Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21198

- Thank you received: 7241

29 May 2021 06:36 #210593

by tommylight

Replied by tommylight on topic Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

During cutting the voltage is set at 130V and on screen it fluctuates between 124 to 131 during cutting at 3.5m/m .

That might be a good trigger point for the plots...

That might be a good trigger point for the plots...

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

29 May 2021 06:40 #210594

by phillc54

Replied by phillc54 on topic Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

OK, I'll make some changes to the comp and push it to master branch tomorrow. The changes won't affect normal operation so it will be safe for everyone to use.During cutting the voltage is set at 130V and on screen it fluctuates between 124 to 131 during cutting at 3.5m/m .

That might be a good trigger point for the plots...

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

29 May 2021 07:33 #210596

by phillc54

Replied by phillc54 on topic Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

Tom, I managed to cobble something together and have pushed it.

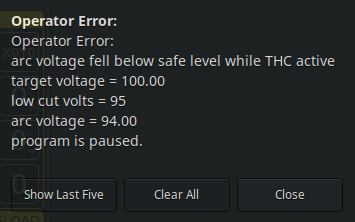

There are three additional pins:this is an input, you can set this so that if the arc voltage is lower than this while THC is active then the machine will pause and give an error message similar to this:

The next two you may not need:This is an output that shows the target arc voltage for THC.

This is an input that defaults to 6. You can change the number of samples needed to set the target voltage for THC.

There are three additional pins:

plasmac.low_cut_voltsThe next two you may not need:

plasmac.target_voltsplasmac.target_samplesAttachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21198

- Thank you received: 7241

29 May 2021 07:37 #210597

by tommylight

Replied by tommylight on topic Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

Thanks, will give it a try after routing the network line to the new shop, all metal cladding so wifi does not work from the other shop.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

29 May 2021 07:38 #210598

by phillc54

Replied by phillc54 on topic Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

There is always something...Thanks, will give it a try after routing the network line to the new shop, all metal cladding so wifi does not work from the other shop.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11653

- Thank you received: 3924

29 May 2021 07:44 #210599

by rodw

Replied by rodw on topic Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

Tommy, I seem to remember you always set your voltage manually. Have you ever tried auto sampling voltage? What if your set point of 130 volts is wrong so Plasmac starts off on the wrong foot?

Try using halscope with the THC disabled to see what the voltage settles to naturally to set your desired voltage.

Try using halscope with the THC disabled to see what the voltage settles to naturally to set your desired voltage.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

29 May 2021 08:11 #210603

by phillc54

If the target was 130 and the arc voltage was heading down to around 80 then it should have raised the z axis, not lowered it.

Replied by phillc54 on topic Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

Tommy, I seem to remember you always set your voltage manually. Have you ever tried auto sampling voltage? What if your set point of 130 volts is wrong so Plasmac starts off on the wrong foot?

Try using halscope with the THC disabled to see what the voltage settles to naturally to set your desired voltage.

If the target was 130 and the arc voltage was heading down to around 80 then it should have raised the z axis, not lowered it.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11653

- Thank you received: 3924

29 May 2021 08:40 #210604

by rodw

Replied by rodw on topic Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

Its almost as if the height adjustments are being sent the wrong direction.If the target was 130 and the arc voltage was heading down to around 80 then it should have raised the z axis, not lowered it.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

29 May 2021 08:41 #210605

by phillc54

Replied by phillc54 on topic Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

It sure is weird ...

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21198

- Thank you received: 7241

29 May 2021 09:04 #210608

by tommylight

I am pretty sure i can manage that with some tuning to go above, but usually when i am near the machines i am cutting something, so no time to play with settings. Either way i have to play with cut feeds and current and other stuff as i change plasma sources often.

Also pretty sure this issue happened also while using auto volts, but do not quote me on that.

Replied by tommylight on topic Is this QTPlasmac Expected behaviour - Cycle Start and Jog disabled.

Yes, several times on all machines, it just settles to low, usually 96 to 102V so the torch remains at under 1mm from the material. All 3 machines have a working voltage of 115 to 132V.Tommy, I seem to remember you always set your voltage manually. Have you ever tried auto sampling voltage?

I am pretty sure i can manage that with some tuning to go above, but usually when i am near the machines i am cutting something, so no time to play with settings. Either way i have to play with cut feeds and current and other stuff as i change plasma sources often.

Also pretty sure this issue happened also while using auto volts, but do not quote me on that.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.259 seconds