Tool Lengths Offsets and Touch off

Category: AXIS

- PCW

13 Jan 2026 19:37 - 13 Jan 2026 19:38

Replied by PCW on topic older 5i25 with 7i76 not working with Linuxcnc 2.9.8

older 5i25 with 7i76 not working with Linuxcnc 2.9.8

Category: Driver Boards

- Lockomat

- Lockomat

13 Jan 2026 19:26

Replied by Lockomat on topic older 5i25 with 7i76 not working with Linuxcnc 2.9.8

older 5i25 with 7i76 not working with Linuxcnc 2.9.8

Category: Driver Boards

- PCW

13 Jan 2026 16:00 - 13 Jan 2026 16:37

Replied by PCW on topic older 5i25 with 7i76 not working with Linuxcnc 2.9.8

older 5i25 with 7i76 not working with Linuxcnc 2.9.8

Category: Driver Boards

- tommylight

13 Jan 2026 15:55

Replied by tommylight on topic older 5i25 with 7i76 not working with Linuxcnc 2.9.8

older 5i25 with 7i76 not working with Linuxcnc 2.9.8

Category: Driver Boards

- tommylight

13 Jan 2026 15:55

- Lockomat

- Lockomat

13 Jan 2026 15:23

older 5i25 with 7i76 not working with Linuxcnc 2.9.8 was created by Lockomat

older 5i25 with 7i76 not working with Linuxcnc 2.9.8

Category: Driver Boards

Time to create page: 0.259 seconds