Trying to sort out the THC with PlasmaC

- Clive S

- Away

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

23 Oct 2019 16:40 - 23 Oct 2019 16:40 #148611

by Clive S

Trying to sort out the THC with PlasmaC was created by Clive S

Ok I have ditched the scratch start plasma and purchased a pilot arc one with machine torch but no cnc socket on it.

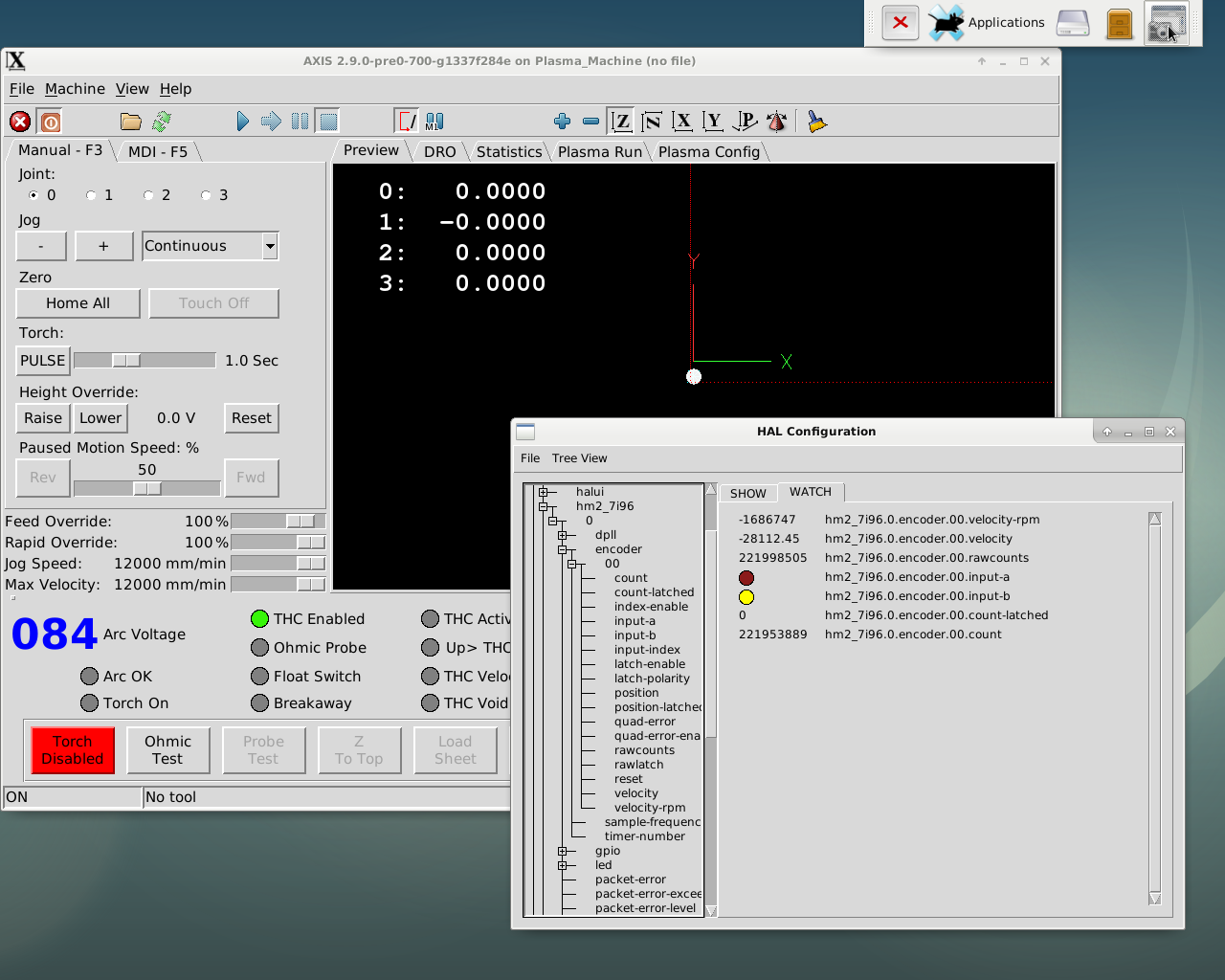

I have wired the Mesa THC-10 inputs via 1 meg R. in each leg. I can now fire the torch via the onscreen pulse button But could not get the arc volts to show.

