Hurco KMB-IS CNC update

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

31 Jul 2020 18:06 #176686

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

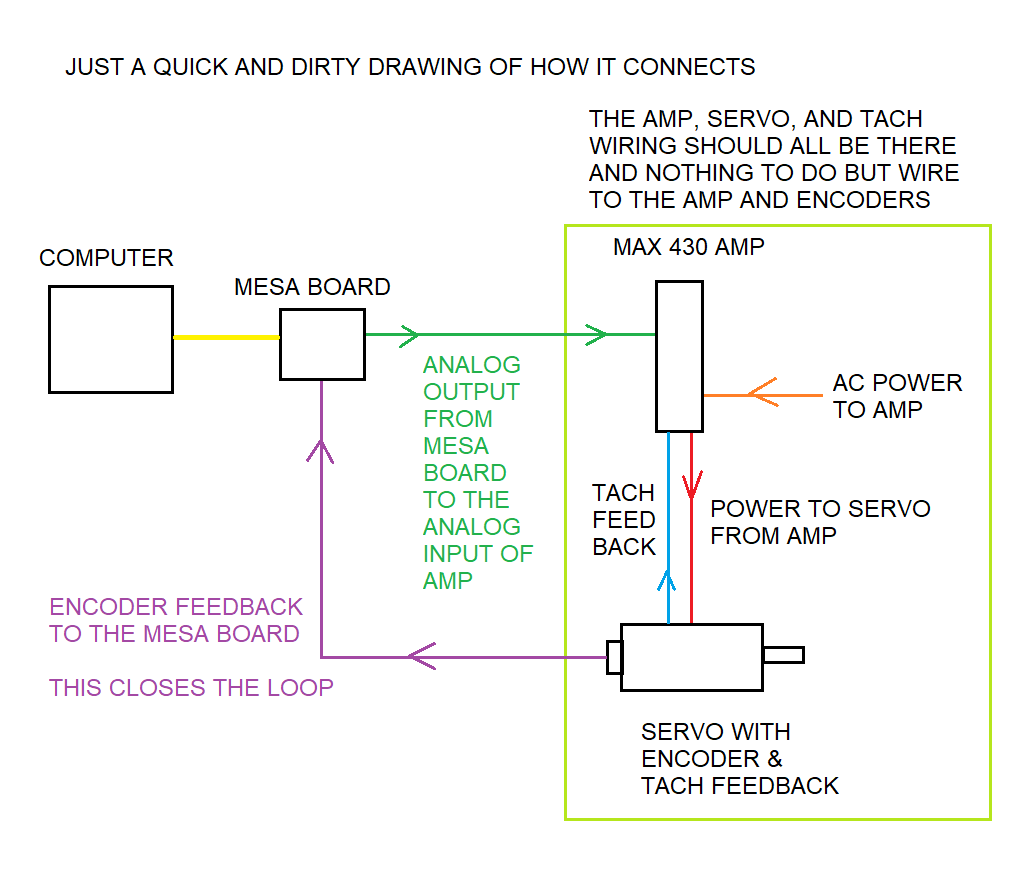

One quick note, I got back on as I did not respond about the Max 430's. I have a manual on the 400's somewhere. I will get it as it will be the same for both models.

Talk to you later,

Robert

One quick note, I got back on as I did not respond about the Max 430's. I have a manual on the 400's somewhere. I will get it as it will be the same for both models.

Talk to you later,

Robert

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

31 Jul 2020 18:19 #176690

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

There is a Raspberry PI 4 tutorial gnipsel.com/linuxcnc/uspace/ Looks pretty straight forward. But you probably need an RPi4 and make sure its got at least 4GB of RAM so that it will run the X11 GUI well.

I had found a MAX-400 instruction manual. But the front panel connectors are definitely different. Don't know enough about these things to know if it matters.

