Hurco KMB-IS CNC update

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

07 Aug 2020 19:26 #177639

by CORBETT

Just realized that you stated about the single contactor in the left panel... (I have too much going on with work and missing some things on replies)

Ok let's assume they did change up the wiring and the transformer off the back is the servo trans and not the step-down.

I still have my doubts and think that big one is a step-down, but lets say its the servo transformer. They may have it where the wiring goes from the max 430s to the big brown trans hanging off the back and then into the left cabinet to the contactor. You could also look at the contactor and see if it is going to the transformer. Since there is only one contactor, lets assume they are using it for the servo amp (ACC contactor on schematic) and that there was NO flood coolant pump option.

In fact, while typing that it just hit me that seems like the flood coolant is a option and you may not even have had that contactor ever in the machine. Yours may not have had flood coolant, but mist coolant only. I will go back and check my paperwork later tomorrow and check to see if it was an option or standard... almost positive it was option now that I think about it and I may have been miss-guiding you on saying 2 contactors. (See how easy it is to get miss information LOL)

So I would trace and see if this may be how it was wired at the end. I am sure Hurco originally had the contactor in the right cabinet, but once again you are coming behind someone and need to keep it in mind.

I keep thinking everything is correct from Hurco. But I need to stop assuming and start thinking like the shop manager who had their plumber or carpenter re-wired it for them LOL.

Talk to you later,

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

Just realized that you stated about the single contactor in the left panel... (I have too much going on with work and missing some things on replies)

Ok let's assume they did change up the wiring and the transformer off the back is the servo trans and not the step-down.

I still have my doubts and think that big one is a step-down, but lets say its the servo transformer. They may have it where the wiring goes from the max 430s to the big brown trans hanging off the back and then into the left cabinet to the contactor. You could also look at the contactor and see if it is going to the transformer. Since there is only one contactor, lets assume they are using it for the servo amp (ACC contactor on schematic) and that there was NO flood coolant pump option.

In fact, while typing that it just hit me that seems like the flood coolant is a option and you may not even have had that contactor ever in the machine. Yours may not have had flood coolant, but mist coolant only. I will go back and check my paperwork later tomorrow and check to see if it was an option or standard... almost positive it was option now that I think about it and I may have been miss-guiding you on saying 2 contactors. (See how easy it is to get miss information LOL)

So I would trace and see if this may be how it was wired at the end. I am sure Hurco originally had the contactor in the right cabinet, but once again you are coming behind someone and need to keep it in mind.

I keep thinking everything is correct from Hurco. But I need to stop assuming and start thinking like the shop manager who had their plumber or carpenter re-wired it for them LOL.

Talk to you later,

Robert

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

07 Aug 2020 21:58 #177659

by CORBETT

Leith,

There is one thing good that has came out of this for me....

They would have hung that large transformer off the back of your machine to get good airflow, plus it was probably not the same size as OEM and would not fit wherever the OEM was located. So it's a good possibility size is what made them put it back there. Someone above them or the procurement person was told to get a transformer. So they got the cheapest thing available and when it came in began the debacle of where to mount it. Of course, all speculation, but I have seen this slow train wreck happen before in other machines.

Ok for me, because of checking out that back cabinet that is sealed made me realize I need to go check out that fan that is directly below the transformer. I need to keep a eye on it and I am probably going to add a thermistor to the cabinet and monitor through LCNC to shunt the amp if temperature spikes. I will either get the correct EtherCAT terminal for the thermistor or wire it into a input like a E-stop to simply shunt the amps.

To be honest, it would have never come across my mind, but when I was looking at the pictures again it hit me about temperature when I saw the fan. You may have saved me from a burn out down the road

I will be back,

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

There is one thing good that has came out of this for me....

They would have hung that large transformer off the back of your machine to get good airflow, plus it was probably not the same size as OEM and would not fit wherever the OEM was located. So it's a good possibility size is what made them put it back there. Someone above them or the procurement person was told to get a transformer. So they got the cheapest thing available and when it came in began the debacle of where to mount it. Of course, all speculation, but I have seen this slow train wreck happen before in other machines.

Ok for me, because of checking out that back cabinet that is sealed made me realize I need to go check out that fan that is directly below the transformer. I need to keep a eye on it and I am probably going to add a thermistor to the cabinet and monitor through LCNC to shunt the amp if temperature spikes. I will either get the correct EtherCAT terminal for the thermistor or wire it into a input like a E-stop to simply shunt the amps.

