Inputs & outputs & relays ohmic

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11738

- Thank you received: 3973

27 Apr 2019 23:15 - 27 Apr 2019 23:16 #132130

by rodw

Replied by rodw on topic Inputs & outputs & relays ohmic

Forgot to mention the manual in the THCAD-10 explains how to calculate the resistance and shows an example for a 300 volt scale. You could probably rework this to a 200 volt scale for a 35 amp machine. The THCAD-10 will handle any overvoltage indefinitely and it would only be a brief spike when you turn the torch on but this will be within the THC on delay period so it won't matter.. But on my old 45A cutter, I never saw volts above about 150

Last edit: 27 Apr 2019 23:16 by rodw.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

28 Apr 2019 00:03 #132135

by tommylight

Replied by tommylight on topic Inputs & outputs & relays ohmic

Mount the divider inside the power source, THCAD outside of it and as far as you can given the conditions. It can be inside the electronics cabinet, but far from other electronics.

Having the divider outside the power source means having wires out that carry over 100V at 40 to 150A so a short there will make some nice fireworks.

THCAD should be mounted as Icelander did, that is the best solution, in a box somewhere in between.

As for the torch, it can not be done, meaning the straightening of the pipes, that would require removing a lot of hard plastic and the tubes are very brittle and break easily. You can just cut the hand holder part in half, that will make it much more manageable.

Oh and getting the voltage from the torch itself is never a good idea, that is where the 15000 to 20000V go to strike an arc. Voltage for the THC should be wired as close to the rectifier as possible or at the capacitor plate located nearby. That capacitor plate is what keeps the rectifier from blowing up every time the arc strikes.

This was as short as i could make it to make sense, hopefully.

Having the divider outside the power source means having wires out that carry over 100V at 40 to 150A so a short there will make some nice fireworks.

THCAD should be mounted as Icelander did, that is the best solution, in a box somewhere in between.

As for the torch, it can not be done, meaning the straightening of the pipes, that would require removing a lot of hard plastic and the tubes are very brittle and break easily. You can just cut the hand holder part in half, that will make it much more manageable.

Oh and getting the voltage from the torch itself is never a good idea, that is where the 15000 to 20000V go to strike an arc. Voltage for the THC should be wired as close to the rectifier as possible or at the capacitor plate located nearby. That capacitor plate is what keeps the rectifier from blowing up every time the arc strikes.

This was as short as i could make it to make sense, hopefully.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

28 Apr 2019 00:15 #132138

by islander261

Replied by islander261 on topic Inputs & outputs & relays ohmic

Tommy

Good thoughts on this. All your points are good.

The OP has a HT 30 so no high voltage, it is a blow back start. Yah the series inductor will cause a minor voltage spike on striking the arc but not bad because it is wired as a series inductance and not as an auto transformer with an arc lamp.

I am so glad that jumped into the LinuxCNC pond after having a couple of proprietary systems sold here. At the worst if there is a problem I can find it and fix it, no tech support telling me I must be doing some wrong because their equipment/software is perfect.

John

Good thoughts on this. All your points are good.

The OP has a HT 30 so no high voltage, it is a blow back start. Yah the series inductor will cause a minor voltage spike on striking the arc but not bad because it is wired as a series inductance and not as an auto transformer with an arc lamp.

I am so glad that jumped into the LinuxCNC pond after having a couple of proprietary systems sold here. At the worst if there is a problem I can find it and fix it, no tech support telling me I must be doing some wrong because their equipment/software is perfect.

John

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

28 Apr 2019 00:39 #132139

by tommylight

Replied by tommylight on topic Inputs & outputs & relays ohmic

I am the tech support for over 15 plasma cutters here, and some other machines, and the best thing is i get called very rarely, like really really rarely, maybe once every 2 to 3 months, even those calls get dealt with over the phone in under five minutes most times. That is a testament to the reliability of Linuxcnc.

Those are all machines that are used all day (7AM-8PM mind you) every day, not every Sunday though. Spring/Summer/Autumn there is no rest for them.

Mechanical issues get dealt with by their owners most of the time.

