New Plasma Build

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11719

- Thank you received: 3967

05 Aug 2018 13:05 #115636

by rodw

Replied by rodw on topic New Plasma Build

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11719

- Thank you received: 3967

05 Aug 2018 13:13 #115637

by rodw

Replied by rodw on topic New Plasma Build

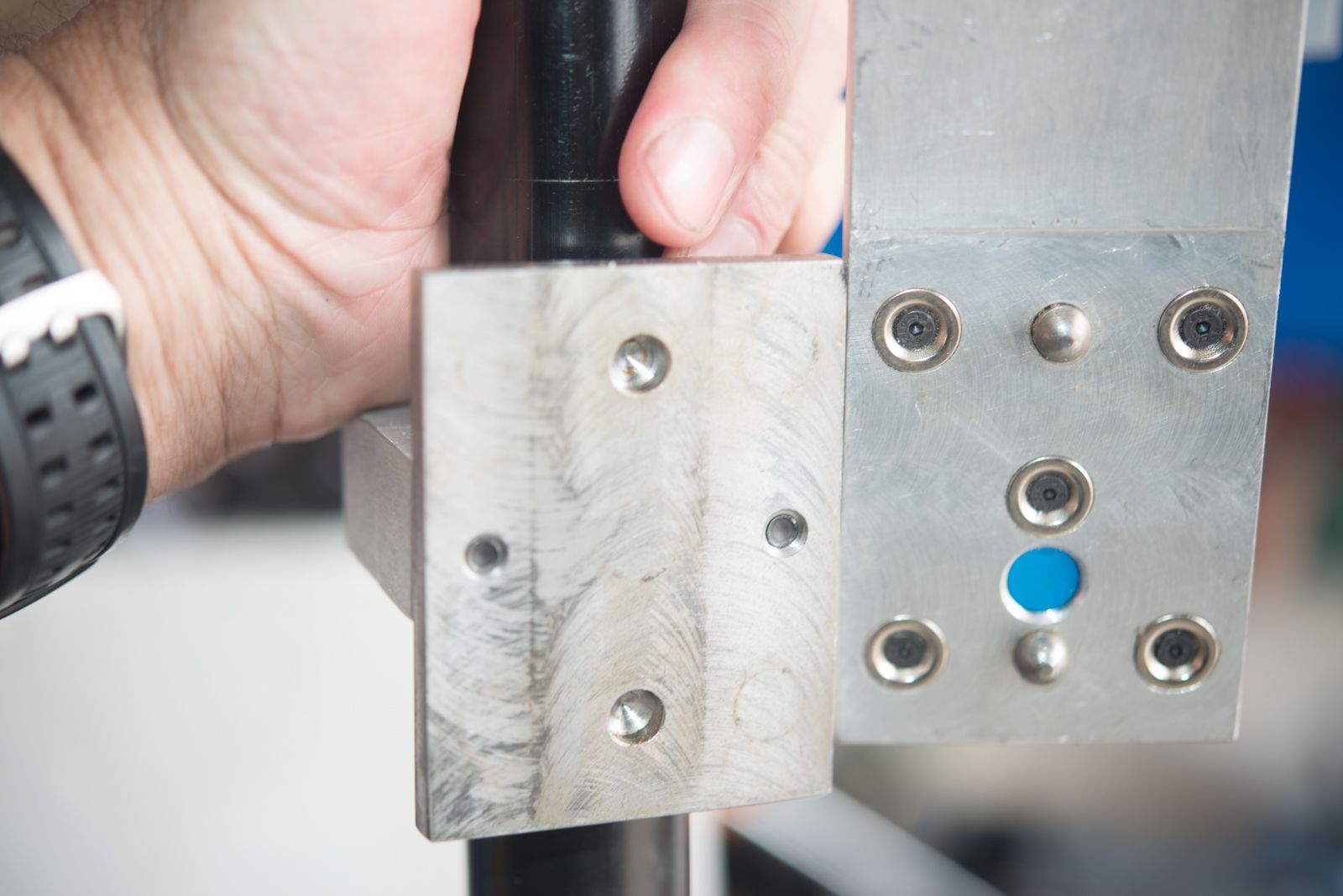

And my home made magnetic torch breakaway. MK II as the first idea failed.

Rounded dowels were machined using a ball turner on my manual lathe. Proximity sensor used as a sensor.

I think if I did it again, I'd be lazy and buy one of these snapncut.com/

Rounded dowels were machined using a ball turner on my manual lathe. Proximity sensor used as a sensor.

I think if I did it again, I'd be lazy and buy one of these snapncut.com/

Please Log in or Create an account to join the conversation.

- tecno

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1850

- Thank you received: 127

05 Aug 2018 14:07 #115639

by tecno

Replied by tecno on topic New Plasma Build

That looks good!

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

06 Aug 2018 03:38 #115663

by islander261

Replied by islander261 on topic New Plasma Build

Sorry guys I'm a bit late to the party. My floating head has about .25" of mechanical travel. The micro switch isn't adjustable leaving me with .09" of offset.

