Inkscape PlasmaC g-code generation

- radek_marko

- Offline

- Senior Member

-

- Posts: 73

- Thank you received: 18

I'm a total newbie in the whole CNC subject - I've built CNC bed, I've attached plasma torch to it, I can do test cuts in X and Y axis from PlasmaC GUI and now I'm trying to move to cut a project created in Inkscape (v1.0.1).

I've generated a simple text, processed the text outline so letters like "O" will not fall from the rest of the cut. Then I've generated the g-code. I've checked it in one of the on-line g-code viewers and discovered that LinuxCNC cannot accept it

Is there a g-code validator for PlasmaC that will tell me what commands are allowed and what are not?

G-code attached

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

- Posts: 21310

- Thank you received: 7279

After that do the usual extensions>gcodetools>path to gcode.

In the folder where the gcode will be saved create a new empty file and name it "header", save it. That will get rid of the first M3 at the top of the gcode so it does not mess up the material.

Please Log in or Create an account to join the conversation.

- radek_marko

- Offline

- Senior Member

-

- Posts: 73

- Thank you received: 18

I have a floating Z sensor - do I need to add special code for that or M3 code will take care of the lowering the torch and firing it when required?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Offline

- Moderator

-

- Posts: 21310

- Thank you received: 7279

Please Log in or Create an account to join the conversation.

- radek_marko

- Offline

- Senior Member

-

- Posts: 73

- Thank you received: 18

I'm totally confused.

First of all - initially I've loaded g-code and LinuxCNC was not throwing any errors to the file content and displayed the image of expected work. Then I've started the job and it didn't use the plasma torch

Next, I've executed few test cuts to check if the plasma is still operational... and it was...

So, I've tried the g-code again and this time the torch was activated (move to approx 30 sec mark on the video below):

Please Log in or Create an account to join the conversation.

- AgentWD40

-

- Offline

- Platinum Member

-

- Posts: 339

- Thank you received: 96

How are you handling that and material selection?

Please Log in or Create an account to join the conversation.

- radek_marko

- Offline

- Senior Member

-

- Posts: 73

- Thank you received: 18

I tried to get fancy and change the feed rate to #<_hal[plasmac.cut-feed-rate]> but it threw an error and reverted back to the default 400. The script expected a numeric instead of a string.

How are you handling that and material selection?

I have done some test custs and created material list - I've selected material from the dropdown list (3mm steel was used in my case).

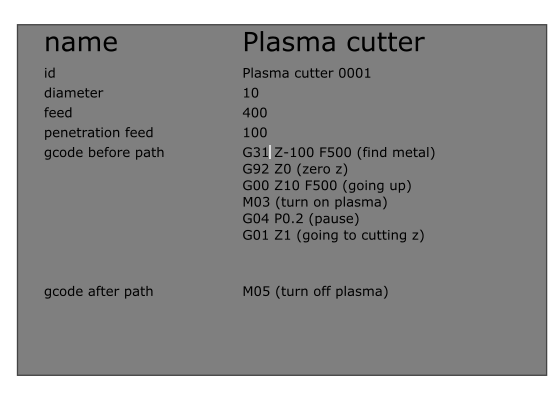

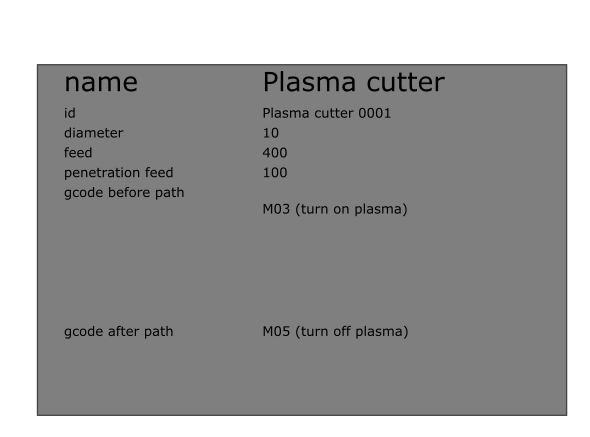

In Inkscape I've changed from

to

I think I know where I've screwed up

The feed rate on my 3mm steel, from tests is 4800!!! I've left Inkscape params unchanged so the g-code was generated for 10mm with feed rate 400...

Am I right?

Please Log in or Create an account to join the conversation.

- AgentWD40

-

- Offline

- Platinum Member

-

- Posts: 339

- Thank you received: 96

fwiw I've poked around the gcode extension's python code and figured out how to make it output #<_hal[plasmac.cut-feed-rate]>. Untested and I don't recommend it but hey, maybe it'll be fine.

Around line #3337 change:

f = " F{:f}".format(tool)

to

f = " F{}".format(tool)

Line 5158 change:

"feed": 400.,

to

"feed": "#<_hal[plasmac.cut-feed-rate]>",

(you can change the rest of your defaults here too)

Line 5347 just comment it out:

self.tool["feed"] = float(self.tool["feed"])

to

#self.tool["feed"] = float(self.tool["feed"])

Line 3091 change:

"feed": 400.0,

to

"feed": "400.0",

I think that's all the changes I made... again, I don't recommend it

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- AgentWD40

-

- Offline

- Platinum Member

-

- Posts: 339

- Thank you received: 96

Please Log in or Create an account to join the conversation.