Inssues Hole cutting

- paulsao

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 22

06 May 2024 19:55 #299961

by paulsao

Inssues Hole cutting was created by paulsao

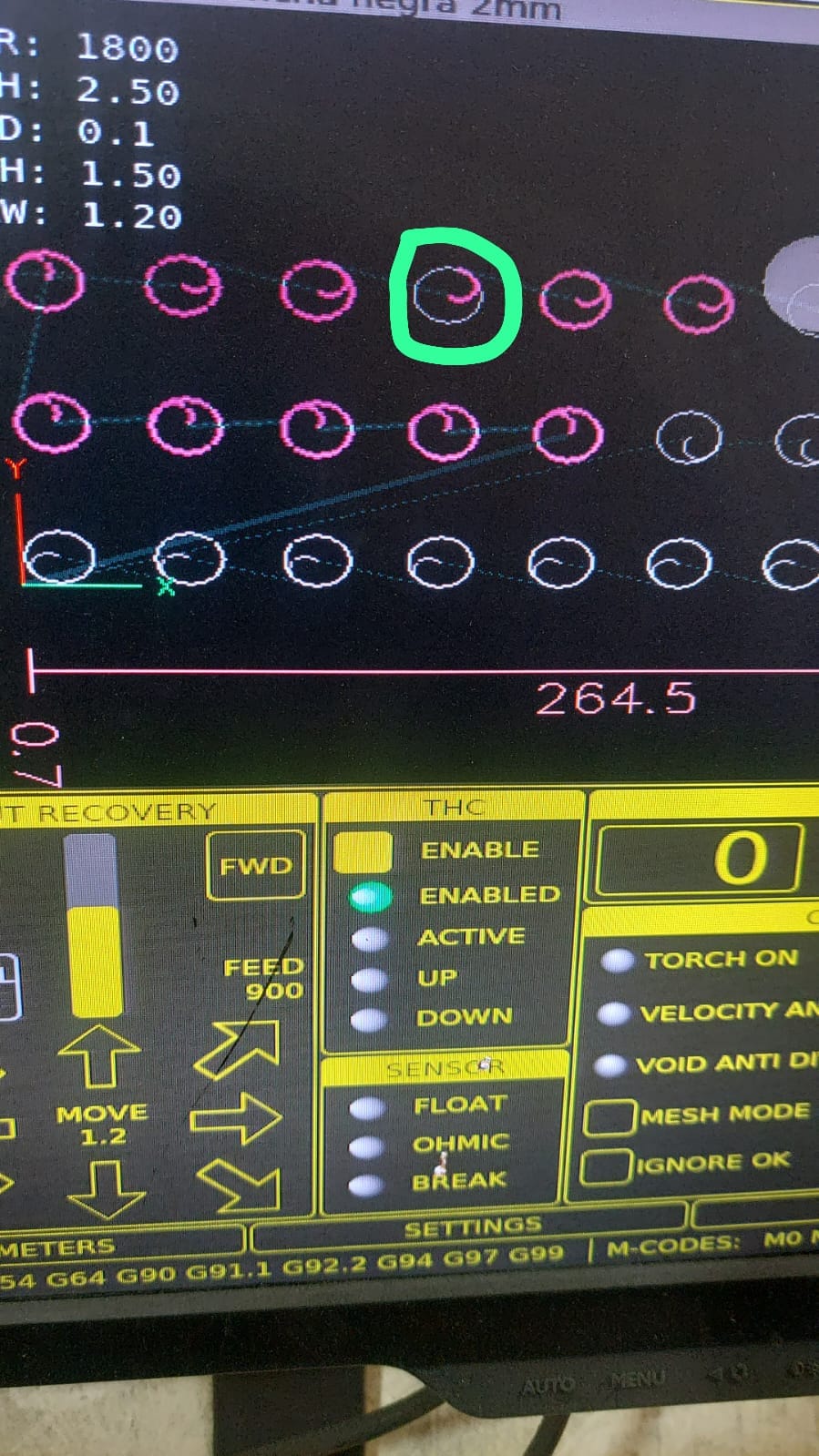

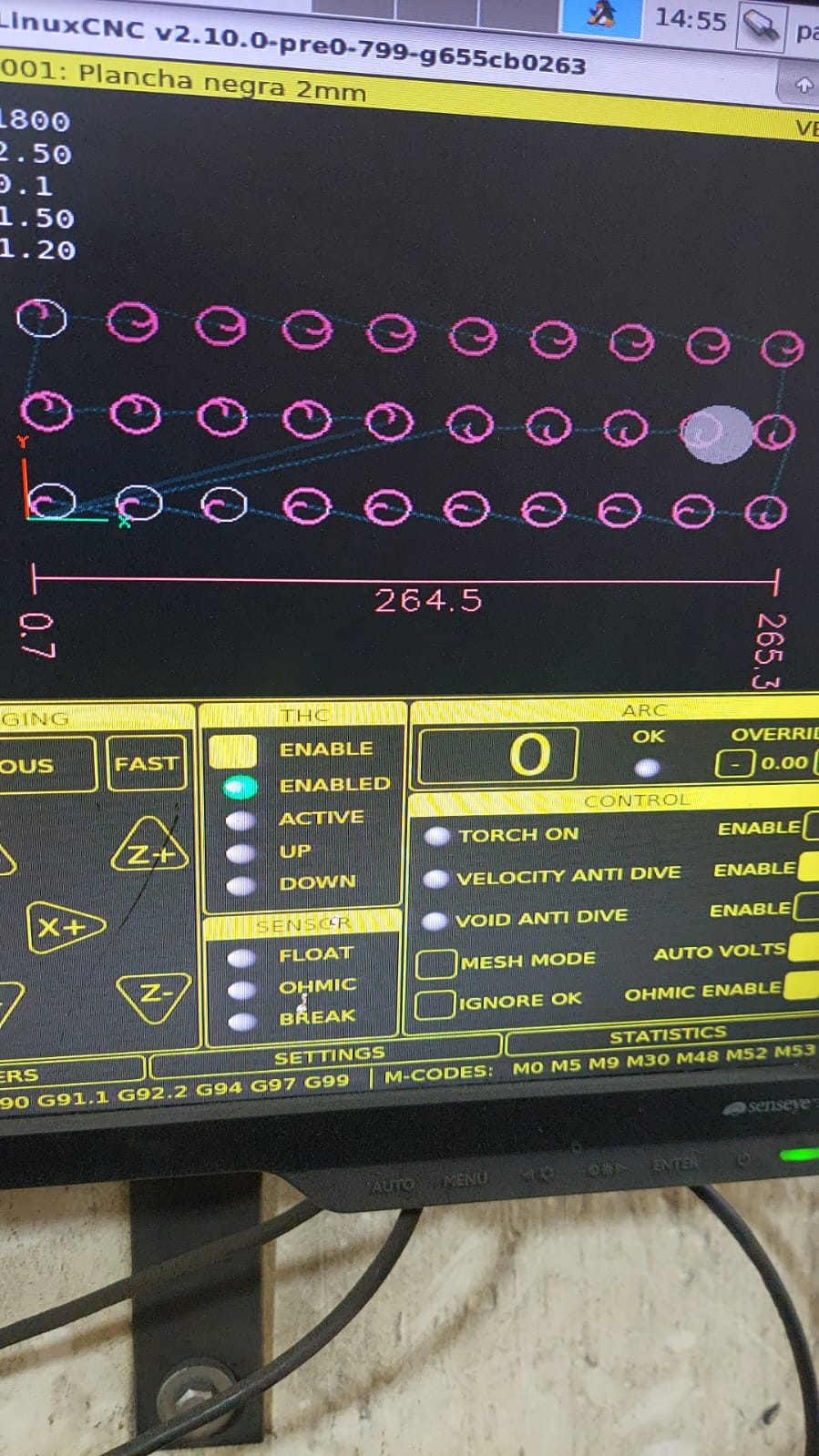

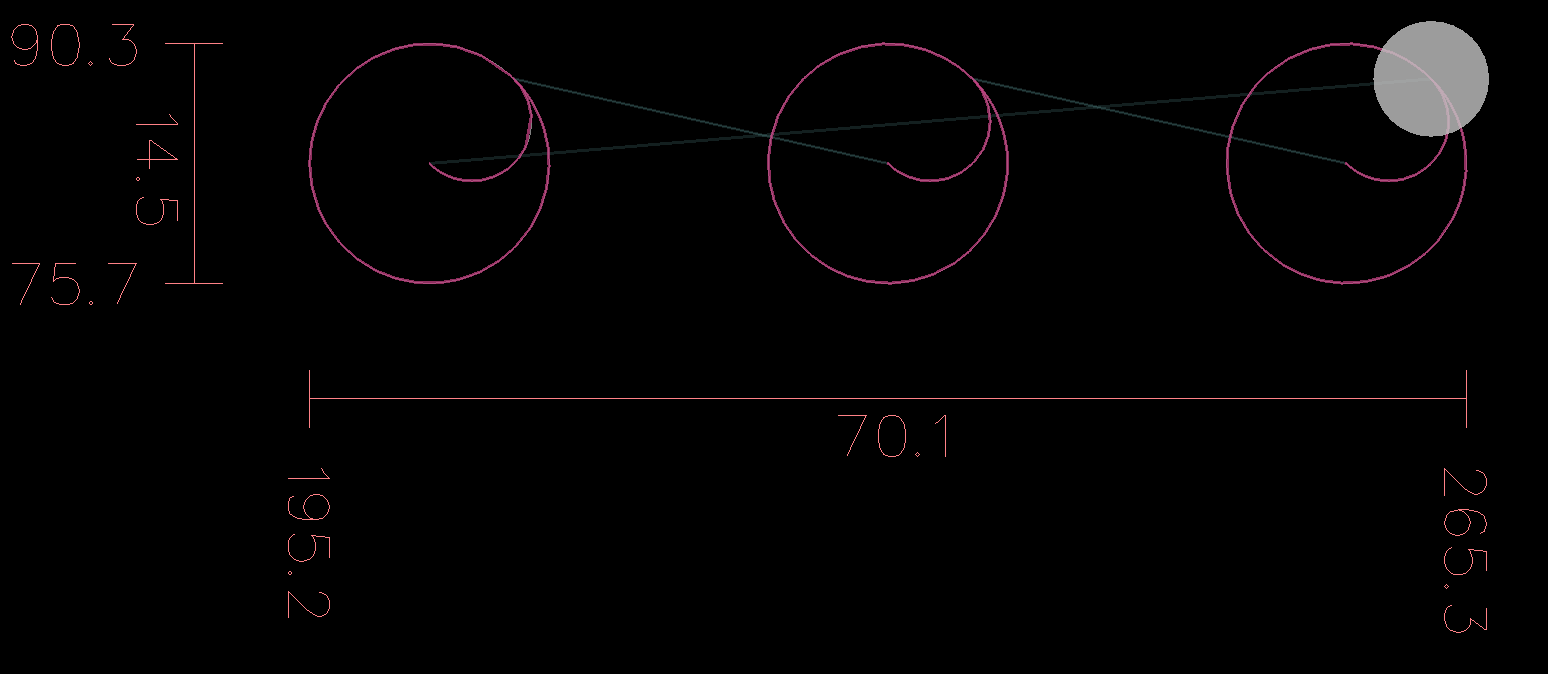

Hello.I am using shetcaam and Qtplasmac making holes with central arc entry and using plasmac's automatic circle creation Option 2. Slowing down and overcutting. The problem is that Qtplasmac detects some holes automatically and others not, and only cuts the arc as it happens in the image. This occurs only at the arch entrance.

Attachments:

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2541

- Thank you received: 867

06 May 2024 20:25 #299964

by snowgoer540

Replied by snowgoer540 on topic Inssues Hole cutting

May be helpful if you could post your g-code, please.

The following user(s) said Thank You: paulsao

Please Log in or Create an account to join the conversation.

- paulsao

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 22

06 May 2024 20:37 - 06 May 2024 20:37 #299966

by paulsao

Replied by paulsao on topic Inssues Hole cutting

Thanks for you reply.

; file name: holes.tap

; date and time: Mon May 06 2024 15:33:00

; postprocessor: LinuxCNC_PlasmaCv1.scpost rev: 0.5

