Open Source Controller with internal THC

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

08 Nov 2018 03:55 - 08 Nov 2018 03:56 #120232

by thefabricator03

Replied by thefabricator03 on topic Open Source Controller with internal THC

So what does Hypertherm, Dynatorch, Advanced Robotic Technology and all of the other large plasma manufactures know in regards to having there THC build into the software?

Why isnt this common among all plasma manufactures nowdays?

Why isnt this common among all plasma manufactures nowdays?

Last edit: 08 Nov 2018 03:56 by thefabricator03.

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11615

- Thank you received: 3908

08 Nov 2018 04:53 #120233

by rodw

Replied by rodw on topic Open Source Controller with internal THC

I think they have the cash resources to build their own. Plasma is a very specialist field for CNC controllers. Pretty sure ART

you mentioned have rebranded a commercial controller.

To really do it well, you have to have the THC tightly integrated with the CNC controller otherwise you have no idea of the current velocity and a host of other plasma related parameters. The external THC's can't do this.

Don't get me wrong, plasma has been done in Linuxcnc for quite a few years but its only the last couple of years that a few of us have really pushed the limit and tried to get that level of sophistication internal to LinuxCNC. Now all of the experimental features and development branches are almost migrated into master branch, including fixes to a few bugs in the trajectory planner we've found along the way. I personally think that external THC's that were necessary in Mach3 will become obsolete technology as the LinuxCNC plasma feature set matures.

Already users like Islander261 and a couple of others are achieving better performance and cut quality than what can be achieved with any external THC or commercial table.

you mentioned have rebranded a commercial controller.

To really do it well, you have to have the THC tightly integrated with the CNC controller otherwise you have no idea of the current velocity and a host of other plasma related parameters. The external THC's can't do this.

Don't get me wrong, plasma has been done in Linuxcnc for quite a few years but its only the last couple of years that a few of us have really pushed the limit and tried to get that level of sophistication internal to LinuxCNC. Now all of the experimental features and development branches are almost migrated into master branch, including fixes to a few bugs in the trajectory planner we've found along the way. I personally think that external THC's that were necessary in Mach3 will become obsolete technology as the LinuxCNC plasma feature set matures.

Already users like Islander261 and a couple of others are achieving better performance and cut quality than what can be achieved with any external THC or commercial table.

The following user(s) said Thank You: tommylight, dvn4life1972

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7269

- Thank you received: 2115

08 Nov 2018 07:34 #120237

by cmorley

I know it's not what you guys are talking about - but I'm pleased someone found Gscreen was useful and worked out how to make a custom screen. This was exactly what it was for yaay - ok back to your thread....

Chris M

Replied by cmorley on topic Open Source Controller with internal THC

CommandCNC is a Gscreen LinuxCNC application. It is wrapped in a proprietary launcher/configuration program so if you just get the GPL source you will need roll your own .ini and .hal files (not hard following the Gscreen examples). I have hacked it to run on my hardware (7i76e and THCad) with my internal THC.

John

I know it's not what you guys are talking about - but I'm pleased someone found Gscreen was useful and worked out how to make a custom screen. This was exactly what it was for yaay - ok back to your thread....

Chris M

The following user(s) said Thank You: tommylight, Grotius, dvn4life1972

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

08 Nov 2018 16:00 #120274

by islander261

Replied by islander261 on topic Open Source Controller with internal THC

I think the biggest problem most DIY machine builders have with THC is that we are trying doing it on wimpy poorly aligned machines and cut thinner material that is subject heat distortion and warpage using cheap imported HF start power supplies and torches. According to one Guru on this subject you need to hold the torch height within +/-.005" of the ideal cut height for best results. This is pretty easy for a stiff high powered industrial CNC machine. Actually many large industrial machines that are used to cut thicker plate don't even use active THC, they just use initial height sensing and the table mapping to adjust during the cut.

Most of the major manufactures actually use an external THC that is tightly coupled to a general purpose CNC controller so both parts know what is happening. I know that Hypertherm has all of their documentation available on their web site if you want to do a little reading.

