THCAD-10 configuration, QtPlasmaC

- sm2wmv

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 4

17 Apr 2021 18:23 - 17 Apr 2021 18:58 #206203

by sm2wmv

THCAD-10 configuration, QtPlasmaC was created by sm2wmv

Hi,

First off I have enjoyed the last few days spending time getting my plasma CNC project working somewhat with linuxcnc.

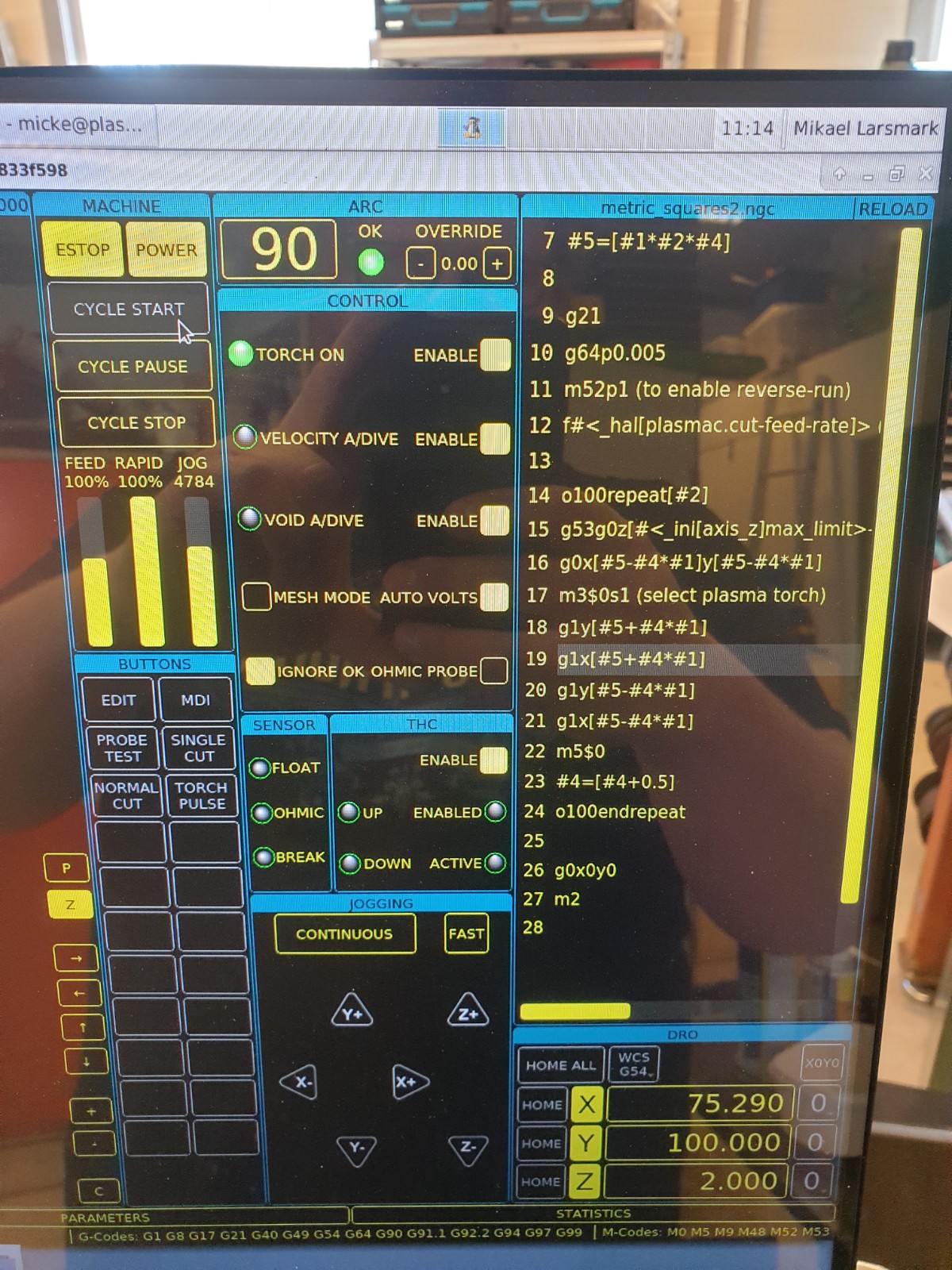

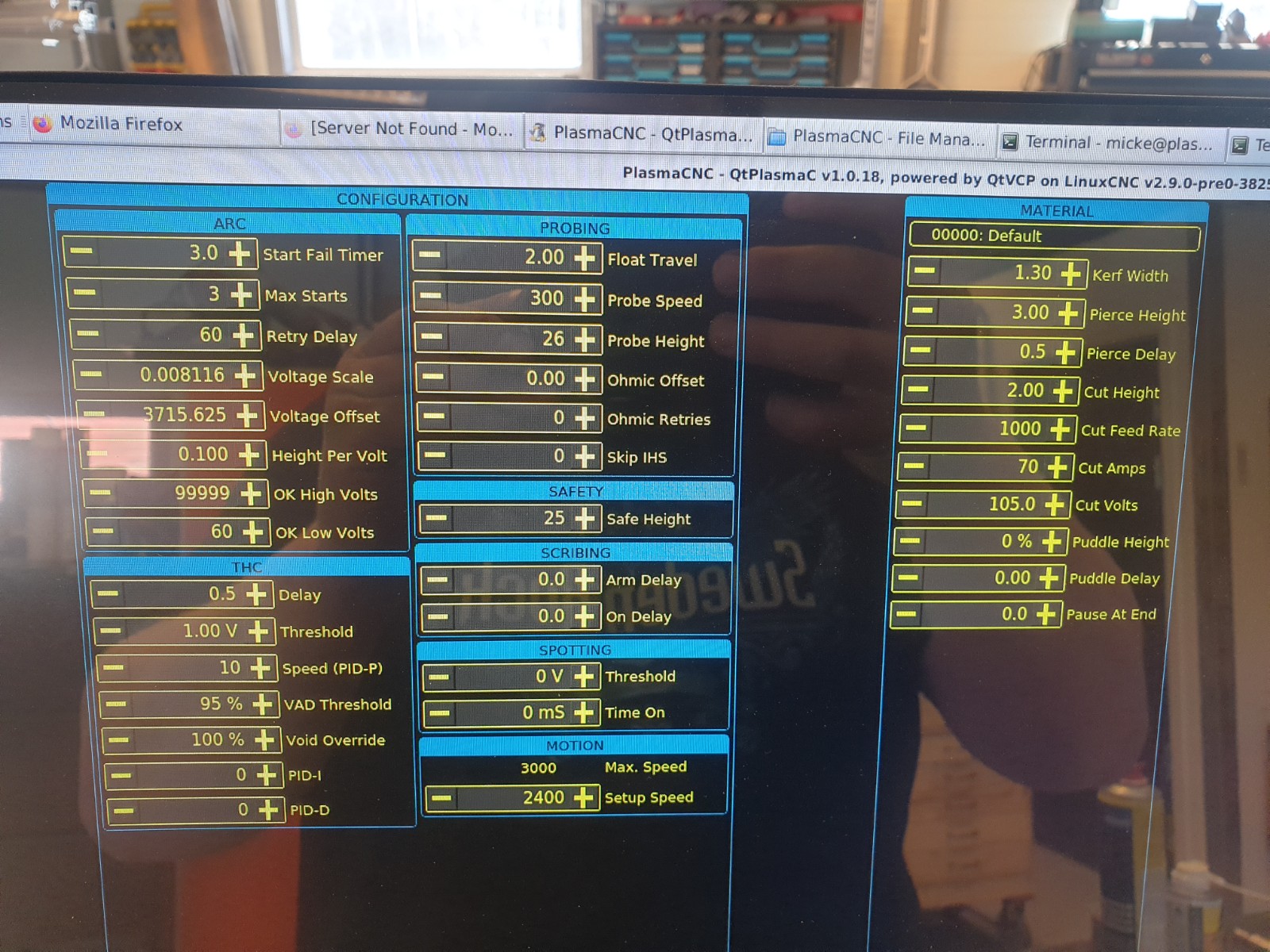

I have been spending a few hours now trying to figure out how to configure the THCAD properly and been reading on the forum. I seem to have it functioning but it does not seem to matter what values I put in the configuration tool. I am using a 7i76e and THCAD-10 with 1 Meg resistors on IN+ and IN-. I try with a DC-voltage to test of 0-60V. The max voltage of 60V produce about 2.8V into the THCAD-10 which gives values on the arc voltage around 110000.

Where do I find the divider ratio and voltage offset in the files? I can't seem to find it anywhere.

I have calculated,

Scale: 0.00789993

Offset: 3718.7500

Here is the first cuts on the 1250x2500mm plasma build

This is from before I went with QtPlasmaC instead,

First off I have enjoyed the last few days spending time getting my plasma CNC project working somewhat with linuxcnc.

