QTPlasmaC issues / questions

- JiiPee

- Offline

- Junior Member

-

- Posts: 20

- Thank you received: 6

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

- Posts: 2202

- Thank you received: 482

I f I move the torch hose from where it exits the drag chain the torch head seems to be moving slightly. I wonder if this, quite small, movement can have such a drastic effect on the quality? The misalignment in X axis direction was also quite minor and it indeed seemed to change things.

If the torch is moving in its mounting it is bound to be giving a bad cut

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11601

- Thank you received: 3900

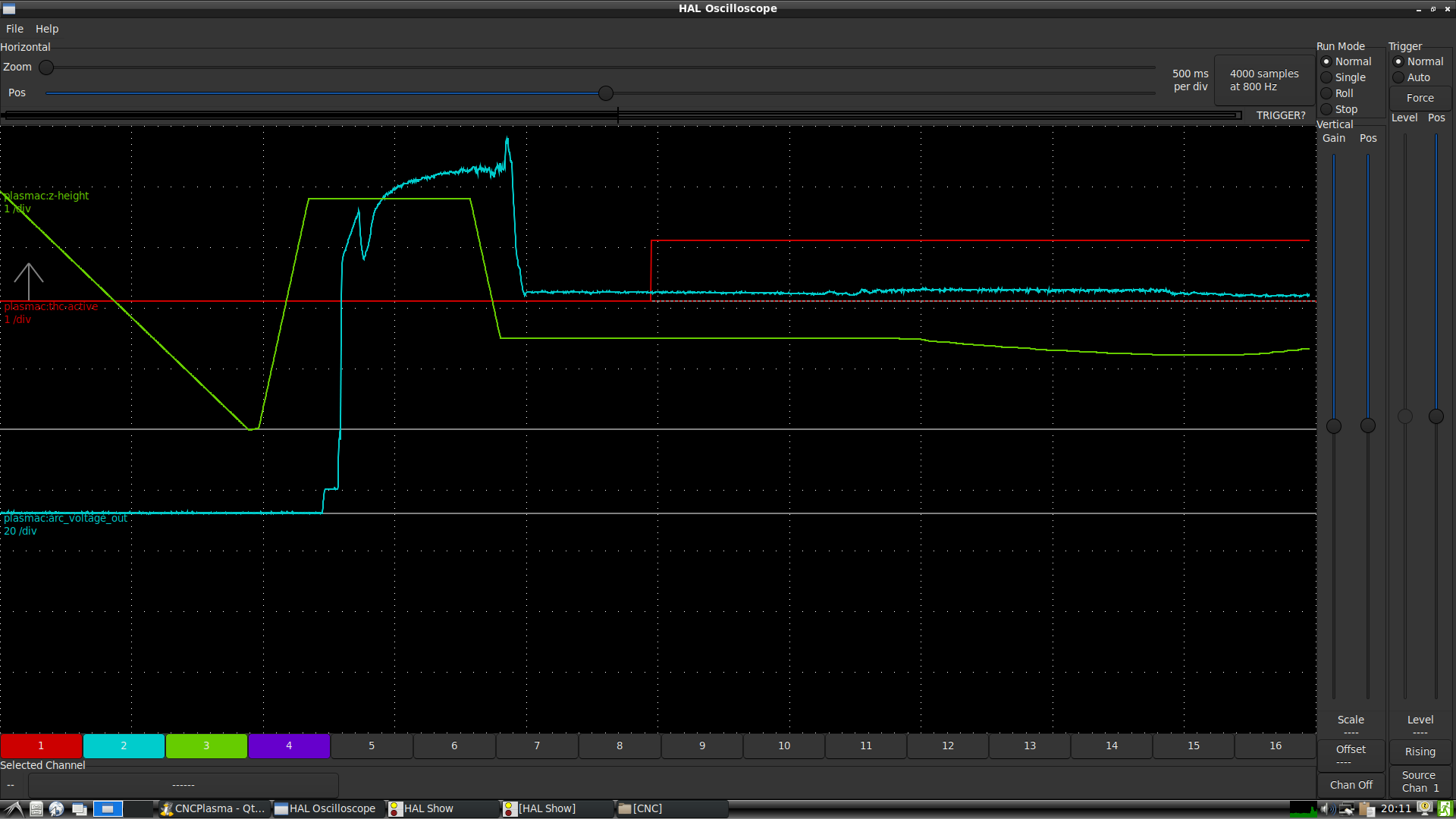

Could you add plasmac.thc-active to your plot? This should show when the THC kicks in.

