Hurco KMB-IS CNC update

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

04 Aug 2020 21:23 #177289

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

I forgot to add earlier that you have the same identical pendant that I had.

Man I could fly on that thing. I could be watching the spindle and reach over punching what ever I needed as I had the whole thing memorized. May sound crazy, but I still do miss using it as I was so verse with it....

Man I could fly on that thing. I could be watching the spindle and reach over punching what ever I needed as I had the whole thing memorized. May sound crazy, but I still do miss using it as I was so verse with it....

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

04 Aug 2020 21:45 - 04 Aug 2020 21:46 #177291

by CORBETT

Leith,

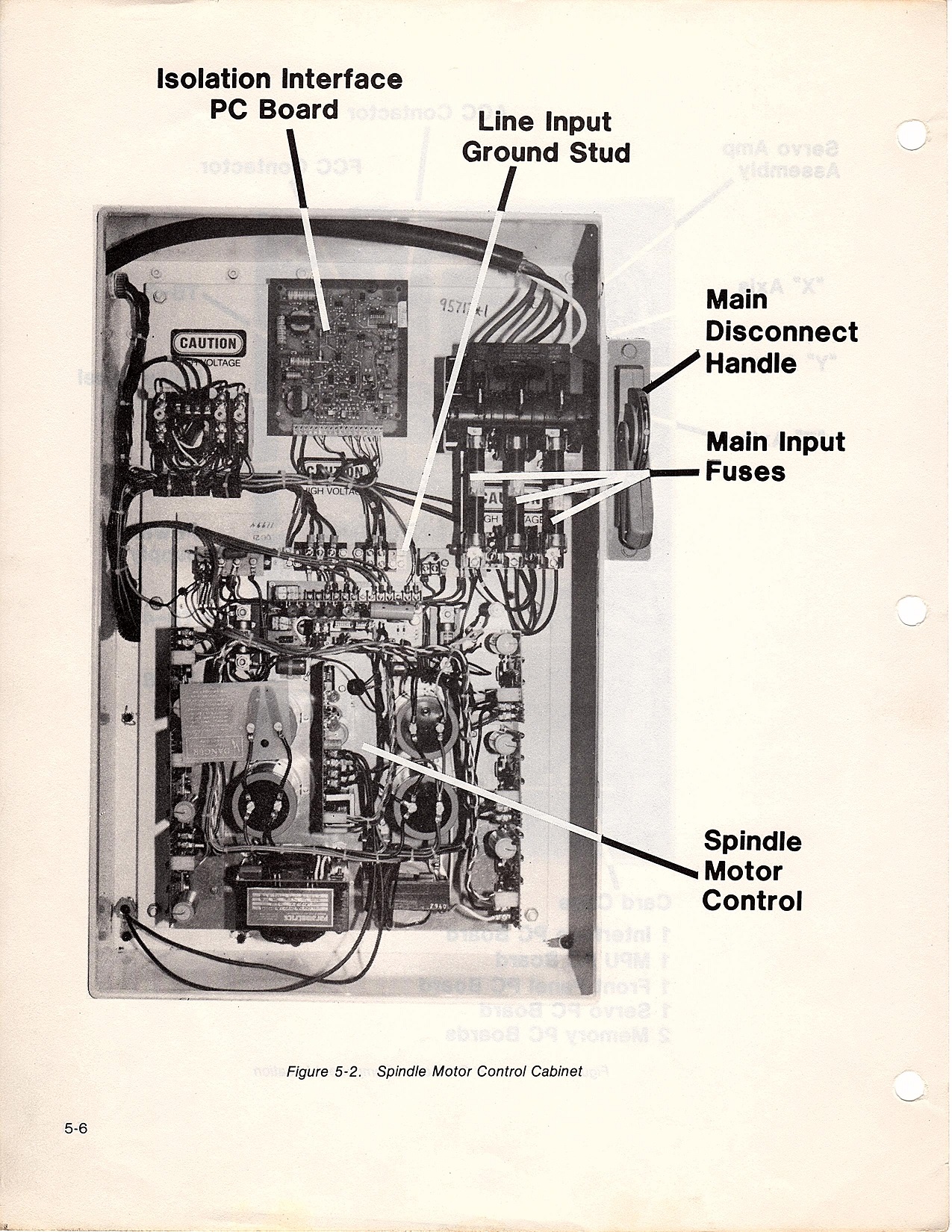

Ok here is a basic drawing from Hurco for the transformers. This is not the drawing that came with the Schematics, but is practically the same. I will try to find the other transformer schematic. Once again, during this time period Hurco tried to keep everything built and looking the same through out all machines. I looked at several big VMC's that had almost the same cabinet layout as mine, just larger contactors for the spindle motor and other added items.

