Hurco KMB-IS CNC update

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

30 Jul 2020 22:45 #176573

by _big_

Hurco KMB-IS CNC update was created by _big_

Purchased a Hurco KMB-IS at an auction for about $0.17 a pound. Scrap iron currently running $0.02 to $0.035 a pound, the CNC function came with a bit of a price uplift  .

.

New to CNC and LinuxCNC.

Plan is to replace the existing CNC electronics with something much more modern.

40+ years experience in computer/electronics industry, so the basic electronics/computer stuff doesn't bother me.

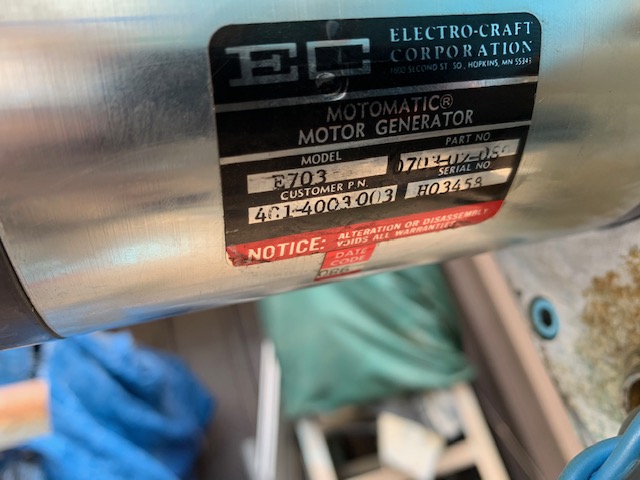

Tried to reuse the servo motors, but figured out they are these prehistoric ElectroCraft motor/generator things and I just don't think its worth trying to use them. I was unable find any specs on the servos from ElectroCraft, or Googling. The issue now is I have no idea what size motor to use. Any comments about how I can figure this out or rules of thumb?

The Teknic/ClearPath stuff appeals to my sensibilities. I sort of know what motion control is and know that's a big part of LinuxCNC. It seems like ClearPath by definition has to encapsulate motion control. Can LinuxCNC be used with a ClearPath like solution? Basically just the GUI and converting G code into step and direction??

New to CNC and LinuxCNC.

Plan is to replace the existing CNC electronics with something much more modern.

40+ years experience in computer/electronics industry, so the basic electronics/computer stuff doesn't bother me.

Tried to reuse the servo motors, but figured out they are these prehistoric ElectroCraft motor/generator things and I just don't think its worth trying to use them. I was unable find any specs on the servos from ElectroCraft, or Googling. The issue now is I have no idea what size motor to use. Any comments about how I can figure this out or rules of thumb?

The Teknic/ClearPath stuff appeals to my sensibilities. I sort of know what motion control is and know that's a big part of LinuxCNC. It seems like ClearPath by definition has to encapsulate motion control. Can LinuxCNC be used with a ClearPath like solution? Basically just the GUI and converting G code into step and direction??

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21231

- Thank you received: 7249

30 Jul 2020 23:32 #176581

by tommylight

Replied by tommylight on topic Hurco KMB-IS CNC update

LinuxCNC can be used with the SD series of clearpath, but i would not use them, might be to weak anyway you look at it.

There should be stickers on those motors so take some pictures and attach them here so we can have a look.

You should be looking at 750 to 1000W motors and drives, from the looks of the machine, so measure the frame of the motors and that would give you an idea of what size you need. Again due to the age of the machine, there might not be some standard frame so might need some adapter plates.

If you do have the cash, look at Yaskawa or Delta servo motor/drives, if not ask Bevins what he used for a retrofit, some quite nice Chinese ones at a very reasonable price.

For more info on what is involved for such a retrofit, might want to check the Maho retrofit done by RotarySMP here on the forum, very detailed .... everything.

There should be stickers on those motors so take some pictures and attach them here so we can have a look.

You should be looking at 750 to 1000W motors and drives, from the looks of the machine, so measure the frame of the motors and that would give you an idea of what size you need. Again due to the age of the machine, there might not be some standard frame so might need some adapter plates.

If you do have the cash, look at Yaskawa or Delta servo motor/drives, if not ask Bevins what he used for a retrofit, some quite nice Chinese ones at a very reasonable price.