;

;begin pre-amble

G21 (units: metric)

G40 (cutter compensation: off)

G90 (distance mode: absolute)

M52 P1 (adaptive feed: on)

M65 P2 (enable THC)

M65 P3 (enable torch)

M68 E3 Q0 (velocity 100%)

G64 P0.254 Q0.025 (tracking tolerances: 0.254mm)

#<holes> = 2

#<h_velocity> = 50

#<h_diameter> = 42

#<oclength> = 4

;end pre-amble

;

;begin material setup

T0 M6 (select plasma tool)

G43 H0 (apply tool offsets)

M66 P3 L3 Q2 (wait for valid change)

F#<_hal[plasmac.cut-feed-rate]>

;end material setup

G0 X119.111 Y45.5

M3 $0 S1 (plasma start)

M67 E3 Q100

G3 X113.985 Y50.627 I-2.563 J2.563

G3 X113.985 Y50.627 I5.127 J-5.127

M5 $0 (plasma end)

G0 X91.333 Y45.5

M3 $0 S1 (plasma start)

G3 X86.207 Y50.627 I-2.563 J2.563

G3 X86.207 Y50.627 I5.127 J-5.127

M5 $0 (plasma end)

G0 X63.556 Y45.5

M3 $0 S1 (plasma start)

G3 X58.429 Y50.627 I-2.563 J2.563

G3 X58.429 Y50.627 I5.127 J-5.127

M5 $0 (plasma end)

G0 X35.778 Y45.5

M3 $0 S1 (plasma start)

G3 X30.651 Y50.627 I-2.563 J2.563

G3 X30.651 Y50.627 I5.127 J-5.127

M5 $0 (plasma end)

G0 X8 Y45.5

M3 $0 S1 (plasma start)

G3 X2.873 Y50.627 I-2.563 J2.563

G3 X2.873 Y50.627 I5.127 J-5.127

M5 $0 (plasma end)

G0 X8 Y83

M3 $0 S1 (plasma start)

G3 X2.873 Y88.127 I-2.563 J2.563

G3 X2.873 Y88.127 I5.127 J-5.127

