THCAD-10 + hypertherm 45 (nonXP)

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

23 Sep 2017 14:02 #99335

by robertspark

Hi Rod, thanks for your reply,

Yes it will be... Sort of... It should not however be so pronounced as to make a 50:1 voltage divider into a 75:1 voltage divider

Looking at the math...

The voltage divider is basically 2 resistors... A high resistance (plus power rated) one and a low resistance one (of nominal power rating)... The relationship is 50:1.... So two standard resistance values are selected that have that ratio relationship

In my case with the pmx45, hypertherm chose a 100k and a 2k resistor... Wired in series...

So total resistance is 102k ohm.

350v / 102k = 3.431 mA of current flow

Therefore the voltage across the resistors will be 3.431mA X 100k and 3.431mA X 2k, which will be 343.137 volts and 6.863volts

This is presuming that there are not external impedances .....

Add in the THCAD-10 across the 50:1 output, we now have a 100K resistor in parallel with the 2K voltage divider resistor

Hence the combined resistance in parallel is calculated as 1 / (1 / 100K + 1 / 2K) .... so the 2K resistance actually becomes ~ 1960.784 ohms [note we're not considering resistance tolerances that may vary this number, just the pure lab condition laser trimmed / text book resistances]

So our voltage divider is now 100K+1960.784 ohms, so our current flow is 3.433mA, so the voltage across the 100K resistor becomes 343.269V and across out parallel resistor arrangement (2K+100K) becomes 6.730 Volts

So our "divided" voltage output becomes closer to 50.999:1 (100K / 1960.784) than a "pure" 50:1 (100K / 2K) divided output.

Couple of caveats ...... If your voltage divider uses something greater than a 2K + 100K resistor combination (say 20K + 1M ohm) then the effect of the 100K parallel resistance will become greater [6:1 voltage divider, and not a 50:1!] (but the noise in your signal may also become more pronounced .... because you're not got very much current flowing through your voltage divider hence it becomes easier to effect a 340uA current with noise than a 3.4mA signal .... and bear in mind that this "maximum" current flow does not occur when the machine is cutting .... as its the open circuit voltage (and of no use to us really inTHC) when our cutting range (+THC tracking range [whether target setpoint / sample and hold ] operation) is 90~150V (1/4 to 1/2 of the current flow i.e. easier to affect with noise and interference)

Rob

Replied by robertspark on topic THCAD-10 + hypertherm 45 (nonXP)

I found the plasma voltage divider resistors were counted by the THCAD as being part of the scaling resistor so my 50:1 divider became 75:1.

Hi Rod, thanks for your reply,

Yes it will be... Sort of... It should not however be so pronounced as to make a 50:1 voltage divider into a 75:1 voltage divider

Looking at the math...

The voltage divider is basically 2 resistors... A high resistance (plus power rated) one and a low resistance one (of nominal power rating)... The relationship is 50:1.... So two standard resistance values are selected that have that ratio relationship

In my case with the pmx45, hypertherm chose a 100k and a 2k resistor... Wired in series...

So total resistance is 102k ohm.

350v / 102k = 3.431 mA of current flow

Therefore the voltage across the resistors will be 3.431mA X 100k and 3.431mA X 2k, which will be 343.137 volts and 6.863volts

This is presuming that there are not external impedances .....

Add in the THCAD-10 across the 50:1 output, we now have a 100K resistor in parallel with the 2K voltage divider resistor

Hence the combined resistance in parallel is calculated as 1 / (1 / 100K + 1 / 2K) .... so the 2K resistance actually becomes ~ 1960.784 ohms [note we're not considering resistance tolerances that may vary this number, just the pure lab condition laser trimmed / text book resistances]

So our voltage divider is now 100K+1960.784 ohms, so our current flow is 3.433mA, so the voltage across the 100K resistor becomes 343.269V and across out parallel resistor arrangement (2K+100K) becomes 6.730 Volts

So our "divided" voltage output becomes closer to 50.999:1 (100K / 1960.784) than a "pure" 50:1 (100K / 2K) divided output.