For more info on what is involved for such a retrofit, might want to check the Maho retrofit done by RotarySMP here on the forum, very detailed .... everything.

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

31 Jul 2020 02:42 #176596

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

Thanks for the info. See attached photos.

The motor/generators are about 9x4.5 inches. Definitely not NEMA. I could not find an IEC match either. I think they are some sort of random thing some ElectroCraft engineer dreamed up one afternoon.

There is an adaptation plate between the motor and the machine. Nothing fancy. Expectation is new motors will be NEMA and require new adaption plates. Easy, if you have a CNC mill to make them with .

.

1+ horsepower seems like a bit much, but what do I know? Rather overkill than under kill.

I have the drives for these motors too. If someone out there needs some prehistoric servo motors and drives to finish their collection, PM me. I'm sure we can make a deal!

The motor/generators are about 9x4.5 inches. Definitely not NEMA. I could not find an IEC match either. I think they are some sort of random thing some ElectroCraft engineer dreamed up one afternoon.

There is an adaptation plate between the motor and the machine. Nothing fancy. Expectation is new motors will be NEMA and require new adaption plates. Easy, if you have a CNC mill to make them with

1+ horsepower seems like a bit much, but what do I know? Rather overkill than under kill.

I have the drives for these motors too. If someone out there needs some prehistoric servo motors and drives to finish their collection, PM me. I'm sure we can make a deal!

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

31 Jul 2020 02:47 #176597

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

@_big_

Hey I have a Hurco KMB1 that I retrofitted with EtherCAT. I have all of the schematics and manuals for the machine. Mine is a 1983 model if I remember correct. I have 2 of these machines, but am just about to start doing the retrofit on the 2nd machine. The 2nd machine is a little bit newer and closer to the SM-1 model look, but with the older KMB1 spindle head.

You can re-use the Electro-craft servos and Servomate amps. They may be 40 years old, but you will be surprised at how good they are, plus you usually can find parts cheap on Ebay.

I re-used everything in the machine and simply removed the OEM computer and power supply. Everything else stayed and I simply wired into the TB-3 and TB-8 connectors. If you get a picture of your controller inside, I should be able to point out everything to you. Both of my models have cabinets on each side of the machine. One cabinet houses the computer, power supply, relay board, amps, and contactors. The other side has the parajust spindle drive. Hopefully you have a upgraded model with a VFD as they are much easier to deal with compared to the parajust control board. Most parajust boards were replaced with VFD's when the board went bad. Both of my machines had been replaced luckily.

There were several "types" of KMB1's. The early 80's models are the one's I like as they are much beefier than the "Late" models. Avoid any "M" model, such as KMB1m. You have to manually adjust the spindle speed, later models added a servo to the manual control. Any models with control cabinets on both sides of the machine will usually be the older heavier models, any model with only one cabinet usually had manual speed control for the spindle and much smaller head.

Both of mine are the early heavy style head. One has CAT30 spindle with 5hp motor and the other has Kwik Switch 200 tooling with a 3hp motor.

I will try and start finding all of my notes if you want to simply replace the computer and re-use everything else. But if you are going to retrofit, do like Tom (Tommylight) suggested and use Yaskawa Sigma 5 amps or Delta ASADA as these are relatively easy to find now a days. Plus Yaskawa is one of the best on the market as they private label build for other companies, and information is plentiful.

I have 1KW Yaskawa Servos and Yaskawa EtherCAT Sigma 5's for the day that I want to replace everything, but honestly I am totally happy with the original Electro-craft Servomate setup in the first machine

I have several Yaskawa and Omron EtherCAT amps and I plan to do the 2nd machine with the Yaskawa setup as I am planning on doing some heavy roughing cuts since it is 5hp cat 30.

I am pretty busy, but will do my best to help you if you have any questions. Hope you enjoy the machine as I really like these particular models.

Robert

Hey I have a Hurco KMB1 that I retrofitted with EtherCAT. I have all of the schematics and manuals for the machine. Mine is a 1983 model if I remember correct. I have 2 of these machines, but am just about to start doing the retrofit on the 2nd machine. The 2nd machine is a little bit newer and closer to the SM-1 model look, but with the older KMB1 spindle head.

You can re-use the Electro-craft servos and Servomate amps. They may be 40 years old, but you will be surprised at how good they are, plus you usually can find parts cheap on Ebay.

