Voltage divider for Mesa THCAD-10?

- mal136

- Offline

- Junior Member

-

Less

More

- Posts: 23

- Thank you received: 2

20 May 2021 19:34 #209682

by mal136

Replied by mal136 on topic Voltage divider for Mesa THCAD-10?

Sounds awesome, i am doing the wiring today. i feel way more confident in what i am doing now. Greatly appreciate your feedback!

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11664

- Thank you received: 3930

20 May 2021 19:52 #209685

by rodw

I told him you could not be trusted!

This diagram pops up a lot. The power supplies bother me a bit. It can't be considered a reference design

1. Stepper motor power supply should be seperate and in the range 48-70 volts depending on drivers used. (doubling volts roughly quadruples torque)

2. The 5V and 24 v power supplies could be DIN rail mount Meanwell MDR which are pretty cheap and nice and compact ( I used caged power supplies way bigger than what was required too).

There is no need to use a mechanical relay for the torch on but polarity needs to be expected or the torch may come on straight away.

ArcOK software debounce of 10 ms minimum is a good idea as some of the relays in the plasma cutter are quite slow switching. Plasmac defaults to 5.

The ArcOK signal needs to have something in hardware to ensure the relay contacts do not oxidise which results in intermittent/failed operation. Traditionally a pulldown resistor is used. A HS10 100 ohm 10W resistor would give 200 mA or so on a 24 V circuit, above the relay 100 mA minimum current. PCW has suggested you could use a capacitor to cause a higher current burst to burn off oxide every time the arcOK relay activates. I use a pulldown resistor.

Replied by rodw on topic Voltage divider for Mesa THCAD-10?

That's my diagram!

I told him you could not be trusted!

This diagram pops up a lot. The power supplies bother me a bit. It can't be considered a reference design

1. Stepper motor power supply should be seperate and in the range 48-70 volts depending on drivers used. (doubling volts roughly quadruples torque)

2. The 5V and 24 v power supplies could be DIN rail mount Meanwell MDR which are pretty cheap and nice and compact ( I used caged power supplies way bigger than what was required too).

There is no need to use a mechanical relay for the torch on but polarity needs to be expected or the torch may come on straight away.

ArcOK software debounce of 10 ms minimum is a good idea as some of the relays in the plasma cutter are quite slow switching. Plasmac defaults to 5.

The ArcOK signal needs to have something in hardware to ensure the relay contacts do not oxidise which results in intermittent/failed operation. Traditionally a pulldown resistor is used. A HS10 100 ohm 10W resistor would give 200 mA or so on a 24 V circuit, above the relay 100 mA minimum current. PCW has suggested you could use a capacitor to cause a higher current burst to burn off oxide every time the arcOK relay activates. I use a pulldown resistor.

The following user(s) said Thank You: AgentWD40

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7248

20 May 2021 20:14 #209688

by tommylight

Never had to use any of this, ever, but it is simple and costs close to nothing.

Replied by tommylight on topic Voltage divider for Mesa THCAD-10?

The ArcOK signal needs to have something in hardware to ensure the relay contacts do not oxidise which results in intermittent/failed operation. Traditionally a pulldown resistor is used. A HS10 100 ohm 10W resistor would give 200 mA or so on a 24 V circuit, above the relay 100 mA minimum current. PCW has suggested you could use a capacitor to cause a higher current burst to burn off oxide every time the arcOK relay activates. I use a pulldown resistor.

Never had to use any of this, ever, but it is simple and costs close to nothing.

The following user(s) said Thank You: snowgoer540

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11664

- Thank you received: 3930

20 May 2021 20:48 #209695

by rodw

It is a real issue for some people so why not develop a robust solution right at the beginning when they build their machine? It won't affect other users if they adopt the same defensive design.

Replied by rodw on topic Voltage divider for Mesa THCAD-10?

Tommy, its not really helpful to dismiss the issue when others in this thread have said:

Never had to use any of this, ever, but it is simple and costs close to nothing.

So far my machine works fine except I'm recently experiencing arkOk issues

It is a real issue for some people so why not develop a robust solution right at the beginning when they build their machine? It won't affect other users if they adopt the same defensive design.