Also expand the torch voltage to amybe 20 or 30 per division so we see a bit more detail.

About 0.9 sec after the torch starts, the voltage drops and stays stable. This is not consistent with autosampling and more like you are specifying a target voltage. Autosampling should pick a point on the line to optimise to.

I want to understand what is going on there.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11601

- Thank you received: 3900

Thanks edited my last postplasmac.thc-active is when THC kicks in, plasmac.thc-enable can be on even when E-Stopped

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

- Posts: 5711

- Thank you received: 2093

forum.linuxcnc.org/plasmac/46760-qtplasm...tions?start=0#250978

As Clive said though, if the torch is rattling around then the cut won't be nice.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21145

- Thank you received: 7221

First check the air supply, then nozzle/electrode and the ceramic ring, then the sealing o rings.

Might not be relevant, but most damages to the torch are from over tightening it when replacing consumables, do this several times to the torch and it is not usable anymore.

Please Log in or Create an account to join the conversation.

- JiiPee

- Offline

- Junior Member

-

- Posts: 20

- Thank you received: 6

Ah I think I used one of those build bot builds to install then latest version of the LinuxCNC. I think I am running the 2.9.0 or something of that sort. The QTPlasmaC version came with that package if I remember correctly. What would be the easiest way to upgrade the QTPlasmaC package?I see that you have a fairly old version of QtPlasmaC, it is probably worthwhile updating as well.

Linux environment itself is a bit new adventure for me too.

Please Log in or Create an account to join the conversation.

- JiiPee

- Offline

- Junior Member

-

- Posts: 20

- Thank you received: 6

Its great you are using halscope. I just leave it run all the time and stop it when I want to look at something.

Could you add plasmac.thc-active to your plot? This should show when the THC kicks in.

Also expand the torch voltage to amybe 20 or 30 per division so we see a bit more detail.

About 0.9 sec after the torch starts, the voltage drops and stays stable. This is not consistent with autosampling and more like you are specifying a target voltage. Autosampling should pick a point on the line to optimise to.

I want to understand what is going on there.

Certainly!

The recording I made was with the ideas I had at the moment. Glad to get some new pointers from all of you guys, much appreciated!

So I took the new recording. I am using the FineCut consumables and 2mm plate here. I have added the HalScope log too so I guess you could then see the actual data if you are interested. But it certainly looks very good to me and the THC goes active only after the voltage has stabilized.

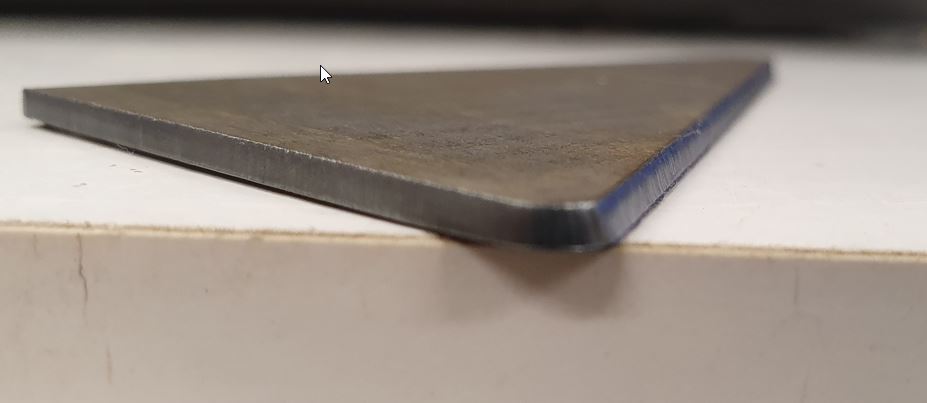

I also attached the photos of the part I made and have been using to dial in the machine. Now that I did the X-axis alignment yesterday it seems to me that edges that are aligned in X-direction are looking pretty good! The diagonal and Y-direction edges however are preeeetty misaligned. anyway it seems the machine can indeed cut based on that one edge!

I starting to lean on what Tommylight said that it might be my not-so-stiff Z axis construction. The torch is pretty well held in X-axis direction but Y-direction has play when twisted even before the magnetic breakout plate breaks off.

Attachments:

Please Log in or Create an account to join the conversation.