There is a lot of good information about air plasma THC available. Look on both Plasmaspider.com and cnczone.com for posts by Jim Colt from Hypertherm, he has posted performance requirements several times at least on both sites. Mr. Caudle from CandCNC is also a frequent poster on both sites and works hard to sell his THC equipment.

LinuxCNC allows the creation of custom functions by the user. This feature has been used by many for plasma torch THC. Some have used an external controller, Proma, CandCNC, Neuron and countless Chinese knock offs. Some have used internal LinuxCNC functions as J.T., Rod W., others and I have. My system presently runs pretty well in almost daily use, I can hold +/- .0025" torch height from ideal when doing 18" test cuts on material that does heat warp during the cut. The biggest stumbling block for most DIY builders is getting the electrical engineering correct for measuring a noisy high voltage signal in real time, this actually isn't too hard now with the off the shelf hardware that is available to work with LinuxCNC. I am using a Mesa 7I76e with a THCad board and am very happy with the performance of both.

John

Most of the major manufactures actually use an external THC that is tightly coupled to a general purpose CNC controller so both parts know what is happening. I know that Hypertherm has all of their documentation available on their web site if you want to do a little reading.

There is a lot of good information about air plasma THC available. Look on both Plasmaspider.com and cnczone.com for posts by Jim Colt from Hypertherm, he has posted performance requirements several times at least on both sites. Mr. Caudle from CandCNC is also a frequent poster on both sites and works hard to sell his THC equipment.

LinuxCNC allows the creation of custom functions by the user. This feature has been used by many for plasma torch THC. Some have used an external controller, Proma, CandCNC, Neuron and countless Chinese knock offs. Some have used internal LinuxCNC functions as J.T., Rod W., others and I have. My system presently runs pretty well in almost daily use, I can hold +/- .0025" torch height from ideal when doing 18" test cuts on material that does heat warp during the cut. The biggest stumbling block for most DIY builders is getting the electrical engineering correct for measuring a noisy high voltage signal in real time, this actually isn't too hard now with the off the shelf hardware that is available to work with LinuxCNC. I am using a Mesa 7I76e with a THCad board and am very happy with the performance of both.

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11615

- Thank you received: 3908

08 Nov 2018 19:33 #120286

by rodw

John touches on the most powerful feature of Linuxcnc. The ability to write your own custom software component and embed it in the system exactly as if it was one of the standard components. Components are the building blocks of LinuxCNC's HAL, the Hardware Abstraction Layer. Components are written in C and compiled and installed by a supplied script using one command from the terminal window.

Whilst it is possible to write one single THC component as PhillC is working on, perhaps a better approach more in keeping with LinuxCNC's design philosophy is to build small discrete components for each individual function. Eg, Velocity anti dive (corner lock), Torch voltage sampling, testing to see if probing is required based on distance from the last pierce, and even triggering air solenoids for downdraft table zoning can all be written in small modules which makes it easy to maintain and debug your system. This feature makes Linuxcnc a good platform for plasma and it is rapidly maturing in this area.

Replied by rodw on topic Open Source Controller with internal THC

LinuxCNC allows the creation of custom functions by the user. This feature has been used by many for plasma torch THC.

John touches on the most powerful feature of Linuxcnc. The ability to write your own custom software component and embed it in the system exactly as if it was one of the standard components. Components are the building blocks of LinuxCNC's HAL, the Hardware Abstraction Layer. Components are written in C and compiled and installed by a supplied script using one command from the terminal window.