Rod

Nice looking magnetic break away. Mine is modeled after seanp's on Plasmaspiders design and works very well, I have posted photos showing it on other topics. I have a mechanical switch and it is very sensitive, a PITA sometimes but it really does save the bacon when hitting a tip up. When the switch finally dies I will replace it with a small prox switch like the HT one uses.

Just a quick refresher I used three about 12mm ball bearings for the locating features ( the old three points define a plane and on an equal lateral triangle so the sesitivity is the same from all directions) and the magnet is out of a hard drive to hold the parts together. The only points of contact are the three locating bearings ( glued to one side of the assembly).

John

Rod

Nice looking magnetic break away. Mine is modeled after seanp's on Plasmaspiders design and works very well, I have posted photos showing it on other topics. I have a mechanical switch and it is very sensitive, a PITA sometimes but it really does save the bacon when hitting a tip up. When the switch finally dies I will replace it with a small prox switch like the HT one uses.

Just a quick refresher I used three about 12mm ball bearings for the locating features ( the old three points define a plane and on an equal lateral triangle so the sesitivity is the same from all directions) and the magnet is out of a hard drive to hold the parts together. The only points of contact are the three locating bearings ( glued to one side of the assembly).

John

Please Log in or Create an account to join the conversation.

- bevins

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

07 Aug 2018 02:57 #115715

by bevins

Replied by bevins on topic New Plasma Build

Floating Z axis for plasma head.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

14 Aug 2018 12:29 #116042

by andypugh

Replied by andypugh on topic New Plasma Build

Catching up...

An option for a floating Z might be leaf-spring suspension. A pair of leaves top and bottom should hold a torch in place repeatedly. No wear parts and nothing to get fouled by grit.

For extra fun you can strain-gauge the flexures as the sensing element.

This isn't entirely my idea, it's based on the Z-height adjusters of a set of machines I used to work on, used to set strikers sub-micron distances above chip wafers to mechanically test bonds .

I wonder if magnetic handbag clasps could be used for a break-away system? I bought some for a project and they do give the impression that they "want" to be used for this sort of task, if mounted in triples.

An option for a floating Z might be leaf-spring suspension. A pair of leaves top and bottom should hold a torch in place repeatedly. No wear parts and nothing to get fouled by grit.

For extra fun you can strain-gauge the flexures as the sensing element.

This isn't entirely my idea, it's based on the Z-height adjusters of a set of machines I used to work on, used to set strikers sub-micron distances above chip wafers to mechanically test bonds .

I wonder if magnetic handbag clasps could be used for a break-away system? I bought some for a project and they do give the impression that they "want" to be used for this sort of task, if mounted in triples.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

24 Jul 2019 17:33 #140441

by Clive S

John . I have just come across this do you have a link to the photo's of it. How are the ball bearings mounted?

Thanks

Replied by Clive S on topic New Plasma Build

Sorry guys I'm a bit late to the party. My floating head has about .25" of mechanical travel. The micro switch isn't adjustable leaving me with .09" of offset.

Rod

Nice looking magnetic break away. Mine is modeled after seanp's on Plasmaspiders design and works very well, I have posted photos showing it on other topics. I have a mechanical switch and it is very sensitive, a PITA sometimes but it really does save the bacon when hitting a tip up. When the switch finally dies I will replace it with a small prox switch like the HT one uses.

Just a quick refresher I used three about 12mm ball bearings for the locating features ( the old three points define a plane and on an equal lateral triangle so the sesitivity is the same from all directions) and the magnet is out of a hard drive to hold the parts together. The only points of contact are the three locating bearings ( glued to one side of the assembly).

John

John . I have just come across this do you have a link to the photo's of it. How are the ball bearings mounted?

Thanks

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

24 Jul 2019 20:05 #140466

by islander261

Replied by islander261 on topic New Plasma Build

The bearing balls are glued in with JB Weld on my version of this which is closer to Sean's Mk1 design.

www.plasmaspider.com/viewtopic.php?f=103...499&p=152510#p152510

www.plasmaspider.com/viewtopic.php?f=103...279&p=117983#p117983

John

www.plasmaspider.com/viewtopic.php?f=103...499&p=152510#p152510

www.plasmaspider.com/viewtopic.php?f=103...279&p=117983#p117983

John

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11719

- Thank you received: 3967

24 Jul 2019 22:45 #140482

by rodw

Replied by rodw on topic New Plasma Build

I had to find a reason to use the ball turner I made so I machined the end of a dowel (which is glued in cos, I got the tolerances wrong for a press fit....

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

25 Jul 2019 07:30 #140510

by Clive S

I have a small lathe Myford S7 this is the creature that got me in to linuxcnc so I should be able to make the dowel ends. If I can work out the code.

Replied by Clive S on topic New Plasma Build

I had to find a reason to use the ball turner I made so I machined the end of a dowel (which is glued in cos, I got the tolerances wrong for a press fit....

I have a small lathe Myford S7 this is the creature that got me in to linuxcnc so I should be able to make the dowel ends. If I can work out the code.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.185 seconds