I re-used everything in the machine and simply removed the OEM computer and power supply. Everything else stayed and I simply wired into the TB-3 and TB-8 connectors. If you get a picture of your controller inside, I should be able to point out everything to you. Both of my models have cabinets on each side of the machine. One cabinet houses the computer, power supply, relay board, amps, and contactors. The other side has the parajust spindle drive. Hopefully you have a upgraded model with a VFD as they are much easier to deal with compared to the parajust control board. Most parajust boards were replaced with VFD's when the board went bad. Both of my machines had been replaced luckily.

There were several "types" of KMB1's. The early 80's models are the one's I like as they are much beefier than the "Late" models. Avoid any "M" model, such as KMB1m. You have to manually adjust the spindle speed, later models added a servo to the manual control. Any models with control cabinets on both sides of the machine will usually be the older heavier models, any model with only one cabinet usually had manual speed control for the spindle and much smaller head.

Both of mine are the early heavy style head. One has CAT30 spindle with 5hp motor and the other has Kwik Switch 200 tooling with a 3hp motor.

I will try and start finding all of my notes if you want to simply replace the computer and re-use everything else. But if you are going to retrofit, do like Tom (Tommylight) suggested and use Yaskawa Sigma 5 amps or Delta ASADA as these are relatively easy to find now a days. Plus Yaskawa is one of the best on the market as they private label build for other companies, and information is plentiful.

I have 1KW Yaskawa Servos and Yaskawa EtherCAT Sigma 5's for the day that I want to replace everything, but honestly I am totally happy with the original Electro-craft Servomate setup in the first machine

I have several Yaskawa and Omron EtherCAT amps and I plan to do the 2nd machine with the Yaskawa setup as I am planning on doing some heavy roughing cuts since it is 5hp cat 30.

I am pretty busy, but will do my best to help you if you have any questions. Hope you enjoy the machine as I really like these particular models.

Robert

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

31 Jul 2020 02:54 #176598

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Yes those silver model in the top picture is what I have . Seems like a model 701 or 703, but would have to go look again. l use to have all of this memorized LOL.

Back in the 80's there were a lot of machines that had the Electro-Craft servos with Servo-Mate amps, they were very popular.

Robert

Back in the 80's there were a lot of machines that had the Electro-Craft servos with Servo-Mate amps, they were very popular.

Robert

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

31 Jul 2020 14:40 #176666

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

Hi Robert,

Sounds like I've found the right guy to help me figure this out! Thanks for your reply.

Here's some more info about the machine.

Labeled as a KMB-1m. I believe to be an early 80's model.

Cabinets on both sides. The left side is spindle power. The spindle VFD is missing. Don't think that's a big deal. New VFD should be under $500.

I believe it has a Kwik Switch 200 spindle. No tooling or wrench. This is potentially a showstopper. I don't know anything about Kwik Switch 200. Availability seems very limited. Any advice here would be appreciated.

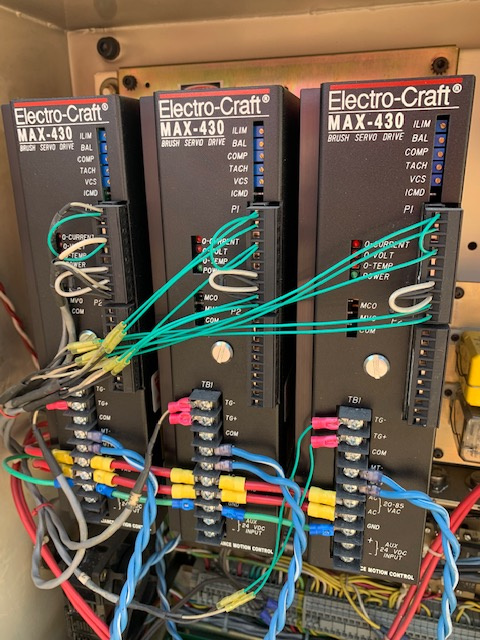

I don't have an overall picture of the right side electronics cabinet. I do have a picture of the drives. They are about the only thing that might be worth saving in the electronics cabinet.

I've been able to find absolutely no documentation about the motors or the drives. You can find a few places that claim to have repaired replacement parts for very high prices.