Anyway, this may help you, but like I said before you should be able to trace the wiring back to the left cabinet and to the step down transformer and then to the disconnect.

Will be back later,

Robert

Here is the PDF schematic

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Ok here is a basic drawing from Hurco for the transformers. This is not the drawing that came with the Schematics, but is practically the same. I will try to find the other transformer schematic. Once again, during this time period Hurco tried to keep everything built and looking the same through out all machines. I looked at several big VMC's that had almost the same cabinet layout as mine, just larger contactors for the spindle motor and other added items.

Anyway, this may help you, but like I said before you should be able to trace the wiring back to the left cabinet and to the step down transformer and then to the disconnect.

Will be back later,

Robert

Here is the PDF schematic

Attachments:

Last edit: 04 Aug 2020 21:46 by CORBETT.

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

05 Aug 2020 01:55 - 05 Aug 2020 01:57 #177333

by CORBETT

Leith,

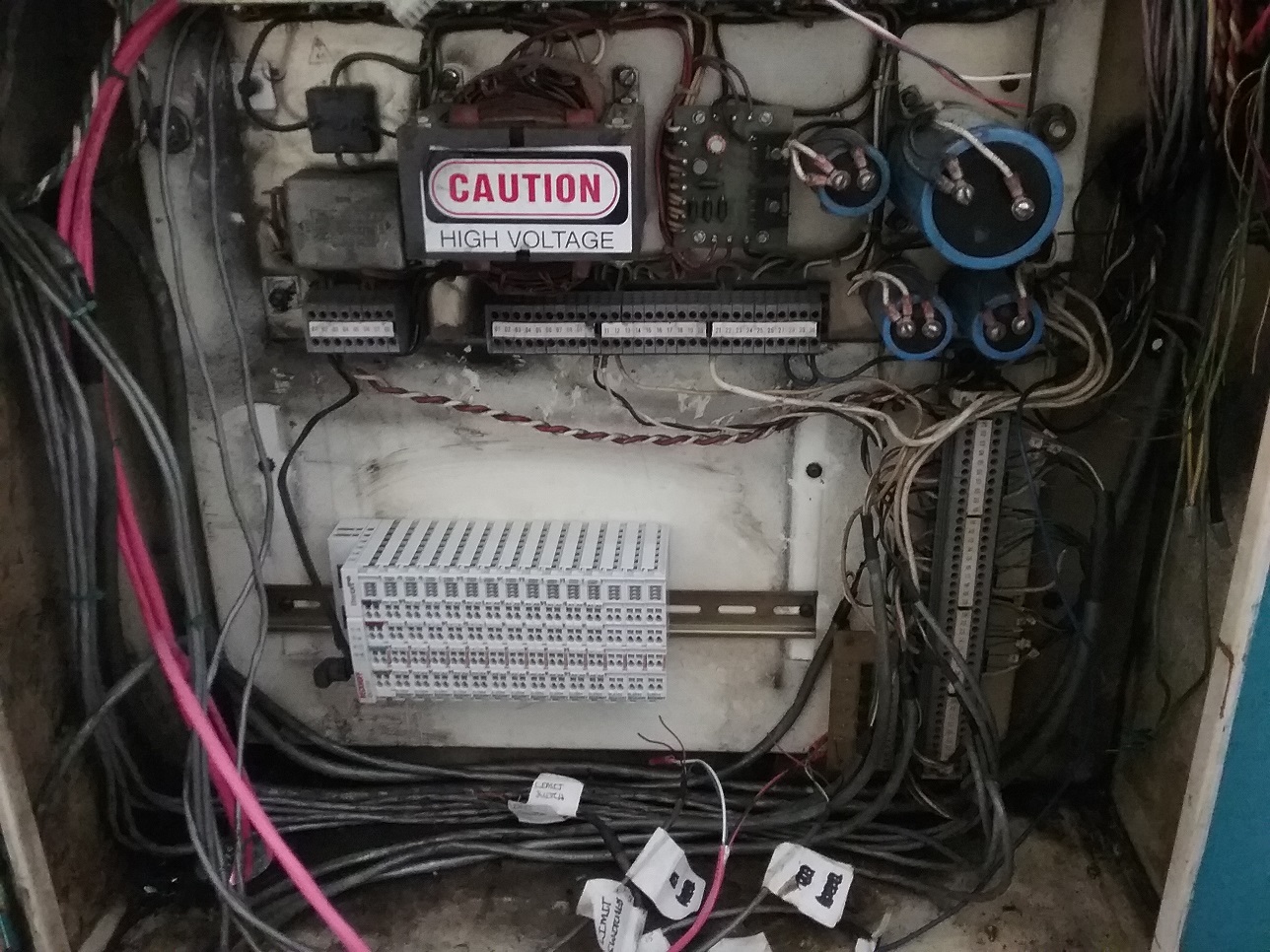

Ok, I went back and looked at the left cabinet where you thought the VFD was located.

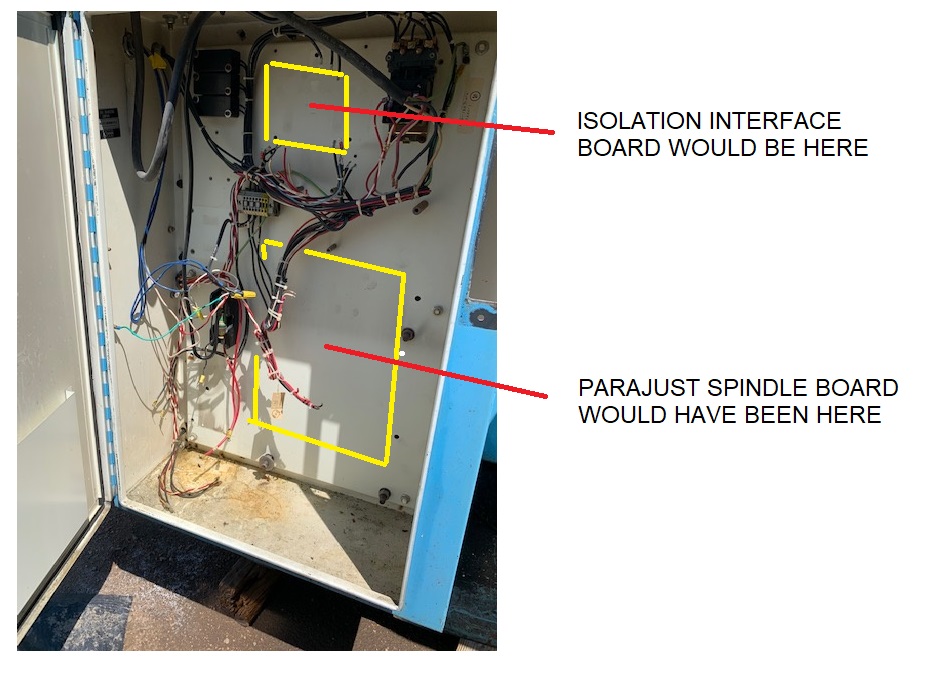

Ok my opinion is this.... after going back and looking, what I think is that the machine was totally working and still had the parajust board. I believe the parajust went out and they pulled it to get repaired and that did not pan out because of cost when they got the price from whoever that they sent it to. The reason I say this is from what the wiring looks like in it's present condition. It literally looks like they unwired and then unbolted the 2 boards. The parajust board is pretty big, and the other board above it is smaller and I can see where it was located originally. The smaller board is just a interface/isolation board, and the parajust is the spindle speed board.

It does not appear that there ever was a VFD installed. If there was, then someone sucked at their wiring and left a lot of hot wires siting open.