M5 $0 (plasma end)

G0 X35.778 Y83

M3 $0 S1 (plasma start)

G3 X40.904 Y88.127 I2.563 J2.563

G3 X40.904 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X63.556 Y83

M3 $0 S1 (plasma start)

G3 X68.682 Y88.127 I2.563 J2.563

G3 X68.682 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X91.333 Y83

M3 $0 S1 (plasma start)

G3 X96.46 Y88.127 I2.563 J2.563

G3 X96.46 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X119.111 Y83

M3 $0 S1 (plasma start)

G3 X124.238 Y88.127 I2.563 J2.563

G3 X124.238 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X146.889 Y83

M3 $0 S1 (plasma start)

G3 X152.015 Y88.127 I2.563 J2.563

G3 X152.015 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X174.667 Y83

M3 $0 S1 (plasma start)

G3 X179.793 Y88.127 I2.563 J2.563

G3 X179.793 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X202.444 Y83

M3 $0 S1 (plasma start)

G3 X207.571 Y88.127 I2.563 J2.563

G3 X207.571 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X230.222 Y83

M3 $0 S1 (plasma start)

G3 X235.349 Y88.127 I2.563 J2.563

G3 X235.349 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X258 Y83

M3 $0 S1 (plasma start)

G3 X263.127 Y88.127 I2.563 J2.563

G3 X263.127 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X258 Y45.5

M3 $0 S1 (plasma start)