I don't think these are the original drives. I'm somewhat hesitant to apply power to 30+ year old power electronics. Power electronics (electrolytic caps) don't age so well. And I don't any clues about how to use them. Many of the wires are unlabeled.

I have considered reusing the motors with new drives. And I think that's still an option. But brushed DC motors have brushes that wear out. And I thought, why potentially throw good money after bad with new drives? Based on this conversation, I've learned I need much larger motors than what I thought. Larger motors are expensive.

Rethinking the motor/drive situation. But I'm going to need some documentation, especially for the drives.

Cheers!

Leith

Sounds like I've found the right guy to help me figure this out! Thanks for your reply.

Here's some more info about the machine.

Labeled as a KMB-1m. I believe to be an early 80's model.

Cabinets on both sides. The left side is spindle power. The spindle VFD is missing. Don't think that's a big deal. New VFD should be under $500.

I believe it has a Kwik Switch 200 spindle. No tooling or wrench. This is potentially a showstopper. I don't know anything about Kwik Switch 200. Availability seems very limited. Any advice here would be appreciated.

I don't have an overall picture of the right side electronics cabinet. I do have a picture of the drives. They are about the only thing that might be worth saving in the electronics cabinet.

I've been able to find absolutely no documentation about the motors or the drives. You can find a few places that claim to have repaired replacement parts for very high prices.

I don't think these are the original drives. I'm somewhat hesitant to apply power to 30+ year old power electronics. Power electronics (electrolytic caps) don't age so well. And I don't any clues about how to use them. Many of the wires are unlabeled.

I have considered reusing the motors with new drives. And I think that's still an option. But brushed DC motors have brushes that wear out. And I thought, why potentially throw good money after bad with new drives? Based on this conversation, I've learned I need much larger motors than what I thought. Larger motors are expensive.

Rethinking the motor/drive situation. But I'm going to need some documentation, especially for the drives.

Cheers!

Leith

Attachments:

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

31 Jul 2020 15:52 #176675

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

I am at work, and will respond better later tonight, just giving you a few thoughts from the pictures.

LOL, yeah hopefully I can be of some help as it is sucky when you cannot get good or any reliable information at all.

Looks like you have the manual spindle, which is a little unfortunate, but its not going to be a game killer. It won't be a problem until you are running a program that has multiple up and down speed changes. Worst case you can build a simple bracket to add a servo on the manual hand wheel that cranks up and down the speed. Later models of this head had a extra servo to do what I talking about. I will find some pictures to help you understand what I am talking about, but if you look at the picture of the spindle head you can see the silver hand wheel to the right. On the newer models with this style of head, they added a servo to the left to do this automatically with the control.

Those Electro-Craft Max 430's are completely fine. I have one Max 400 but have never had to use it. I know that the 400's and especially the 430's were an upgrade when the Servo-Mate drive would give up. If I remember correctly, Midwest CNC was the company that did the most Max 430 upgrades. You are actually set up pretty well for the getting going on the moving the table and spindle as you can wire right to the 430's. Just from the looks of the wiring it does look like a upgrade from Midwest. They may have been OEM for your machine depending on the age, but from the wiring it looks like a upgrade.

The Kwik Switch tooling can be expensive at times, but there is a few places around to find it along and along. Once you use it, you will be hooked on it or any type of "quick change" tooling for that matter. I have been building my collection for several years now and I have most everything I need... multiple collet holders, T&C tapping heads, end mill holders, shell mill arbors, drill chucks, etc... Universal Engineering, TSD, DeVlieg, Collis and others make the tooling, but it is expensive new and I buy all of mine used. I believe Universal Eng and DeVlieg merged.. I know they are all quality products and not cheap knock offs. I would start with just the basic end mill holders such as 3/8, 1/2, and 3/4. Then maybe 2 collet holders to get started making chips. You can easily buy things that you may never need or use, so that is why I state start with the basics until you get a feel of what you need for what you intend to do.

I was running my machine for a few years fully OEM and then I came in one morning and the machine would not boot completely as the computer stopped working correctly. I already was going to retrofit the computer as once in a while the machine would just simply flake out and race to the home position in all axis. This was a huge problem when running a program as most of the time the end mill would snap and go flying through the shop like a bullet. Very scary the first time it happened.