Couple of caveats ...... If your voltage divider uses something greater than a 2K + 100K resistor combination (say 20K + 1M ohm) then the effect of the 100K parallel resistance will become greater [6:1 voltage divider, and not a 50:1!] (but the noise in your signal may also become more pronounced .... because you're not got very much current flowing through your voltage divider hence it becomes easier to effect a 340uA current with noise than a 3.4mA signal .... and bear in mind that this "maximum" current flow does not occur when the machine is cutting .... as its the open circuit voltage (and of no use to us really inTHC) when our cutting range (+THC tracking range [whether target setpoint / sample and hold ] operation) is 90~150V (1/4 to 1/2 of the current flow i.e. easier to affect with noise and interference)

Rob

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19767

- Thank you received: 4589

03 Oct 2017 15:47 #99818

by andypugh

Replied by andypugh on topic THCAD-10 + hypertherm 45 (nonXP)

Bear in mind that the _actual_ voltage isn't that critical as long as you know that your machine cuts material A best at a setting of "100 Rob Units" all is well.

Please Log in or Create an account to join the conversation.

- cruzinone

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 0

03 Oct 2017 16:09 #99820

by cruzinone

Replied by cruzinone on topic THCAD-10 + hypertherm 45 (nonXP)

Im in the process of setting up the thcad-10 as well. I ordered a cable from hyper therm and have to pick it up today.

Can I just hook up the cable to the pm45 and the other ends on to the thcad card and 7i76. Or do I need to add resistors like this? thanks for all the help guys.

Can I just hook up the cable to the pm45 and the other ends on to the thcad card and 7i76. Or do I need to add resistors like this? thanks for all the help guys.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

03 Oct 2017 18:09 #99827

by robertspark

Replied by robertspark on topic THCAD-10 + hypertherm 45 (nonXP)

Hello, you don't need resistors, you can just hook it up.

The above was a specific discussion about improving resolution (or at least the possibility of attempting to do that)

Rob

The above was a specific discussion about improving resolution (or at least the possibility of attempting to do that)

Rob

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

03 Oct 2017 18:18 #99828

by robertspark

Yes that is correct, the numbers don't mean much really

I have a neuron lite thc and that can both use a "setpoint" and "sample + hold"

The sample and hold works on the principle of torch fires, arc stabalizers, arcOK signal goes active, pierce delay active, after pierce delay, torch decends to cut height and motion begins (THC is locked, no up or down movement) and after a thc delay period (to allow the voltage to stabalize ), the neuron samples the voltage and tracks that voltage whatever it is until the end of the cut.

Rob

Replied by robertspark on topic THCAD-10 + hypertherm 45 (nonXP)

Bear in mind that the _actual_ voltage isn't that critical as long as you know that your machine cuts material A best at a setting of "100 Rob Units" all is well.

Yes that is correct, the numbers don't mean much really

I have a neuron lite thc and that can both use a "setpoint" and "sample + hold"

The sample and hold works on the principle of torch fires, arc stabalizers, arcOK signal goes active, pierce delay active, after pierce delay, torch decends to cut height and motion begins (THC is locked, no up or down movement) and after a thc delay period (to allow the voltage to stabalize ), the neuron samples the voltage and tracks that voltage whatever it is until the end of the cut.

Rob

Please Log in or Create an account to join the conversation.

- skunkworks

- Offline

- Moderator

-

Less

More

- Posts: 349

- Thank you received: 152

03 Oct 2017 18:23 #99829

by skunkworks

Replied by skunkworks on topic THCAD-10 + hypertherm 45 (nonXP)