I have been spending a few hours now trying to figure out how to configure the THCAD properly and been reading on the forum. I seem to have it functioning but it does not seem to matter what values I put in the configuration tool. I am using a 7i76e and THCAD-10 with 1 Meg resistors on IN+ and IN-. I try with a DC-voltage to test of 0-60V. The max voltage of 60V produce about 2.8V into the THCAD-10 which gives values on the arc voltage around 110000.

Where do I find the divider ratio and voltage offset in the files? I can't seem to find it anywhere.

I have calculated,

Scale: 0.00789993

Offset: 3718.7500

Here is the first cuts on the 1250x2500mm plasma build

This is from before I went with QtPlasmaC instead,

Last edit: 17 Apr 2021 18:58 by sm2wmv.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21310

- Thank you received: 7278

17 Apr 2021 19:40 #206212

by tommylight

Replied by tommylight on topic THCAD-10 configuration, QtPlasmaC

QTPlasmaC has that on the "parameters" tab, the "ARC" section.

Please Log in or Create an account to join the conversation.

- sm2wmv

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 4

17 Apr 2021 20:09 #206220

by sm2wmv

Replied by sm2wmv on topic THCAD-10 configuration, QtPlasmaC

Wow, how did I miss that? I was looking everywhere except in the GUI itself.

Thanks, will try tomorrow.

Thanks, will try tomorrow.

Please Log in or Create an account to join the conversation.

- sm2wmv

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 4

18 Apr 2021 07:29 #206273

by sm2wmv

Replied by sm2wmv on topic THCAD-10 configuration, QtPlasmaC

Put in the new values and it seem to work perfectly!

What are reasonable PID values to start with on the THC?

What are reasonable PID values to start with on the THC?

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

18 Apr 2021 07:44 #206274

by phillc54

Replied by phillc54 on topic THCAD-10 configuration, QtPlasmaC

The default of P:10, I:0, D:0 is quite common.

Please Log in or Create an account to join the conversation.

- sm2wmv

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 4

18 Apr 2021 09:22 #206278

by sm2wmv

Replied by sm2wmv on topic THCAD-10 configuration, QtPlasmaC

I seem to be missing something fundamental when it comes to the THC. It measures the voltage all OK. I have set it to 110V just to see if it regulates but it does not show THC Enabled LED lit up, so I must be missing something. I tried to add M65 P2 in the G-code but without luck.

I also noticed that having any of the cables from the computer near the plasma torch is a bad idea, luckily it survived fine

I also noticed that having any of the cables from the computer near the plasma torch is a bad idea, luckily it survived fine

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

18 Apr 2021 09:27 #206280

by phillc54

Replied by phillc54 on topic THCAD-10 configuration, QtPlasmaC

You have IGNORE ARC OK set, that disables THC.

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_ignore-ok

linuxcnc.org/docs/devel/html/plasma/qtplasmac.html#qt_ignore-ok

Please Log in or Create an account to join the conversation.

- sm2wmv

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 4

18 Apr 2021 09:35 #206281

by sm2wmv

Replied by sm2wmv on topic THCAD-10 configuration, QtPlasmaC

Yes, that solved that issue. However the reason I disabled it is because I don't have any ARC OK signal and use Mode 0 for that reason. But when I have IGNORE ARC off it just triggers for a split second and alarms that ARC is not OK.

Probably something more I have overlooked I guess I should probably try to get a reed relay and fix an ARC OK signal as well, but eager to get it working

I guess I should probably try to get a reed relay and fix an ARC OK signal as well, but eager to get it working

Probably something more I have overlooked

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

18 Apr 2021 09:40 #206282

by phillc54

Replied by phillc54 on topic THCAD-10 configuration, QtPlasmaC

Some plasma cutters just don't work with the soft arc ok, the reed is very reliable.I guess I should probably try to get a reed relay and fix an ARC OK signal as well, but eager to get it working

Please Log in or Create an account to join the conversation.

- sm2wmv

- Offline

- Junior Member

-

Less

More

- Posts: 22

- Thank you received: 4

18 Apr 2021 09:51 #206286

by sm2wmv

Replied by sm2wmv on topic THCAD-10 configuration, QtPlasmaC

I've ordered some reed relays and I will try it again.

Thanks for all the help, I must say I am really impressed with LinuxCNC. I managed to get most of it up and running without asking for help.

I have an Morbidelli Author 400 CNC that I have used to mill all parts for this plasma table and I have intentions to convert that one later to use LinuxCNC as well.

Thanks for all the help, I must say I am really impressed with LinuxCNC. I managed to get most of it up and running without asking for help.

I have an Morbidelli Author 400 CNC that I have used to mill all parts for this plasma table and I have intentions to convert that one later to use LinuxCNC as well.

The following user(s) said Thank You: phillc54

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.119 seconds