Whilst it is possible to write one single THC component as PhillC is working on, perhaps a better approach more in keeping with LinuxCNC's design philosophy is to build small discrete components for each individual function. Eg, Velocity anti dive (corner lock), Torch voltage sampling, testing to see if probing is required based on distance from the last pierce, and even triggering air solenoids for downdraft table zoning can all be written in small modules which makes it easy to maintain and debug your system. This feature makes Linuxcnc a good platform for plasma and it is rapidly maturing in this area.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

08 Nov 2018 22:29 - 08 Nov 2018 23:12 #120295

by Grotius

Replied by Grotius on topic Open Source Controller with internal THC

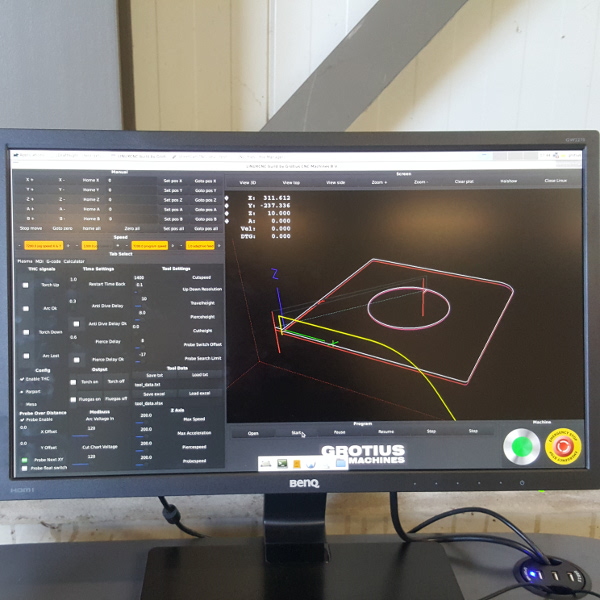

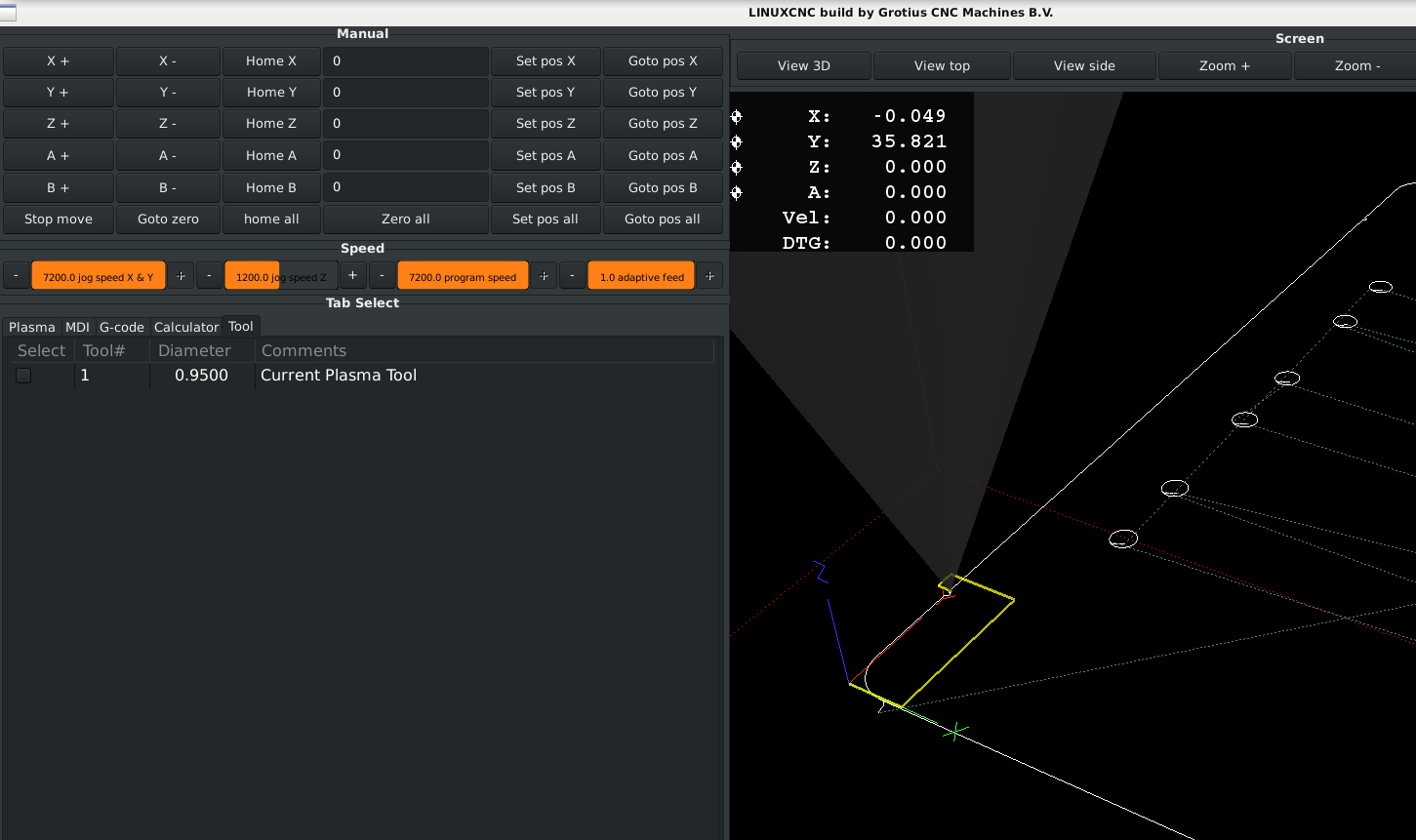

Just for info what linux is capable to, thanks to Mr. Chris Morley, for making his user interface python code.

Without his magic, it would be problably not easy to go with linuxcnc on this level.

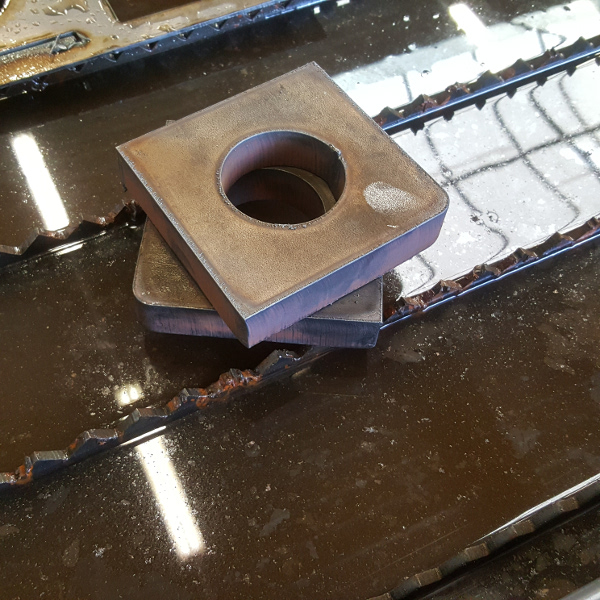

20mm steel test cut during linuxcnc training course today.

Cutted at 105 amp, with powermax 105. First cut without improvement's.

Linuxcnc plasma software application with universal thc component.

A machine that cut's, my last machine of model 2018, up next is new model 2019.

Without his magic, it would be problably not easy to go with linuxcnc on this level.

20mm steel test cut during linuxcnc training course today.

Cutted at 105 amp, with powermax 105. First cut without improvement's.

Linuxcnc plasma software application with universal thc component.

A machine that cut's, my last machine of model 2018, up next is new model 2019.

Last edit: 08 Nov 2018 23:12 by Grotius.

The following user(s) said Thank You: rodw, thefabricator03, dvn4life1972

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

09 Nov 2018 06:03 #120310

by thefabricator03

Replied by thefabricator03 on topic Open Source Controller with internal THC

Your machine looks very well built, Did you build it yourself?

With my machine using a Powermax 125 I have been able to cut 25mm plate with the same quality,

What program did you used to generate the G-code? Sheetcam?

With my machine using a Powermax 125 I have been able to cut 25mm plate with the same quality,

Attachment not found

Attachment not found

What program did you used to generate the G-code? Sheetcam?

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

09 Nov 2018 23:14 - 10 Nov 2018 00:01 #120361

by Grotius

Replied by Grotius on topic Open Source Controller with internal THC

Hi Stefan,

Thanks. Yes me is the builder.

