Plasma build basic questions

- Chris J

-

Topic Author

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

I've been planning to build a setup using the Mesa board for over a year now and need to finally get moving.

I've got a Mesa 7I96 as well as a THCAD-10 and a THCAD-5.

I wanted to get some input before I start just so I know what should be expected and what's impossible.

Right now I'm using a low end 5x10 table that for the money paid has more than paid for it self many times over. It's been abused and has given everything that could be expected. It uses a MyPlasm CNC controller.

That being said, there are a few complaints I have about it that I'm hoping my own build can either get rid of, or at least improve on.

The biggest one is what I believe are the steppers losing distance due to drag etc and the system doesn't know this and just keeps cutting. This isn't very fun when large pieces of stainless are being wasted.

Can any DIY builds improve on this? What are my options? I assume stronger steppers would help just through brute force, but how much? Would servos solve this completely or would the software still not know the actual location of the torch?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21345

- Thank you received: 7284

forum.linuxcnc.org/plasma-laser/38974-di...rything-in-one-place

forum.linuxcnc.org/plasma-laser/35349-cn...uilding-them?start=0

And a very long build thread with 4 machines by now :

forum.linuxcnc.org/show-your-stuff/38547...plasma-build?start=0

As for the servo/stepper thingy, i use both, steppers on smaller machines and servos on bigger ones and retrofits of industrial machines, they work perfectly well when set up properly.

Servos are better due to feedback, steppers are much better as they are more immune to interference from a plasma cutter.

Lately i have been doing a bit more cutting ( not much cutting till now just fix the machines and move on ) so i do a lot of dimensional checks (forgot to tram the machine, wasted some material), and it is all perfectly within 0.1 or 0.2mm depending on what is being done. This is on a stepper machine linked above.

The loosing position issue can always be traced down to bad mechanical construction, binding on the rails, loose screws, not properly set timings and drives, weak motors, direct drive from motor to a big pinion/pulley, or combination of the above.

Grounding and shielding is the single most important part of a plasma machine, often overlooked and ending up in tears. This can also cause lost position on every torch start .

Please Log in or Create an account to join the conversation.

- Chris J

-

Topic Author

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

Some lite reading :

forum.linuxcnc.org/plasma-laser/38974-di...rything-in-one-place

forum.linuxcnc.org/plasma-laser/35349-cn...uilding-them?start=0

And a very long build thread with 4 machines by now :

forum.linuxcnc.org/show-your-stuff/38547...plasma-build?start=0

As for the servo/stepper thingy, i use both, steppers on smaller machines and servos on bigger ones and retrofits of industrial machines, they work perfectly well when set up properly.

Servos are better due to feedback, steppers are much better as they are more immune to interference from a plasma cutter.

Lately i have been doing a bit more cutting ( not much cutting till now just fix the machines and move on ) so i do a lot of dimensional checks (forgot to tram the machine, wasted some material), and it is all perfectly within 0.1 or 0.2mm depending on what is being done. This is on a stepper machine linked above.

The loosing position issue can always be traced down to bad mechanical construction, binding on the rails, loose screws, not properly set timings and drives, weak motors, direct drive from motor to a big pinion/pulley, or combination of the above.

Grounding and shielding is the single most important part of a plasma machine, often overlooked and ending up in tears. This can also cause lost position on every torch start .

Hi Tommy,

Thank you for taking the time to respond.

What would you consider a big machine? Our current one is 5'x10' or 1.5m x 3m.

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2203

- Thank you received: 482

This is also a good readHi Tommy,

Thank you for taking the time to respond.

What would you consider a big machine? Our current one is 5'x10' or 1.5m x 3m.

forum.linuxcnc.org/plasmac/37234-plasmac-documentation

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2541

- Thank you received: 867

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21345

- Thank you received: 7284

No particular line there, but that one i would consider "middle" sized since i service and maintain an 8X2.5 and a 12X3 meter ones, those i consider big, well 6X2 should be considered big as they usually require forklifts to be moved.What would you consider a big machine? Our current one is 5'x10' or 1.5m x 3m.

For now i have a 1.5X2.5, a 1.5X3 and a 2X3 meter ones as can be seen on the build log i linked above, the others are gone!

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11727

- Thank you received: 3972

So what voltage are you running your dives at?

Please Log in or Create an account to join the conversation.

- Chris J

-

Topic Author

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

I just want to try to not make the same mistakes building my own.