G3 X263.127 Y40.373 I2.563 J-2.563

G3 X263.127 Y40.373 I-5.127 J5.127

M5 $0 (plasma end)

G0 X258 Y8

M3 $0 S1 (plasma start)

G3 X263.127 Y2.873 I2.563 J-2.563

G3 X263.127 Y2.873 I-5.127 J5.127

M5 $0 (plasma end)

G0 X230.222 Y8

M3 $0 S1 (plasma start)

G3 X225.096 Y2.873 I-2.563 J-2.563

G3 X225.096 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X202.444 Y8

M3 $0 S1 (plasma start)

G3 X197.318 Y2.873 I-2.563 J-2.563

G3 X197.318 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X174.667 Y8

M3 $0 S1 (plasma start)

G3 X169.54 Y2.873 I-2.563 J-2.563

G3 X169.54 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X146.889 Y8

M3 $0 S1 (plasma start)

G3 X141.762 Y2.873 I-2.563 J-2.563

G3 X141.762 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X119.111 Y8

M3 $0 S1 (plasma start)

G3 X113.985 Y2.873 I-2.563 J-2.563

G3 X113.985 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X91.333 Y8

M3 $0 S1 (plasma start)

G3 X86.207 Y2.873 I-2.563 J-2.563

G3 X86.207 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X63.556 Y8

M3 $0 S1 (plasma start)

G3 X58.429 Y2.873 I-2.563 J-2.563

G3 X58.429 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X35.778 Y8

M3 $0 S1 (plasma start)

G3 X30.651 Y2.873 I-2.563 J-2.563

G3 X30.651 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X8 Y8

M3 $0 S1 (plasma start)

G3 X2.873 Y2.873 I-2.563 J-2.563

G3 X2.873 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X146.889 Y45.5

M3 $0 S1 (plasma start)

G3 X152.015 Y40.373 I2.563 J-2.563

G3 X152.015 Y40.373 I-5.127 J5.127

M5 $0 (plasma end)

G0 X174.667 Y45.5

M3 $0 S1 (plasma start)

G3 X179.793 Y40.373 I2.563 J-2.563

G3 X179.793 Y40.373 I-5.127 J5.127

M5 $0 (plasma end)

G0 X202.444 Y45.5

M3 $0 S1 (plasma start)

G3 X207.571 Y40.373 I2.563 J-2.563

G3 X207.571 Y40.373 I-5.127 J5.127

M5 $0 (plasma end)

G0 X230.222 Y45.5

M3 $0 S1 (plasma start)

G3 X235.349 Y40.373 I2.563 J-2.563

G3 X235.349 Y40.373 I-5.127 J5.127

M5 $0 (plasma end)

;

;begin post-amble

G40 (cutter compensation: off)

G90 (distance mode: absolute)

M65 P2 (enable THC)

M65 P3 (enable torch)

M68 E3 Q0 (velocity 100%)

M5 $-1 (backup stop)

;end post-amble

;

;begin statistics

;Pierces = 30

; Cuts = 30, Length = 1708.24mm

;end statistics

;

M30 (end program)

; file name: holes.tap

; date and time: Mon May 06 2024 15:33:00

; postprocessor: LinuxCNC_PlasmaCv1.scpost rev: 0.5

;

;begin pre-amble

G21 (units: metric)

G40 (cutter compensation: off)

G90 (distance mode: absolute)

M52 P1 (adaptive feed: on)

M65 P2 (enable THC)

M65 P3 (enable torch)

M68 E3 Q0 (velocity 100%)

G64 P0.254 Q0.025 (tracking tolerances: 0.254mm)

#<holes> = 2

#<h_velocity> = 50

#<h_diameter> = 42

#<oclength> = 4

;end pre-amble

;

;begin material setup

T0 M6 (select plasma tool)

G43 H0 (apply tool offsets)

M66 P3 L3 Q2 (wait for valid change)

F#<_hal[plasmac.cut-feed-rate]>

;end material setup

G0 X119.111 Y45.5

M3 $0 S1 (plasma start)

M67 E3 Q100

G3 X113.985 Y50.627 I-2.563 J2.563

G3 X113.985 Y50.627 I5.127 J-5.127

M5 $0 (plasma end)

G0 X91.333 Y45.5

M3 $0 S1 (plasma start)

G3 X86.207 Y50.627 I-2.563 J2.563

G3 X86.207 Y50.627 I5.127 J-5.127

M5 $0 (plasma end)

G0 X63.556 Y45.5

M3 $0 S1 (plasma start)

G3 X58.429 Y50.627 I-2.563 J2.563

G3 X58.429 Y50.627 I5.127 J-5.127

M5 $0 (plasma end)

G0 X35.778 Y45.5

M3 $0 S1 (plasma start)

G3 X30.651 Y50.627 I-2.563 J2.563

G3 X30.651 Y50.627 I5.127 J-5.127

M5 $0 (plasma end)

G0 X8 Y45.5

M3 $0 S1 (plasma start)

G3 X2.873 Y50.627 I-2.563 J2.563

G3 X2.873 Y50.627 I5.127 J-5.127

M5 $0 (plasma end)

G0 X8 Y83

M3 $0 S1 (plasma start)

G3 X2.873 Y88.127 I-2.563 J2.563

G3 X2.873 Y88.127 I5.127 J-5.127

M5 $0 (plasma end)