But could not get the arc volts to show.

I then read the manual 16.2 told me to put setp ~~~~~~~~encoder.00.scale -1 and~~~~~~encoder.00.counter-mode 1 In the ini file

I think that was a misprint in the original manual. It has changed to section 18 with the same lines but says put it in the hal file.I have connected a 9V battery (actual measure 9.68V) to the input terminals on the THC the arc voltage on screen shows random 56-112V

Please see Hal Show and my config files. ~~~encoder.00.input-a flashes on & off with the battery connected

Should the ~~~encoder.00.velocity be showing -ve

I have wired the Mesa THC-10 inputs via 1 meg R. in each leg. I can now fire the torch via the onscreen pulse button

I then read the manual 16.2 told me to put setp ~~~~~~~~encoder.00.scale -1 and~~~~~~encoder.00.counter-mode 1 In the ini file

I think that was a misprint in the original manual. It has changed to section 18 with the same lines but says put it in the hal file.I have connected a 9V battery (actual measure 9.68V) to the input terminals on the THC the arc voltage on screen shows random 56-112V

Please see Hal Show and my config files. ~~~encoder.00.input-a flashes on & off with the battery connected

Should the ~~~encoder.00.velocity be showing -ve

Last edit: 23 Oct 2019 16:40 by Clive S.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

23 Oct 2019 22:58 - 24 Oct 2019 01:45 #148647

by phillc54

Replied by phillc54 on topic Trying to sort out the THC with PlasmaC

Have you set Voltage Scale and Voltage Offset in the Config Panel?

Edit: My 7i96 has the encoder jumpers set as:

W2 = right

W3 = left

W4 = right

Edit2: I just noticed that the User Guide on the LinuxCNC site is a bit different to the one on mine, I don't know why yet...

home.iprimus.com.au/phillcarter/plasma/plasmac-user-guide.html

Edit3: fixed...

Edit: My 7i96 has the encoder jumpers set as:

W2 = right

W3 = left

W4 = right

home.iprimus.com.au/phillcarter/plasma/plasmac-user-guide.html

Edit3: fixed...

Last edit: 24 Oct 2019 01:45 by phillc54.

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- Clive S

- Away

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

24 Oct 2019 09:54 #148686

by Clive S

Many Thanks Phil.

W3 was incorrect. I have changed the scale to .01 and the offset high = 230 Low = 10 (for testing)

With the above (I have the torch on a static mount off the machine about 2mm from a metal plate) It will now simulate cutting the wrench out with the torch firing and being kept on for the duration of the cut.

Not quite sure how to calibrate the above the sticker on the back of the THC states 0V = 117.6 khz 10v = 924.3 khz

the 9V battery measures 9.68v

Replied by Clive S on topic Trying to sort out the THC with PlasmaC

Have you set Voltage Scale and Voltage Offset in the Config Panel?

Edit: My 7i96 has the encoder jumpers set as:

W2 = right

W3 = left

W4 = right

Edit2: I just noticed that the User Guide on the LinuxCNC site is a bit different to the one on mine, I don't know why yet...

home.iprimus.com.au/phillcarter/plasma/plasmac-user-guide.html

Edit3: fixed...

Many Thanks Phil.

W3 was incorrect. I have changed the scale to .01 and the offset high = 230 Low = 10 (for testing)

With the above (I have the torch on a static mount off the machine about 2mm from a metal plate) It will now simulate cutting the wrench out with the torch firing and being kept on for the duration of the cut.

Not quite sure how to calibrate the above the sticker on the back of the THC states 0V = 117.6 khz 10v = 924.3 khz

the 9V battery measures 9.68v

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

24 Oct 2019 10:12 #148687

by phillc54

Replied by phillc54 on topic Trying to sort out the THC with PlasmaC

I think you have 2 X 1M resistors so:

for scale it would be 21/((924300−117600)/32/10) = 0.00833023

for offset it would be 117600/32 = 3675

linuxcnc.org/docs/devel/html/plasma/plas...ng_the_divider_ratio

linuxcnc.org/docs/devel/html/plasma/plas...#_calibration_values

for scale it would be 21/((924300−117600)/32/10) = 0.00833023

for offset it would be 117600/32 = 3675

linuxcnc.org/docs/devel/html/plasma/plas...ng_the_divider_ratio

linuxcnc.org/docs/devel/html/plasma/plas...#_calibration_values

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- Clive S

- Away

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

24 Oct 2019 11:30 #148690

by Clive S

Thanks Phil. That did it, now the display is steady and at zero before the run command is started.