Please Log in or Create an account to join the conversation.

- AgentWD40

-

- Offline

- Platinum Member

-

Less

More

- Posts: 339

- Thank you received: 96

20 May 2021 21:32 #209698

by AgentWD40

Replied by AgentWD40 on topic Voltage divider for Mesa THCAD-10?

Rod, can you draw up those hardware options in a schematic? I think more than a few of us grunts are more comfy with pretty pictures.

I apologize to op for inadvertantly derailing your thread. I've seen this particular tangent spin off a few times. Perhaps rod or someone could start a definitive thread to address the possible solutions (with lots of pretty pictures of course)

I apologize to op for inadvertantly derailing your thread. I've seen this particular tangent spin off a few times. Perhaps rod or someone could start a definitive thread to address the possible solutions (with lots of pretty pictures of course)

The following user(s) said Thank You: mal136, CarterKraft

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2534

- Thank you received: 864

20 May 2021 21:47 #209700

by snowgoer540

Nor I, but to your point I have a cheap ceramic capacitor on standby

The mechanical relay, in my case, was 100% necessary.

Just putting that out there only because the best answer is really to not rely on any one user’s experience(s)/advice/rants/etc. and consider all of the input and then do some of your own testing, etc. to find out what works for your table with the guaranteed-to-be-different-than-he-who-slings-definitive-advice’s hardware arrangement.

Replied by snowgoer540 on topic Voltage divider for Mesa THCAD-10?

Never had to use any of this, ever, but it is simple and costs close to nothing.

Nor I, but to your point I have a cheap ceramic capacitor on standby

The mechanical relay, in my case, was 100% necessary.

Just putting that out there only because the best answer is really to not rely on any one user’s experience(s)/advice/rants/etc. and consider all of the input and then do some of your own testing, etc. to find out what works for your table with the guaranteed-to-be-different-than-he-who-slings-definitive-advice’s hardware arrangement.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

20 May 2021 23:20 - 20 May 2021 23:24 #209707

by bevins

That's not accurate. More voltage will give you more torque when the torque starts to fall at higher speeds.

Your better off using more current and/or less microstepping.

Replied by bevins on topic Voltage divider for Mesa THCAD-10?

That's my diagram!

I told him you could not be trusted!

(doubling volts roughly quadruples torque)

That's not accurate. More voltage will give you more torque when the torque starts to fall at higher speeds.

Your better off using more current and/or less microstepping.

Last edit: 20 May 2021 23:24 by bevins.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

21 May 2021 00:38 #209709

by phillc54

Replied by phillc54 on topic Voltage divider for Mesa THCAD-10?

The "software" and "hardware" solutions are not for the same issue, they are for two separate issues.

The "software" solution is used to overcome the effects of a bouncing contact from a mechnical relay. Almost all mechnical relays will exhibit some contact bounce. Is has nothing to do with the operation time of the relay, only the bouncing of the contacts. The lower you can set the debounce time and have reliable switching the better.

The "hardware" solutions are to overcome the effects of mechnical relay contact oxidisation/passivation. Reputable manufaturers will specify if a minimum current is required. For example a relay used in some Hypertherms requires a minimum current of 100mA @5V which equates to around 21mA @ 24V so you could use a 1200Ω resistor that would dissipate 0.48W. A simple solution would be a 0.1μF capacitor across the contacts.

It is possible that only one of the above conditions needs to be addressed or maybe both need to.

The "software" solution is used to overcome the effects of a bouncing contact from a mechnical relay. Almost all mechnical relays will exhibit some contact bounce. Is has nothing to do with the operation time of the relay, only the bouncing of the contacts. The lower you can set the debounce time and have reliable switching the better.

The "hardware" solutions are to overcome the effects of mechnical relay contact oxidisation/passivation. Reputable manufaturers will specify if a minimum current is required. For example a relay used in some Hypertherms requires a minimum current of 100mA @5V which equates to around 21mA @ 24V so you could use a 1200Ω resistor that would dissipate 0.48W. A simple solution would be a 0.1μF capacitor across the contacts.

It is possible that only one of the above conditions needs to be addressed or maybe both need to.