G0 X35.778 Y83

M3 $0 S1 (plasma start)

G3 X40.904 Y88.127 I2.563 J2.563

G3 X40.904 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X63.556 Y83

M3 $0 S1 (plasma start)

G3 X68.682 Y88.127 I2.563 J2.563

G3 X68.682 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X91.333 Y83

M3 $0 S1 (plasma start)

G3 X96.46 Y88.127 I2.563 J2.563

G3 X96.46 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X119.111 Y83

M3 $0 S1 (plasma start)

G3 X124.238 Y88.127 I2.563 J2.563

G3 X124.238 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X146.889 Y83

M3 $0 S1 (plasma start)

G3 X152.015 Y88.127 I2.563 J2.563

G3 X152.015 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X174.667 Y83

M3 $0 S1 (plasma start)

G3 X179.793 Y88.127 I2.563 J2.563

G3 X179.793 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X202.444 Y83

M3 $0 S1 (plasma start)

G3 X207.571 Y88.127 I2.563 J2.563

G3 X207.571 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X230.222 Y83

M3 $0 S1 (plasma start)

G3 X235.349 Y88.127 I2.563 J2.563

G3 X235.349 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X258 Y83

M3 $0 S1 (plasma start)

G3 X263.127 Y88.127 I2.563 J2.563

G3 X263.127 Y88.127 I-5.127 J-5.127

M5 $0 (plasma end)

G0 X258 Y45.5

M3 $0 S1 (plasma start)

G3 X263.127 Y40.373 I2.563 J-2.563

G3 X263.127 Y40.373 I-5.127 J5.127

M5 $0 (plasma end)

G0 X258 Y8

M3 $0 S1 (plasma start)

G3 X263.127 Y2.873 I2.563 J-2.563

G3 X263.127 Y2.873 I-5.127 J5.127

M5 $0 (plasma end)

G0 X230.222 Y8

M3 $0 S1 (plasma start)

G3 X225.096 Y2.873 I-2.563 J-2.563

G3 X225.096 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X202.444 Y8

M3 $0 S1 (plasma start)

G3 X197.318 Y2.873 I-2.563 J-2.563

G3 X197.318 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X174.667 Y8

M3 $0 S1 (plasma start)

G3 X169.54 Y2.873 I-2.563 J-2.563

G3 X169.54 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X146.889 Y8

M3 $0 S1 (plasma start)

G3 X141.762 Y2.873 I-2.563 J-2.563

G3 X141.762 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X119.111 Y8

M3 $0 S1 (plasma start)

G3 X113.985 Y2.873 I-2.563 J-2.563

G3 X113.985 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X91.333 Y8

M3 $0 S1 (plasma start)

G3 X86.207 Y2.873 I-2.563 J-2.563

G3 X86.207 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X63.556 Y8

M3 $0 S1 (plasma start)

G3 X58.429 Y2.873 I-2.563 J-2.563

G3 X58.429 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X35.778 Y8

M3 $0 S1 (plasma start)

G3 X30.651 Y2.873 I-2.563 J-2.563

G3 X30.651 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X8 Y8

M3 $0 S1 (plasma start)

G3 X2.873 Y2.873 I-2.563 J-2.563

G3 X2.873 Y2.873 I5.127 J5.127

M5 $0 (plasma end)

G0 X146.889 Y45.5

M3 $0 S1 (plasma start)

G3 X152.015 Y40.373 I2.563 J-2.563

G3 X152.015 Y40.373 I-5.127 J5.127

M5 $0 (plasma end)

G0 X174.667 Y45.5

M3 $0 S1 (plasma start)

G3 X179.793 Y40.373 I2.563 J-2.563

G3 X179.793 Y40.373 I-5.127 J5.127

M5 $0 (plasma end)

G0 X202.444 Y45.5

M3 $0 S1 (plasma start)

G3 X207.571 Y40.373 I2.563 J-2.563

G3 X207.571 Y40.373 I-5.127 J5.127

M5 $0 (plasma end)

G0 X230.222 Y45.5

M3 $0 S1 (plasma start)

G3 X235.349 Y40.373 I2.563 J-2.563

G3 X235.349 Y40.373 I-5.127 J5.127

M5 $0 (plasma end)

;

;begin post-amble

G40 (cutter compensation: off)

G90 (distance mode: absolute)

M65 P2 (enable THC)

M65 P3 (enable torch)

M68 E3 Q0 (velocity 100%)

M5 $-1 (backup stop)

;end post-amble

;

;begin statistics

;Pierces = 30

; Cuts = 30, Length = 1708.24mm

;end statistics

;

M30 (end program)

Attachments:

Last edit: 06 May 2024 20:37 by paulsao.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2541