I spent right at 2 years fully converting the machine to LinuxCNC with EtherCAT, and I am super happy with the results. I had the same problem you are facing, NO RELIABLE INFORMATION ON THE WEB. I spent so many nights reading and a lot of searching wiring in the machine. Just removing the OEM computer and power supply go rid of nearly half of all the wiring in the machine. I am glad I got help from Tom (Tommylight) and Albert (Chimeno). Those two guys have helped me big time in the past. Plus several others over the years have helped... Andy (andypugh), Todd (Todd Zuercher) and Pete Wallace (PCW).

I need to get back to work, but I will try and get back with you tonight. Hopefully my notes can be helpful to you, if anything at least keep you from wasting a lot of time like I did.

Robert

I am at work, and will respond better later tonight, just giving you a few thoughts from the pictures.

LOL, yeah hopefully I can be of some help as it is sucky when you cannot get good or any reliable information at all.

Looks like you have the manual spindle, which is a little unfortunate, but its not going to be a game killer. It won't be a problem until you are running a program that has multiple up and down speed changes. Worst case you can build a simple bracket to add a servo on the manual hand wheel that cranks up and down the speed. Later models of this head had a extra servo to do what I talking about. I will find some pictures to help you understand what I am talking about, but if you look at the picture of the spindle head you can see the silver hand wheel to the right. On the newer models with this style of head, they added a servo to the left to do this automatically with the control.

Those Electro-Craft Max 430's are completely fine. I have one Max 400 but have never had to use it. I know that the 400's and especially the 430's were an upgrade when the Servo-Mate drive would give up. If I remember correctly, Midwest CNC was the company that did the most Max 430 upgrades. You are actually set up pretty well for the getting going on the moving the table and spindle as you can wire right to the 430's. Just from the looks of the wiring it does look like a upgrade from Midwest. They may have been OEM for your machine depending on the age, but from the wiring it looks like a upgrade.

The Kwik Switch tooling can be expensive at times, but there is a few places around to find it along and along. Once you use it, you will be hooked on it or any type of "quick change" tooling for that matter. I have been building my collection for several years now and I have most everything I need... multiple collet holders, T&C tapping heads, end mill holders, shell mill arbors, drill chucks, etc... Universal Engineering, TSD, DeVlieg, Collis and others make the tooling, but it is expensive new and I buy all of mine used. I believe Universal Eng and DeVlieg merged.. I know they are all quality products and not cheap knock offs. I would start with just the basic end mill holders such as 3/8, 1/2, and 3/4. Then maybe 2 collet holders to get started making chips. You can easily buy things that you may never need or use, so that is why I state start with the basics until you get a feel of what you need for what you intend to do.

I was running my machine for a few years fully OEM and then I came in one morning and the machine would not boot completely as the computer stopped working correctly. I already was going to retrofit the computer as once in a while the machine would just simply flake out and race to the home position in all axis. This was a huge problem when running a program as most of the time the end mill would snap and go flying through the shop like a bullet. Very scary the first time it happened.

I spent right at 2 years fully converting the machine to LinuxCNC with EtherCAT, and I am super happy with the results. I had the same problem you are facing, NO RELIABLE INFORMATION ON THE WEB. I spent so many nights reading and a lot of searching wiring in the machine. Just removing the OEM computer and power supply go rid of nearly half of all the wiring in the machine. I am glad I got help from Tom (Tommylight) and Albert (Chimeno). Those two guys have helped me big time in the past. Plus several others over the years have helped... Andy (andypugh), Todd (Todd Zuercher) and Pete Wallace (PCW).

I need to get back to work, but I will try and get back with you tonight. Hopefully my notes can be helpful to you, if anything at least keep you from wasting a lot of time like I did.

Robert

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

31 Jul 2020 16:55 #176680

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith

Here is a plan of the Electro-Craft servo motor, just for the future if you need to make brackets. I was going down the same road you were about to go with changing out the servos and drives until I looked up the Nm of the Electro-Craft models and realized how powerful they were. Technically my 1kw Yaskawa's do not develop as many Nm so on paper they are under rated compared to the Electro-Craft models.

I went with the approach of don't change what was working for Hurco, but fix the problem I had which was the controller. This was a win win as I fixed the machine and retrofitted to LinuxCNC with minimal cost.

