The "THC ACTIVE" indicator is not active.

- Egor

- Offline

- New Member

-

- Posts: 9

- Thank you received: 0

1. Hardware - Orange PI PC Plus

2. Software - LinuxCNC / AXIS Version 2.8.1 + AllwinCNC (allwincnc.github.io/index.html) - (mode2)

Due to the lack of THC modeling it with the help of the buttons. In general, the part works - to change the "Float Switch" and "Arc OK" signals, it is regulates correctly, however, the "THC ACTIVE" and "UP <THC> DN" indicators are not activated in any way and the corresponding variance of the z axis during the head movement is not controlled.

Please tell me what could be the problem?

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

"THC ACTIVE" can only be on if all the following are true.

The macine is cutting.

THC is Auto or Enabled in the THC frame of the Run Panel

THC is enabled in the Cut Parameters frame of the Run Panel

The cut velocity has reached 99.9% of the Cut FeedRate in the Cut Parameters frame of the Run Panel

The THC Delay in the THC frame of the Config Panel has timed out.

Please Log in or Create an account to join the conversation.

- Egor

- Offline

- New Member

-

- Posts: 9

- Thank you received: 0

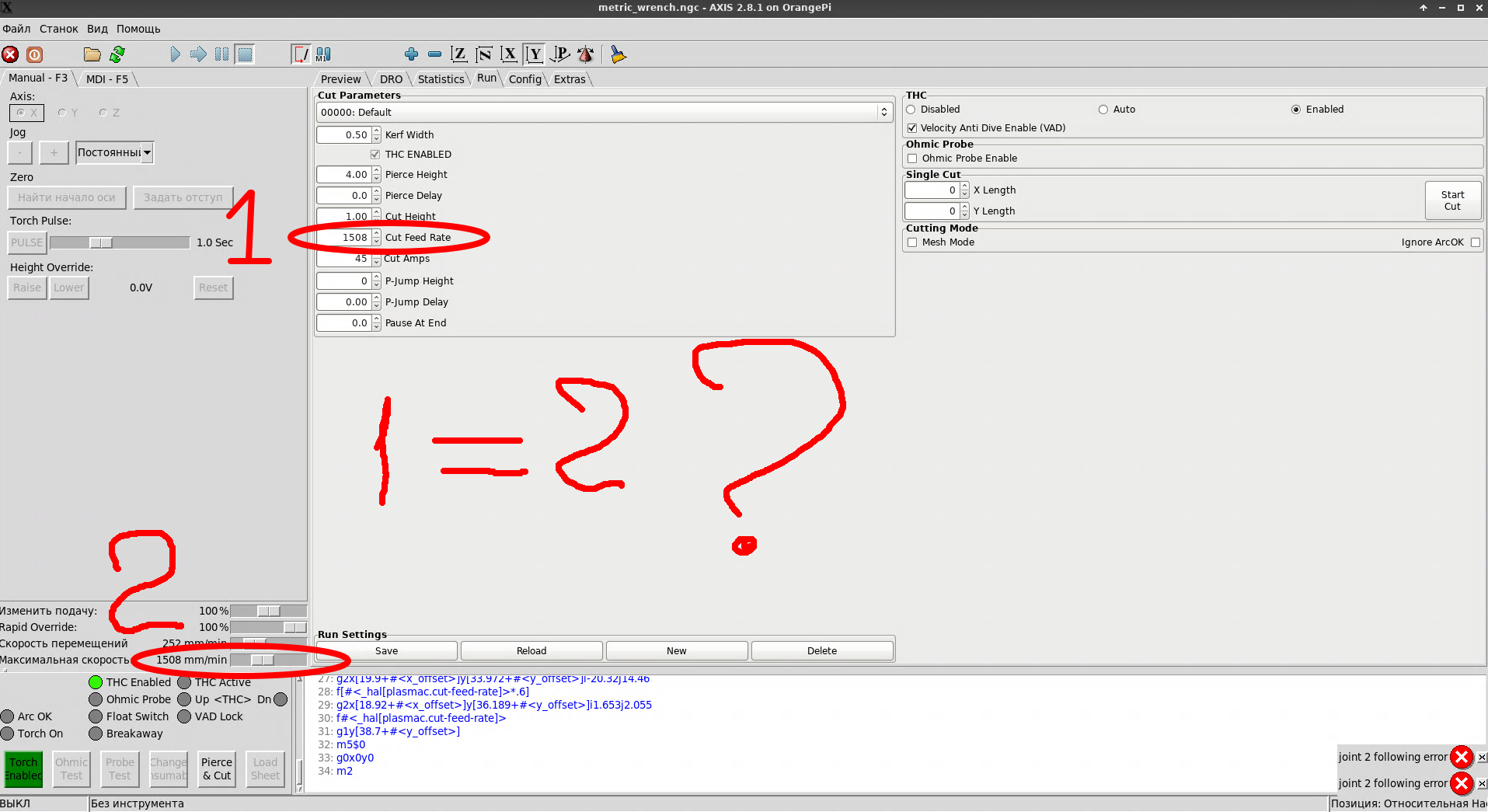

It turns out "1" and "2" should always be equal?