The following user(s) said Thank You: snowgoer540

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11664

- Thank you received: 3930

21 May 2021 01:10 #209711

by rodw

This is the trouble. No plasma cutter manufacturer I've seen specifies a minimum current. You have to open the machine, locate the ArcOK relay, identify it and find the datasheet.

I think its probably to do with a transition from an analog to a digital world becasue the digital circuits are low impedance circuits so the current draw is not enough for the relays carried forward from the old world.

Its entirely up to you to design a reliable system. There are many views on how to do this becasue there are several solutions and different views on the optimal component values.

Replied by rodw on topic Voltage divider for Mesa THCAD-10?

The "hardware" solutions are to overcome the effects of mechnical relay contact oxidisation/passivation. Reputable manufaturers will specify if a minimum current is required.

This is the trouble. No plasma cutter manufacturer I've seen specifies a minimum current. You have to open the machine, locate the ArcOK relay, identify it and find the datasheet.

I think its probably to do with a transition from an analog to a digital world becasue the digital circuits are low impedance circuits so the current draw is not enough for the relays carried forward from the old world.

Its entirely up to you to design a reliable system. There are many views on how to do this becasue there are several solutions and different views on the optimal component values.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11664

- Thank you received: 3930

21 May 2021 01:18 - 21 May 2021 01:18 #209712

by rodw

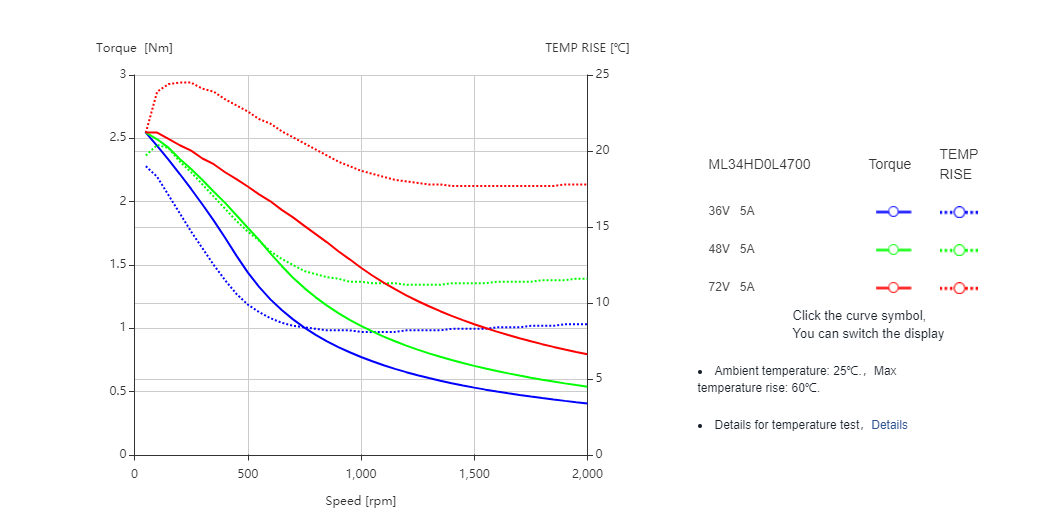

This is a torque curve for a Moon Industries ML34HD0L4700 motor

Solid red line is double the voltage of the solid blue line.

Maybe not quadrupled, but there is a significant increase in torque from 36 volts to 72 volts.

Ref: www.moonsindustries.com/p/nema-34-standa...0-000004611110010545

Replied by rodw on topic Voltage divider for Mesa THCAD-10?

I still don't think we have it right.

That's not accurate. More voltage will give you more torque when the torque starts to fall at higher speeds.Your better off using more current and/or less microstepping.

I told him you could not be trusted!That's my diagram!

(doubling volts roughly quadruples torque)

This is a torque curve for a Moon Industries ML34HD0L4700 motor

Solid red line is double the voltage of the solid blue line.

Maybe not quadrupled, but there is a significant increase in torque from 36 volts to 72 volts.

Ref: www.moonsindustries.com/p/nema-34-standa...0-000004611110010545

Last edit: 21 May 2021 01:18 by rodw.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.234 seconds