To be honest, it would have never come across my mind, but when I was looking at the pictures again it hit me about temperature when I saw the fan. You may have saved me from a burn out down the road

I will be back,

Robert

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

08 Aug 2020 22:37 #177720

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

There is the DC supply transformer. Which appears to have been moved to improve cooling. I have a schematic and all make sense.

The serial number label on the machine says 220V 3 phase. The quill motor is 3 phase 220 or 440. OK.

Now I need 120VAC input for the DC supply transformer and ~80VAC for the servo drives.

I think there is only one more transformer. The brown one mounted on the back. It looks like there is a single pair of input wires and a single pair of output wires.

The brown transformer is relatively large, but only about 1/3 of its volume is windings/core. The top and bottom thirds are empty. I think the top and bottom serve to help cool the core.

I've got one transformer, but I need two. Perhaps there was another that was removed? Don't know.

Probably the best way to solve the mystery is trace the wires. Where do the servo drive AC input go? Where does the 120 VAC input for the DC supply go?

Seems like I'm missing a transformer. We'll see.

The serial number label on the machine says 220V 3 phase. The quill motor is 3 phase 220 or 440. OK.

Now I need 120VAC input for the DC supply transformer and ~80VAC for the servo drives.

I think there is only one more transformer. The brown one mounted on the back. It looks like there is a single pair of input wires and a single pair of output wires.

The brown transformer is relatively large, but only about 1/3 of its volume is windings/core. The top and bottom thirds are empty. I think the top and bottom serve to help cool the core.

I've got one transformer, but I need two. Perhaps there was another that was removed? Don't know.

Probably the best way to solve the mystery is trace the wires. Where do the servo drive AC input go? Where does the 120 VAC input for the DC supply go?

Seems like I'm missing a transformer. We'll see.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21318

- Thank you received: 7279

09 Aug 2020 08:25 #177737

by tommylight

Replied by tommylight on topic Hurco KMB-IS CNC update

That might be a choke/line filter/current limiter.The brown transformer is relatively large, but only about 1/3 of its volume is windings/core. The top and bottom thirds are empty. I think the top and bottom serve to help cool the core.

The following user(s) said Thank You: CORBETT

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

09 Aug 2020 14:54 #177754

by CORBETT

Leith,

I couldn't respond yesterday as I was too busy with work.

Tom could be correct, so keep a open mind that it could be some type of filter. Here in USA we have pretty clean power, but Hurco did have line filters on the a/c control side, so you never know what someone's intentions were. Plus you are coming behind someone and I think you said in the past that you couldn't find the tag.

But with what you described, I believe it will be the servo transformer. With two inputs and two outputs it sounds like a single phase transformer. I know there is a way to find out as you can re-wind transformers and seems like you check Ohms, but there is a way to test.

Ok I have figured out some things.....

I was laying in bed and it hit me... yours is probably the same year as mine or it could be a year newer. I am not sure what year Hurco introduced the KMB1, I believe it was 1980 but not sure. I think it only was only around for a short period of time, roughly 1980-1983. It is pretty hard to get info, but there are some guy's out there that know all of this era as they bought during Hurco's Blue phase.

Your machine is simply the manual speed control model, and mine is the programable/automatic speed control model. So with this in mind, I have given you some wrong info. You probably never had the big parajust board in the left cabinet, but a simpler set-up for just getting power to the spindle motor, most likely only a contactor to supply power to motor.

I believe there is another KMB1 schematic out there that is for your machine. I may be completely wrong on all of this, but it hit me that Hurco would not have spent money for the expensive parajust speed control board to just make a contact to the motor when a cheaper magnetic starter would work.

I am assuming your machine is the same year model as mine (1981) and they simply built a smaller head for the manual control, which they ended up implementing the "programmable" speed control in your type of head down the road (around 1984) in the KM3P model. I remember stating a few post back about they added a servo to your model to get the speed control, that actually was the KM3P model, and not on the KMB1m. A lot of things are starting to come back from memory as in the past I had read a lot of things on the internet over the yeas, with some correct, and some not but I realized that I had stated some things wrong. The KM3 is the next generation of our machine with the same smaller manual speed head like yours, but with the twin screen Ultimax control. The KM3P model would be the programmable model for automatic speed control, with the P in the KM3P being "Programmable". There is the chance that yours is just a year or two newer and that model is the morphing between mine and the KM3 style. The original KM1 is much simpler and basically like a Bridgeport mill with servo motors and a stand alone enclosure with the monitor, real basic style, but this was at the beginning of CNC Knee mill for Hurco.