- Thank you received: 867

06 May 2024 21:34 #299972

by snowgoer540

Replied by snowgoer540 on topic Inssues Hole cutting

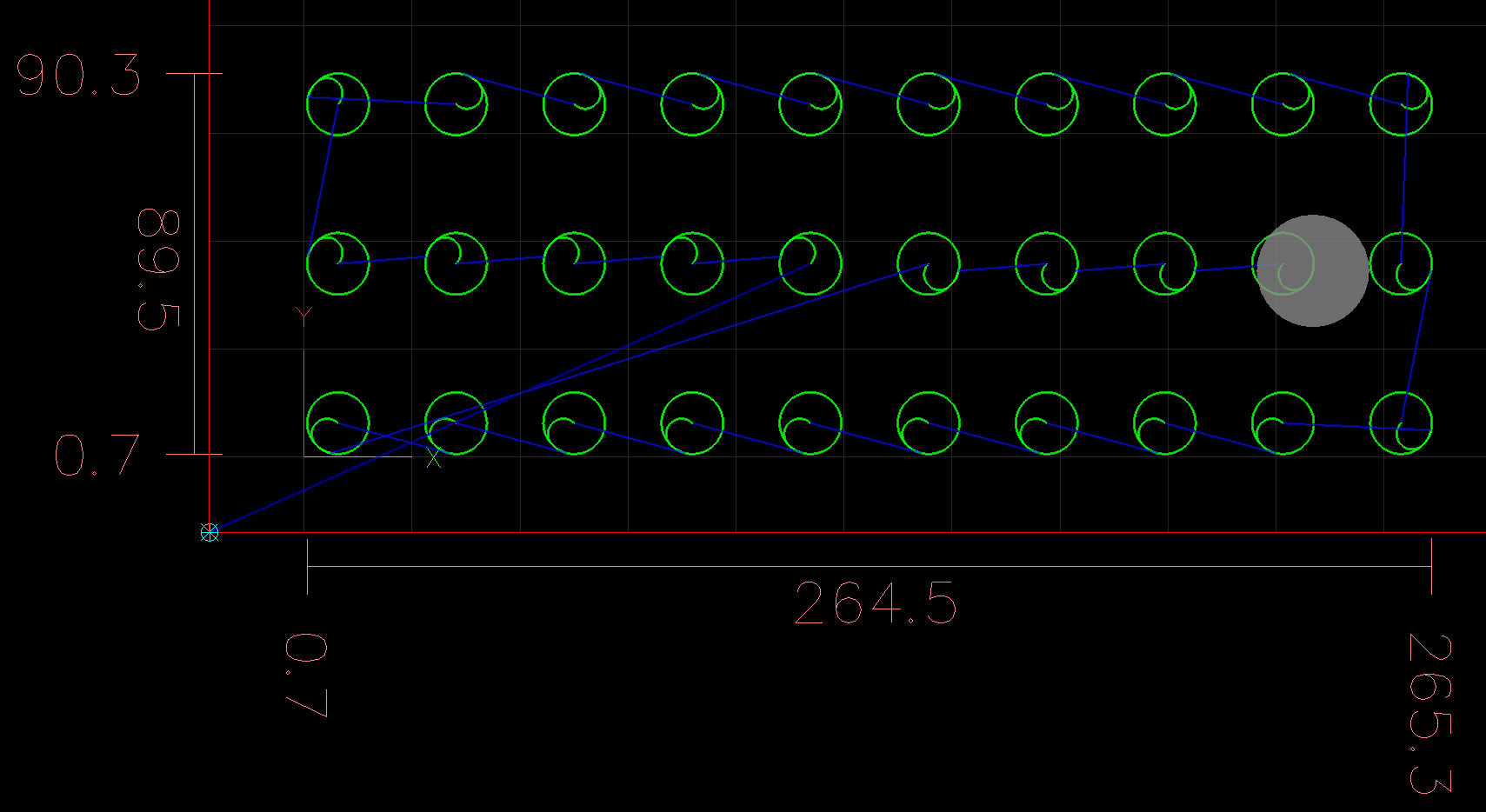

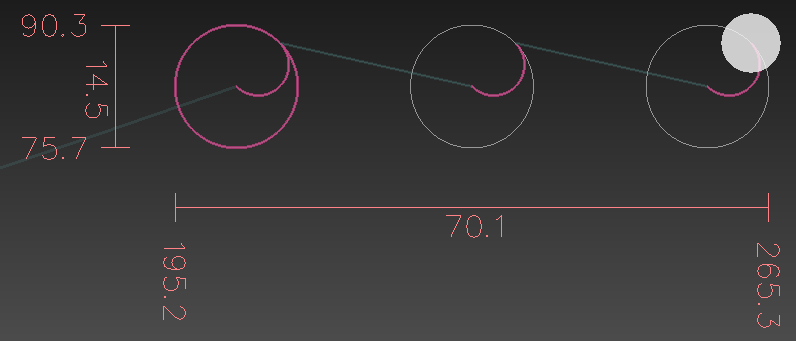

It runs fine here on my virtual machine. I did notice that it's running at 49.6% of the material feed rate, instead of 50%, I am not really sure why, but perhaps rounding error as I'm running this on an imperial simulation. Ignore the differences in colors, I change the color of the plotter via stylesheets.

Attachments:

The following user(s) said Thank You: paulsao

Please Log in or Create an account to join the conversation.

- paulsao

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 22

06 May 2024 21:51 #299973

by paulsao

Replied by paulsao on topic Inssues Hole cutting

Attachments:

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2541

- Thank you received: 867

07 May 2024 01:00 #299985

by snowgoer540

Replied by snowgoer540 on topic Inssues Hole cutting

I only had a few minutes this evening, I should have ran it through a metric config as well. Phill might be able to pick up where I left off this evening.