One thing I would emphasize, if you are not verse with LInuxCNC then you may definitely want to go down the path of using Mesa or Pico for the interface hardware. They are both well documented, especially Mesa. Pete (PCW) is on here all the time, I am not sure if Jon Elson is still, but either of those guys are good to deal with for hardware and help. Jon Elson is one of the original guys that I can remember back when LCNC was called EMC and EMC2. I still have my EMC software put up and notes from Jon back in the late 90's and early 2000's.

EtherCAT is kind of a "No Man's Land" and there is very very little info or people to help. I had to read so much that I feel that I lost part of my life to EtherCAT. LOL... Plus the terminal parts are expensive even with shopping over time. BUT the EtherCAT bus speeds is what got me and I was hooked on how Beckhoff built their terminals for ease of installation. DIN mount with quick terminal wiring connections. I love the Beckhoff setup and every machine that I retrofit at this point will be Beckhoff EtherCAT. Where as the Mesa or Pico cards are around $300 or so to get everything connected together, excluding computer cost much much cheaper than what it cost in EtherCAT. I was lucky and I have about $500 in my setup from doing hard core watching every day for the terminals.

Robert

Here is a plan of the Electro-Craft servo motor, just for the future if you need to make brackets. I was going down the same road you were about to go with changing out the servos and drives until I looked up the Nm of the Electro-Craft models and realized how powerful they were. Technically my 1kw Yaskawa's do not develop as many Nm so on paper they are under rated compared to the Electro-Craft models.

I went with the approach of don't change what was working for Hurco, but fix the problem I had which was the controller. This was a win win as I fixed the machine and retrofitted to LinuxCNC with minimal cost.

One thing I would emphasize, if you are not verse with LInuxCNC then you may definitely want to go down the path of using Mesa or Pico for the interface hardware. They are both well documented, especially Mesa. Pete (PCW) is on here all the time, I am not sure if Jon Elson is still, but either of those guys are good to deal with for hardware and help. Jon Elson is one of the original guys that I can remember back when LCNC was called EMC and EMC2. I still have my EMC software put up and notes from Jon back in the late 90's and early 2000's.

EtherCAT is kind of a "No Man's Land" and there is very very little info or people to help. I had to read so much that I feel that I lost part of my life to EtherCAT. LOL... Plus the terminal parts are expensive even with shopping over time. BUT the EtherCAT bus speeds is what got me and I was hooked on how Beckhoff built their terminals for ease of installation. DIN mount with quick terminal wiring connections. I love the Beckhoff setup and every machine that I retrofit at this point will be Beckhoff EtherCAT. Where as the Mesa or Pico cards are around $300 or so to get everything connected together, excluding computer cost much much cheaper than what it cost in EtherCAT. I was lucky and I have about $500 in my setup from doing hard core watching every day for the terminals.

Robert

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

31 Jul 2020 17:10 #176682

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

Hi Robert,

Wow. You have been massively helpful already. Thanks!

I'm game for resurrecting the MAX-430s.... but I want to know something about them first. I'm totally clueless right now. Do you suppose Midwest CNC would be able to provide some documentation?

Servo-izing the spindle speed sounds like a good idea, but that'll have to wait until I get the basic machine operating.

My basic idea for the computer/LinuxCNC is a Raspberry PI4 with a Mesa 7I92 interface card. But this is just a guess since I'm clueless about what needs to be connected to the MAX-430s???

The machine has a compressed air input. But I don't know what its used for. Best guess is some powered drawbar??

And just out of curiosity, what is your approximate location? I'm located near Fort Collins Colorado. Mountain Time Zone.

Leith

Wow. You have been massively helpful already. Thanks!

I'm game for resurrecting the MAX-430s.... but I want to know something about them first. I'm totally clueless right now. Do you suppose Midwest CNC would be able to provide some documentation?

Servo-izing the spindle speed sounds like a good idea, but that'll have to wait until I get the basic machine operating.

My basic idea for the computer/LinuxCNC is a Raspberry PI4 with a Mesa 7I92 interface card. But this is just a guess since I'm clueless about what needs to be connected to the MAX-430s???

The machine has a compressed air input. But I don't know what its used for. Best guess is some powered drawbar??