I don't know this part for a fact, as this is my speculation of the KMB1 model number.... K = knee... M = mill... B = b control... 1 = model generation.

I know there was a ATC (Automatic Tool Changer) for the KMB1 as it is stated as a option, but I have never seen one ever with it on there. I have read about 2 machines that had it on them, but one guy said it was clunky to him. I believe it will be the same ATC as was on the MB1, but not sure of that at all. I don't like the look of the MB1, but it is much more rigid as its a bed mill.

Also, I did check my manual and the "Flood Coolant" was a option. So you would have not had 2 contractors, but only 1 for the servo transformer power. Totally my bad for the wrong info in the past, and once again either there is another schematic out there or your machine is a couple of years newer with a different different layout. I still think yours is basically the same year as mine, but without the parajsut board and a simpler left cabinet layout with the right cabinet being practically identical to mine. I saved a lot of schematics over the years and I will dig into what I have and try to get a answer.

In response to your last post, yes you are probably missing the step-down transformer, but when you follow the servo amp wiring you will find out about what is feeding the amps... that will be the fastest way to figure out what they did.

Also, I will still put together a line drawing on what I would do, just haven't had time yet.

Hope this clears up some miss information that I have given about the parajust board, as I believe at this point it did not have it

Will check back later

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

I couldn't respond yesterday as I was too busy with work.

Tom could be correct, so keep a open mind that it could be some type of filter. Here in USA we have pretty clean power, but Hurco did have line filters on the a/c control side, so you never know what someone's intentions were. Plus you are coming behind someone and I think you said in the past that you couldn't find the tag.

But with what you described, I believe it will be the servo transformer. With two inputs and two outputs it sounds like a single phase transformer. I know there is a way to find out as you can re-wind transformers and seems like you check Ohms, but there is a way to test.

Ok I have figured out some things.....

I was laying in bed and it hit me... yours is probably the same year as mine or it could be a year newer. I am not sure what year Hurco introduced the KMB1, I believe it was 1980 but not sure. I think it only was only around for a short period of time, roughly 1980-1983. It is pretty hard to get info, but there are some guy's out there that know all of this era as they bought during Hurco's Blue phase.

Your machine is simply the manual speed control model, and mine is the programable/automatic speed control model. So with this in mind, I have given you some wrong info. You probably never had the big parajust board in the left cabinet, but a simpler set-up for just getting power to the spindle motor, most likely only a contactor to supply power to motor.

I believe there is another KMB1 schematic out there that is for your machine. I may be completely wrong on all of this, but it hit me that Hurco would not have spent money for the expensive parajust speed control board to just make a contact to the motor when a cheaper magnetic starter would work.

I am assuming your machine is the same year model as mine (1981) and they simply built a smaller head for the manual control, which they ended up implementing the "programmable" speed control in your type of head down the road (around 1984) in the KM3P model. I remember stating a few post back about they added a servo to your model to get the speed control, that actually was the KM3P model, and not on the KMB1m. A lot of things are starting to come back from memory as in the past I had read a lot of things on the internet over the yeas, with some correct, and some not but I realized that I had stated some things wrong. The KM3 is the next generation of our machine with the same smaller manual speed head like yours, but with the twin screen Ultimax control. The KM3P model would be the programmable model for automatic speed control, with the P in the KM3P being "Programmable". There is the chance that yours is just a year or two newer and that model is the morphing between mine and the KM3 style. The original KM1 is much simpler and basically like a Bridgeport mill with servo motors and a stand alone enclosure with the monitor, real basic style, but this was at the beginning of CNC Knee mill for Hurco.

I don't know this part for a fact, as this is my speculation of the KMB1 model number.... K = knee... M = mill... B = b control... 1 = model generation.

I know there was a ATC (Automatic Tool Changer) for the KMB1 as it is stated as a option, but I have never seen one ever with it on there. I have read about 2 machines that had it on them, but one guy said it was clunky to him. I believe it will be the same ATC as was on the MB1, but not sure of that at all. I don't like the look of the MB1, but it is much more rigid as its a bed mill.