Those are all machines that are used all day (7AM-8PM mind you) every day, not every Sunday though. Spring/Summer/Autumn there is no rest for them.

Mechanical issues get dealt with by their owners most of the time.

Please Log in or Create an account to join the conversation.

- JTknives

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

28 Apr 2019 02:16 #132145

by JTknives

Replied by JTknives on topic Inputs & outputs & relays ohmic

I had just thought that putting the voltage devider resistors in the plasma unit would reduce the voltage coming down the line to the controller and I would not have the dangerous voltage and amps exposed in a external wire. Yeah my plasma is a 30XP so no high voltage start. What is the max arc voltage of the 30XP. I thought it was 300v but I guess I’m wrong. Thanks agian guys.

Please Log in or Create an account to join the conversation.

- JTknives

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

28 Apr 2019 02:22 #132146

by JTknives

Replied by JTknives on topic Inputs & outputs & relays ohmic

Attachments:

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

28 Apr 2019 02:33 #132147

by islander261

Replied by islander261 on topic Inputs & outputs & relays ohmic

Well I haven't taken one apart but given the way it is rated I would guess that on 120VAC input they use a voltage doubler circuit. So a full wave capacitive input power supply with 240 input has an approximate maximum output voltage of 340VDC (at arc start only). Now when the unit is cutting this will be far less around 125VDC for the usual HT air plasma voltage. I would shoot for a voltage divider in the 15:1 to 20:1 range, the THCad card is very tolerant of over voltage inputs to greater than 500V.

John

John

Please Log in or Create an account to join the conversation.

- JTknives

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 243

- Thank you received: 32

28 Apr 2019 02:45 - 28 Apr 2019 02:52 #132148

by JTknives

Replied by JTknives on topic Inputs & outputs & relays ohmic

After looking at the THCAD10 I can see how thy are picking off the voltage. Power goes in and stright back out through a cap. Then thy are picking off borh sides of these resistors and looking at the voltage compared to the ratio of the resistors up stream. So if the added resistors where just tossed inline then full voltage is still heading out down the wire. But the THCAD is only taking the voltage in the ratio of their resisters to the ones I added. If there is no added resistance then there is nothing to devide against so it reads the voltage as is. So you could technically build a voltage devider that outputs voltage to the THCAD as a max of 10v and there would only be 10v on the external wire.

But I could be completely wrong lol

But I could be completely wrong lol

Last edit: 28 Apr 2019 02:52 by JTknives.

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

28 Apr 2019 02:51 #132150

by islander261

Replied by islander261 on topic Inputs & outputs & relays ohmic

The full directions for the THCad divider are in the documentation for it. The only thing I have to add is to put 1/2 of the computed resistor value in each leg.

John

John

Please Log in or Create an account to join the conversation.

- rodw

-

- Away

- Platinum Member

-

Less

More

- Posts: 11738

- Thank you received: 3973

28 Apr 2019 04:23 #132156

by rodw

Replied by rodw on topic Inputs & outputs & relays ohmic

As long as you have resistors internally on each leg I would not be too stressed about the raw arc voltage leaving the plasma cutter as all of the machines with a CNC port do it. The resistors will take the sting out of it

