PlasmaC Fiber laser 1Kw head height control + auto focuas

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

27 May 2022 17:35 #244009

by taloot

Replied by taloot on topic PlasmaC Fiber laser 1Kw head height control + auto focuas

this is my fiber laser build, now equppied with 1.5kw laser. but i will install 3kw next week

www.youtube.com/shorts/fWQGUGTbuyo

www.youtube.com/shorts/fWQGUGTbuyo

The following user(s) said Thank You: phillc54, tommylight, Clive S

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2533

- Thank you received: 865

27 May 2022 19:39 #244023

by snowgoer540

Would it be possible to make a similar video but show the screen while LinuxCNC is driving the table?

Replied by snowgoer540 on topic PlasmaC Fiber laser 1Kw head height control + auto focuas

this is my fiber laser build, now equppied with 1.5kw laser. but i will install 3kw next week

www.youtube.com/shorts/fWQGUGTbuyo

Would it be possible to make a similar video but show the screen while LinuxCNC is driving the table?

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- Lilow

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 2

28 May 2022 07:01 #244039

by Lilow

Replied by Lilow on topic PlasmaC Fiber laser 1Kw head height control + auto focuas

taloot.

Thank you for the video.

I mentioned the LFS-AP01 capacitive sensor, you mentioned the BCL-Amp was better.

Can you explain how this could be ?

I went back and tested a BCL-Amp and it didn't register any reading of signals out.

The LFS-AP01 I am testing registers 0.03v to 0.04v sensitivity, do I need a better read value than this ?

When the LFS-AP01 is put through the DT-115 it reads 0.003v sensitivity.

Are you using G and M codes for your operation ?

It would good to see the header and footer notes in the file.

Cheers.

Thank you for the video.

I mentioned the LFS-AP01 capacitive sensor, you mentioned the BCL-Amp was better.

Can you explain how this could be ?

I went back and tested a BCL-Amp and it didn't register any reading of signals out.

The LFS-AP01 I am testing registers 0.03v to 0.04v sensitivity, do I need a better read value than this ?

When the LFS-AP01 is put through the DT-115 it reads 0.003v sensitivity.

Are you using G and M codes for your operation ?

It would good to see the header and footer notes in the file.

Cheers.

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

29 May 2022 23:19 - 29 May 2022 23:21 #244157

by taloot

Replied by taloot on topic PlasmaC Fiber laser 1Kw head height control + auto focuas

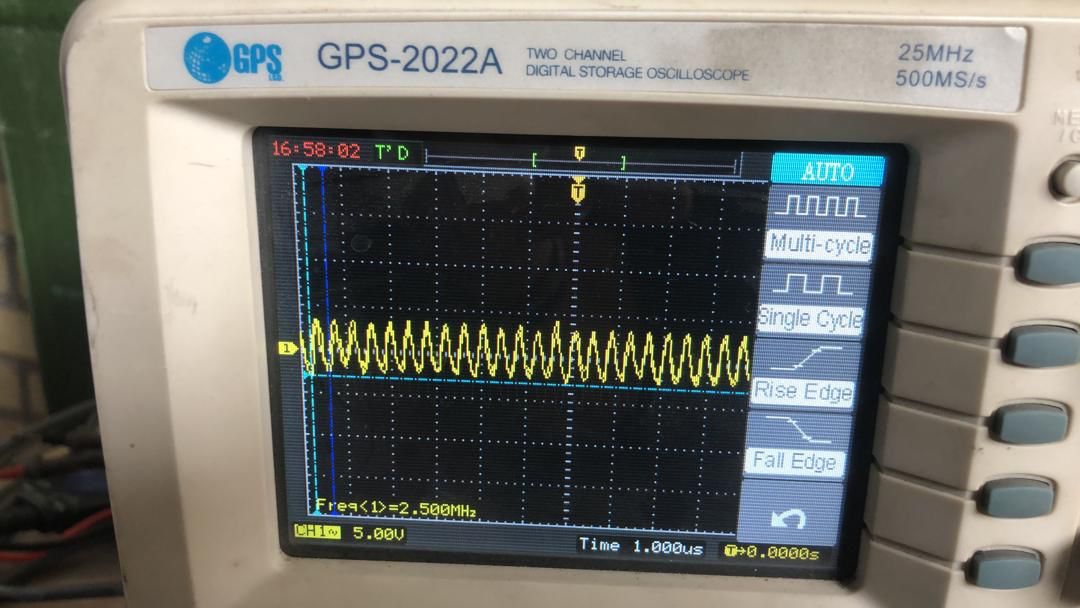

Attachments:

Last edit: 29 May 2022 23:21 by taloot.

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

29 May 2022 23:22 - 29 May 2022 23:25 #244158

by taloot

Replied by taloot on topic PlasmaC Fiber laser 1Kw head height control + auto focuas

taloot.

Thank you for the video.

I mentioned the LFS-AP01 capacitive sensor, you mentioned the BCL-Amp was better.

Can you explain how this could be ?

I went back and tested a BCL-Amp and it didn't register any reading of signals out.

The LFS-AP01 I am testing registers 0.03v to 0.04v sensitivity, do I need a better read value than this ?

When the LFS-AP01 is put through the DT-115 it reads 0.003v sensitivity.

Are you using G and M codes for your operation ?

It would good to see the header and footer notes in the file.

Cheers.

problem with response time and accuracy

Last edit: 29 May 2022 23:25 by taloot.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

29 May 2022 23:40 #244159

by taloot

Replied by taloot on topic PlasmaC Fiber laser 1Kw head height control + auto focuas

sure,,,

the system using cypcut2000s now,, i will use it as benchmark, as its refined version for old machinem,

and i guess my best bet, is to drive the whole system with -10 +10 servo,

the chinese system using pulse/step for axis, and analog for head follewer,.,

using analog for axis, elminate the lag lines,

and the biggest limitation on the chinese system that u cant use gcode,, for milling steel and make molds, using fiber laser milling. as this interfer with the main job of the follower.

at the moment linuxcnc should work i will start using it in a secondry machine, as it need a non production machine so i can fix it and work in it without intefering with my business, it will be laser tube cutter my 1st project with linuxcnc laser..

but if someone have the time and resources, we can work togthert on it, step by step.

the system using cypcut2000s now,, i will use it as benchmark, as its refined version for old machinem,

and i guess my best bet, is to drive the whole system with -10 +10 servo,

the chinese system using pulse/step for axis, and analog for head follewer,.,

using analog for axis, elminate the lag lines,

and the biggest limitation on the chinese system that u cant use gcode,, for milling steel and make molds, using fiber laser milling. as this interfer with the main job of the follower.

at the moment linuxcnc should work i will start using it in a secondry machine, as it need a non production machine so i can fix it and work in it without intefering with my business, it will be laser tube cutter my 1st project with linuxcnc laser..

but if someone have the time and resources, we can work togthert on it, step by step.

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

29 May 2022 23:50 - 29 May 2022 23:57 #244161

by taloot

Replied by taloot on topic PlasmaC Fiber laser 1Kw head height control + auto focuas

youtube.com/shorts/A14i4FbI5zw

if ur follower have similar speed then lets try it,

lasersource needs 0-10v for power and modulation freq and enable pin

also u need 0-10v for o2 proptional valvue

the exact model is SMC ITV2050-31if u have those we can try it,

if ur follower have similar speed then lets try it,

lasersource needs 0-10v for power and modulation freq and enable pin

also u need 0-10v for o2 proptional valvue

the exact model is SMC ITV2050-31if u have those we can try it,

Last edit: 29 May 2022 23:57 by taloot.

Please Log in or Create an account to join the conversation.

- Lilow

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 2

30 May 2022 07:47 - 30 May 2022 07:49 #244190

by Lilow

Replied by Lilow on topic PlasmaC Fiber laser 1Kw head height control + auto focuas

taloot.

Thanks for the reply.

After reading all the posts regarding your Fibre Laser, seeing all the changes required put up by persons at Linux CNC.