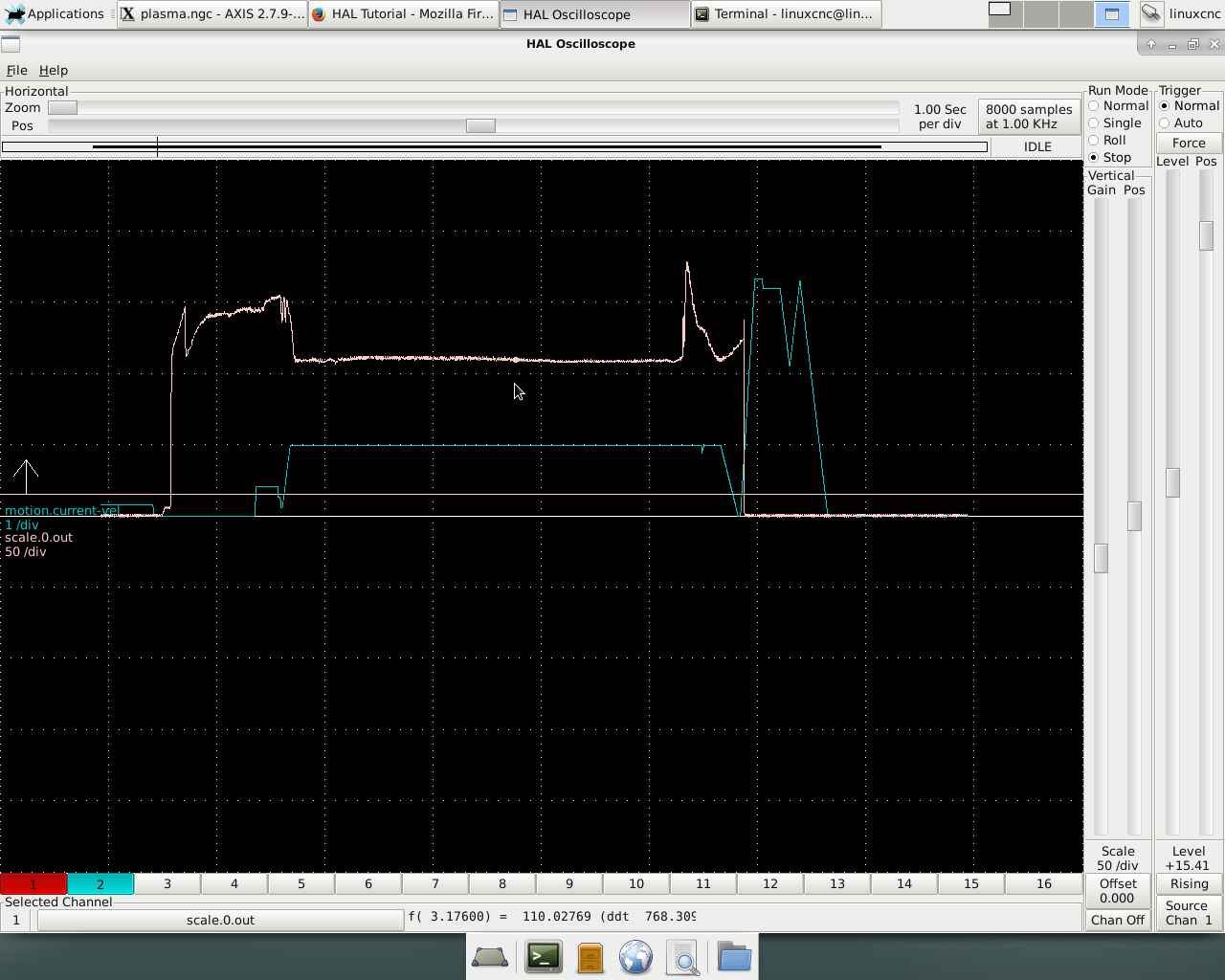

Here is the THCAD-10 hooked to a hypertherm 45. (making a 1 inch square without thc yet.) Just playing around. The voltage is scaled and offset using a single scale component in hal. The left is the pierce - the right is overlapping cut. The middle keeps a pretty consistent voltage on a flat piece of metal - 1/4 thick steel. first couple cuts.. (what ever the hypertherm book said - about 60ipm)

Just getting a feel for plasma cutting - I have run systems - first time setting up.

Just getting a feel for plasma cutting - I have run systems - first time setting up.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

03 Oct 2017 18:31 #99830

by robertspark

Replied by robertspark on topic THCAD-10 + hypertherm 45 (nonXP)

Nice,

Please Log in or Create an account to join the conversation.