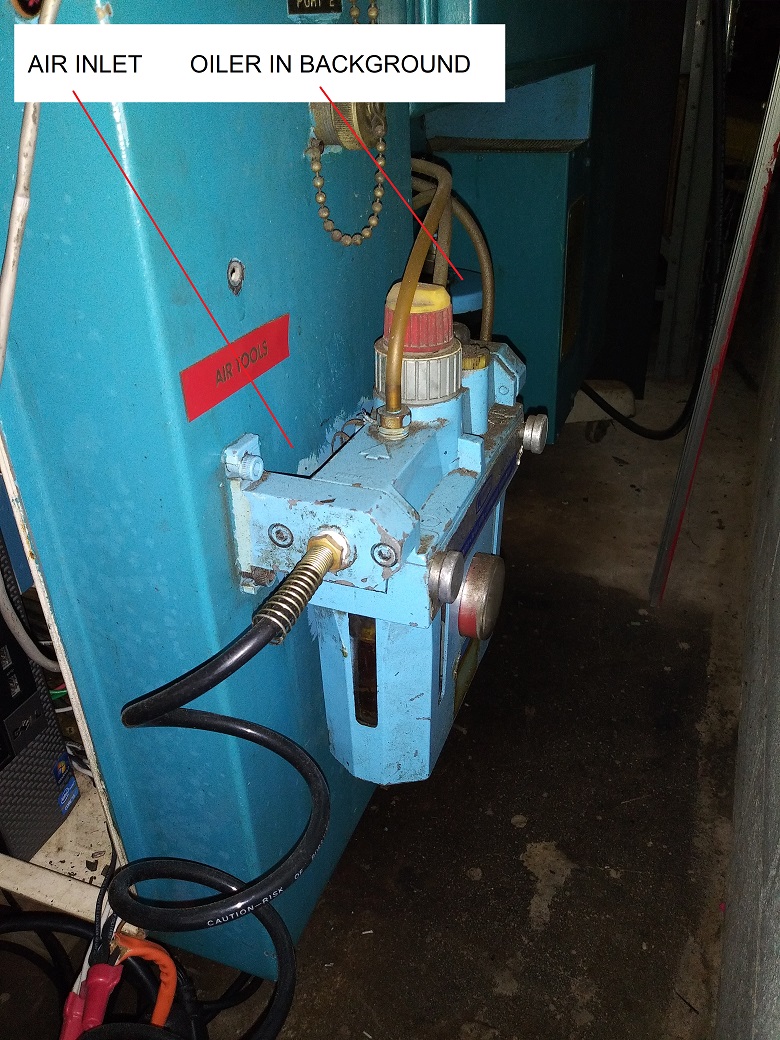

Was wondering about the compressed air. The input port looks a little munged.

For some reason the oiler is detached and in a separate box. Hopefully it works or can be easily repaired.

Leith

I had found a MAX-400 instruction manual. But the front panel connectors are definitely different. Don't know enough about these things to know if it matters.

Was wondering about the compressed air. The input port looks a little munged.

For some reason the oiler is detached and in a separate box. Hopefully it works or can be easily repaired.

Leith

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

01 Aug 2020 00:10 #176713

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Yeah Gnipsel should be John Thornton and he is another one of the guys that has done a lot for LCNC. I have read some of his tutorials and has good information.

I will get some pics of my oiler and you can compare to see if it is the same. I have the manual for it and will find it also. The inlet should be a standard 1/4" or 3/8" pipe thread (NPT). Depending on how bad it is you may be able to simply re-chase the threads. If I remember correctly it is aluminum, so yeah if someone hit with a forklift or etc, then it could be in bad shape and need to replace.

The 3 things I would emphasize to get working before ever moving any of the 3 axis is to get the Emergency Stop wired, oiler working and your limit switches working. Hurco used a 3 wire proximity switch and if you are not familiar with them I will show you how to wire them up. They take 5V so don't send 12, 15, or 24V to them. They work extremely well and are accurate for homing also. The reason you want to get your limit switches working perfect before any movement is the fact that if you fire up the servos and they decide to take off in toward one axis you can crash the table or spindle and then you will be in a very bad expensive mess. Nothing worse than to finally get it to move and you crash the table. SO make sure you get them working fully in LCNC before ever applying power to the servo amps. They are easy to trip, you simply move a screw driver or any metal object and that will trip them. Don't get fooled by people on the web saying remove them and put regular limit switches in. Limit switches are great, but you can get chips in them and they hang up and not work. Proximity switches are magnetic and do not need a physical contact to get to work and therefore that is why most all of the major manufactures use them for the safety.