Also, I did check my manual and the "Flood Coolant" was a option. So you would have not had 2 contractors, but only 1 for the servo transformer power. Totally my bad for the wrong info in the past, and once again either there is another schematic out there or your machine is a couple of years newer with a different different layout. I still think yours is basically the same year as mine, but without the parajsut board and a simpler left cabinet layout with the right cabinet being practically identical to mine. I saved a lot of schematics over the years and I will dig into what I have and try to get a answer.

In response to your last post, yes you are probably missing the step-down transformer, but when you follow the servo amp wiring you will find out about what is feeding the amps... that will be the fastest way to figure out what they did.

Also, I will still put together a line drawing on what I would do, just haven't had time yet.

Hope this clears up some miss information that I have given about the parajust board, as I believe at this point it did not have it

Will check back later

Robert

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

09 Aug 2020 15:37 #177758

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

The documentation that came with the machine includes parajust documentation. There are quite a few notes on the parajust documentation. My assumption is somebody tried to fix the parajust.

And, it looks like there is a spot in the LH cabinet for the parajust. I think the machine was originally equipped with the parajust.

The compressed air regulator is missing. The main power disconnect is also missing. Kinda strange and not likely to be related to the missing parajust. My guess is this machine broke down and then became the parts donor machine. I've worked as a maintenance technician in industrial shops. This is what happens in the real world.

Like I said earlier, the LH cabinet pretty much a disaster zone. Things are missing. I'm not so bothered by this. Given we have the schematics, I think I can figure out how to put things back in workable order.

And, it looks like there is a spot in the LH cabinet for the parajust. I think the machine was originally equipped with the parajust.

The compressed air regulator is missing. The main power disconnect is also missing. Kinda strange and not likely to be related to the missing parajust. My guess is this machine broke down and then became the parts donor machine. I've worked as a maintenance technician in industrial shops. This is what happens in the real world.

Like I said earlier, the LH cabinet pretty much a disaster zone. Things are missing. I'm not so bothered by this. Given we have the schematics, I think I can figure out how to put things back in workable order.

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

09 Aug 2020 16:45 #177762

by CORBETT

Leith,

Ok well yeah if you have the documentation, then it must have came with it for sure. It's just odd they would add the speed control board with a manual head, unless they were trying to keep continuity for diagnosis and repair.

Yeah I agree completely with you in the real world about a machine becoming the donor. We have worked in most of the major factories here in Georgia and Florida (not to mention other states) for all the different industries and have definitely seen first hand how companies will hobble along and gut one machine to fix two. Money dictates that more than anything.

I was simply stating in the past that I think Lockheed keeps them in pretty good shape and not as prone to gutting like most places. The person I dealt with at Lockheed told me any machine on the floor would be fully operational and if not operational would be locked out and repaired very quickly. I had questioned him when I got there as we had bough 3 machines sight unseen and I am always cautious when we do any purchase.... but after he took me on the floor and showed me their setup, I was not hesitant at all. I was super impressed with this facility as it was very nice equipment and where I would want to work if I was a full time machinist. I was lucky to get the grand tour, of all the factories I have seen I liked this one.

With that said, obviously every facility is different and maybe they did do some gutting, even could have been the riggers that took the machine out of Lockheed... we will never know LOL.

Ok so are you in good shape with everything and not needing anything else at the moment? Don't want to inundate you with info if you don't need or want.

I can still get things together if you want or need, like the manual and whatever other schematics you might need. Let know and I will help you out the best I can.

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Ok well yeah if you have the documentation, then it must have came with it for sure. It's just odd they would add the speed control board with a manual head, unless they were trying to keep continuity for diagnosis and repair.

Yeah I agree completely with you in the real world about a machine becoming the donor. We have worked in most of the major factories here in Georgia and Florida (not to mention other states) for all the different industries and have definitely seen first hand how companies will hobble along and gut one machine to fix two. Money dictates that more than anything.

I was simply stating in the past that I think Lockheed keeps them in pretty good shape and not as prone to gutting like most places. The person I dealt with at Lockheed told me any machine on the floor would be fully operational and if not operational would be locked out and repaired very quickly. I had questioned him when I got there as we had bough 3 machines sight unseen and I am always cautious when we do any purchase.... but after he took me on the floor and showed me their setup, I was not hesitant at all. I was super impressed with this facility as it was very nice equipment and where I would want to work if I was a full time machinist. I was lucky to get the grand tour, of all the factories I have seen I liked this one.