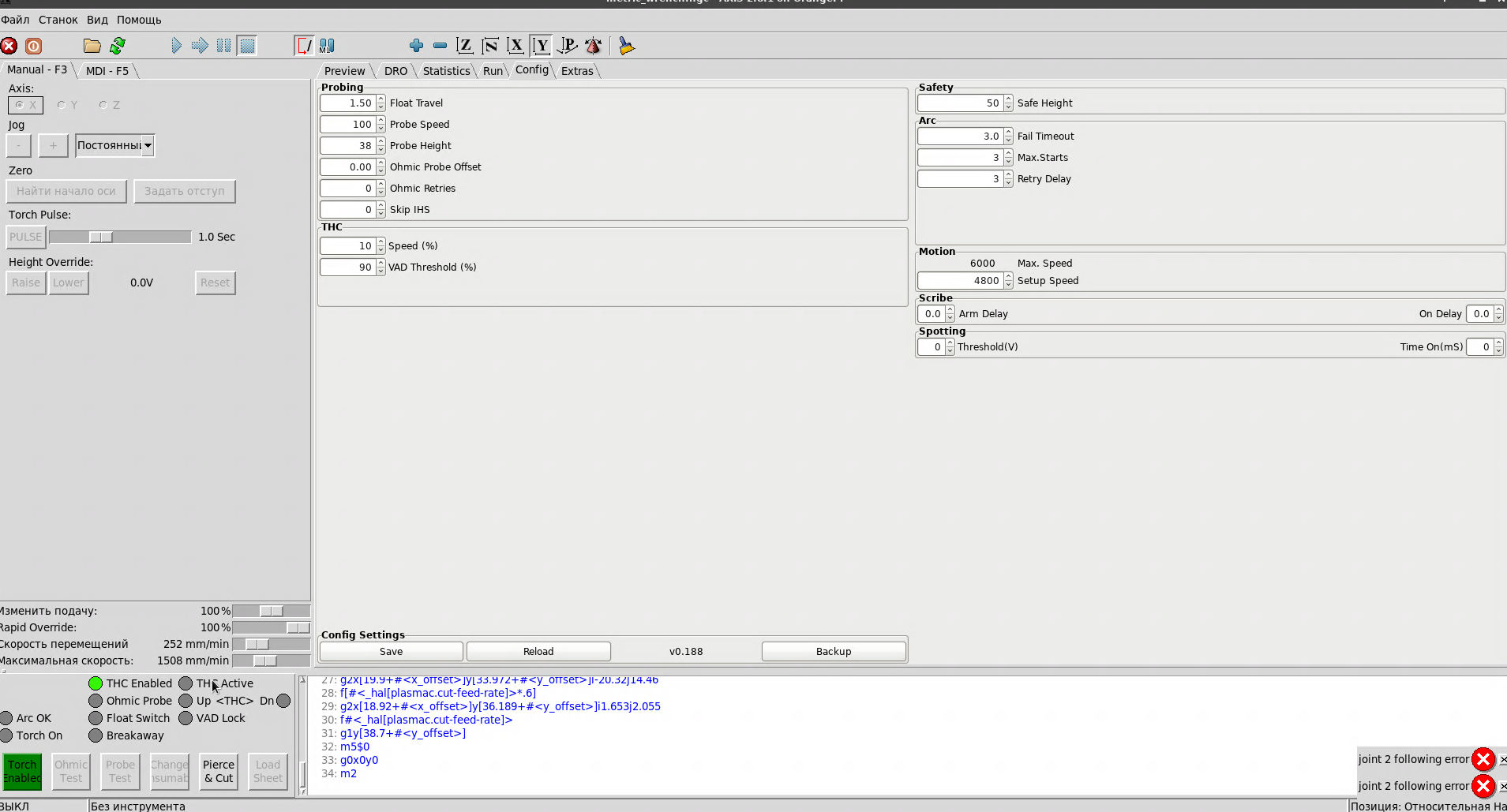

Where on "Config Panel" is the option "THS delay"?

Another questions:

1. What a mistake in the lower right corner - "joint 2 following error"

2. When operating in 0 mode, the ark-voltage-in input signal is supplied to what form (analog voltage, PWM with a certain frequent)? Can I enter analog voltage after a voltage divider 50: 1?

Attachments:

Please Log in or Create an account to join the conversation.

- Egor

- Offline

- New Member

-

- Posts: 9

- Thank you received: 0

where the minimum distance is configured to which the head will move, after receiving the signals Move Down, Move

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21229

- Thank you received: 7249

There is no distance to set i PlasmaC or QtPlasmaC, not chinese THC.

The reaction speed can be set usually just by changing the P value from default 10.

Please Log in or Create an account to join the conversation.

- Egor

- Offline

- New Member

-

- Posts: 9

- Thank you received: 0

That is set by the PID settings and the thc velocity.

There is no distance to set i PlasmaC or QtPlasmaC, not chinese THC.

The reaction speed can be set usually just by changing the P value from default 10.

Where can I find PID settings?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21229

- Thank you received: 7249

Set it to 12 and test.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

No. the actual velocity during cutting has to reach 99.9% of "1" before THC Active LED is on.It turns out "1" and "2" should always be equal?

Sorry, that does not apply for Mode 2.Where on "Config Panel" is the option "THS delay"?

The ArcVoltage input is a floating point value. Most folk get it by using a Mesa THCAD connected to an encoder and then use the velocity output of the encoder.When operating in 0 mode, the ark-voltage-in input signal is supplied to what form (analog voltage, PWM with a certain frequent)? Can I enter analog voltage after a voltage divider 50: 1?

Please Log in or Create an account to join the conversation.

- Egor

- Offline

- New Member

-

- Posts: 9

- Thank you received: 0

The ArcVoltage input is a floating point value. Most folk get it by using a Mesa THCAD connected to an encoder and then use the velocity output of the encoder.

Can I enter analog voltage to ArcVoltage after a voltage divider 50: 1 from plasma?

Please Log in or Create an account to join the conversation.

- Egor

- Offline

- New Member

-

- Posts: 9

- Thank you received: 0

Please Log in or Create an account to join the conversation.