It is odd that everything ran at 49.6% velocity instead of 50%. Maybe it’s somehow related ¯\_(ツ)_/¯

It is odd that everything ran at 49.6% velocity instead of 50%. Maybe it’s somehow related ¯\_(ツ)_/¯

The following user(s) said Thank You: paulsao

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

07 May 2024 07:00 #300006

by phillc54

Replied by phillc54 on topic Inssues Hole cutting

I can confirm that this is an issue on both QtPlasmaC and plasmac2 in both LinuxCNC 2.9 and master.

I have been able to consistently observe it on metric configs but it does not appear to happen on imperial configs, this is with both configs run both a metric g-code and a imperial g-code.

It does not happen on PlasmaC in LinuxCNC 2.8, nor does it seem to happen on AXIS in LinuxCNC 2.9.

It also happens with all hole detection features commented out, a simple piece of code like below does not run the second G3 line on some holes:Adding a G4 P1 or a G0 X2.873 Y50.627 between the G3 lines appears to make no difference.

Currently I have no idea what is causing it...

In the meantime if you need to cut this job then changing the leadins to perpendicular should work.

I have been able to consistently observe it on metric configs but it does not appear to happen on imperial configs, this is with both configs run both a metric g-code and a imperial g-code.

It does not happen on PlasmaC in LinuxCNC 2.8, nor does it seem to happen on AXIS in LinuxCNC 2.9.

It also happens with all hole detection features commented out, a simple piece of code like below does not run the second G3 line on some holes:

G0 X8 Y45.5

M3 $0 S1 (plasma start)

G3 X2.873 Y50.627 I-2.563 J2.563

G3 X2.873 Y50.627 I5.127 J-5.127

M5 $0 (plasma end)Currently I have no idea what is causing it...

In the meantime if you need to cut this job then changing the leadins to perpendicular should work.

The following user(s) said Thank You: paulsao

Please Log in or Create an account to join the conversation.

- paulsao

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 233

- Thank you received: 22

07 May 2024 13:14 #300032

by paulsao

Replied by paulsao on topic Inssues Hole cutting

Thanks Phill for confirming it, if I am going to change to perpendicular, in arc I got better results in the holes but I will have to change to do the job. Thank you anyway.