I fully believe the parajust went out, they pulled both boards thinking it was either of the two as the spindle control was giving them problems and the rest of the machine is fully operational. I would isolate the wiring in that left cabinet, check the step down transformer input to see if wired 220 or 440, and put power to the cabinet and see if it fires up. i really am starting to believe the everything else is fine. This would make sense as what would happen is some shop was tight on money. They pulled the board, or a service guy pulled it and they had the intention to fix the board. When they got the price, they balked at fixing it as it would probably have cost a couple of thousand for the total repair. And they had no clue how to wire in and implement a traditional VFD as the parajust wiring would have stumped them, so the final outcome was it sat until they got rid of it. In other words from a business standpoint, in their eyes the machine was not worth fixing as it was good money thrown after bad in a old machine when they could invest that money in a new or newer machine. I think it has been sitting in that condition for awhile, but if you isolate the parajust board wiring that you could possibly get it fired up pretty easy to check the servos.

Here is your picture where the boards would have been. Will find some pics of real thing.

I will be back in a bit, wanted to get that on to you so you could be thinking about it. Still have a lot to get done in order to send you more pics and info, but working on it.

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Ok, I went back and looked at the left cabinet where you thought the VFD was located.

Ok my opinion is this.... after going back and looking, what I think is that the machine was totally working and still had the parajust board. I believe the parajust went out and they pulled it to get repaired and that did not pan out because of cost when they got the price from whoever that they sent it to. The reason I say this is from what the wiring looks like in it's present condition. It literally looks like they unwired and then unbolted the 2 boards. The parajust board is pretty big, and the other board above it is smaller and I can see where it was located originally. The smaller board is just a interface/isolation board, and the parajust is the spindle speed board.

It does not appear that there ever was a VFD installed. If there was, then someone sucked at their wiring and left a lot of hot wires siting open.

I fully believe the parajust went out, they pulled both boards thinking it was either of the two as the spindle control was giving them problems and the rest of the machine is fully operational. I would isolate the wiring in that left cabinet, check the step down transformer input to see if wired 220 or 440, and put power to the cabinet and see if it fires up. i really am starting to believe the everything else is fine. This would make sense as what would happen is some shop was tight on money. They pulled the board, or a service guy pulled it and they had the intention to fix the board. When they got the price, they balked at fixing it as it would probably have cost a couple of thousand for the total repair. And they had no clue how to wire in and implement a traditional VFD as the parajust wiring would have stumped them, so the final outcome was it sat until they got rid of it. In other words from a business standpoint, in their eyes the machine was not worth fixing as it was good money thrown after bad in a old machine when they could invest that money in a new or newer machine. I think it has been sitting in that condition for awhile, but if you isolate the parajust board wiring that you could possibly get it fired up pretty easy to check the servos.

Here is your picture where the boards would have been. Will find some pics of real thing.

I will be back in a bit, wanted to get that on to you so you could be thinking about it. Still have a lot to get done in order to send you more pics and info, but working on it.

Robert

Attachments:

Last edit: 05 Aug 2020 01:57 by CORBETT. Reason: spelling

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

05 Aug 2020 02:04 #177335

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Attachments:

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

05 Aug 2020 02:57 #177338

by CORBETT

Leith,

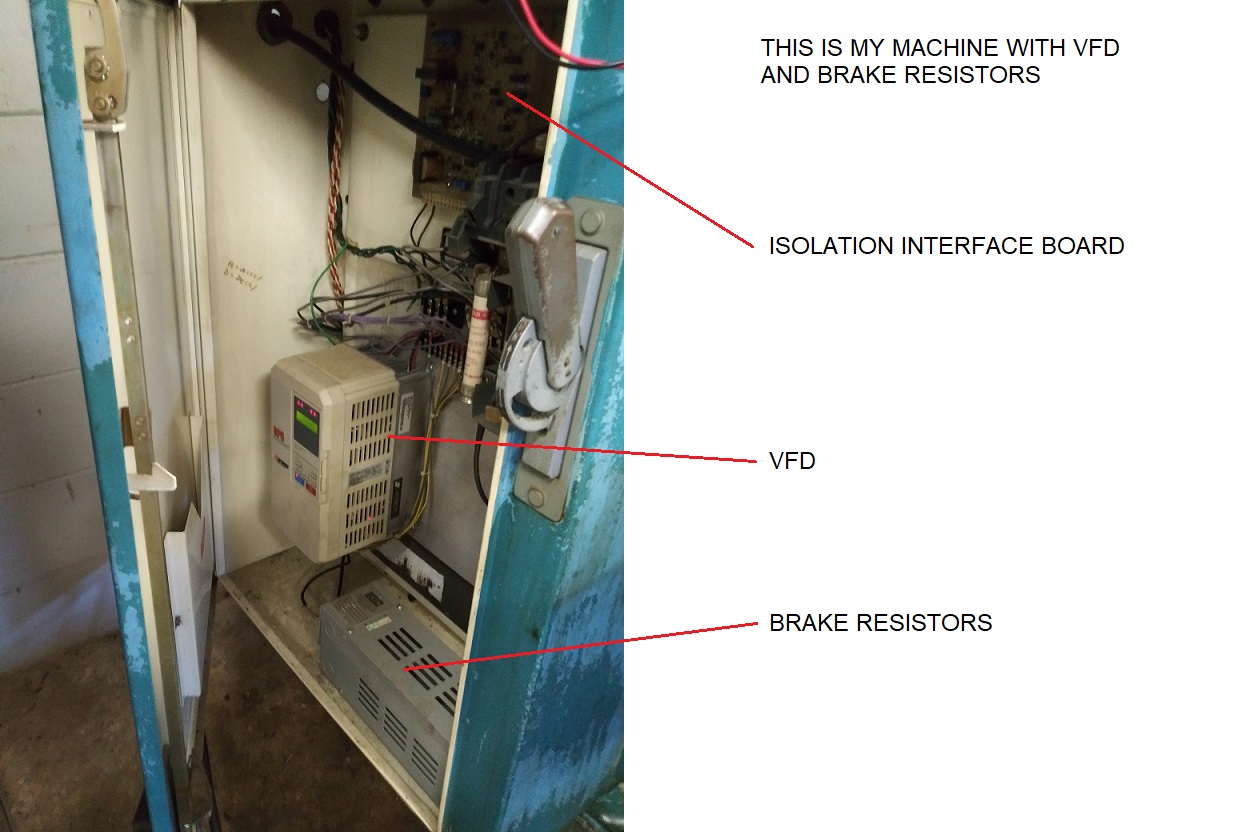

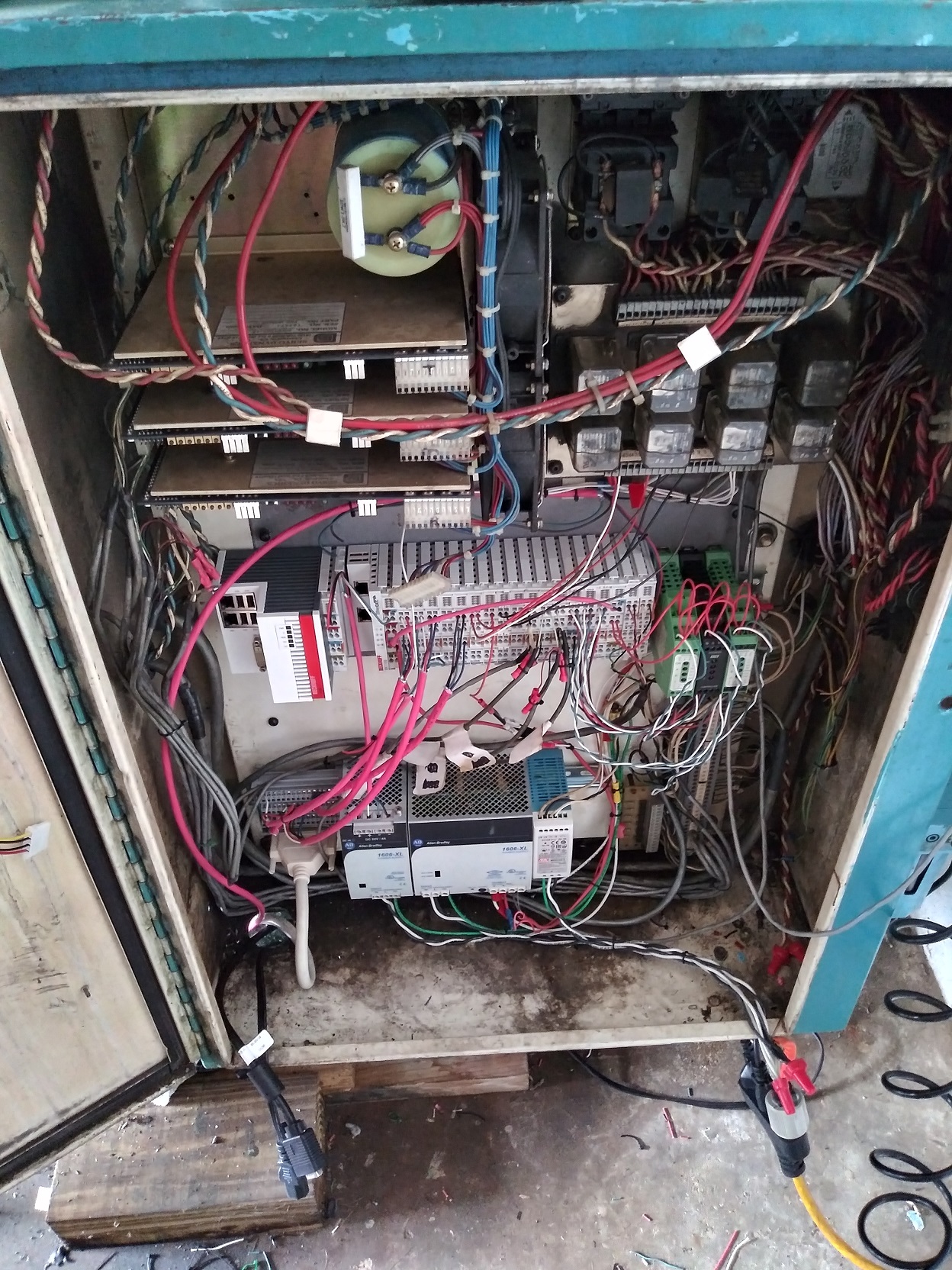

Ok this is not the best picture and I will try to get a better one. This is my cabinet with the VFD, Isolation Board, and Brake Resistors.

You should not need the isolation board, so don't freak out not having it. I still have mine, but that was because I still had the OEM computer. When the computer was replaced, I bypassed the isolation board and wired my analog output terminal (EtherCAT EL4132) to the VFD direct. The isolation board would have been there still for the OEM computer is why mine was still there. Now it is abandoned, but I am going to remove it sometime soon to get it out of the cabinet.

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Ok this is not the best picture and I will try to get a better one. This is my cabinet with the VFD, Isolation Board, and Brake Resistors.

You should not need the isolation board, so don't freak out not having it. I still have mine, but that was because I still had the OEM computer. When the computer was replaced, I bypassed the isolation board and wired my analog output terminal (EtherCAT EL4132) to the VFD direct. The isolation board would have been there still for the OEM computer is why mine was still there. Now it is abandoned, but I am going to remove it sometime soon to get it out of the cabinet.

Attachments:

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

05 Aug 2020 03:27 #177339

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Attachments:

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

05 Aug 2020 03:48 - 05 Aug 2020 03:49 #177341

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Just a throw back pic of my cabinet when first started retrofitting. My cabinet was ultra dirty. They had left the door open for years apparently as it took a ton of cleaning to get it halfway better.

The computer is removed and the EtherCAT terminals are mounted where it was originally. I did not keep them at this location, ended up realizing this was a bad location, and laid out everything I needed to mount so that everything would fit

The computer is removed and the EtherCAT terminals are mounted where it was originally. I did not keep them at this location, ended up realizing this was a bad location, and laid out everything I needed to mount so that everything would fit

Attachments:

Last edit: 05 Aug 2020 03:49 by CORBETT.

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

05 Aug 2020 04:00 #177342

by CORBETT

Replied by CORBETT on topic Hurco KMB-IS CNC update

Here is the cabinet when I was about 3/4 done. I had all of the 110V electronics wired to a drop chord so I did not have to keep firing up the entire machine, especially the servo amps and wasting power. Plus potential for messing something up. I got LCNC working totally and everything flowing correctly through the K5 relays. Then was able to test proximity switches, contactors, and get analog output and encoders working without the 220V powering anything. This definitely made it a lot safer working in the cabinet.

