QTPlasmaC issues / questions

- JiiPee

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 6

02 Sep 2022 17:39 #251042

by JiiPee

I knew about the overtightening risk in these kinds of torches as I had Hypertherm Powermax 30 before this unit and also I have been using Kemppi's TIG welders for years. They have the same "issues" that people tend to overtighten the consumables when disassembling / assembling the torch.

Good point to make though. Not everyone knows that.

Replied by JiiPee on topic QTPlasmaC issues / questions

Heh it is a mystery to me as well. I mean it really doesn't seem that changing cut parameters make any meaningful difference at all. It really might be the torch alignment / sloppiness in the Z axis.I still wonder, 2mm thick and getting slopes????

First check the air supply, then nozzle/electrode and the ceramic ring, then the sealing o rings.

Might not be relevant, but most damages to the torch are from over tightening it when replacing consumables, do this several times to the torch and it is not usable anymore.

I knew about the overtightening risk in these kinds of torches as I had Hypertherm Powermax 30 before this unit and also I have been using Kemppi's TIG welders for years. They have the same "issues" that people tend to overtighten the consumables when disassembling / assembling the torch.

Good point to make though. Not everyone knows that.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11719

- Thank you received: 3967

02 Sep 2022 20:52 #251059

by rodw

Replied by rodw on topic QTPlasmaC issues / questions

Your halscope looks fine.

What is the book voltage for your cut and how does it compare with the plot value?

I make it about 65 volts which seems low.

I don't use a Hypertherm but I thought fine cut was generally used for thin material, eg HVAC stuff and most would use normal coonsumables for 2mm. Maybe Clive has some feedback there.

Are you using the ArcOK signal from the Hypertherm? Eg Mode 1

The spike before the voltage peaks could confuse other modes (eg synthesised arcOK) MOde 0

Are we just chasing the cut bevel issue now?

What is the book voltage for your cut and how does it compare with the plot value?

I make it about 65 volts which seems low.

I don't use a Hypertherm but I thought fine cut was generally used for thin material, eg HVAC stuff and most would use normal coonsumables for 2mm. Maybe Clive has some feedback there.

Are you using the ArcOK signal from the Hypertherm? Eg Mode 1

The spike before the voltage peaks could confuse other modes (eg synthesised arcOK) MOde 0

Are we just chasing the cut bevel issue now?

The following user(s) said Thank You: JiiPee

Please Log in or Create an account to join the conversation.

- JiiPee

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 6

02 Sep 2022 21:07 - 02 Sep 2022 21:35 #251060

by JiiPee

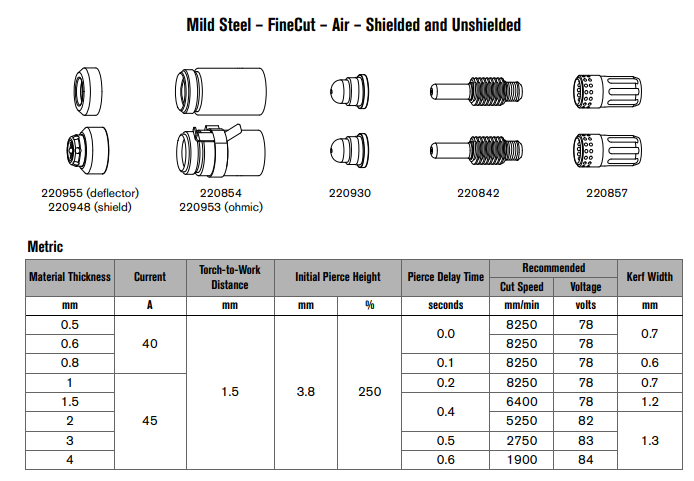

My vertical alignment is quite bad on that scope-view. To me it seems though that it is a bit higher than 68v. I will check tomorrow from the Halscope directly. The table value is 78V if I remember correctly and the 2mm sheet is the lowest value the normal consumable table goes. I thought trying out with fineCut stuff as I had them also around. It really makes great quality cut where it doesnt bevel. No dross and extremely fine edge

And yes I am reading the Arc Ok signal and use that as the start trigger for the torch movement.

Replied by JiiPee on topic QTPlasmaC issues / questions

Yeah basically bevel issue is the last remaining bigger thing now. I think I have gotten around the other stuff thanks to all you guys! Bevel with thinner materials is noticeably worse than with thick. Thick stuff like 5mm and 8mm has it way better but not without problems there either. I really think that my next course of action is to rebuild the Z-axis from better parts and make it stiffer to the point that there is no visible play in the torch even if twisted by hand.Your halscope looks fine.

What is the book voltage for your cut and how does it compare with the plot value?

I make it about 65 volts which seems low.

I don't use a Hypertherm but I thought fine cut was generally used for thin material, eg HVAC stuff and most would use normal coonsumables for 2mm. Maybe Clive has some feedback there.

Are you using the ArcOK signal from the Hypertherm? Eg Mode 1

The spike before the voltage peaks could confuse other modes (eg synthesised arcOK) MOde 0

Are we just chasing the cut bevel issue now?

My vertical alignment is quite bad on that scope-view. To me it seems though that it is a bit higher than 68v. I will check tomorrow from the Halscope directly. The table value is 78V if I remember correctly and the 2mm sheet is the lowest value the normal consumable table goes. I thought trying out with fineCut stuff as I had them also around. It really makes great quality cut where it doesnt bevel. No dross and extremely fine edge

And yes I am reading the Arc Ok signal and use that as the start trigger for the torch movement.

Attachments:

Last edit: 02 Sep 2022 21:35 by JiiPee. Reason: Typos

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- JiiPee

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 6

05 Sep 2022 11:19 #251225

by JiiPee

Could you give me some advice how to update the QtPlasmaC component. I think I got the LinuxCNC package itself using the buildbot. Is there some linux apt-command to upgrade packages?

Replied by JiiPee on topic QTPlasmaC issues / questions

Hey Phillc!I see that you have a fairly old version of QtPlasmaC, it is probably worthwhile updating as well.

Could you give me some advice how to update the QtPlasmaC component. I think I got the LinuxCNC package itself using the buildbot. Is there some linux apt-command to upgrade packages?

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2541

- Thank you received: 867

05 Sep 2022 13:34 #251228

by snowgoer540

Replied by snowgoer540 on topic QTPlasmaC issues / questions

The following user(s) said Thank You: JiiPee

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.281 seconds