Search Results (Searched for: )

- AlessandroEmm

- AlessandroEmm

17 Feb 2026 19:20 - 17 Feb 2026 19:48

Replied by AlessandroEmm on topic Remora - Rpi Software Stepping Using External Microcontroller via SPI

Remora - Rpi Software Stepping Using External Microcontroller via SPI

Category: Computers and Hardware

- 2tinker

- 2tinker

17 Feb 2026 19:18

- tuxcnc

- tuxcnc

17 Feb 2026 18:56

Replied by tuxcnc on topic EtherCAT driver as simply positioner

EtherCAT driver as simply positioner

Category: EtherCAT

- PCW

17 Feb 2026 18:55

Replied by PCW on topic HURCO KMB-1 Control Update

HURCO KMB-1 Control Update

Category: Milling Machines

- PCW

17 Feb 2026 18:50

Replied by PCW on topic Configure Mesa 7i96s and pktuart with Omron MX2 (wj200)

Configure Mesa 7i96s and pktuart with Omron MX2 (wj200)

Category: Advanced Configuration

- amanker

- amanker

17 Feb 2026 18:49

Replied by amanker on topic Remora - Rpi Software Stepping Using External Microcontroller via SPI

Remora - Rpi Software Stepping Using External Microcontroller via SPI

Category: Computers and Hardware

- Finngineering

- Finngineering

17 Feb 2026 18:45

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- DerKlotz

- DerKlotz

17 Feb 2026 18:35

Replied by DerKlotz on topic Add Buttons in Probe Basic

Add Buttons in Probe Basic

Category: QtPyVCP

- AlessandroEmm

- AlessandroEmm

17 Feb 2026 18:30

Replied by AlessandroEmm on topic Remora - Rpi Software Stepping Using External Microcontroller via SPI

Remora - Rpi Software Stepping Using External Microcontroller via SPI

Category: Computers and Hardware

- Hakan

- Hakan

17 Feb 2026 18:26

Replied by Hakan on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- Stephan@work

- Stephan@work

17 Feb 2026 18:16

Replied by Stephan@work on topic Configure Mesa 7i96s and pktuart with Omron MX2 (wj200)

Configure Mesa 7i96s and pktuart with Omron MX2 (wj200)

Category: Advanced Configuration

- andrax

17 Feb 2026 17:55

- Finngineering

- Finngineering

17 Feb 2026 16:13

Replied by Finngineering on topic XHC WHB04B development?

XHC WHB04B development?

Category: General LinuxCNC Questions

- NWE

17 Feb 2026 16:08

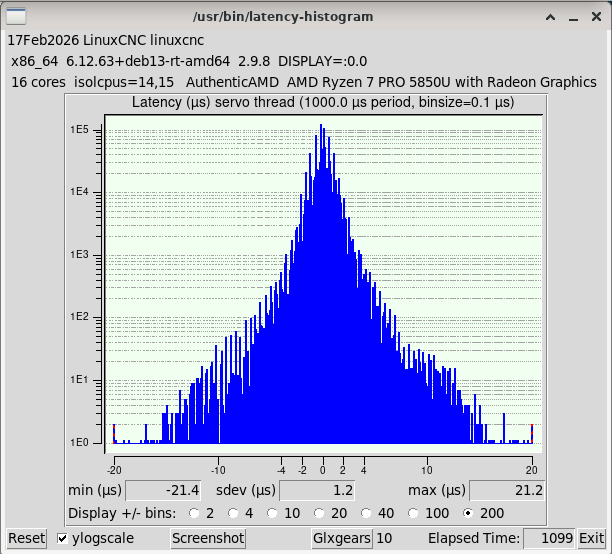

Replied by NWE on topic Lenovo T14 Gen2 AMD - CRAZY High Latency - Am I screwed?

Lenovo T14 Gen2 AMD - CRAZY High Latency - Am I screwed?

Category: Computers and Hardware

- Looby

- Looby

17 Feb 2026 15:01

Replied by Looby on topic Lenovo T14 Gen2 AMD - CRAZY High Latency - Am I screwed?

Lenovo T14 Gen2 AMD - CRAZY High Latency - Am I screwed?

Category: Computers and Hardware

Time to create page: 0.452 seconds