With that said, obviously every facility is different and maybe they did do some gutting, even could have been the riggers that took the machine out of Lockheed... we will never know LOL.

Ok so are you in good shape with everything and not needing anything else at the moment? Don't want to inundate you with info if you don't need or want.

I can still get things together if you want or need, like the manual and whatever other schematics you might need. Let know and I will help you out the best I can.

Robert

Please Log in or Create an account to join the conversation.

- _big_

- Offline

- Premium Member

-

Less

More

- Posts: 87

- Thank you received: 13

09 Aug 2020 17:57 #177767

by _big_

Replied by _big_ on topic Hurco KMB-IS CNC update

Hi Robert,

First of all, thanks for all your help. You've helped me understand the Hurco far faster than I would have ever been able to do on my own.

The next thing that needs to happen is to move the Hurco somewhere where I can really work on it. The owner was out of town last week. He's the guy with the capability to move The Beast. I don't know what his schedule is, but he's a pretty guy.

Hang tight. Once I get this thing in a place where I can really work on it, I'm sure there will be more questions.

Leith

First of all, thanks for all your help. You've helped me understand the Hurco far faster than I would have ever been able to do on my own.

The next thing that needs to happen is to move the Hurco somewhere where I can really work on it. The owner was out of town last week. He's the guy with the capability to move The Beast. I don't know what his schedule is, but he's a pretty guy.

Hang tight. Once I get this thing in a place where I can really work on it, I'm sure there will be more questions.

Leith

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

09 Aug 2020 19:02 #177771

by CORBETT

Leith,

Not a problem.. I know how hard it is to find info, just didn't want to become a burden.

Yeah definitely need it moved where you can work on it, but I know how that can be with someone else involved. Especially moving a machine with someone that may not like to get dirty LOL. Me or my Father usually take charge as only one idiot needs to be in control, not both of us idiots LOL.

But yeah I will keep looking through my info, and try to get some things up over time. I have my parents isolated because of the virus as both of them are recovering from cancer, so I cannot go in their house. I unfortunately have all of the main manuals, electrical schematics, and the parts manuals there. I will get my Dad to get them or either scan them over time and get you copies. The machine parts manual is super valuable to me. I am big on figuring out how it came apart with the manual before taking apart to keep from damaging anything. Parts are expensive and I try to minimize damage from my stupidity LOL. Most things are pretty much cut and dry and don't need the manual as you can see what to do, but there are a few things that do help to see before disassembly. I know yours has a different head, but the base should be about the same.

Plus over time, maybe someone will chime in that has the exact machine. Someone out there has to know about your machine, as there are shops out there that got them back going with Mesa or Pico. Pete Wallace (PCW) probably knows someone that has one of these exact models, as some were done using Mesa for sure. Plus there has to be a die hard blue guy out there somewhere.

I will be watching for when you get ready... time is not a problem, wish I had more of it.

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Not a problem.. I know how hard it is to find info, just didn't want to become a burden.

Yeah definitely need it moved where you can work on it, but I know how that can be with someone else involved. Especially moving a machine with someone that may not like to get dirty LOL. Me or my Father usually take charge as only one idiot needs to be in control, not both of us idiots LOL.

But yeah I will keep looking through my info, and try to get some things up over time. I have my parents isolated because of the virus as both of them are recovering from cancer, so I cannot go in their house. I unfortunately have all of the main manuals, electrical schematics, and the parts manuals there. I will get my Dad to get them or either scan them over time and get you copies. The machine parts manual is super valuable to me. I am big on figuring out how it came apart with the manual before taking apart to keep from damaging anything. Parts are expensive and I try to minimize damage from my stupidity LOL. Most things are pretty much cut and dry and don't need the manual as you can see what to do, but there are a few things that do help to see before disassembly. I know yours has a different head, but the base should be about the same.

Plus over time, maybe someone will chime in that has the exact machine. Someone out there has to know about your machine, as there are shops out there that got them back going with Mesa or Pico. Pete Wallace (PCW) probably knows someone that has one of these exact models, as some were done using Mesa for sure. Plus there has to be a die hard blue guy out there somewhere.

I will be watching for when you get ready... time is not a problem, wish I had more of it.

Robert

Please Log in or Create an account to join the conversation.