I am super glad I got them wired as there was a few times my table took off while I was tweaking the HAL code and doing rough PID tuning. I still need to fine tune my PID, but it is pretty close.

I will be back later, I have several things to get done real quick before dark, but will get you some info together.

Robert

Yeah Gnipsel should be John Thornton and he is another one of the guys that has done a lot for LCNC. I have read some of his tutorials and has good information.

I will get some pics of my oiler and you can compare to see if it is the same. I have the manual for it and will find it also. The inlet should be a standard 1/4" or 3/8" pipe thread (NPT). Depending on how bad it is you may be able to simply re-chase the threads. If I remember correctly it is aluminum, so yeah if someone hit with a forklift or etc, then it could be in bad shape and need to replace.

The 3 things I would emphasize to get working before ever moving any of the 3 axis is to get the Emergency Stop wired, oiler working and your limit switches working. Hurco used a 3 wire proximity switch and if you are not familiar with them I will show you how to wire them up. They take 5V so don't send 12, 15, or 24V to them. They work extremely well and are accurate for homing also. The reason you want to get your limit switches working perfect before any movement is the fact that if you fire up the servos and they decide to take off in toward one axis you can crash the table or spindle and then you will be in a very bad expensive mess. Nothing worse than to finally get it to move and you crash the table. SO make sure you get them working fully in LCNC before ever applying power to the servo amps. They are easy to trip, you simply move a screw driver or any metal object and that will trip them. Don't get fooled by people on the web saying remove them and put regular limit switches in. Limit switches are great, but you can get chips in them and they hang up and not work. Proximity switches are magnetic and do not need a physical contact to get to work and therefore that is why most all of the major manufactures use them for the safety.

I am super glad I got them wired as there was a few times my table took off while I was tweaking the HAL code and doing rough PID tuning. I still need to fine tune my PID, but it is pretty close.

I will be back later, I have several things to get done real quick before dark, but will get you some info together.

Robert

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

01 Aug 2020 03:45 #176743

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Attachments:

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

01 Aug 2020 04:06 #176745

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Attachments:

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

01 Aug 2020 04:32 #176748

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Attached at the bottom is the PDF manual for the oiler, hopefully the same as yours.

Also some models also came with a Bijur Oiler on the bottom left side of the knee as you are facing the machine. I will try and find a pic of one I have.

Robert

Attached at the bottom is the PDF manual for the oiler, hopefully the same as yours.

Also some models also came with a Bijur Oiler on the bottom left side of the knee as you are facing the machine. I will try and find a pic of one I have.

Robert

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

01 Aug 2020 05:17 #176751

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Attachments:

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

01 Aug 2020 05:30 #176754

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Ok I will get more together tomorrow as it is 1:30am here. Hope this gets you going in the right direction. Will be back tomorrow.

Robert

Ok I will get more together tomorrow as it is 1:30am here. Hope this gets you going in the right direction. Will be back tomorrow.

