Cut rules

- CBEAR

- Offline

- Senior Member

-

- Posts: 64

- Thank you received: 46

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11613

- Thank you received: 3907

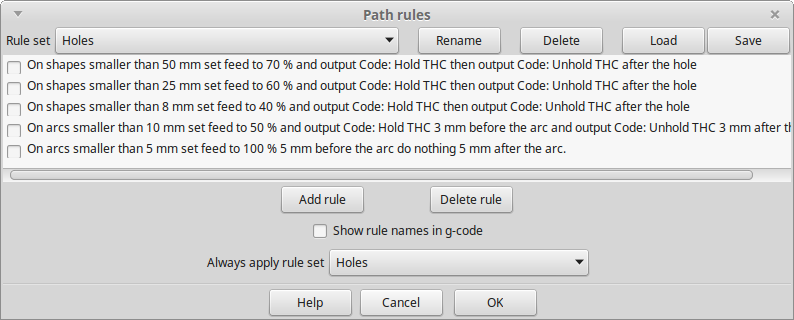

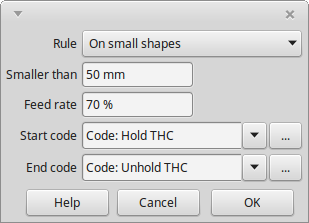

Can you advise how you are applying the slow down and what gcode you are using?

Plasmac is not Mach so I don't think its necessary to embed specific cut rules into the job itself.

I have a slow project that should take this out of gcode altogether. I have modified the Linuxcnc core code to add real time pins that report the arc radius and if the arc is a hole or not in hal. This will enable much more sophisticated hole and arc processing so a separate component could apply a dynamic adaptive feed rate override based on some algorithm (which could be as simple as using the lincurve component).

Some high end controllers do centripetal limiting based on the arc radius that can be traversed at the current cut speed without slowing down. I think I finally have the maths right to do this and need to confirm if the trajectory planner uses the same approach to calculate the velocity to slow to on tight arcs. I've asked a couple of others to review my maths before proceeding too far becasue on one (yet to be confirmed) observation, the Trajectory planner is a long way off my calculated values.

So if there are any mathematicians here, please hold up your hand as it would be great to get feedback on my maths..

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2534

- Thank you received: 864

You could be cutting a 6" line, turn the THC off half way, it will slow up and then speed up again. Turn the THC on again, it will slow up temporarily then speed up again.

When I talked to him earlier he was going to make a video demonstrating the above.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11613

- Thank you received: 3907

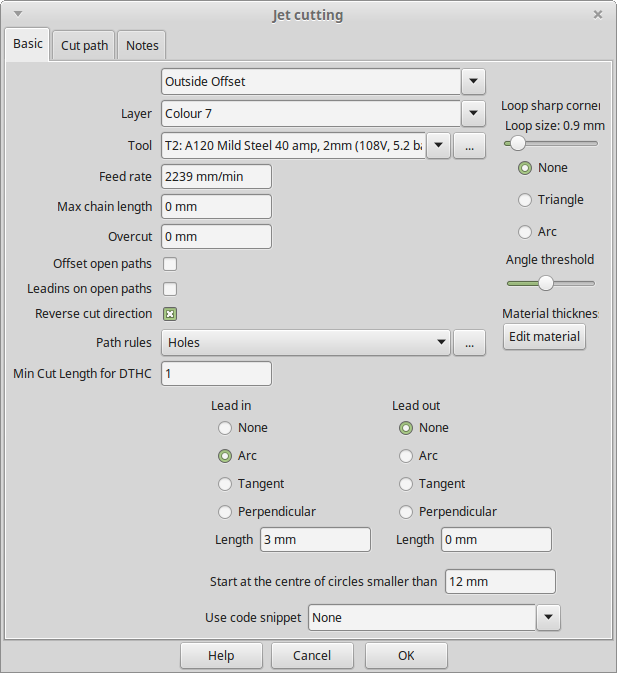

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11613

- Thank you received: 3907

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11613

- Thank you received: 3907

Attachments:

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11613

- Thank you received: 3907

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

I see in the docs that M64 and M65 will break blending.

As Rod said, if your velocity is 80% then if it is below the VAD percentage (default 90%) in the config panel it will lock out THC.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

- Posts: 2534

- Thank you received: 864

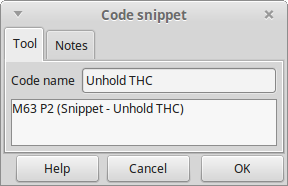

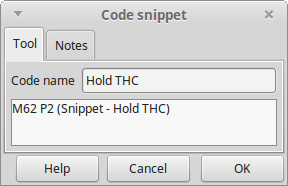

Are you using M62 and M63?

I see in the docs that M64 and M65 will break blending.

As Rod said, if your velocity is 80% then if it is below the VAD percentage (default 90%) in the config panel it will lock out THC.

I'm still a bit fuzzy on the difference between synchronized with motion, and immediately.

EDIT: Also, one question about the VAD percentage, so it considers 100% feed rate the feed rate with no M67 applied? As opposed to 100% being when it reaches the commanded 60% of the material's feed rate... if that makes sense?

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

From my understanding:[I'm still a bit fuzzy on the difference between synchronized with motion, and immediately.

Synchronised means motion continues on it merry way and when the next G1/2/3 move after the M62/62 is reached it will enact that code.

Immediate means motion moves along then stops, the M64/65 is enacted then motion start again

This is the percentage of the cut feed rate of the current material.EDIT: Also, one question about the VAD percentage, so it considers 100% feed rate the feed rate with no M67 applied? As opposed to 100% being when it reaches the commanded 60% of the material's feed rate... if that makes sense?

Please Log in or Create an account to join the conversation.