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2541

- Thank you received: 867

07 May 2024 22:11 #300071

by snowgoer540

Replied by snowgoer540 on topic Inssues Hole cutting

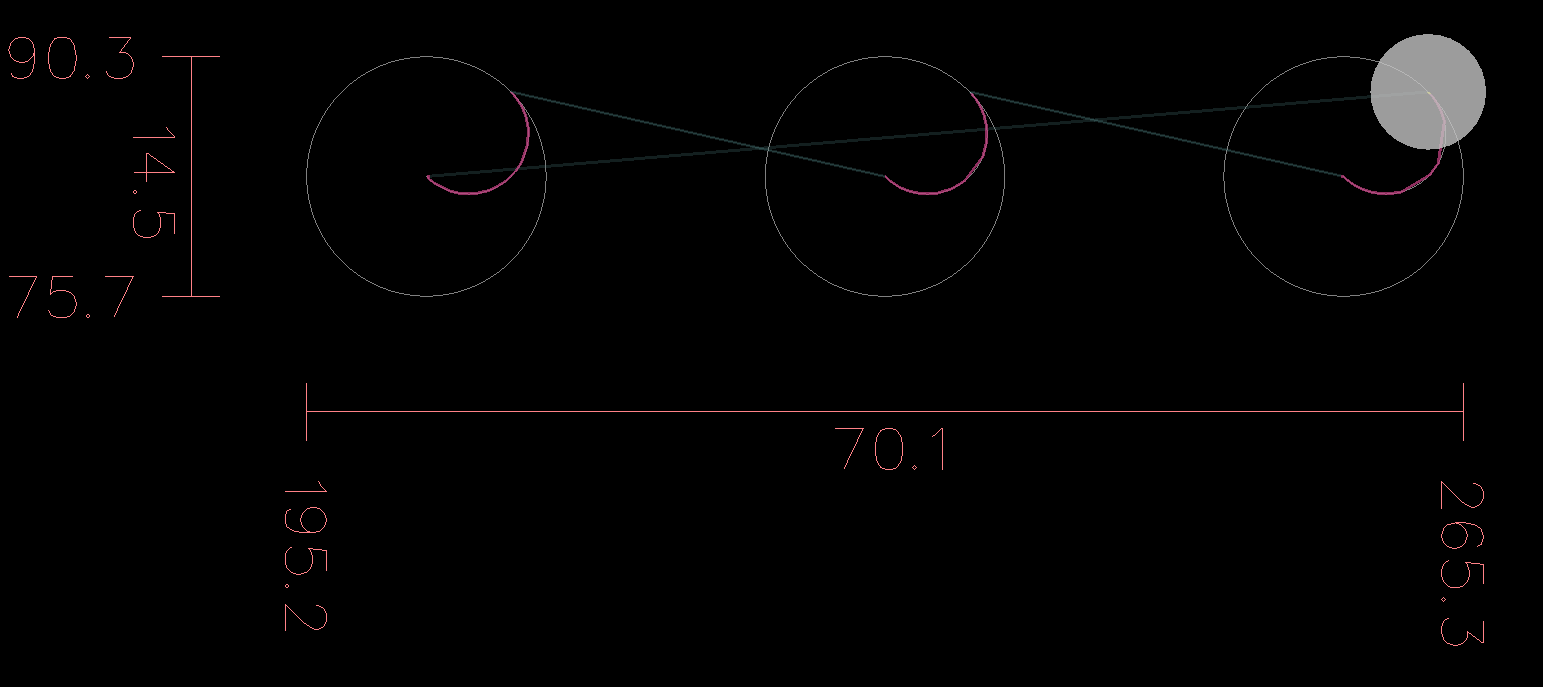

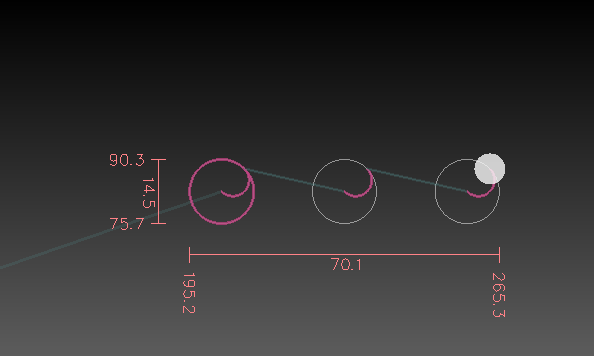

It's odd, because the code Phill posted, works for me. But running paulsao's code, I get 3 holes in a row that don't work, so I isolated them and started playing around. I dont know why, but if I change the starting point coordinates by 0.001mm, it works:

Before:

Result:

After:

Result:

I do see this issue in the following GUIs:

QtDragon HD XYZ (although not for all the circles)

QtDragon XYZ Metric:

No idea why, but the following GUIs ran OK:

QtAxis

Axis

Total g-code, because I wonder if these holes work on either of your setups:

Before:

G0 X202.444 Y83

G3 X207.571 Y88.127 I2.563 J2.563

G3 X207.571 Y88.127 I-5.127 J-5.127

G0 X230.222 Y83

G3 X235.349 Y88.127 I2.563 J2.563

G3 X235.349 Y88.127 I-5.127 J-5.127

G0 X258.000 Y83

G3 X263.127 Y88.127 I2.563 J2.563

G3 X263.127 Y88.127 I-5.127 J-5.127Result:

After:

G0 X202.445 Y83

G3 X207.571 Y88.127 I2.563 J2.563

G3 X207.571 Y88.127 I-5.127 J-5.127

G0 X230.223 Y83

G3 X235.349 Y88.127 I2.563 J2.563

G3 X235.349 Y88.127 I-5.127 J-5.127

G0 X258.001 Y83

G3 X263.127 Y88.127 I2.563 J2.563

G3 X263.127 Y88.127 I-5.127 J-5.127Result:

I do see this issue in the following GUIs:

QtDragon HD XYZ (although not for all the circles)

QtDragon XYZ Metric:

No idea why, but the following GUIs ran OK:

QtAxis

Axis

Total g-code, because I wonder if these holes work on either of your setups:

G21 (units: metric)

G40 (cutter compensation: off)

G90 (distance mode: absolute)

F10000

G0 X202.444 Y83

G3 X207.571 Y88.127 I2.563 J2.563

G3 X207.571 Y88.127 I-5.127 J-5.127

G0 X230.222 Y83

G3 X235.349 Y88.127 I2.563 J2.563

G3 X235.349 Y88.127 I-5.127 J-5.127

G0 X258.000 Y83

G3 X263.127 Y88.127 I2.563 J2.563

G3 X263.127 Y88.127 I-5.127 J-5.127

M30 (end program)Attachments:

Please Log in or Create an account to join the conversation.

- snowgoer540

-

- Offline

- Moderator

-

Less

More

- Posts: 2541

- Thank you received: 867

07 May 2024 23:00 - 07 May 2024 23:03 #300073

by snowgoer540

Replied by snowgoer540 on topic Inssues Hole cutting

Well, I did some digging as I remembered some stuff around arcs and circles and what not. Long journey short, I came across this:

github.com/LinuxCNC/linuxcnc/commit/ad91...6d2b50d1fff275200941

Andy added the comment:

Which lead me to change line 717 of posemath.h to change the CART_FUZZ value from 1.0e-8 to 1.0e-7, and that worked, the arcs transitioned into the circles as intended.

Then I noticed that Phill you commented on Andy's commit. So I changed CART_FUZZ back to 1.0e-8, and made a change at line 1851 of _posemath.c to:

To open the check up a little bit, and that also works. Since your commit and comment on andy's commit had to do with movement around circles, maybe the latter change is more appropriate?

I am honestly not sure which is more appropriate.

github.com/LinuxCNC/linuxcnc/commit/ad91...6d2b50d1fff275200941

Andy added the comment:

// andypugh 5/2/22 This seems to be interpreted to be in config units.Which lead me to change line 717 of posemath.h to change the CART_FUZZ value from 1.0e-8 to 1.0e-7, and that worked, the arcs transitioned into the circles as intended.

Then I noticed that Phill you commented on Andy's commit. So I changed CART_FUZZ back to 1.0e-8, and made a change at line 1851 of _posemath.c to:

if (d < CART_FUZZ) {To open the check up a little bit, and that also works. Since your commit and comment on andy's commit had to do with movement around circles, maybe the latter change is more appropriate?

I am honestly not sure which is more appropriate.

Last edit: 07 May 2024 23:03 by snowgoer540.

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.199 seconds