Robert

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

01 Aug 2020 17:48 - 01 Aug 2020 18:02 #176803

by CORBETT

Leith,

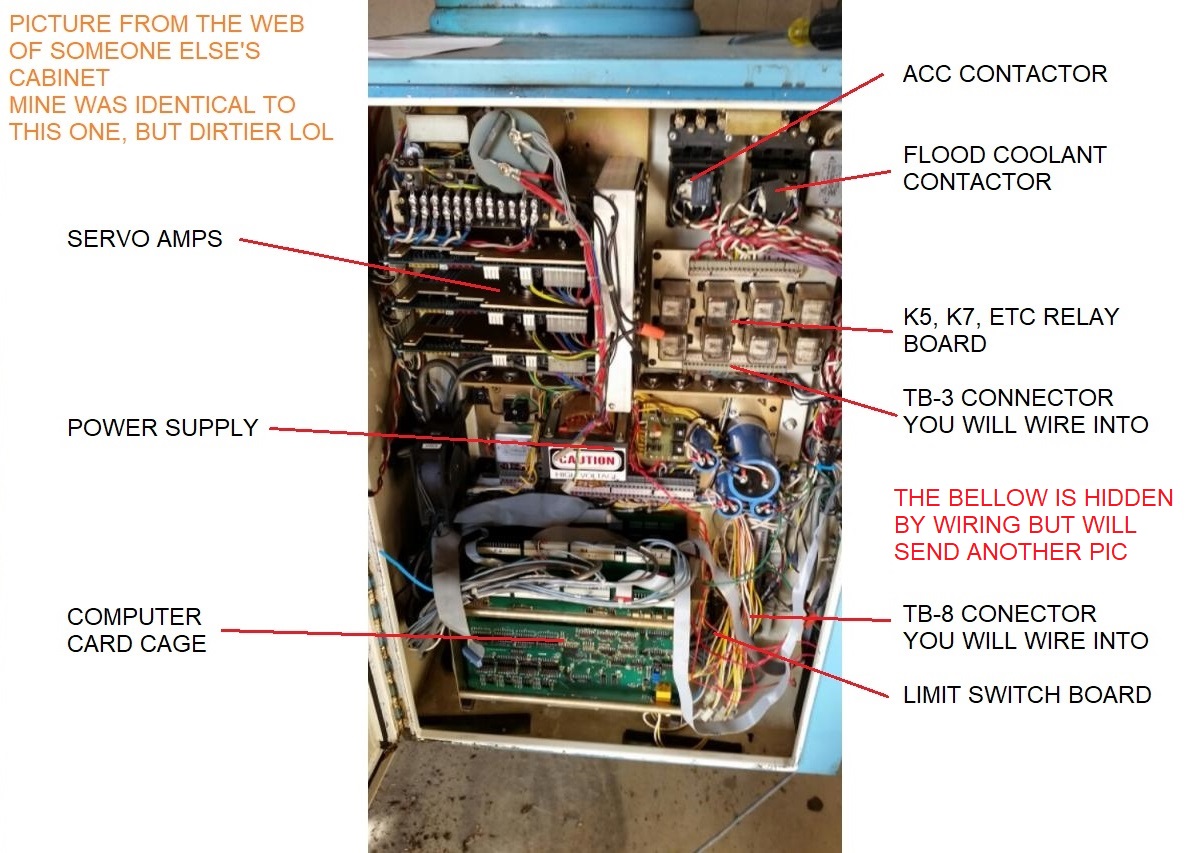

Here is a pic of a cabinet like mine. Mine was much dirtier, and I would have to find the pics from 2 years ago before tearing out the computer cage and power supply. But this pic on the web was much cleaner inside.

I am going to go try and make a few parts for my Dad and his projects. I will be back along and along to try and upload some more pics and info.

Later tonight I will send you a copy of my manual for the machine.