Attachments:

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

05 Aug 2020 05:55 - 05 Aug 2020 05:56 #177347

by CORBETT

Leith,

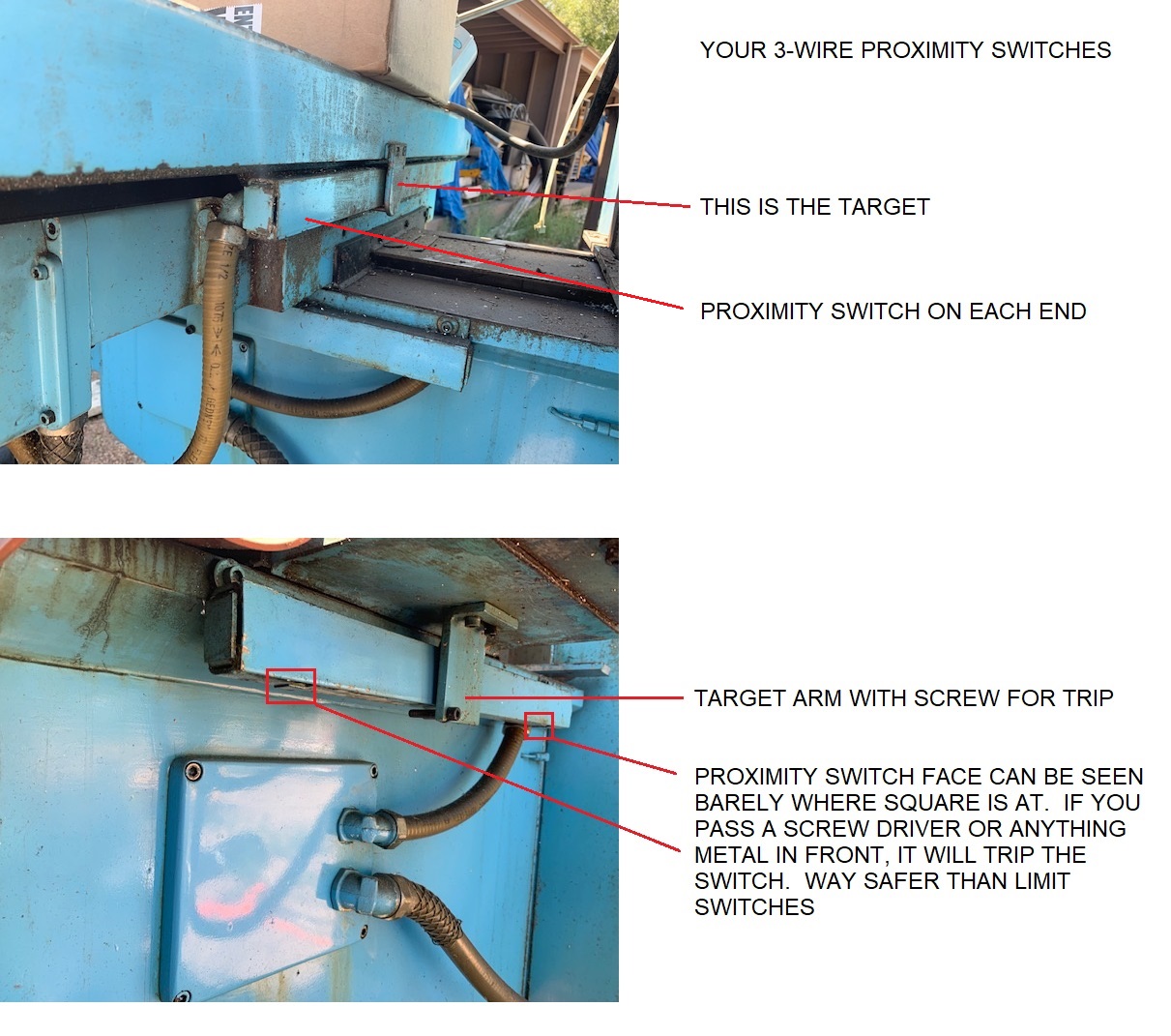

One thing I forgot to mention. In the pics of the proximity switches, I saw where your table is already centered on both axis, or it appears to be. If so, then you don't have to even move it. That is good for when you fire up the servos the first time.

Got to get sleep, up too late LOL. Will be back tomorrow.

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

One thing I forgot to mention. In the pics of the proximity switches, I saw where your table is already centered on both axis, or it appears to be. If so, then you don't have to even move it. That is good for when you fire up the servos the first time.

Got to get sleep, up too late LOL. Will be back tomorrow.