And just out of curiosity, what is your approximate location? I'm located near Fort Collins Colorado. Mountain Time Zone.

Leith

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

31 Jul 2020 17:48 #176684

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Hey glad I can help... I know how it is...

I am in Valdosta, Georgia (Eastern Time Zone).

I have a Pi3, but have never tried it with LinuxCNC. I know there are people that have done it, but I am not sure how well it runs LCNC.

I am big on reliability and how fast/well LCNC runs on the computer. I have been using Dell OptiPlex computers and have great luck with them. Specifically the USFF 7010, but these are only good for EtherNet or EtherCAT connections as they do not have PCI slots or parallel ports.

I will have to look up the Mesa 7192, but if using Pi4 then it must be a EtherNet connection.

IF you need to go the route of say Mesa with a PCI card like the 7I77-6I25 PLUG-N-GO KIT, then I would use the Dell OptiPlex SFF model or the Full Size as they will have PCI slots for the card. I was having problems with just one particular terminal that held me up for a year. I got the machine running again very slow by using a dell optiplex 9020 and adding a DB25 card and using Parallel port software encoding for the encoders. This was terrible and only a temporary work around until I could get the EL5151 terminal figured out. with the help of (Chimeno).... super great thanks to Albert, He's the Man... He is from Spain and helped walk me through Beckhoff's TwinCat Software, which the TC2 version is a pain. I battled that software until he got me to use TC3 and down the right path.

Ok that compressed air input is super needed. They don't use a drawbar as the Kwik Switch receiver has a locking nut and no drawbar needed Don't do like other's on the web that tore it all out. That is what powers the Spindle Brake and most importantly the Machine Way Oiler that is located on the back of the machine. If you go to the back of the machine where the air line comes in from the left, you will see the pressure switch, the air regulator and from three it will go over to the Oiler that is at the bottom in the middle. You need to keep this filled up with Way Oil. I use Chevron 68, I will get you the exact data on the tag, but that is what I remember from memory. When you get the machine working, you will always want to make sure you hear the oiler work when you power up the servos as this will give the ways a shot of oil before movement. Oil is critical or you will seize a ball screw.

I will catch back up with you later, I have to get out of here and up to the post office. Hope this helps.

Robert

Hey glad I can help... I know how it is...

I am in Valdosta, Georgia (Eastern Time Zone).

I have a Pi3, but have never tried it with LinuxCNC. I know there are people that have done it, but I am not sure how well it runs LCNC.

I am big on reliability and how fast/well LCNC runs on the computer. I have been using Dell OptiPlex computers and have great luck with them. Specifically the USFF 7010, but these are only good for EtherNet or EtherCAT connections as they do not have PCI slots or parallel ports.

I will have to look up the Mesa 7192, but if using Pi4 then it must be a EtherNet connection.

IF you need to go the route of say Mesa with a PCI card like the 7I77-6I25 PLUG-N-GO KIT, then I would use the Dell OptiPlex SFF model or the Full Size as they will have PCI slots for the card. I was having problems with just one particular terminal that held me up for a year. I got the machine running again very slow by using a dell optiplex 9020 and adding a DB25 card and using Parallel port software encoding for the encoders. This was terrible and only a temporary work around until I could get the EL5151 terminal figured out. with the help of (Chimeno).... super great thanks to Albert, He's the Man... He is from Spain and helped walk me through Beckhoff's TwinCat Software, which the TC2 version is a pain. I battled that software until he got me to use TC3 and down the right path.

Ok that compressed air input is super needed. They don't use a drawbar as the Kwik Switch receiver has a locking nut and no drawbar needed Don't do like other's on the web that tore it all out. That is what powers the Spindle Brake and most importantly the Machine Way Oiler that is located on the back of the machine. If you go to the back of the machine where the air line comes in from the left, you will see the pressure switch, the air regulator and from three it will go over to the Oiler that is at the bottom in the middle. You need to keep this filled up with Way Oil. I use Chevron 68, I will get you the exact data on the tag, but that is what I remember from memory. When you get the machine working, you will always want to make sure you hear the oiler work when you power up the servos as this will give the ways a shot of oil before movement. Oil is critical or you will seize a ball screw.

I will catch back up with you later, I have to get out of here and up to the post office. Hope this helps.

Robert

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.178 seconds