- CORBETT

-

- Offline

- Elite Member

-

Less

More

- Posts: 286

- Thank you received: 113

10 Aug 2020 03:50 - 10 Aug 2020 04:02 #177790

by CORBETT

Leith,

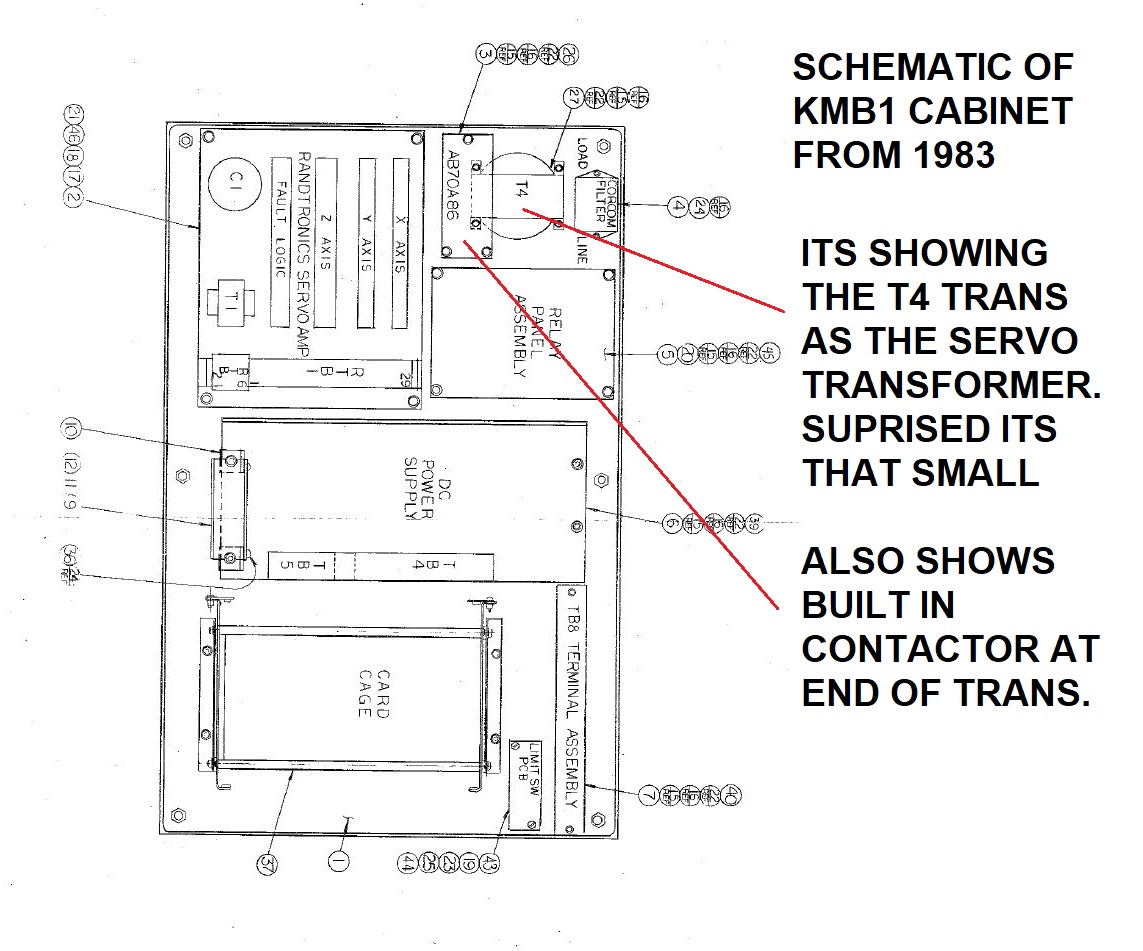

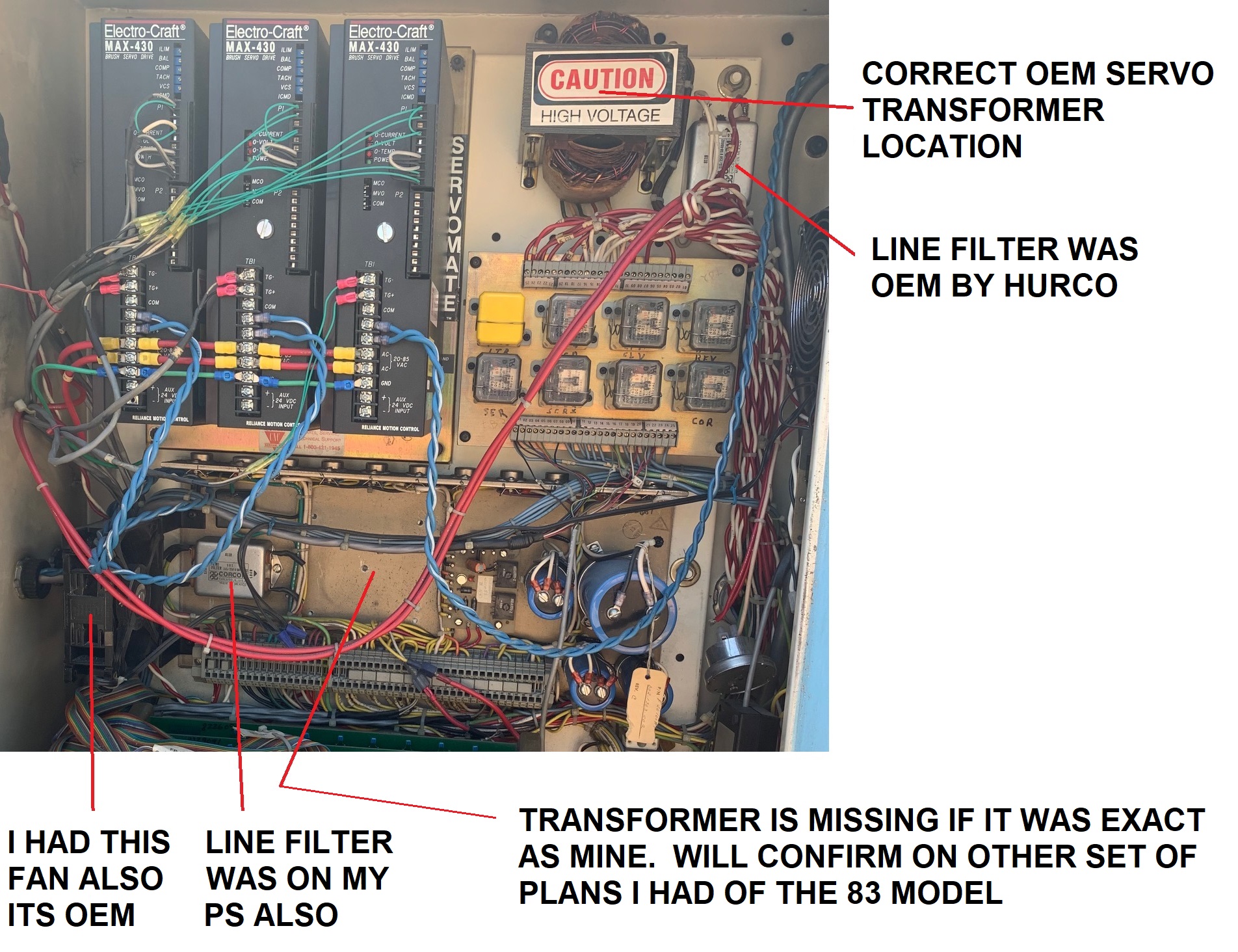

Look what I found.... looks like your layout. So yours must be around a 83 model. We were overlooking the servo transformer all along as it is much smaller for this machine. Surprised it's that small.

I can't go any further tonight as I have to get in bed for work tomorrow, have to drive up to the middle of the state. I will be back tomorrow night, probably pretty late.

Anyway, something to look at until I can get Hurco part numbers to confirm everything.

Will be back tomorrow,

Robert

Replied by CORBETT on topic Hurco KMB-IS CNC update

Leith,

Look what I found.... looks like your layout. So yours must be around a 83 model. We were overlooking the servo transformer all along as it is much smaller for this machine. Surprised it's that small.

I can't go any further tonight as I have to get in bed for work tomorrow, have to drive up to the middle of the state. I will be back tomorrow night, probably pretty late.

Anyway, something to look at until I can get Hurco part numbers to confirm everything.

Will be back tomorrow,

Robert

Attachments:

Last edit: 10 Aug 2020 04:02 by CORBETT. Reason: ADDED REAL PIC OF CONTROLLER

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.135 seconds