I thought you were using G and M codes.

I could have bought Cypcut as well.

But that would take the challenge out of the support that was shown here.

I saw what you were doing and the interest shown.

It can be done.

Just maybe it's not the way you went about it.

Thanks for the info on the BLM-Amp, the Chinese told me 5v.

Pin 1 - 5v, pin 2 - 0v, pin 3 - signal, pin 4 - ground shielded cable.

You may want to source a LPC-PLUS6 laser power controller, these are mainly used in robotic arm cutting and welding situations.

But trigger the same protocol for the Fibre Laser application.

Really hard to find.

It gives 0 to 10v for power, 0-24v for PWM and 23v for the laser source enable plus 2 input signals for any error to the CNC controller.

Why I asked for a sample of the G and M code footer is because it is a difficult post processor.

Cheers.

Thanks for the reply.

After reading all the posts regarding your Fibre Laser, seeing all the changes required put up by persons at Linux CNC.

I thought you were using G and M codes.

I could have bought Cypcut as well.

But that would take the challenge out of the support that was shown here.

I saw what you were doing and the interest shown.

It can be done.

Just maybe it's not the way you went about it.

Thanks for the info on the BLM-Amp, the Chinese told me 5v.

Pin 1 - 5v, pin 2 - 0v, pin 3 - signal, pin 4 - ground shielded cable.

You may want to source a LPC-PLUS6 laser power controller, these are mainly used in robotic arm cutting and welding situations.

But trigger the same protocol for the Fibre Laser application.

Really hard to find.

It gives 0 to 10v for power, 0-24v for PWM and 23v for the laser source enable plus 2 input signals for any error to the CNC controller.

Why I asked for a sample of the G and M code footer is because it is a difficult post processor.

Cheers.

Last edit: 30 May 2022 07:49 by Lilow.

Please Log in or Create an account to join the conversation.

- taloot

- Offline

- Elite Member

-

Less

More

- Posts: 175

- Thank you received: 88

30 May 2022 14:09 #244212

by taloot

Replied by taloot on topic PlasmaC Fiber laser 1Kw head height control + auto focuas

what do u mean by lpc-plus.

github.com/taloot/LaserC/tree/main/laserc

there u can find applet for laser so u assign all values on the applet, like pircing and cutting settings, it will control the gas for u

github.com/taloot/LaserC/tree/main/laserc

there u can find applet for laser so u assign all values on the applet, like pircing and cutting settings, it will control the gas for u

The following user(s) said Thank You: razplaz

Please Log in or Create an account to join the conversation.

- Lilow

- Offline

- New Member

-

Less

More

- Posts: 14

- Thank you received: 2

31 May 2022 08:13 - 31 May 2022 08:18 #244265

by Lilow

Replied by Lilow on topic PlasmaC Fiber laser 1Kw head height control + auto focuas

taloot.

The LPC-PLUS6 is in the photos attached.

It may save all the pain of what you have been doing.

This could save all the problems of regulating 0 to 10v for power, 0 to 24v for PWM modulation, gives 23v for the laser enable plus the 2 signals as feedback.

It also has 8 pre-programing situations you can sort yourself for different applications.

Screen, 75% of power 7.399v.

60% of Duty circle ( PWM ) 14.013v.

The 22.930v is the enable signal for the source.

The 3.263v is the reading of the LFS-AP01 capacitive sensor.

Cheers.

The LPC-PLUS6 is in the photos attached.

It may save all the pain of what you have been doing.

This could save all the problems of regulating 0 to 10v for power, 0 to 24v for PWM modulation, gives 23v for the laser enable plus the 2 signals as feedback.

It also has 8 pre-programing situations you can sort yourself for different applications.

Screen, 75% of power 7.399v.

60% of Duty circle ( PWM ) 14.013v.

The 22.930v is the enable signal for the source.

The 3.263v is the reading of the LFS-AP01 capacitive sensor.

Cheers.

Last edit: 31 May 2022 08:18 by Lilow.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.182 seconds