- skunkworks

- Offline

- Moderator

-

Less

More

- Posts: 349

- Thank you received: 152

03 Oct 2017 18:42 - 03 Oct 2017 18:43 #99832

by skunkworks

Replied by skunkworks on topic THCAD-10 + hypertherm 45 (nonXP)

Hmm - now you got me wondering if I am measuring actual voltage (the 100k input impedance of the thc-10 steering the 0-7v out of the hypertherm) (the 60ipm cut at 45A and 1/4 thick is showing 110ish volts)

easy enough to test - measure the voltage out of the signal unplugged from the thc-10 and compare to the plugged in.

sam

easy enough to test - measure the voltage out of the signal unplugged from the thc-10 and compare to the plugged in.

sam

Last edit: 03 Oct 2017 18:43 by skunkworks.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

03 Oct 2017 19:12 #99834

by robertspark

Replied by robertspark on topic THCAD-10 + hypertherm 45 (nonXP)

depending upon your setup + which hypertherm you have the book should provide the target voltage.

a hypertherm PMX 45 (nonXP) with sheilded consumables on 1/4" Mild Steel has a feedrate of 60ipm (quality cut), and a target voltage of 120V, upping the feedrate to 75 ipm (production) will reduce the target voltage to 116V

unsheilded consumpables in both cases feedrate remains the same, but voltage is 118V

Also are you SURE that your cut height was 0.08in?

I don't believe that the 100K input impediance of the THCAD-10 will affect the sensed voltage that much

The combined resistance of the voltage divider will be 101961 Ohm (against 102 000Ohm) [0.3% variance], also allow for the tollerance of the resistors (expect 1% to 5% [I've not checked them]) The voltage you read could be slightly out.

Suggestion,..... do a touchoff at the start of the cut, zero the torch, then modify your gcode to stop at the end of the cut and then do a probe at the end of the cut and check the cut height (you may need to move slightly of your workpiece has any top dross). the numbers should be similar (i.e. both end at zero under the probing [not got into Linuxcnc yet, presume G31?]

All you do is apply an offset within Linux CNC.

a hypertherm PMX 45 (nonXP) with sheilded consumables on 1/4" Mild Steel has a feedrate of 60ipm (quality cut), and a target voltage of 120V, upping the feedrate to 75 ipm (production) will reduce the target voltage to 116V

unsheilded consumpables in both cases feedrate remains the same, but voltage is 118V

Also are you SURE that your cut height was 0.08in?

I don't believe that the 100K input impediance of the THCAD-10 will affect the sensed voltage that much

The combined resistance of the voltage divider will be 101961 Ohm (against 102 000Ohm) [0.3% variance], also allow for the tollerance of the resistors (expect 1% to 5% [I've not checked them]) The voltage you read could be slightly out.

Suggestion,..... do a touchoff at the start of the cut, zero the torch, then modify your gcode to stop at the end of the cut and then do a probe at the end of the cut and check the cut height (you may need to move slightly of your workpiece has any top dross). the numbers should be similar (i.e. both end at zero under the probing [not got into Linuxcnc yet, presume G31?]

All you do is apply an offset within Linux CNC.

Please Log in or Create an account to join the conversation.

- robertspark

- Offline

- Platinum Member

-

Less

More

- Posts: 915

- Thank you received: 216

03 Oct 2017 19:29 #99836

by robertspark

Replied by robertspark on topic THCAD-10 + hypertherm 45 (nonXP)

I've not tried it, but there is also an option to try to use an autoleveler to correct z-axis motion for any variance between your material and your torch....

www.autoleveller.co.uk/

If you're not aware of the software it's worth a look on youtube just to be aware of it

You could use this to setup a number of calibration cuts where you log the voltage between points A-B where your machine corrects for any changes in material height by adding z axis corrections from point A - B via a set of probes between points A-B you then cut your material knowing that from points A-B with a material thickness that is unlikey to bevel / change with heat [much] you have a fairly consistent cut height...

Like I said I've not tried it (but may give it a go some time.... projects permitting....)

www.autoleveller.co.uk/

If you're not aware of the software it's worth a look on youtube just to be aware of it

You could use this to setup a number of calibration cuts where you log the voltage between points A-B where your machine corrects for any changes in material height by adding z axis corrections from point A - B via a set of probes between points A-B you then cut your material knowing that from points A-B with a material thickness that is unlikey to bevel / change with heat [much] you have a fairly consistent cut height...

Like I said I've not tried it (but may give it a go some time.... projects permitting....)

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.108 seconds