Search Results (Searched for: )

- liutas4x4

- liutas4x4

14 Dec 2025 14:02

Replied by liutas4x4 on topic Adding second spindle control to pyVCP: is it complicated?

Adding second spindle control to pyVCP: is it complicated?

Category: pyVCP

- Sandro

- Sandro

14 Dec 2025 11:36 - 14 Dec 2025 11:38

Replied by Sandro on topic Axis deflecting while jogging in G54

Axis deflecting while jogging in G54

Category: QtPyVCP

- Hakan

- Hakan

14 Dec 2025 10:54

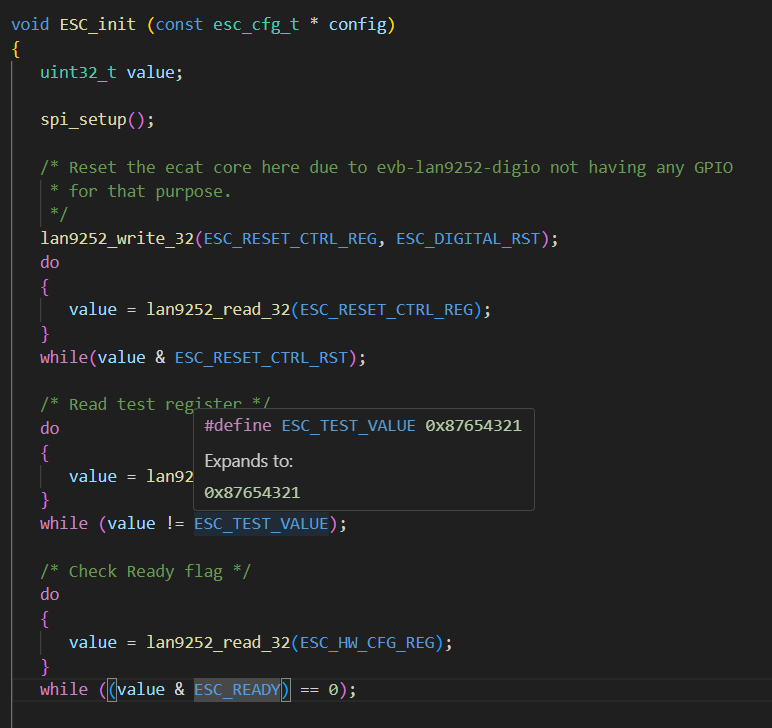

Replied by Hakan on topic Ethercat compatible Encoder board tentative STM32F4 + LAN9252

Ethercat compatible Encoder board tentative STM32F4 + LAN9252

Category: EtherCAT

- BoMadsen

- BoMadsen

14 Dec 2025 09:25

Replied by BoMadsen on topic Issues with simple input on 7i76eu

Issues with simple input on 7i76eu

Category: Driver Boards

- vibram

- vibram

14 Dec 2025 09:16

Replied by vibram on topic Ethercat compatible Encoder board tentative STM32F4 + LAN9252

Ethercat compatible Encoder board tentative STM32F4 + LAN9252

Category: EtherCAT

- rodw

14 Dec 2025 08:23 - 14 Dec 2025 08:39

Replied by rodw on topic Long initialization of Ethercat on servo drive SV660N

Long initialization of Ethercat on servo drive SV660N

Category: EtherCAT

- rodw

14 Dec 2025 08:05

Replied by rodw on topic Long initialization of Ethercat on servo drive SV660N

Long initialization of Ethercat on servo drive SV660N

Category: EtherCAT

- Hakan

- Hakan

14 Dec 2025 07:46

Replied by Hakan on topic Long initialization of Ethercat on servo drive SV660N

Long initialization of Ethercat on servo drive SV660N

Category: EtherCAT

- rodw

14 Dec 2025 07:33

Replied by rodw on topic Issues with simple input on 7i76eu

Issues with simple input on 7i76eu

Category: Driver Boards

- BoMadsen

- BoMadsen

14 Dec 2025 06:49

Issues with simple input on 7i76eu was created by BoMadsen

Issues with simple input on 7i76eu

Category: Driver Boards

- Hakan

- Hakan

14 Dec 2025 03:18

Replied by Hakan on topic Can't get EL4001 to work - all other devices work

Can't get EL4001 to work - all other devices work

Category: EtherCAT

- MaHa

- MaHa

14 Dec 2025 02:15

Replied by MaHa on topic Axis deflecting while jogging in G54

Axis deflecting while jogging in G54

Category: QtPyVCP

- spumco

- spumco

14 Dec 2025 01:54

Replied by spumco on topic Clearpath HLFB amp.joint.delay

Clearpath HLFB amp.joint.delay

Category: HAL

- NWE

14 Dec 2025 01:24

- dfarnainekl

- dfarnainekl

13 Dec 2025 23:48

Can't get EL4001 to work - all other devices work was created by dfarnainekl

Can't get EL4001 to work - all other devices work

Category: EtherCAT

Time to create page: 0.282 seconds