Robert

Last edit: 05 Aug 2020 05:56 by CORBETT. Reason: spelling

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

05 Aug 2020 15:49 #177398

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

Hi Robert,

Thanks again for the pics and info.

Trying to connect the dots. Various pieces of information with assorted pedigrees.

Here's a little more of the known history of the Hurco. It was owned by Lockheed/Martin. In 2005 it was donated to Colorado State University with a claimed value of $31,000. It was also claimed to be working at this time. It apparently sat in the corner of this CSU workshop for 15 years until they got tired of looking at it and put it up for auction. A friend of mine bought the machine at auction. I'm helping him to try and resurrect the beast.

Its likely the "parajust" spindle controller was the cause of retirement. Not only has it been removed (didn't somebody say the machine was working?), in the documentation I have, there are quite a few notes probably made by some technician trying to fix the thing. And probably they decided the parajust was defunct and given the oddball Hurco controller, retrofitting a new VFD was out of the question.

The left side cabinet is basically a disaster zone. Parts removed, power cord totally disconnected, servo upgrade, a challenge to correlate what's there with the various schematics. I'm not hugely bothered by this. Expecting to install a new VFD. I'll figure it out.

It does look like the DC supply is powered off of 120VAC. Although with what I see in the left hand cabinet, I'm not sure where that was coming from. I need to dig more through the wiring and mystery of the transformer attached poorly to the rear of the machine. This was from the servo upgrade. I don't have any schematics on that. In the short term, if I can power the DC supply and the servos off of 120VAC, that's most convenient. My plan is to get the logic controller and servos working first. Once that's working I can move on to the spindle motor and its VFD. The ultimate goal is to power the machine off of 3 phase 440. Its likely I will need to find a new transformer(s) to generate the 120VAC and the servo drive 80 VAC.

I did find a schematic for the Hurco DC supply. Its pretty straight forward and correlates well with what I see in the right hand cabinet. I recognize the linear regulator part numbers. If I blow one up, I should be able to find a replacement.

My plan is to remove the drive belts from all the servos. This will absolutely prevent any crashing. And facilitate testing of the various limit switches and E-stop buttons. When I re-install the belts, I should have good confidence in the protection system.

Leith

Thanks again for the pics and info.

Trying to connect the dots. Various pieces of information with assorted pedigrees.

Here's a little more of the known history of the Hurco. It was owned by Lockheed/Martin. In 2005 it was donated to Colorado State University with a claimed value of $31,000. It was also claimed to be working at this time. It apparently sat in the corner of this CSU workshop for 15 years until they got tired of looking at it and put it up for auction. A friend of mine bought the machine at auction. I'm helping him to try and resurrect the beast.

Its likely the "parajust" spindle controller was the cause of retirement. Not only has it been removed (didn't somebody say the machine was working?), in the documentation I have, there are quite a few notes probably made by some technician trying to fix the thing. And probably they decided the parajust was defunct and given the oddball Hurco controller, retrofitting a new VFD was out of the question.

The left side cabinet is basically a disaster zone. Parts removed, power cord totally disconnected, servo upgrade, a challenge to correlate what's there with the various schematics. I'm not hugely bothered by this. Expecting to install a new VFD. I'll figure it out.

It does look like the DC supply is powered off of 120VAC. Although with what I see in the left hand cabinet, I'm not sure where that was coming from. I need to dig more through the wiring and mystery of the transformer attached poorly to the rear of the machine. This was from the servo upgrade. I don't have any schematics on that. In the short term, if I can power the DC supply and the servos off of 120VAC, that's most convenient. My plan is to get the logic controller and servos working first. Once that's working I can move on to the spindle motor and its VFD. The ultimate goal is to power the machine off of 3 phase 440. Its likely I will need to find a new transformer(s) to generate the 120VAC and the servo drive 80 VAC.

I did find a schematic for the Hurco DC supply. Its pretty straight forward and correlates well with what I see in the right hand cabinet. I recognize the linear regulator part numbers. If I blow one up, I should be able to find a replacement.

My plan is to remove the drive belts from all the servos. This will absolutely prevent any crashing. And facilitate testing of the various limit switches and E-stop buttons. When I re-install the belts, I should have good confidence in the protection system.

Leith

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.253 seconds