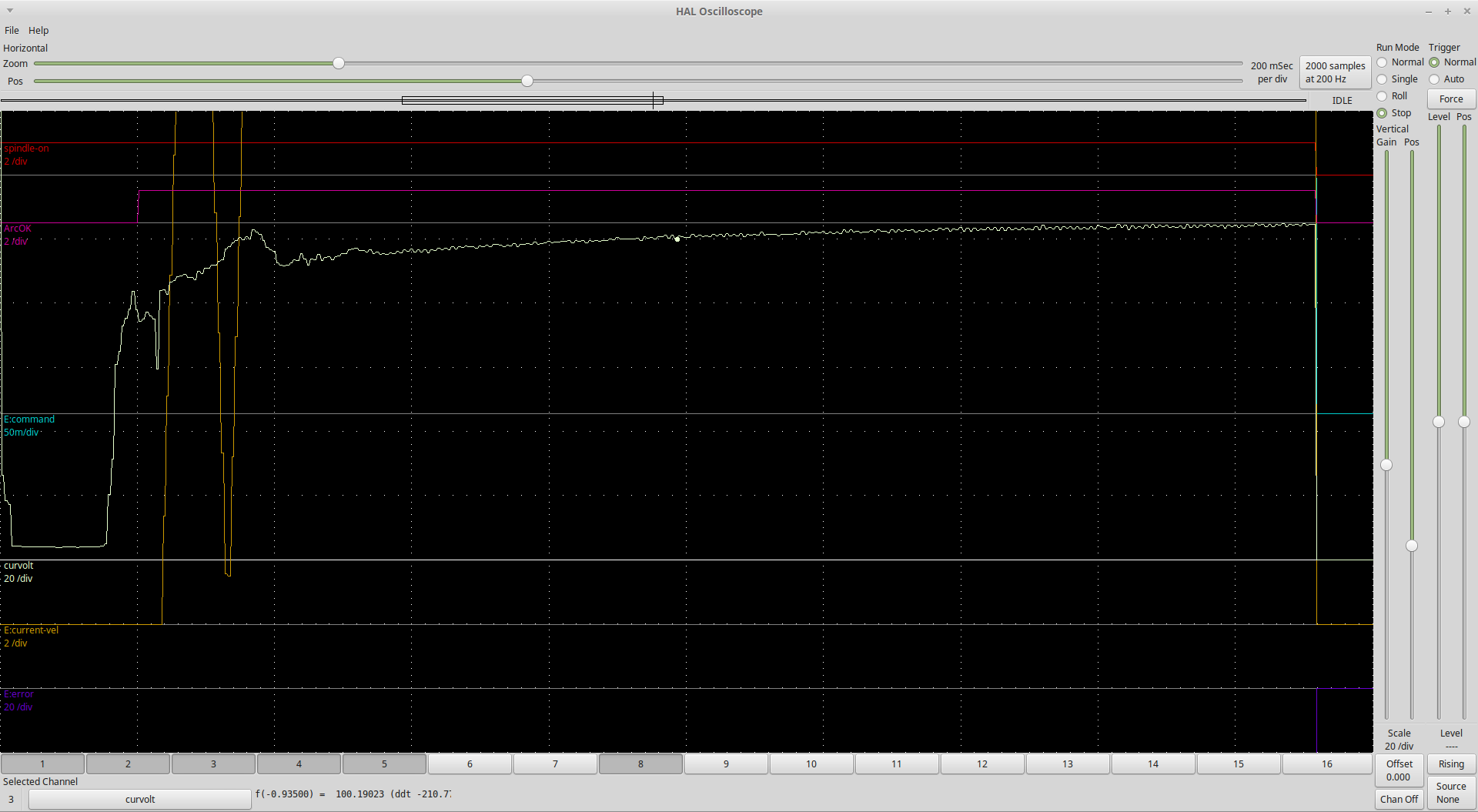

As far as arc voltage goes it seems your machine has a max voltage of 125 volts. This sounds about right to me. Here is a plot of my old 50 amp everlast machine. If you zoom in, you will see the dotted line divisions and they are 20 volts apart. The white dot is at 100 volts. You can see there is quite a peak on voltage at the beginning of the cut before it settles quickly.

I'd set the max volts to be about 150 volts. PCW says its quite alright to allow the voltage to exceed the full scale reading in this start up phase as it gives you more resolution and you are not using it to control a THC at this point in the step. I like to see the THC to come on about 1.5 seconds after a cut starts to skip this voltage peak.

As far as arc voltage goes it seems your machine has a max voltage of 125 volts. This sounds about right to me. Here is a plot of my old 50 amp everlast machine. If you zoom in, you will see the dotted line divisions and they are 20 volts apart. The white dot is at 100 volts. You can see there is quite a peak on voltage at the beginning of the cut before it settles quickly.

I'd set the max volts to be about 150 volts. PCW says its quite alright to allow the voltage to exceed the full scale reading in this start up phase as it gives you more resolution and you are not using it to control a THC at this point in the step. I like to see the THC to come on about 1.5 seconds after a cut starts to skip this voltage peak.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.166 seconds