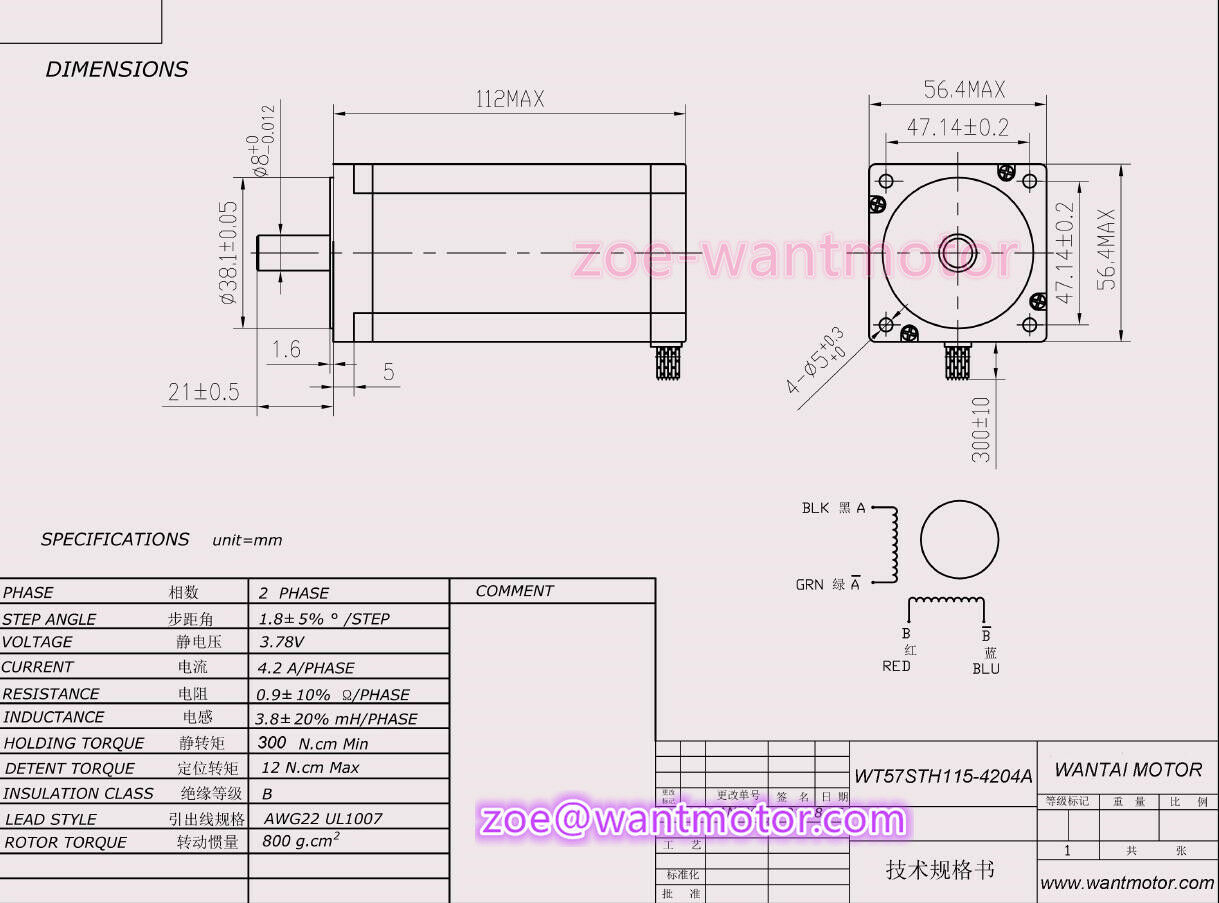

The motors on the table I'm using are Wantai WT57STH115-4204A. 4.2A 1.8 deg

The drives are Me 2H Microstep Driver DQ856MA

They are set to 4A RMS / 6.6A peak and 3200 pulse.

The power supplies are 48 volts.

I've attached the info I found on the motors. I assume they're nothing great,

There's two on the Y axis and one for Z and one for X. All but Z are setup as a rack and pinion. Don't know the ratio right now.

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11727

- Thank you received: 3972

I think What Tommy said about grounding might be required. Bolt a seperate wire to a mounting bolt on each motor and run it back to a star ground point.

I would also seperate the motors from the racks so you can push the gantry around. I can push mine with my little finger like this. If there is any binding, work out what it is and fix it. Then remove the motors so avoid any back emf and do the same thing with the rack and pinion engaged. Perhaps this is the first step. I have a little bit of binding on my X axis rack and pinion when engaged. I think becasue of crappy rack and pinion.

Please Log in or Create an account to join the conversation.

- Chris J

-

Topic Author

Topic Author

- Offline

- New Member

-

- Posts: 8

- Thank you received: 0

They look like they should work depending on gantry weight.

I think What Tommy said about grounding might be required. Bolt a seperate wire to a mounting bolt on each motor and run it back to a star ground point.

I would also seperate the motors from the racks so you can push the gantry around. I can push mine with my little finger like this. If there is any binding, work out what it is and fix it. Then remove the motors so avoid any back emf and do the same thing with the rack and pinion engaged. Perhaps this is the first step. I have a little bit of binding on my X axis rack and pinion when engaged. I think becasue of crappy rack and pinion.

Removing the motors so I can feel things move on their own is a good idea, I didn't think of that.

Something I can't wrap my head around is cutting 1/4" 304 SS I had issues with round holes not even being close to round and I thought it was because the plate was warped. Yet, I just tried burning a bunch of test holes in some 1/4" steel and they came out perfect. I then put the plate on a pretty steep angle and they still came out good. So, I don't know if it's an issue with SS, or that specific SS, or what's going on.

I'm running a Hypertherm Powermax 125 and was using 45A at those times. I usually get a pretty good cut, but, there's sometimes where not so much.

Please Log in or Create an account to join the conversation.