Nice too see your picture's. Very nice output.

It's generated with sheetcam. I did some test in the past with dxf2gcode to load a dxf straight into linuxcnc without seeing the program dxf2gcode opening actually.

Tonight i did some more test's. I coupled the tool.tbl tool file within the grotius gui python code.So when we are going to use dynamic tool libraries for plasma in the future, the plasma kerf widht (tooldiameter) is actually working nice with (G40/G41/G42) to my surprise. It's has the reloading possibility without restarting Linuxcnc. Just what we need.

In other word's, we can soon do a simple way of cam processing also in linuxcnc for plasma.

What i noticed about the startpoint is, sheetcam wil allway's start at the cone point on the picture, standard. At that point there is a little press brake mark with radius 2mm. But i don't want to start at that point so i have to modify start point's each time with sheetcam. Okey dxf2gcode is starting at outside contour at a better point, without modifiying start point's. So that is nice.

Generated with dxf2gode :

I think goal of many users is open linuxcnc :

1. click button "tool library" or a button name you want to have on your screen.

2. click your way to the database (.odb file) pop up screen's, select dynamic input fields one by one, everything about the tool is set.

-- cutting chart's in odb format. ( python pluging code for acces databases, full plasma tool databases, also editable off-line )

-- the rs485 (modbus connection) to plasma inverter is set this way. ( also for standard modbus i/o module, standard plasma inverter conversion with modbuss connection. )

-- The kerf width is set this way.

-- The real time plasma THC component is set this way.

-- The G1 speed is set this way. (trick is to use this in the python code for reloading parameters of speed :

self.c.mode(self.cnc.MODE_MANUAL)

self.c.wait_complete()

self.widgets.gremlin.reloadfile(None)

The G0 speed is available in user gui. Master speed is adaptive feed -1 to 1. Feed override is set to max tuning parameters.

3. select dxf file you want to cut. (behind this, the dxf2gcode is autogenerated and loaded into linuxcnc)

4. start your machine.

Thanks. Yes me is the builder.

Nice too see your picture's. Very nice output.

It's generated with sheetcam. I did some test in the past with dxf2gcode to load a dxf straight into linuxcnc without seeing the program dxf2gcode opening actually.

Tonight i did some more test's. I coupled the tool.tbl tool file within the grotius gui python code.

self.widgets.tooledit1.set_filename("tool.tbl")

self.widgets.tooledit1.set_visible("pabcxyzuvwijq", False) #here i say, dont show too much stuff i don't useIn other word's, we can soon do a simple way of cam processing also in linuxcnc for plasma.

What i noticed about the startpoint is, sheetcam wil allway's start at the cone point on the picture, standard. At that point there is a little press brake mark with radius 2mm. But i don't want to start at that point so i have to modify start point's each time with sheetcam. Okey dxf2gcode is starting at outside contour at a better point, without modifiying start point's. So that is nice.

Generated with dxf2gode :

I think goal of many users is open linuxcnc :

1. click button "tool library" or a button name you want to have on your screen.

2. click your way to the database (.odb file) pop up screen's, select dynamic input fields one by one, everything about the tool is set.

-- cutting chart's in odb format. ( python pluging code for acces databases, full plasma tool databases, also editable off-line )

-- the rs485 (modbus connection) to plasma inverter is set this way. ( also for standard modbus i/o module, standard plasma inverter conversion with modbuss connection. )

-- The kerf width is set this way.

-- The real time plasma THC component is set this way.

-- The G1 speed is set this way. (trick is to use this in the python code for reloading parameters of speed :

self.c.mode(self.cnc.MODE_MANUAL)

self.c.wait_complete()

self.widgets.gremlin.reloadfile(None)

The G0 speed is available in user gui. Master speed is adaptive feed -1 to 1. Feed override is set to max tuning parameters.

3. select dxf file you want to cut. (behind this, the dxf2gcode is autogenerated and loaded into linuxcnc)

4. start your machine.