Will be back later,

Robert

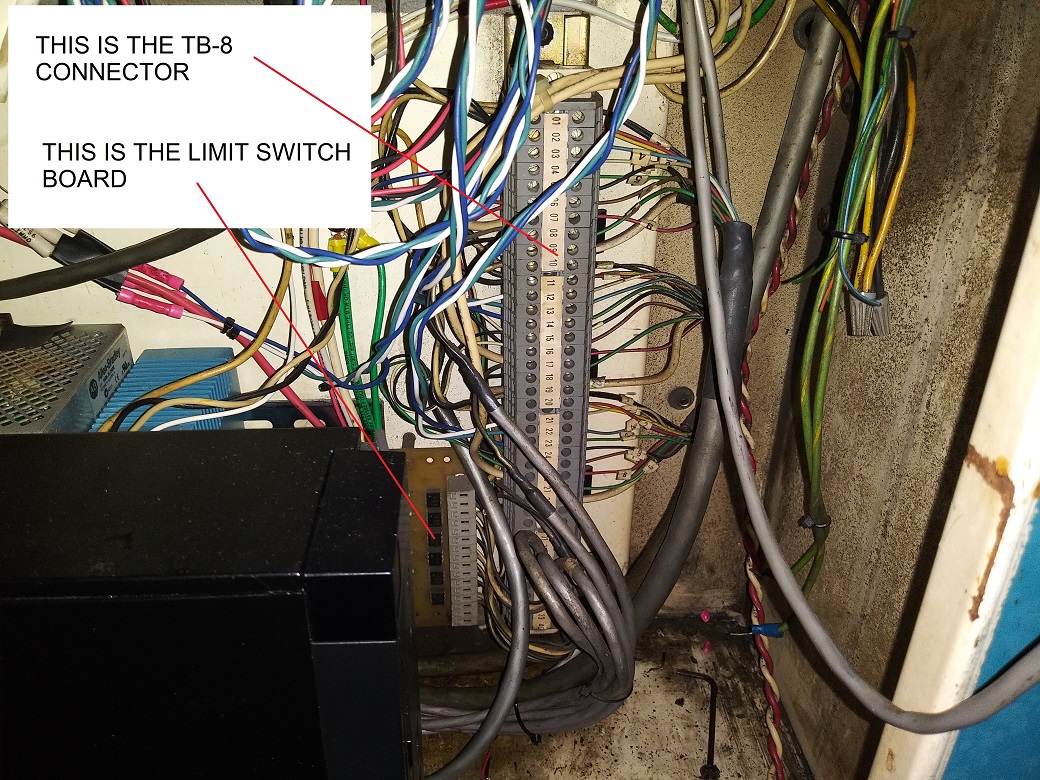

The below pics were taken last night of my cabinet. Excuse my wiring as I am going to clean everything up, I simply needed to get it back working asap.

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Here is a pic of a cabinet like mine. Mine was much dirtier, and I would have to find the pics from 2 years ago before tearing out the computer cage and power supply. But this pic on the web was much cleaner inside.

I am going to go try and make a few parts for my Dad and his projects. I will be back along and along to try and upload some more pics and info.

Later tonight I will send you a copy of my manual for the machine.

Will be back later,

Robert

The below pics were taken last night of my cabinet. Excuse my wiring as I am going to clean everything up, I simply needed to get it back working asap.

Last edit: 01 Aug 2020 18:02 by CORBETT. Reason: To clarify my post for bottom pics

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

01 Aug 2020 19:27 #176808

by CORBETT

Leith,

One other thing I did not mention is that you don't want to tear out any wiring and definitely not the relay board with wring coming off the TB-3 connector until I can send you schematics to understand everything.

Hurco put a lot of safety loops in by using the relays and that is why I wired directly into the TB-2 connector as it kept all of the downstream safety blocks in place so that it was mechanically safe. Most all people when retrofitting tear out all of the wiring and relays, but at the same time you loose the safety. I have an external Emergency Stop switch wired not only to LCNC but to the machine keeping the original emergency stop loop that Hurco implemented. This way if LCNC did flake out for some reason, I am still wired directly to the machine and can kill the servo amps, spindle, and everything else without worry that it will not stop. Plus this will enact the spindle brake just incase it's something bad happening at the spindle.

There is a ton of wiring that comes from the computer cage to multiple places in the machine, but most all connections are at the TB-3 and TB-8 that you will need to do. Most all of the other wiring is removed as it is simply wiring passing between the different computer cards and power supply.

Will be back later,

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

One other thing I did not mention is that you don't want to tear out any wiring and definitely not the relay board with wring coming off the TB-3 connector until I can send you schematics to understand everything.

Hurco put a lot of safety loops in by using the relays and that is why I wired directly into the TB-2 connector as it kept all of the downstream safety blocks in place so that it was mechanically safe. Most all people when retrofitting tear out all of the wiring and relays, but at the same time you loose the safety. I have an external Emergency Stop switch wired not only to LCNC but to the machine keeping the original emergency stop loop that Hurco implemented. This way if LCNC did flake out for some reason, I am still wired directly to the machine and can kill the servo amps, spindle, and everything else without worry that it will not stop. Plus this will enact the spindle brake just incase it's something bad happening at the spindle.

There is a ton of wiring that comes from the computer cage to multiple places in the machine, but most all connections are at the TB-3 and TB-8 that you will need to do. Most all of the other wiring is removed as it is simply wiring passing between the different computer cards and power supply.

Will be back later,

Robert

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 1.278 seconds