Search Results (Searched for: 7i77 spindle)

Yesterday 00:57

Replied by Peakcounter on topic Mill Project, Looking for driver Board advice

Mill Project, Looking for driver Board advice

Category: Driver Boards

01 May 2024 18:36

Replied by NT4Boy on topic Mesa 7i95t and 7i83 Analogue servo card

Mesa 7i95t and 7i83 Analogue servo card

Category: Basic Configuration

19 Apr 2024 07:38

Replied by RotarySMP on topic Advise on new lathe project

Advise on new lathe project

Category: Turning

03 Apr 2024 14:09

01 Apr 2024 14:24 - 01 Apr 2024 14:26

01 Apr 2024 12:00

01 Apr 2024 11:24

01 Apr 2024 01:03

31 Mar 2024 22:59

27 Feb 2024 17:03

Replied by NT4Boy on topic Hurco KMB-1 Retrofit options

Hurco KMB-1 Retrofit options

Category: Milling Machines

24 Feb 2024 14:32 - 24 Feb 2024 14:34

23 Feb 2024 19:16

22 Feb 2024 15:30

Replied by B.Reilly01 on topic Hurco KMB-1 Retrofit options

Hurco KMB-1 Retrofit options

Category: Milling Machines

18 Feb 2024 22:32

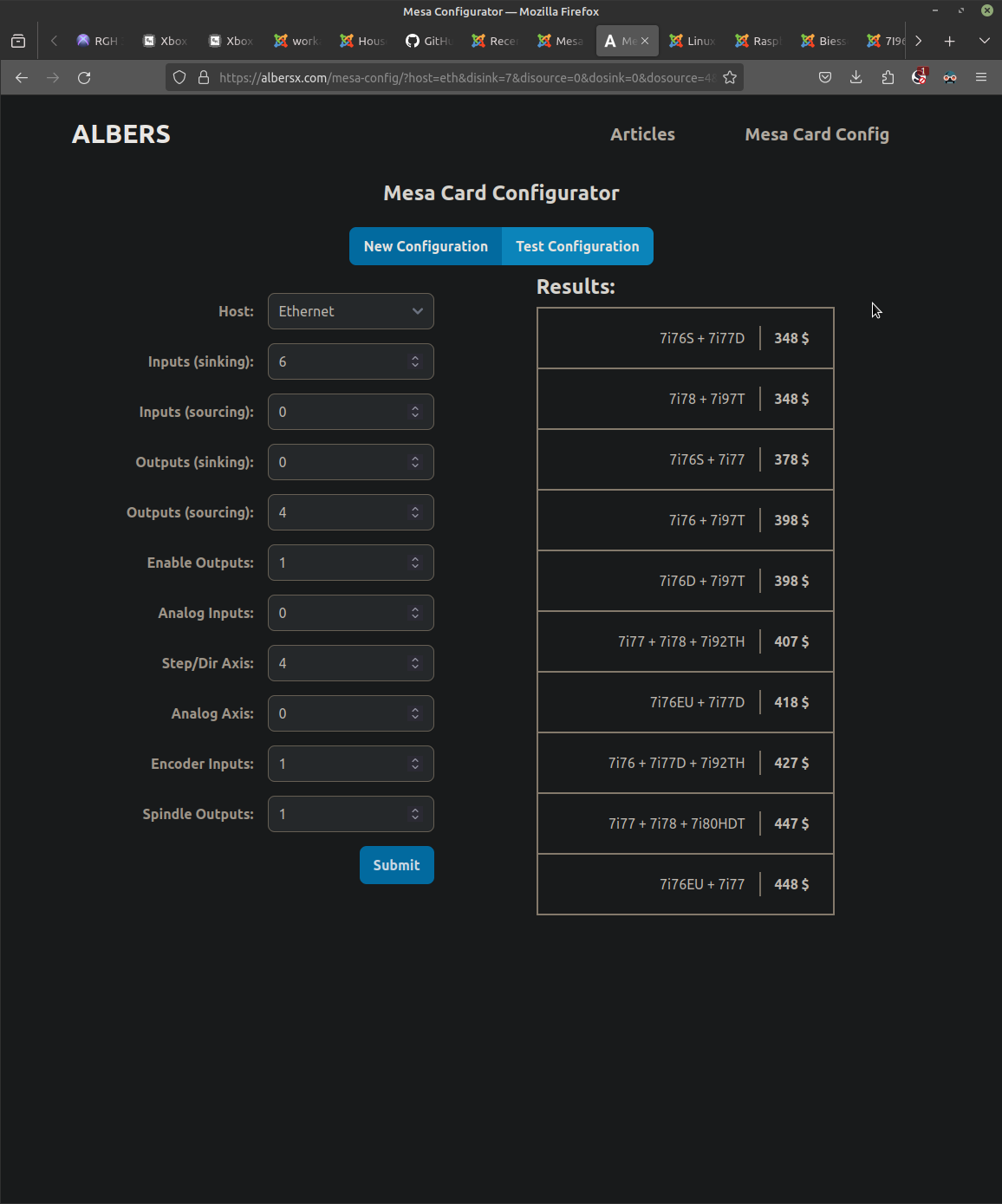

Replied by tommylight on topic Mesa Card Combination Tool

Mesa Card Combination Tool

Category: Driver Boards

18 Feb 2024 20:58

Replied by tommylight on topic Mesa Card Combination Tool

Mesa Card Combination Tool

Category: Driver Boards

Time to create page: 0.925 seconds