Last edit: 10 Nov 2018 00:01 by Grotius.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

10 Nov 2018 00:05 - 10 Nov 2018 00:48 #120365

by Grotius

Replied by Grotius on topic Open Source Controller with internal THC

Steve,

Related to your first post.

I called Hypertherm last week. They have no distribution to Australia. I have same problem in Servie with Thermal Dynamics.

So what i can do is order a hypertherm and send it to you with ups. That's the only way. I am oem hypertherm distributor.

We need to do some paper work for custom's, but that is quite easy. In this way you could set up a legal Hypertherm stock and selling point in Australia. I think I would prefer to do this relationship with Rod. He is i think the man to import this at stock at

his new wharehouse.

Also for Thermal Dynamic's Autocut 200 and Ultracut 100 - 200 HD we could do this. It would be a good idea i think to start with.

Don't forget. If you do nothing you will get nowhere.

One guy so far i know has done this. He has privat github repro's. He is also a very good c programmer. He know's how to write some code from scratch.

Better is to go with the mainstream flow at this moment.

Only reverse feed has to be merged at this moment. It was reverted the next day.

I think the german have to check some code and must check the program for working correctly very, very good...

My own repro is online for this student to check his code, after he has merged reverse adaptive feed from Rob Ellenberg, i get it offline because i am working on other thing's that are important at this moment.

Related to your first post.

I called Hypertherm last week. They have no distribution to Australia. I have same problem in Servie with Thermal Dynamics.

So what i can do is order a hypertherm and send it to you with ups. That's the only way. I am oem hypertherm distributor.

We need to do some paper work for custom's, but that is quite easy. In this way you could set up a legal Hypertherm stock and selling point in Australia. I think I would prefer to do this relationship with Rod. He is i think the man to import this at stock at

his new wharehouse.

Also for Thermal Dynamic's Autocut 200 and Ultracut 100 - 200 HD we could do this. It would be a good idea i think to start with.

Don't forget. If you do nothing you will get nowhere.

If you want to do that. You must have high level skill's. Look at TTY, that is i think used for embedded linuxcnc in the background.Where would be a good starting point for me to learn to create my own user interface that uses linuxcnc in the background.

One guy so far i know has done this. He has privat github repro's. He is also a very good c programmer. He know's how to write some code from scratch.

Better is to go with the mainstream flow at this moment.

Only reverse feed has to be merged at this moment. It was reverted the next day.

I think the german have to check some code and must check the program for working correctly very, very good...

My own repro is online for this student to check his code, after he has merged reverse adaptive feed from Rob Ellenberg, i get it offline because i am working on other thing's that are important at this moment.

Last edit: 10 Nov 2018 00:48 by Grotius.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

Topic Author

Topic Author

- Visitor

-

10 Nov 2018 02:13 #120369

by thefabricator03

Replied by thefabricator03 on topic Open Source Controller with internal THC

Basically what I want to acheive is what CandCNC have done and have a program similar to CommandCNC but has internal THC and has the ability to communicate with servo drives via ethercat or any modern field bus.

I am set on ethercat as my open source robot controllers use ethercat to control the multiple axis's in real time.And ethercat is the fastest field bus currently available.

I was speaking to a guy from Hypertherm about their controllers and he was telling me that they use ethercat for there new machines and it is necessary to use for there newer technologies such as true hole.

Do you think it would be possible to implement a open source version of Hypertherms true hole technology with linuxcnc?

Also with Linuxcnc do you think it would be possible to use Hypertherms range of high definition plasmas?

I am set on ethercat as my open source robot controllers use ethercat to control the multiple axis's in real time.And ethercat is the fastest field bus currently available.

I was speaking to a guy from Hypertherm about their controllers and he was telling me that they use ethercat for there new machines and it is necessary to use for there newer technologies such as true hole.

Do you think it would be possible to implement a open source version of Hypertherms true hole technology with linuxcnc?

Also with Linuxcnc do you think it would be possible to use Hypertherms range of high definition plasmas?

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 5.721 seconds