Replied by Clive S on topic Trying to sort out the THC with PlasmaC

I think you have 2 X 1M resistors so:

for scale it would be 21/((924300−117600)/32/10) = 0.00833023

for offset it would be 117600/32 = 3675

linuxcnc.org/docs/devel/html/plasma/plas...ng_the_divider_ratio

linuxcnc.org/docs/devel/html/plasma/plas...#_calibration_values

Thanks Phil. That did it, now the display is steady and at zero before the run command is started.

Please Log in or Create an account to join the conversation.

- Clive S

- Away

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

26 Oct 2019 17:24 #148844

by Clive S

Replied by Clive S on topic Trying to sort out the THC with PlasmaC

Sorry more questions on setup . Phill

I have the machine now cutting. I have cut out the test Spanner at 5mm with quite a lot of dross

The machine probes OK and fires OK I had the cut height set to 1.25mm but pretty sure it is more like 5mm

Q1. When doing a probe test. The z does probes down at G0 speed to the probe height 30mm then probes down at probe speed OK

then it moves up a few mm then after a delay it move further up about 25mm.

Does the first move up signify cut height ?

When run with the torch enable button, disabled. I can see then that it is trying to cut too high at 5mm

What would cause this?

I have the machine now cutting. I have cut out the test Spanner at 5mm with quite a lot of dross

The machine probes OK and fires OK I had the cut height set to 1.25mm but pretty sure it is more like 5mm

Q1. When doing a probe test. The z does probes down at G0 speed to the probe height 30mm then probes down at probe speed OK

then it moves up a few mm then after a delay it move further up about 25mm.

Does the first move up signify cut height ?

When run with the torch enable button, disabled. I can see then that it is trying to cut too high at 5mm

What would cause this?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

Less

More

- Posts: 21348

- Thank you received: 7285

26 Oct 2019 17:56 #148846

by tommylight

Replied by tommylight on topic Trying to sort out the THC with PlasmaC

I think you are using floating switch for probing, right ?

In that case the "float travel" is set to high. If it still stays high during cut, lower the voltage or disable "auto volts".

In that case the "float travel" is set to high. If it still stays high during cut, lower the voltage or disable "auto volts".

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

26 Oct 2019 23:11 #148856

by phillc54

Replied by phillc54 on topic Trying to sort out the THC with PlasmaC

On a probe test:

Notes:

- Z down at Setup Seed (Config Panel) to Probe Height (Config Panel)

- Z down at Probe Speed (Config Panel) until contact detected

- Z up at .001mm (0.00004") until contact lost. This is then Z0

- Z up at Setup Speed to Pierce Height (Run Panel)

- Wait for amount of seconds in ini file (BUTTON_n_CODE = probe-test 30). This allows time to check the height.

- Z up at Setup Speed to where it started from.

Notes:

- The DRO display for Z in the GUI has no relationship to any of the heights that PlasmaC uses.

- Probe Height is the height above the Z axis minimum limit.

The following user(s) said Thank You: tommylight, Clive S

Please Log in or Create an account to join the conversation.

- Clive S

- Away

- Platinum Member

-

Less

More

- Posts: 2203

- Thank you received: 482

31 Oct 2019 14:14 #149288

by Clive S

Replied by Clive S on topic Trying to sort out the THC with PlasmaC

Phill

Q. Under JOG in axis should the box that has "continues " in it . be able to drop down for jog increments like 5mm,1, 0.1mm etc. If so it is not working on mine.

Q. Under JOG in axis should the box that has "continues " in it . be able to drop down for jog increments like 5mm,1, 0.1mm etc. If so it is not working on mine.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

31 Oct 2019 21:50 #149309

by phillc54

Replied by phillc54 on topic Trying to sort out the THC with PlasmaC

Yes, there should be a JOG_INCREMENTS setting in the [DISPLAY] section of the .ini file.

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.154 seconds